- Main types

- Self-assembly of wall-mounted gas heating boilers

- Connecting the boiler to the central line

- Normative documents

- Installation on different walls

- Installation on a reinforced concrete wall

- Brick wall installation

- Is it possible to hang the boiler on a wooden wall

- Can it be hung on drywall

- Mounting the boiler on foam concrete and aerated concrete

- Equipment Installation Rules

- General requirements at the design stage

- Document preparation process

- fire safety requirements

- Requirements for doors and windows in a gas boiler room

- Norms of illumination of the boiler room on gas

- Rules for the energy supply of the boiler room

- wall

- Device installation requirements

Main types

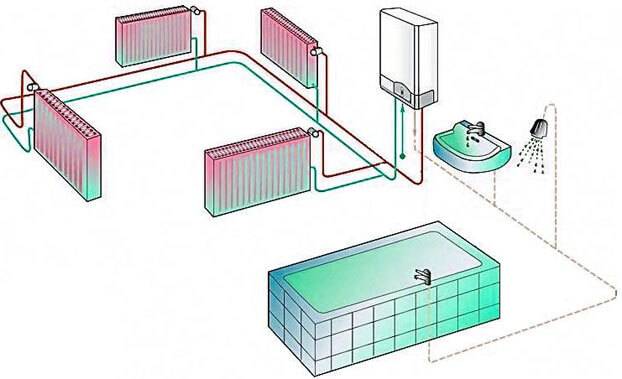

Gas boilers are classified according to various criteria: purpose, power output, type of thrust and installation method. Single-circuit boilers are installed exclusively for heating the house, double-circuit boilers allow not only to warm the premises, but also to provide the house with water with the possibility of heating it.

Low-power boilers are regulated according to a single-stage principle, units of medium productivity - according to a two-stage principle. In high-performance boilers, modulated power control is usually provided.

Boilers of closed type operate on ventilation draft.There are also gas boilers with natural draft - open type, or atmospheric.

Installation of gas boilers in a private house is carried out either by mounting on a wall or on the floor. In the first case, copper heat exchangers are used, and in the second, cast iron or steel.

The optimal solution for use in a private house is considered to be a flow-through double-circuit boiler with a boiler operating on automation. It provides space heating in the cold season and water heating for cooking, washing dishes, taking a shower.

The automatic system, which includes a double thermostat and a microprocessor, greatly simplifies the process of adjusting the equipment, allows you to monitor the temperature in rooms and on the street, set a program to reduce heating to a minimum if there are no people in the house (for example, in the daytime, when everyone has gone to job).

Installing a fully automatic boiler will save you 30% to 70% fuel compared to manual or semi-automatic boilers.

At the same time, in the absence of electricity, an automatic home boiler room will not be able to provide full-fledged heating of the house, therefore, when installing the boiler, force majeure situations must also be foreseen.

When buying a gas boiler, be sure to check the availability of a certificate and equipment. If necessary, additionally purchase fasteners for mounting the unit on the wall.

Self-assembly of wall-mounted gas heating boilers

Do-it-yourself installation of a gas boiler - we do it rightHowever, not all manufacturers of gas heating equipment allow the installation of their heating units on their own:

- companies Ariston, Viessmann, Bosch and a number of others oblige buyers to install a wall-mounted gas boiler exclusively by employees of certified centers;

- some manufacturers, such as BAXI, Ferroli, Electrolux, are more loyal to this issue, do not prohibit unauthorized installation of wall appliances. But in any case, for commissioning activities during the arrangement of the heating structure, services will be needed from specialists who have permission to connect gas and electrical equipment.

Connecting the boiler to the central line

It is best to start this stage by connecting the main pipe to the corresponding boiler element.

Tow can be taken as a reliable seal, since none of the materials proposed today can guarantee a high tightness of the joint. For a classic heating boiler, it is better to choose copper pipes with a diameter of 1 to 4 cm.

Some craftsmen choose corrugated hoses. Rubberized parts are prohibited, as they crack over time, which is fraught with depressurization of the system.

