- Preparation of related installation materials

- What equipment is needed for arranging the structure

- Preparation of related installation materials

- Well pump cleaning and minor repairs

- Choosing a pump for a well

- Pump installation step by step

- Pump activation algorithm

- Well station selection criteria

- Types of surface pumps

- Selection Options

- Water flow and pump performance

- Lifting height (pressure)

- Immersion depth

- Well diameter

- Surface pump for a well 30 meters

- Video - Hand pump for a well without a foundation

Preparation of related installation materials

The cable has the following requirements:

- reliability and strength, expressed by the ability to withstand loads that are 5 times the weight of the suspended equipment;

- resistance to the damaging effects of dampness, since certain parts of the product are under water.

It is allowed to use improvised materials to damp vibrations. A piece of medical tourniquet or elastic hose will do. Hanging the mechanism on a metal cable or wire is not worth it because of the likelihood of damage to the mount.

The next element that allows you to properly install a deep-well pump into a well is a cable for supplying equipment with power. It is better to take a wire with a small margin in length.

Water is supplied from an autonomous source to consumption points in the house through a water main. The best option is polymer pipes with a cross section of 32 mm or more. With a smaller diameter, it is impossible to provide sufficient pressure.

It is allowed to use a metal pipeline when installing a borehole pump. At the same time, threaded connections must be sealed with FUM tape, flax fiber or a special Tangit tool. To further strengthen the linen winding, a silicone-based sealant is used.

In addition, before installing the pump on the well, you need to prepare the following materials:

- manometer;

- attachment point made of durable steel;

- fittings for fixing the electric cable on the pipe line (clamps can be used);

- check valve;

- shut-off valve that shuts off the water supply, etc.

A nipple adapter is installed on the outlet pipe of the pump. In the absence of a pumping unit in the factory, this device is purchased separately.

During the initial pumping of the well, a large volume of heavily contaminated fluid is removed from it. For the procedure, it is recommended to use powerful models that can pump dirty water. After that, you can proceed with the installation of a standard borehole pump for further operation.