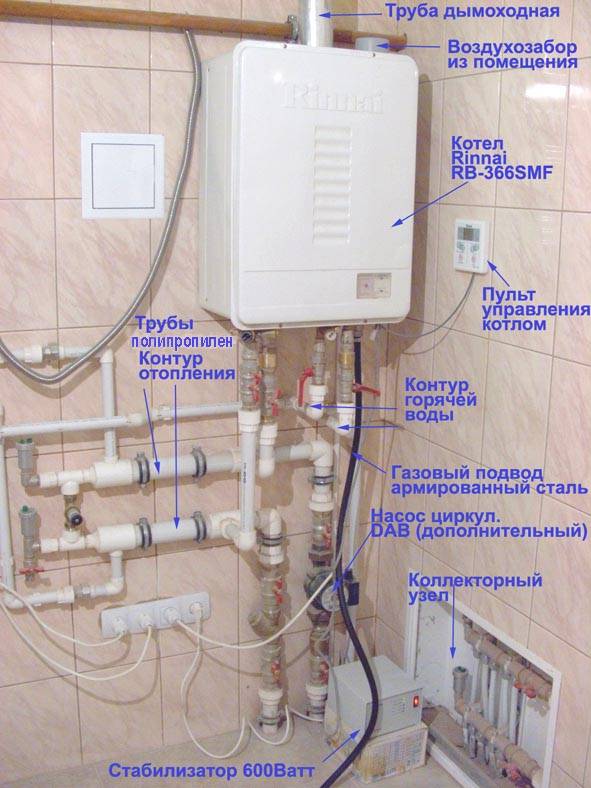

The result of a professional connection of all connecting parts

The result of a professional connection of all connecting parts

Normative documents

Gas equipment

Before making the final decision to install rather expensive equipment, you need to carefully study the official documents. These are the standards that regulate the procedure for the use of gas boilers by the population.

They have the general name "Building Norms and Rules" (SNiP), contain general rules and specific clear requirements for those wishing to equip home boiler rooms.

The main profile SNiPs, where you can find all the information of interest, are collected in the table:

| SNiP number | Name | regulate |

|---|---|---|

| 31-02-2001 | Residential single-family houses | Performance and safety requirements |

| 41-01-2003 | Heating, ventilation and air conditioning | Installation and use of heating systems |

| 21-01-97* | Fire safety of buildings and structures | Fire protection rules for premises |

| 42-01-2002 | Gas distribution systems | Design of gas distribution networks |

Infrared ceiling heater with thermostat - modern technology in your home (Prices) + Reviews

Installation on different walls

The boilers are quite heavy, and therefore problems can arise if you do not take into account the reliability of fixing to the wall. There are certain standards for the installation of boilers, which indicate that installation work must be carried out only on a rigid wall.

Requirements can vary greatly depending on the material that was used in the construction of the walls in the house. There are standards for wooden, reinforced concrete, plasterboard and brick surfaces.

Installation on a reinforced concrete wall

Reinforced concrete walls are the most suitable options for mounting a wall-mounted gas boiler. They have increased strength and are completely non-flammable. Therefore, it is not necessary to use additional methods of protection in the form of cladding. To fix the body of the heat generator, metal anchors are used, on which the mounting plate is fixed. After that, the unit is installed on the prepared site.

Any type of heating systems can be installed on concrete walls: those with high power or a conventional storage type broiler.

Brick wall installation

In the installation standards, the conditions for attaching to a brick wall are separately prescribed.Brick is another high-quality non-combustible material, and therefore the equipment is installed directly on the wall, but this time you will have to prepare the surface.

Source

Source

In order not to violate the requirements of the gas workers, the wall must be plastered before installation work. During these works, you will need to mount a special bar. After finishing the plaster, two bolts should stick out of the wall, which serve as a seat for the equipment.

Is it possible to hang the boiler on a wooden wall

Installing a wall-mounted gas boiler in a wooden house is a difficult task due to a number of nuances. A wooden wall can catch fire, so you need to take care of safety measures.

To properly mount the heating boiler, you will have to fulfill several special conditions:

- Carefully process the wood at the installation site. It is quite simple to do this with your own hands - there are special antipyrines in hardware stores. They will need to plentifully process the wall.

- The wall must first be covered with plaster (thickness - 15 mm). This is the minimum value that guarantees protection against high temperatures. You can also clad the wall with roofing steel.

If there is no desire to use plaster or metal cladding, you can put a gypsum fiber board at the place where the heat generator is attached, and then overlay it with ceramic tiles.

So that the heavy heating boiler does not fall from the established place, it is necessary to strengthen the platform with a powerful beam, which is placed under the facing material. Thus, it will be possible to securely fix the heat generator on the wall.

Can it be hung on drywall

When installing drywall, voids cannot be avoided.This creates problems with fastening a heavy heat generator. However, there is an option to eliminate this defect.

Boiler on plasterboard wall. Source

Boiler on plasterboard wall. Source

When the metal frame is being manufactured, it is necessary to select in advance a place for fixing the boiler and carry out preparatory work. It is necessary to securely strengthen the site using a wooden beam and a metal profile.

For installation on fragile drywall, special clamps are used. These are plastic plugs that are screwed into the facing material. Hardware must be mounted already in the installed plug.

Experts say that finished fasteners are gradually loosened, which leads to a deterioration in fixation.

Mounting the boiler on foam concrete and aerated concrete

If the house is built of aerated concrete or foam concrete, then several methods can be used to install the boiler:

- Fasteners are pre-installed at the moment when the blocks are laid. The installation of the boiler is carried out when the masonry mixture has completely hardened.

- In stores you can find screws for fixing in foam concrete. They are very similar to the cork used to work with drywall. But they have a deeper thread and a larger pitch. As soon as the material is screwed into foam concrete or aerated concrete, any anchor can be installed in the screws that will securely hold the gas equipment.

- Another reliable method of fixation is with studs. They are installed with a small gap from each other, and a bar is mounted into the wall (on each side), which is firmly fixed with bolts for maximum reliability.

- You can also use liquid, chemical anchors. They provide a strong fixation, but are more expensive than previous options.

Equipment Installation Rules

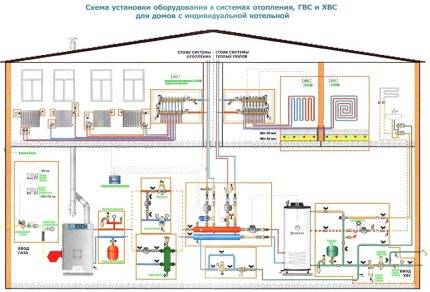

Installation and connection of the boiler to the system should begin after the design stage, when a place in the house has been prepared for the unit. If you install it in violation of the requirements, the specialists of the gas distribution company will not connect the equipment to the gas main.

General requirements at the design stage

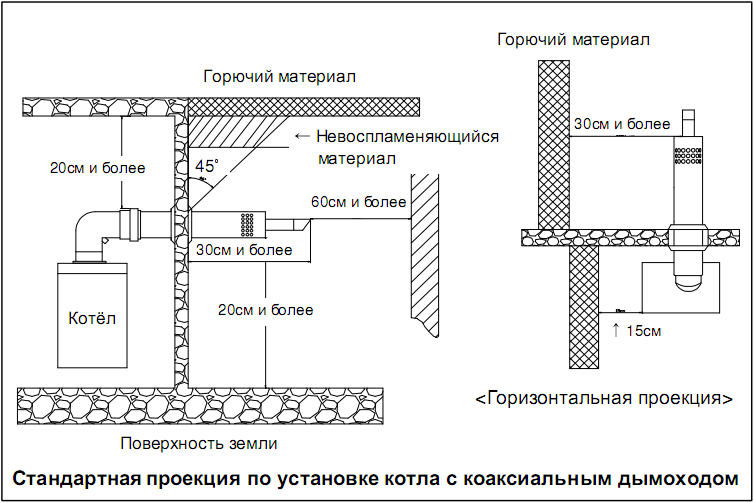

The basic standards for the installation of gas equipment are prescribed in SNiP 42-01-2002. Auxiliary information is also contained in the already invalid, but useful SNiP 2.04.08-87.

Usually all the rules are taken into account by the design engineer, but it is also useful for yourself to know them. The room for the location of the boiler can be a kitchen, if the power of the device varies in the range up to 60 kW. A separate or attached furnace is relevant for units with a power rating of up to 150 kW.