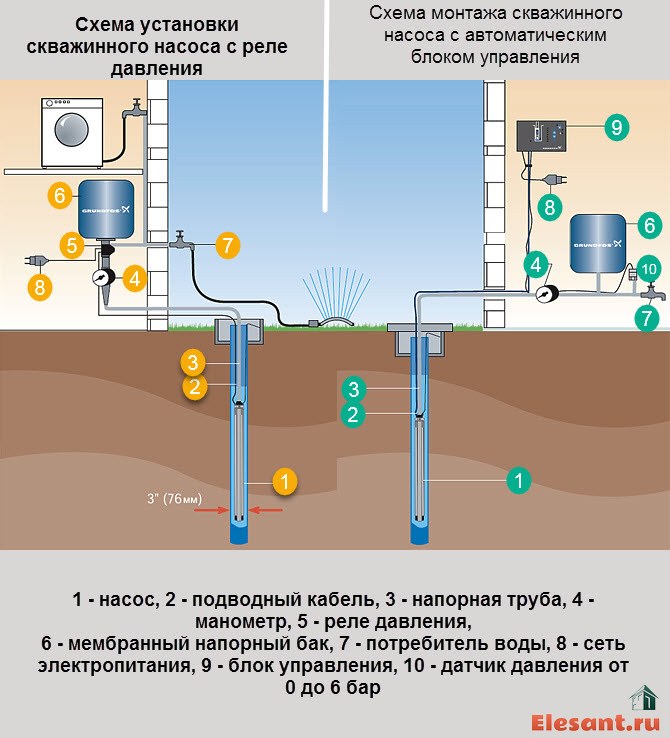

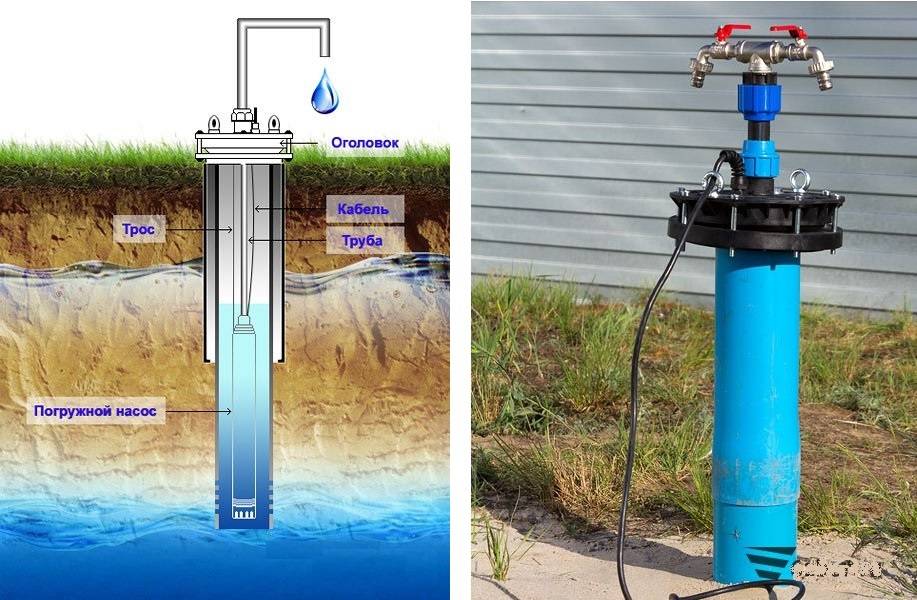

What equipment is needed for arranging the structure

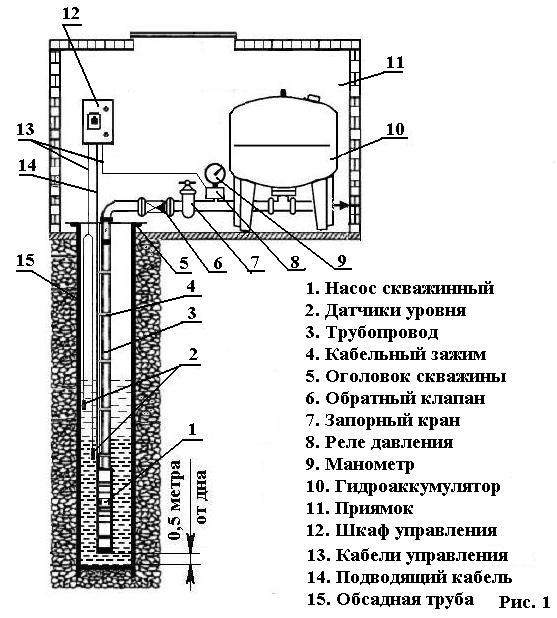

To equip an artesian well with your own hands, you will need:

- water lifting equipment;

- cap;

- hydraulic tank;

- additional equipment for pressure, level, water flow control;

- frost protection: pit, caisson or adapter.

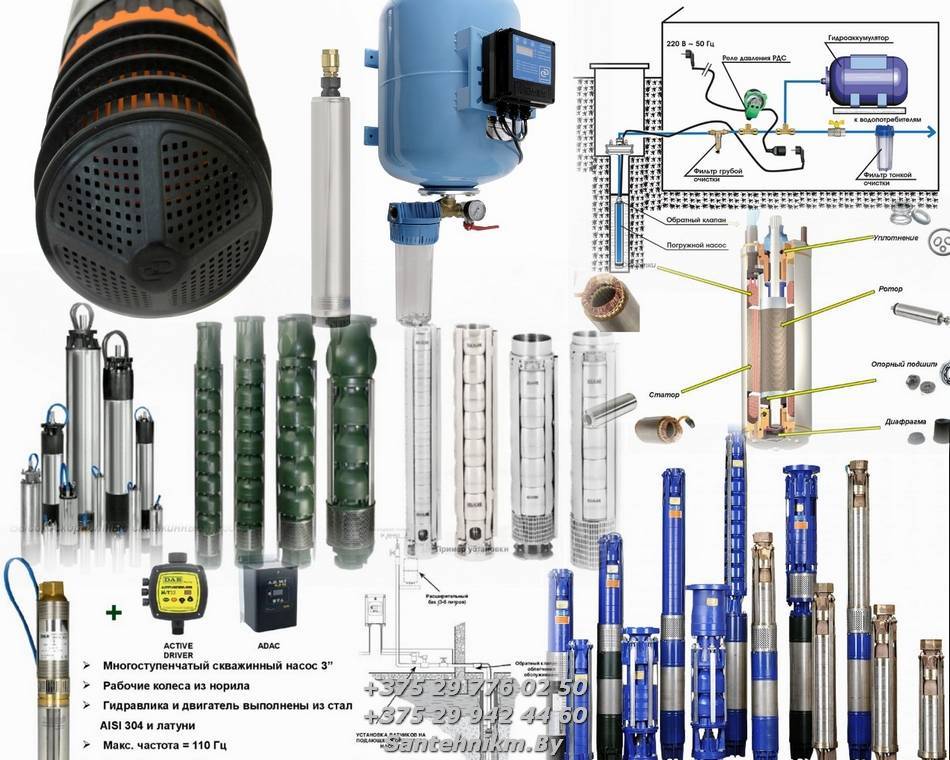

When buying a submersible pump, it is important to correctly calculate the required power.The model is selected according to performance and diameter. You can’t save on this equipment, because

the performance of the entire water supply system of the site depends on it

You can’t save on this equipment, because. the performance of the entire water supply system of the site depends on it.

The best option is a model in a high-strength hermetic case, equipped with sensors, filter units, and automation. As for brands, Grundfos water-lifting equipment deserves special attention.

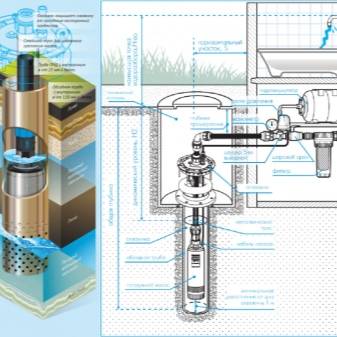

Typically, a submersible pump is installed at a height of about 1-1.5 m from the bottom of the hydraulic structure, however, in an artesian well, it can be located much higher, because. pressure waters rise above the horizon.

The immersion depth for an artesian source should be calculated based on the indicators of static and dynamic water levels.

To keep artesian water crystal clear, the production pipe must be protected from debris, surface water and other adverse environmental factors. This structural element is used to securely fasten the submersible pump cable.

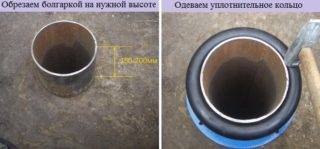

The head consists of a cover, clamps, carabiner, flange and seal. Models of industrial production do not need to be welded to the casing, they are fastened with bolts that press the cover against the seal, thus ensuring a complete seal of the wellhead. Features of mounting homemade heads depend on the design of the devices.