Additional norms for the installation of gas equipment are given in SNiP on boiler plants, as well as on heating, ventilation, air conditioning

Additional norms for the installation of gas equipment are given in SNiP on boiler plants, as well as on heating, ventilation, air conditioning

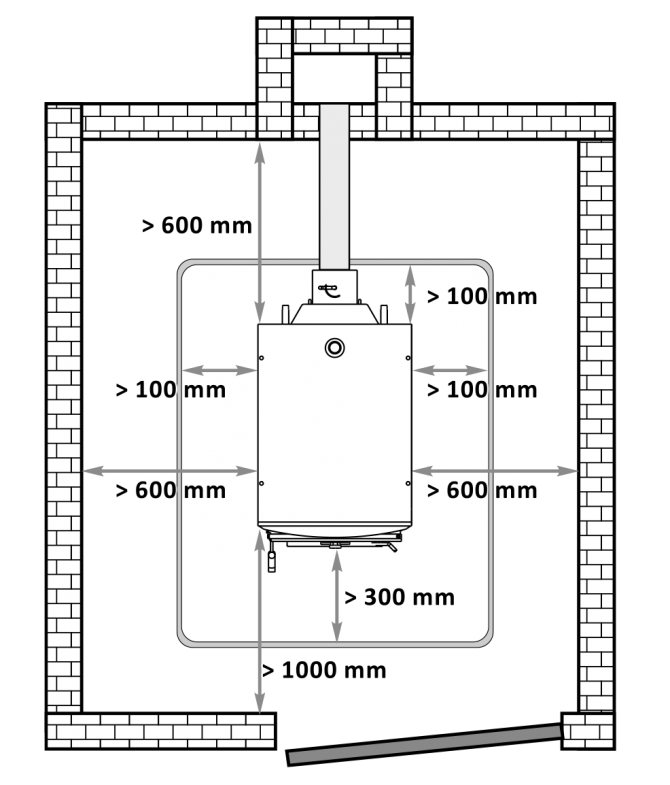

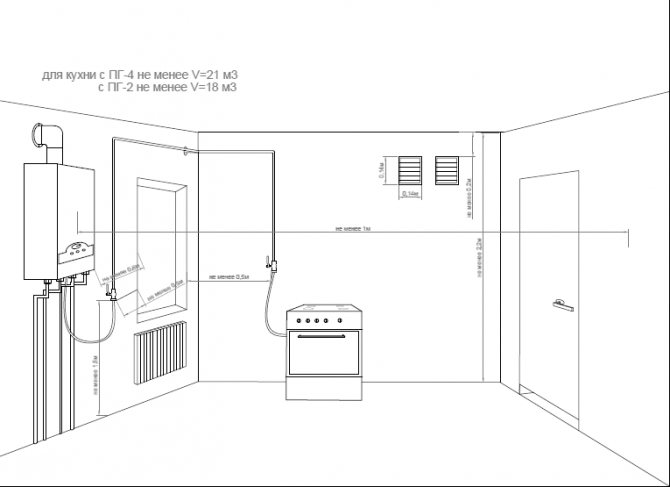

The space requirements are as follows:

- The minimum room height is 2 m, the volume is 7.5 m3. If there are two or more gas appliances, the parameters change to 2.5 m and 13.5 m3, respectively.

- Not suitable for installation: basements, balconies, bathrooms, corridors, rooms without vents.

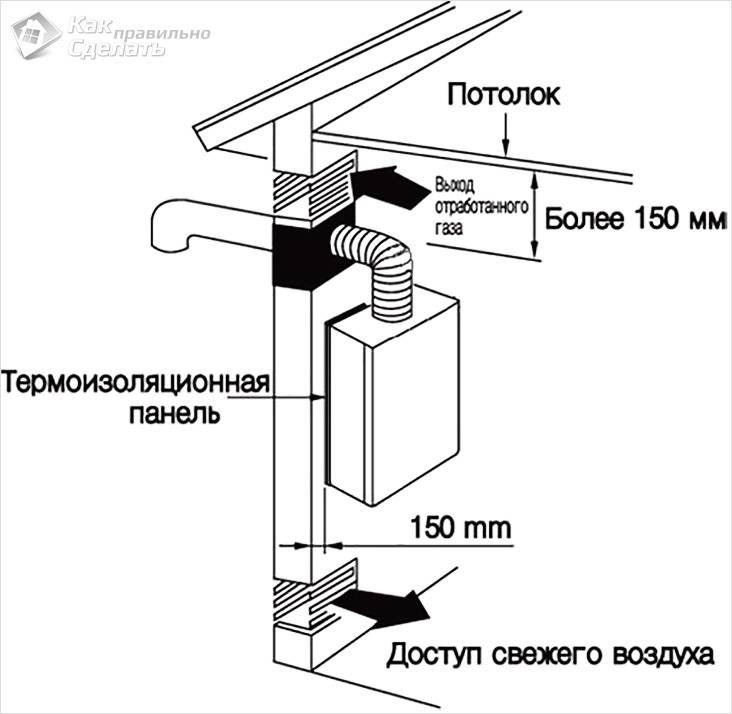

- The walls of the room must be covered with non-combustible materials or protected with special panels.