The hydraulic accumulator is an important unit of an autonomous water supply system. It is necessary to ensure the normal operation of the water supply, protect the pump from constant on-off and prevent water hammer.The battery is a water tank, additionally equipped with pressure sensors and automation.

When the pump is turned on, water first enters the tank, and from it is supplied to the draw-off points. The water levels at which the pump turns on and off can be controlled using pressure sensors. On sale there are hydraulic tanks with a capacity of 10 to 1000 liters. Each well owner can choose the model that best suits their system.

The well must be protected from freezing. For these purposes, you can make a pit, install a caisson, an adapter. The traditional option is a pit. It is a small pit, the walls of which are reinforced with concrete or brickwork. From above, the structure is closed with a heavy lid with a hatch. It is undesirable to install any equipment in the pit, because even with good waterproofing, the walls still let moisture through, the design is not airtight.

A more modern and technological analogue of the pit is the caisson. This design is best purchased at a specialized store. Industrial production caissons are pre-designed to accommodate all the necessary equipment. Plastic models are well insulated and airtight. Metal caissons often need additional insulation.

For a single-pipe artesian well, an arrangement using a pitless adapter is suitable. In this case, the function of the protective structure is performed by the casing pipe itself. The adapter can only be installed if the column is made of metal. There are serious difficulties with the operation of a plastic pipe, and the service life of the structure may be short-lived.

Preparation of related installation materials

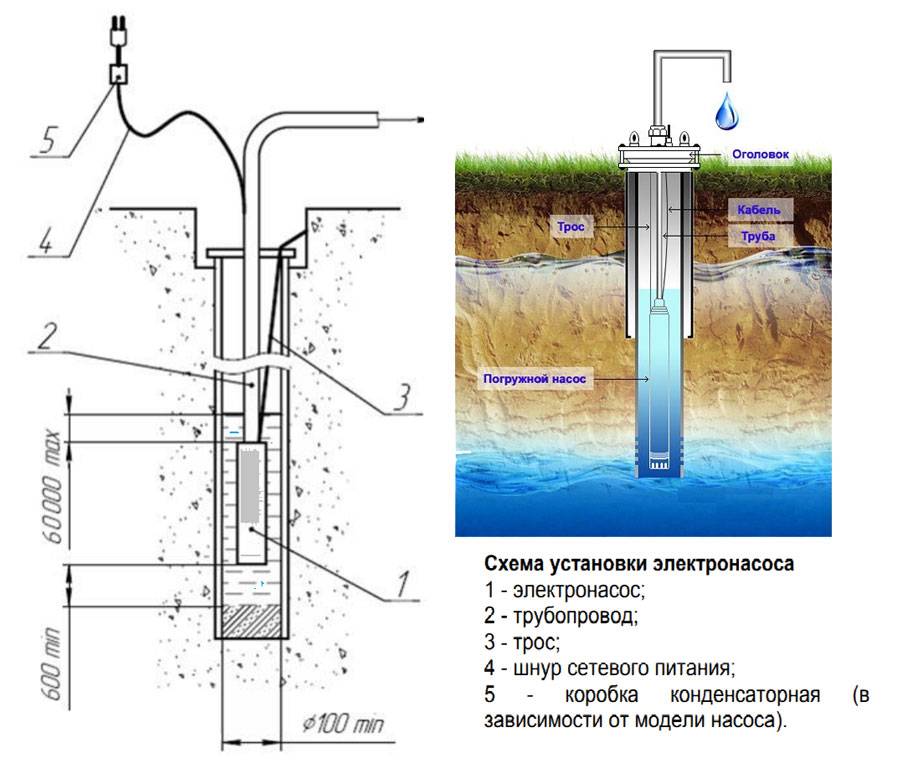

A pump stuck in the casing can be a major headache. And it is necessary to pull it out (as well as lower it) with the help of a special cable. If the pump is already equipped with a polymer cord, you must make sure that it is of high quality and of sufficient length. Sometimes it makes more sense to purchase this item separately.

It is considered that a reliable cable or cord should be designed for a load that is at least five times the weight of the equipment attached to it. Of course, it must tolerate the effects of moisture well, since part of it will constantly be in the water.

If the device is suspended relatively shallow, less than ten meters from the surface, you need to take care of additional depreciation of the equipment during its operation. To do this, use a piece of flexible rubber or a medical tourniquet. A metal cable or suspension wire is not suitable as it does not dampen the vibration but may destroy the mount.

A special electrical cable is used to power the pump. Its length must be sufficient so that the cable lies freely and is not under tension.

To supply water from the pump to the house water supply, special plastic pipes are used. Designs with a diameter of 32 mm or larger are recommended. Otherwise, the water pressure in the system will be insufficient.

For installation of a submersible pump, a special cable is used, which is designed for long-term operation under water. Its cross section must comply with the technical requirements specified in the product passport.

Pipes can be used both metal and plastic. There is controversy regarding the connection of metal pipes. Some experts object to a threaded connection as less reliable.It is recommended to use flanges, and the bolt should be on top, this will prevent it from accidentally falling into the well.

But the threaded connection in wells is used quite successfully. During installation, winding is mandatory. Some experts recommend taking linen or Tangit sealing tape instead of the usual FUM tape or tow. Linen winding is additionally strengthened with silicone sealant or similar material.

The characteristics of the water supply pipe should be selected in accordance with the conditions of its operation. For depths up to 50 meters, HDPE pipes are used, designed for a pressure of 10 atm. For a depth of 50-80 m, pipes capable of operating under a pressure of 12.5 atm will be needed, and for deeper wells, pipes of 16 atm are used.

In addition to the pump, pipes and cord or cable, before installing a submersible pump in a well, it is recommended to stock up on the following materials:

- clamps for fixing the electric cable on the pipe;

- check valve;

- pressure gauge;

- shut-off valve for the water pipe;

- steel mount;

- power cable, etc.

Before connecting the pipe to the pump, a nipple adapter must be attached to its outlet. Usually, modern submersible pumps are equipped with such a device, but if it is not, this unit must be purchased separately.

It should be remembered that for pumping a well immediately after drilling, i.e. to remove a large amount of very dirty water from the well, such a pump cannot be used. It will quickly fail. Usually, the well is pumped with a separate pump, which is cheaper and works better when working with dirty water.

Well pump cleaning and minor repairs

There are times when the downhole pump device does not rotate and its owner needs to disassemble the pump. Please note: the device does not have an internal filter, and a mesh that traps stones and coarse sand is attached outside between the engine and the pump part. For this reason, the cessation of rotation, as a rule, is caused by breakage or clogging of the impellers. Not a large blockage, it is possible to try to eliminate it yourself.

You need to clean in several stages:

– Remove the protective grid. In new models, it is fixed with a special clip that opens by prying with a screwdriver or by lightly pressing in the middle. On the old ones - there are two ordinary bolts that are easily unscrewed

- On wide models of pumps, it is also possible to remove the cable channel - a small metal groove that protects the cord from defects.

– The engine can be dismantled and disconnected from the pump part by unscrewing the four bolts with a 10 wrench. After that, it is necessary to remove the couplings that direct the engine power to the pump.

- The disassembled apparatus is carefully placed on a horizontal surface

It is very important not to damage the cord

- Next, you need to scroll the shaft with a 12 head or a socket wrench, be sure to support the upper part of the device. When the shaft moves, it is necessary to apply a jet of water to the pumping part in order to remove parts from there due to which the device is stuck. After making sure that the shaft can rotate, carefully wash the pump, and assemble it in the reverse order.

Not infrequently, there are cases when the owner of the pump, noticing that the axle in the pump part does not rotate, decides that the bearing is jammed.But in the pump part there is one plain bearing and, accordingly, cannot jam. Here there was a problem with the impellers and it is best to replace them. If you have spare parts, you can try to fix the pump yourself. For this you need:

- Rest against the brass part of the bottom of the apparatus and with force squeeze the shell from below and from above.

- Using narrow teeth, remove the retaining ring. The ring is in a special groove and will loosen if the shell is squeezed hard.

- Remove all impellers one by one, then remove the thrust cover with bearing.

- Eliminate the cause of jamming and fold the parts in reverse order.

Choosing a pump for a well

- choose exclusively from centrifugal units of the borehole type, since other types, in particular, vibration, are designed for other operating conditions. The price of such devices is the lowest on the market, the quality, respectively, too;

- one of the most important characteristics is the performance of the pump, which, first of all, must meet your needs. Productivity refers to the number of liters of water that the device can pump in one hour. You need to rely on a level of performance that will ensure uninterrupted water supply to target areas;

- Also, the diameter of the pump housing is considered to be of no small importance. This value should correspond to the inner diameter of the casing pipes, which are the walls of the well. Here it is necessary to take into account that the closer to the bottom of the well, the smaller its diameter.

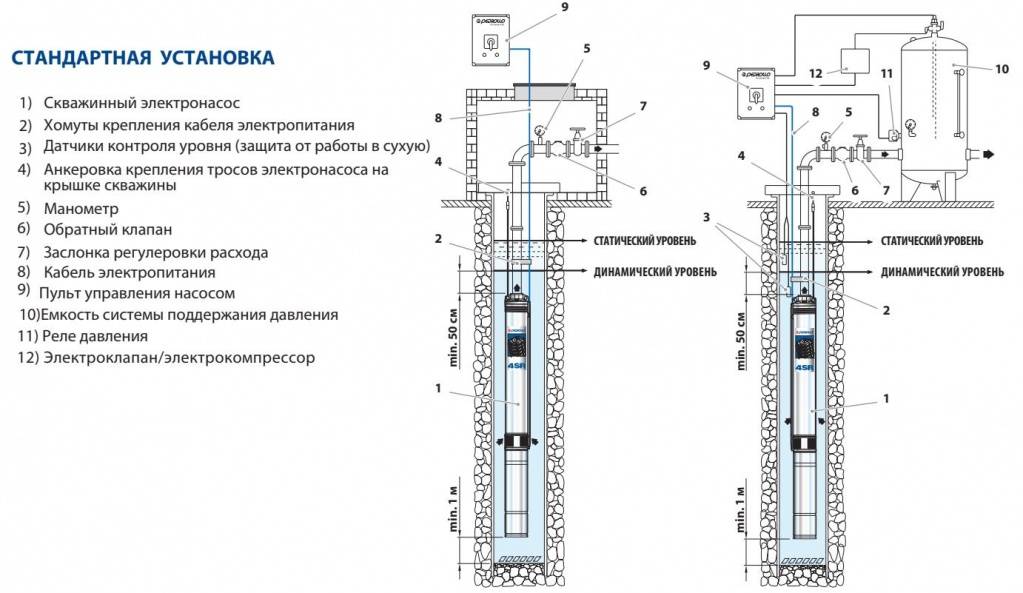

Pump installation step by step

Well head preparation

Well head preparation

After preparing all the tools and consumables, you can start installing the submersible pump in the well.The main element to work with is the casing pipe. Install it in the well immediately after drilling. The pump is lowered into it during installation.