- Lighting: for 10 m3 of a room there is at least 0.3 m2 of a window. In the event of a gas explosion, the windows are an easily dropped structure, which increases the safety of equipment operation.

- Must have grounding, cold water pipeline.

- The cross section of the chimney corresponds to the power of the installed equipment.

- Space left around the device: in front - from 1.25 m, on the sides (if maintenance is necessary) - from 0.7 m.

- The distance from the vertical chimney to the unit is observed - no more than 3 m.

Ventilation should also be provided. Natural is calculated in the amount of 3 room volumes per hour. When organizing a supply air, combustion air is added to this value (the parameter is indicated in the boiler passport).

Requirements apply not only to premises. The distance from the attachment to the nearest structures is also regulated. This information is specified by the manufacturer in the instructions for the equipment.

If a double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a mineralite slab is attached to it. If the equipment is not located in the kitchen, asbestos is also possible.

If a double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a mineralite slab is attached to it. If the equipment is not located in the kitchen, asbestos is also possible.

Floor models of boilers are installed on non-combustible bases. If the surface is wooden, a metal substrate is required.

It is recommended to place the device as close as possible to the gas pipe. The use of special hoses is acceptable, but they should not be long. On sale there are bellows hoses up to 5 m, they are allowed for installation, but according to European standards, the length is limited to two meters.

Document preparation process

After a general acquaintance with how to technically connect double-circuit gas boilers, you can begin to prepare documentation. The first stage is obtaining the TU. It is necessary to apply to the regional gas service with a statement indicating the expected volume of blue fuel consumption per hour.

Specifications are issued in 1-2 weeks.The document is a permit to connect housing to the gas main.

The second stage - according to the specifications, a project for the installation of equipment is being developed. The third is the approval of the prepared documentation by the engineers of the service gas distribution company.

The project includes both the installation diagram of the boiler itself and the gasket gas pipeline from the connection point to the highway. If we are talking about a private house, a drawing of communications on the site is added

The project includes both the installation diagram of the boiler itself and the gasket gas pipeline from the connection point to the highway. If we are talking about a private house, a drawing of communications on the site is added

The technical passport of the boiler, operating instructions, certificates, an expert opinion on the compliance of the device with all standards are submitted to the controlling organization. The necessary papers are provided by the manufacturer of the double-circuit boiler.

Coordination of documentation can take place in a week or last up to 3 months, it all depends on the complexity of the project. In case of refusal, the inspection is obliged to provide a list of edits to eliminate deficiencies. If all requirements are met, seals are affixed and you can proceed to connect the equipment.

fire safety requirements

Fire regulations for gas boilers, separately stipulate the requirements for industrial and domestic boilers. To clarify the existing restrictions, the premises used for the installation of heating equipment are classified according to the type of explosion and fire hazard. The class assigned to gas boilers is B1-B4.

The current fire safety requirements for the premises of private houses with installed domestic gas boilers include the following:

- It is allowed to install atmospheric boilers on the basement floor and on the roof of the building, provided that the premises comply with the standards specified in SNiP.Connection and operation of boilers with an open combustion chamber in the basement is prohibited. Heat generators with a closed combustion chamber are mounted in the basement and any non-residential premises in the house. Installation of the boiler in the attic is possible, provided that there is good thermal insulation and compliance with fire cuts and breaks.

- Requirements for building materials - the boiler room is fenced on all sides with fire-resistant partitions with a minimum fire resistance limit of at least EI45 (0.75 hours).

- Doors must open outwards.

- In domestic boiler houses, fire alarms are not mandatory, but recommended measures to prevent emergencies.

- Floor, walls and ceiling of the boiler room (in case of installation of mounted heating equipment)? lined with non-combustible materials - ceramic tiles, drywall, plaster, etc.

For industrial boilers, similar standards apply with a few exceptions:

- A gas leak and fire warning system must be installed.

- The fire alarm and fire warning system in a gas-fired boiler room must comply with the requirements set forth in Federal Law N 123. If the boiler room is classified as class G, it is imperative to equip it with a gas leak monitoring device. All sensors are connected to the boiler controller, which gives a signal to turn off the heating equipment, if the allowable carbon monoxide content in the air has exceeded the maximum value.