It is important to make sure that the well remains even throughout its entire length, it has no narrowing and curvature.

Installation steps:

-

Determination of the difference between the internal section of the well pipe and the diameter of the body of the lowered equipment. If the pipe comes out end-to-end, any imperfections in it can cause damage to the equipment. If the pipe size is too large, it will not cool properly and will fail soon. It is necessary to clarify the exact gap parameter in the documentation accompanying the equipment.

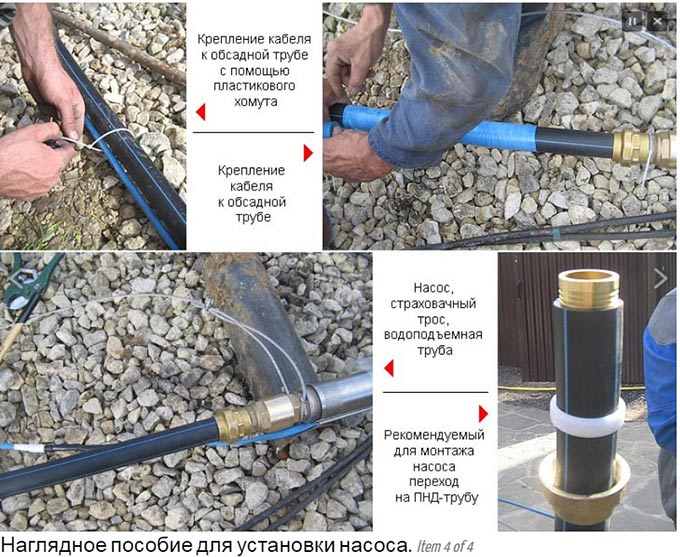

- Fixing all pipes and cords. Connect with the help of flanges all elements of the hydraulic pipeline.

-

The descent of the hydraulic machine into the well with the help of a polyamide cord. The cord is tied to the body, then the technique is gradually lowered down. The cord should ideally be able to easily support a weight that is 5 times the weight of the hydraulic machine. The knot of the cord must be at least 10 cm from the entry holes of the machine, and the ends must be cut off.

- Use of a spring hanger when installed to a depth of less than 10 m. If the pump is installed to the specified depth, use a spring hanger mounted on the casing. It can be a medical tourniquet or a piece of rubber. Wire and metal cable are not suitable for these functions, as they can break the fasteners on the machine body.

- The use of additional elements during the descent. Together with the pump, a power cord and a metal-plastic pipe are lowered into the casing pipe, which is connected to the branch pipe. They are fastened with insulating tape in increments of 70 to 130 cm.The first bundle of electrical tape should be 20 cm from the discharge pipe.

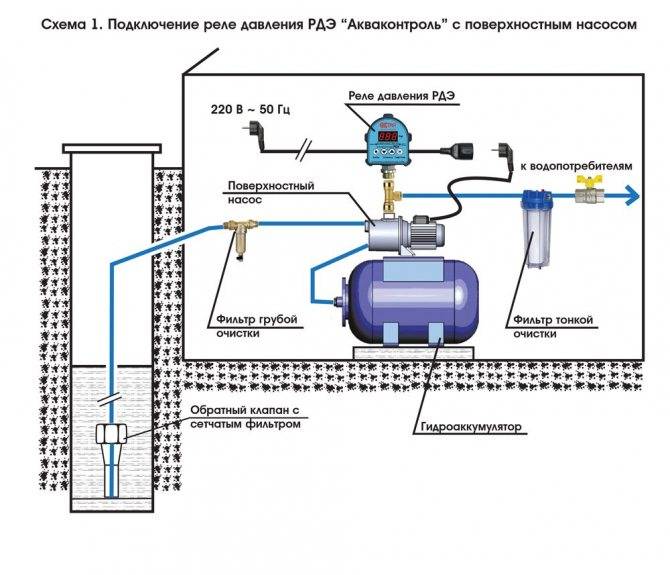

Pump activation algorithm

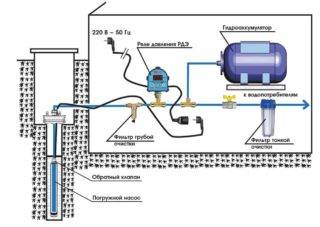

Connecting a borehole pump to the power supply through a pressure switch

Connecting a borehole pump to the power supply through a pressure switch

As soon as the installation of the deep pump in the well is completed, the first connection of the equipment is started.

It is very important to connect all the elements correctly, otherwise it will affect the service life of the equipment:

- The end of the pipe connected to the branch pipe is fixed on the base plate of the well.

- If there is no check valve in the design of the hydraulic machine, it is bought separately and installed on the discharge line.

- They install valves, a branch elbow and a pressure gauge on the discharge pipe, which will allow you to keep the pressure level under control.

- Connect the elbow extending from the pipe to the pipeline, which will distribute the liquid to the points of consumption.