The presence of grounding for a gas boiler is a prerequisite for putting the equipment into operation.

Requirements for doors and windows in a gas boiler room

High requirements of SNiP apply to windows and doors located in a gas boiler room:

- Windows - the boiler room provides sufficient natural lighting. The width of the window opening is calculated depending on the volume of the room. The presence of a window is a must.

- Doors - a door leaf is installed, at least 80 cm wide. Doors leading from the boiler room directly to the street are provided. All door leafs facing the house and the street must open outward. The box is installed without a lower threshold.

In household boiler rooms, a luminous emergency exit indicator is installed, directly above the door.

Norms of illumination of the boiler room on gas

Artificial and natural lighting of the room is provided. Switches are installed outside the boiler room. For industrial boiler equipment, sealed lamps with a metal sheath are mounted.{banner_downtext}The calculation of the width of the window opening is calculated by the formula - 1 m³ of the room = 0.03 m² of the window opening. The calculations do not take into account partitions and window frames. The calculation is carried out according to the window opening. The window must have a window.

Rules for the energy supply of the boiler room

Construction norms for installation gas boiler in a private house, provide for recommended and mandatory requirements affecting the energy supply of boiler equipment. These include:

- Volatile boilers are connected to the power supply network through a voltage stabilizer and a UPS. The capacity of the uninterruptible power supply is selected so as to ensure uninterrupted operation of the boiler for 12 hours.

- Be sure to install a ground loop.During operation, a boiler of any type generates low-potential voltage. Under certain circumstances, a spark of static electricity can cause a fire and explosion.

- The boiler room is connected directly from the switchboard.

To make sure that the location of the boiler and the room that is planned to be used as a boiler room complies with the standards described with SNiP, FZ and SP, before starting design work, you should get competent advice from a representative of the gas industry.

wall

The nuances of installing wall-mounted boilers:

- For work, you will need two heat exchangers and four pipes, which are necessary for reliable fixation of pipes. One such element heats the coolant for the heating system, but the second one is installed to supply water to the DHW compartment.

- Installing a double-circuit wall-mounted gas heating boiler in a private wooden house is more difficult than in a stone one. Requirements for the installation of equipment are related to the fact that the base heat exchanger is connected to the heating, and the second such element is connected to the water supply. Each model has its own network laying points, so you must first read the installation instructions for the equipment.

The coolant circulates from the base heat exchanger to the additional compartment and back. According to this scheme, the liquid picks up the temperature that is optimal for operation, in this case we can safely talk about the high efficiency of heating water for domestic needs (heating the liquid up to +85 ° C).

Device installation requirements

Installed gas equipment

The homeowner can perform installation work on placing the device on a prepared section of the floor or wall, connecting it to ventilation and removing the chimney on his own.However, it is safest to entrust the performance of these works to professionals from specialized organizations.

Direct fastening and installation of outdoor equipment is carried out taking into account the following rules:

- minimum distance to the opposite wall - 1.25 m

- free space on both sides for maintenance - 0.7 m each

- clearance to the wall - 5 cm from the rear wall of the device

When installed on a wooden floor, fireproof material is placed under the device: roofing steel or basalt cardboard. On 3 sides, the lining extends beyond the dimensions of the device by 10 cm, in front - 70 cm longer. The walls are also sheathed with mineralite slabs, asbestos sheets or galvanized steel sheets with a thickness of more than 1 mm.

Mounted gas boiler

If the boiler is mounted, then the minimum indents should have the following values:

- to the ceiling or overhanging structure - 45 cm

- to the floor - 30 cm

- on the sides - 20 cm

- to the opposite wall or other obstacle - 1 m

A hinged appliance in a room made of wood is also isolated from the walls with fireproof material 100 mm protruding beyond the dimensions. The length of the steel or asbestos gasket must be 700 mm longer than the length of the boiler from below. The thickness of the insulating material is ideally 3 cm or more.

The simplest conditions are put forward when installing a parapet device. The key requirement is that the room has window and door openings larger than 80 cm. This boiler is also considered the safest, because the ventilation and chimney system is enclosed in one pipe.

Do-it-yourself furniture and other wood products: drawings of benches, tables, swings, birdhouses and other household items (85+ Photos & Videos)