After all the manipulations, it is necessary to measure the resistance of the motor winding and the electric cable, which is immersed in a liquid medium. To do this, use a megohmmeter. Now you can connect the pump to the control station and test run the equipment.

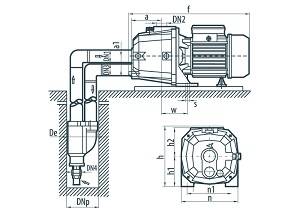

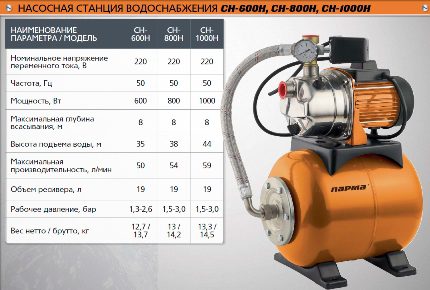

Well station selection criteria

When buying a pumping station, you should pay attention to the parameters of the pump and the factors characterizing the source of water (in our case, a well), including its distance from the building. For example, it would not be superfluous to specify the following values:

For example, it would not be superfluous to specify the following values:

Maximum depth of water intake. We are interested in the dynamic water level, that is, the average for 1-2 days with constant use of water

If you take into account the static level, then you can make mistakes in the calculations.

Rated head of the unit. The conditional height of the water column that pumping equipment can create

It is calculated by the formula, summing up the suction value, the length of the horizontal sections of the pipeline, the vertical lift and the losses for transportation through the pipeline.

performance of the pumping station. For calculations, you can take the average water consumption at all points of water intake (for example, a sink faucet - 0.15 m / s, a shower or washing machine - 0.3 m / s). The total value should not be higher than the well flow rate, otherwise the source will not be able to cope with the supply.

Power supply voltage. In household networks, this is 220 V (except for powerful stations with three-phase motors, where the voltage is 380 V).

Power consumption. The spread of energy consumed by stations is impressive. On average 500-2000 watts. The choice of the type of circuit breaker directly depends on the power.

The volume of the accumulator tank. From 24 liters (for a family of 1-2 people) to 100 liters (6 people or more).

It is clear that without knowledge of the technical nuances, before choosing and purchasing a unit, it is better to consult with a specialist who is well versed in household pumping equipment.

The characteristics of the pumping station are indicated in the technical data sheet of the product, to select the desired model, they must be compared with their own calculations

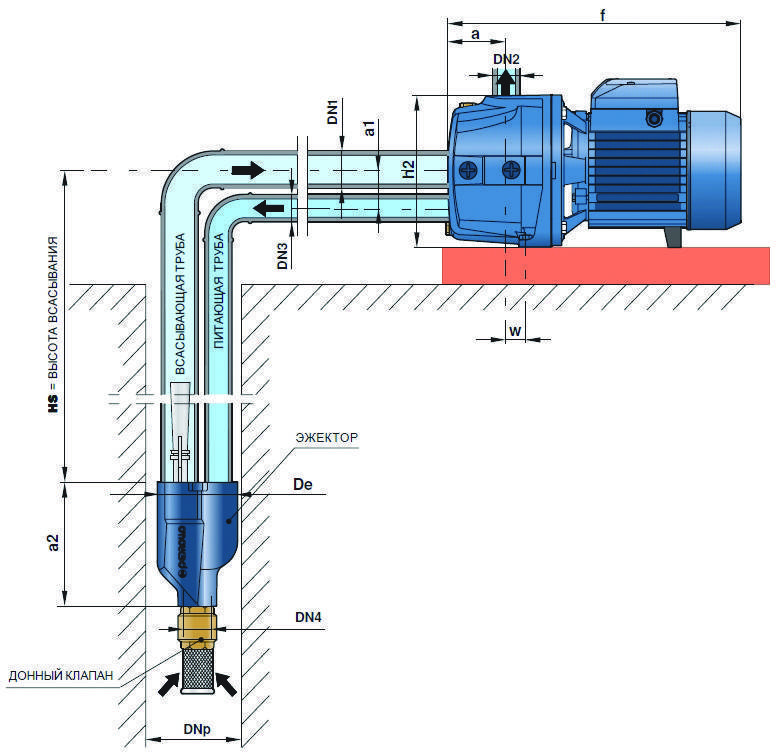

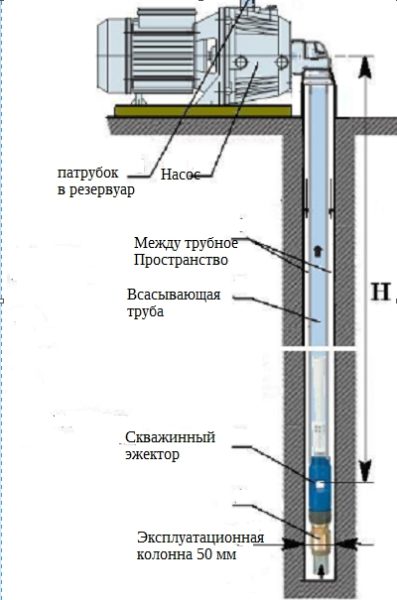

The choice of a pumping station for a well depends on the depth of development. For example, if the depth reaches 12-15 m, a device with a built-in ejector is needed, more than 20 m - with an external ejector. Due to the looped suction, the lifting force of the water increases, but the efficiency drops sharply and energy consumption increases.

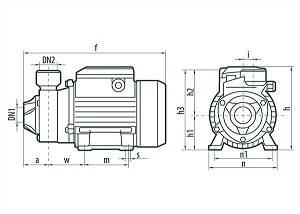

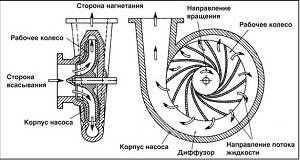

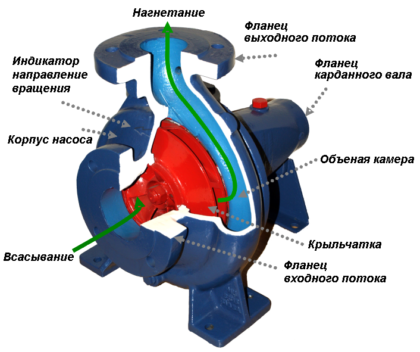

Types of surface pumps

Surface pumps are of three types - centrifugal, ejector and vortex. They differ from each other in design features and working qualities.

Table. Types of surface pumps.

|

Vortex | Inside the body of such a pump there is a special axis, on which the so-called impeller is fixed, on which the blades are located. It is they who will transfer the energy of movement to the water during the rotation of the main axis. These are small units and are inexpensive. They have a small suction depth, so they are more often used not for pumping water into a hydraulic accumulator, but for adjusting pressure indicators in the plumbing system, watering, pumping water from the basement during spring floods. Efficiency - only about 45%. Not recommended for use as a pump for filling hydraulic accumulators. |

|

Centrifugal | Such a pump is also called self-priming and has special wheels inside, which during the operation of the device create the necessary pressure. They rotate due to the working shaft, based on bearings. The power is higher than that of a vortex pump, and therefore it can pump water from a greater depth and can be used to organize a water supply system for a residential building. This is a more expensive, but at the same time reliable and robust type of device with an efficiency of up to 92%. Can be used to create a pumping station in the house. |

|

ejector | Such a pump consists of two circulation circuits: in one of them, liquid is supplied to the ejector, where a pressure difference is formed due to the Bernoulli effect, and water flows from the second circuit. This design allows you to lower the pump to a depth, which will solve the problem with a small suction head.But recently, such installations have not been in demand, as there are more efficient submersible pumps. |

The principle of operation of self-priming pumps

Based on the above, it can be noted that it is best to purchase a centrifugal pump. This is the best option. Let's take a closer look at its device: a pair of discs is installed on the gear shaft inside the mechanism. A small hole is made in one of them, connected to the free space between these parts. In this gap there are plates inclined at a certain angle - they create special tubules from the center of the free space to the edge. These "passes" are connected to a diffuser, which, in turn, is connected to a supply conduit. And the suction hose is connected to the disc hole.

Horizontal surface centrifugal pump

The space between the disks and the suction hose are filled with water, then the reducer is started, and the vane plates begin to rotate and push the water out. This process occurs due to centrifugal force. As a result, a rarefied space is created in the center, and along the edges and in the diffuser, on the contrary, the pressure increases. To equalize this "skew", the system will seek to equalize the indicators and begin to pump water. This is how this setup works.

The electric pump will automatically supply water to the house, which is very convenient and practical.

Selection Options

Well pumps are easy to distinguish even by their appearance. They are an elongated cylinder made of stainless steel or plastic. Naturally, stainless steel models are more expensive - the steel must be of high quality (usually food grade AISI304). Pumps in a plastic case are much cheaper.Although they are made of a special impact-resistant plastic, they must be handled with care - it still does not tolerate shock loads very well. All other parameters will have to be selected.

Brief technical characteristics of the pump for the well

Water flow and pump performance

In order for the water in the house or in the country to be with sufficient pressure, equipment is needed that can deliver the required volume of liquid. This parameter is called pump performance, measured in liters or milliliters (grams) per unit of time:

- ml/s - milliliters per second;

- l / min - liters per minute;

- l / h or cubic / h (m³ / h) - liters or cubic meters per hour (one cubic meter is equal to 1000 liters).

Borehole pumps can lift from 20 liters/min to 200 liters/min. The more productive the unit, the greater the power consumption and the higher the price. Therefore, we choose this parameter with a reasonable margin.

One of the key parameters for selecting a well pump is performance

The required amount of water is calculated by two methods. The first takes into account the number of people living and the total expense. If four people live in the house, then the water consumption per day will be at the rate of 800 liters (200 l / person). If there is not only water supply from the well, but also irrigation, then some more moisture must be added. We divide the total amount by 12 (not by 24 hours, because at night we use water supply to a minimum). We get how much we will spend on average per hour. Dividing it by 60, we get the required pump performance.

For example, for a family of four and watering a small garden, it takes 1,500 liters per day. Divide by 12, we get 125 liters / hour. In a minute it will be 2.08 l / min.If you often have guests, you may need a little more water, so we can increase the consumption by about 20%. Then you will need to look for a pump with a capacity of about 2.2-2.3 liters per minute.

Lifting height (pressure)

When choosing a pump for a well, you will inevitably study the technical specifications. There are parameters such as lifting height and immersion depth. Lifting height - also called pressure - is a calculated value. It takes into account the depth from which the pump will pump water, the height to which it must be raised in the house, the length of the horizontal section and the resistance of the pipes. Calculated according to the formula:

The formula for calculating the pump head

An example of calculating the required pressure. Let it be necessary to raise water from a depth (pump installation site) of 35 meters. The horizontal section is 25 meters, which equates to 2.5 meters of elevation. The house is two-story, the highest point is a shower on the second floor at a height of 4.5 m. Now we consider: 35 m + 2.5 m + 4.5 m = 42 m. We multiply this figure by the correction factor: 42 * 1.1 5 = 48.3 m. That is, the minimum pressure or lifting height is 50 meters.

If there is a hydraulic accumulator in the water supply system of the house, it is not the distance to the highest point that is taken into account, but its resistance. It depends on the pressure in the tank. One atmosphere is equal to 10 meters of pressure. That is, if the pressure in the GA is 2 atm, when calculating, instead of the height of the house, substitute 20 m.

Immersion depth

Another important parameter in the technical specifications is the immersion depth. This is the amount with which the pump can pump out water. It varies from 8-10 m for very low-power models to 200 m and more. That is, when choosing a pump for a well, you need to look at both characteristics at once.

For different wells, the depth of immersion is different

How to determine how deep to lower the pump? This figure should be in the passport for the well. It depends on the total depth of the well, its size (diameter) and flow rate (the rate at which water arrives). In general, the recommendations are as follows: the pump should be at least 15-20 meters below the water surface, but even lower is better. When the pump is turned on, the liquid level drops by 3-8 meters. The amount remaining above it is pumped out. If the pump is very productive, it pumps quickly, it must be lowered lower, otherwise it will often turn off due to lack of water.

Well diameter

An important role in the selection of equipment is played by the diameter of the well. Most domestic well pumps have sizes from 70 mm to 102 mm. In general, this parameter is usually measured in inches. If so, then the easiest way to find three and four inch specimens. The rest are made to order.

The well pump must fit in the casing

Surface pump for a well 30 meters

With increasing depth, the pressure increases, so for a static level of 30 m, you will need a pump more powerful than the DP-100.

Surface pump with remote ejector LEO AJDm110/4H

The maximum suction height is 40 meters, which guarantees a certain power reserve for lifting water from a depth of 30 meters.

The manufacturer LEO launches a new type of flexible shaft pumps for deep wells.

It is installed at the wellhead. A flexible shaft is produced with a length of 25, 45 meters - the depth from which water can be pumped out. This type of pump is more semi-submersible than surface. They are mounted on a production string with a diameter of 50 mm. Can be an alternative to a hand pump.

The hydraulic part consists of 2 hoses inserted one into the other. A flexible shaft is passed inside, connected to a screw-type pump head.

screw pump

Despite its small size, the maximum capacity is 1.8 m3/h and the head is 90 meters. The hose is lowered into the well to a predetermined depth, the flexible shaft is connected to the shaft of the electric motor gearbox. The advantage of the pump is that the electric motor is at the top. In case of clogging of the pump, the flexible shaft is disconnected, the hose is pulled out, and washed.

Let's make a table of the top 10 surface pumps that are most in demand among buyers.

Table 2. The best surface pumps.

| brand | Type of | Pressure, bar | Head, m | Consumption, m 3 / h | Water level depth, m |

|---|---|---|---|---|---|

| Grundfos MQ 3-35 | multi-stage, self-priming | 7.5 | 44 | 4.1 | 8 |

| AJDm110/4H | with external ejector | 9 | 100 | 2.2 | 30-40 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming with integrated ejector | 7 | 37 | 4.8 | 8,5-9 |

| Pedrollo JSWm 2CX (JSWm 10MX | self-priming, vortex | 8 | 38 | 8 | |

| APM 100, 150, 200 (Speroni) | with remote ejector | 7 | 64 | 1,8 2,7 | 10-40 |

| BG and BGM (3, 5, 7, 9, 11 (Lowara) | self-priming with integrated ejector | 9 | 46-60 | 2-4 | 8-9 |

| JET 112 T by DAB | self-priming with integrated ejector | 6-8 | 50 | 2-3 | 8-9 |

| Calpeda NGLM 4/A | self-priming with integrated ejector | 8 | 50 | 2-4 | 9 |

| JMC 100 | centrifugal self-priming | 7.5 | 44.5 | 3 | 8 |

| Gilex Jumbo 70/50 N / 3702 | self-priming | 8 | 50 | 4.2 | 9 |

| The best pumping stations for deep water lifting | |||||

| Grundfos JPD 4-54 PT-V | with remote ejector | 6 | 54 | 27 | |

| ELITECH CAB 800/24E | with remote ejector | 6 | 45 | 2.4 | 25 |

| Gilex Jumbo 50/28 Ch-18 | with remote ejector | 3 | 28 |

Here, stations and pumps with a built-in ejector or an external version are selected. To automate the process of extracting water from wells, it is recommended to purchase a hydraulic accumulator with a pressure switch for these pumps. Usually they buy a ready-made pumping station.The manufacturer has calculated the optimal tank volume for this type of pump.

In order for the pumping equipment to work smoothly, it is necessary to choose the right pump. In addition to the static, dynamic level, well flow rate, average consumption per person per day, it is necessary to determine the total height of water rise from the mirror to the highest point of supply. Do not forget the horizontal section, 6% -10% of which must be added to the height of the lift. So determine the required pressure.

Self-priming surface pumps without a built-in ejector are best installed in basements or caissons. The shorter the distance to the water surface, the lower the hydraulic losses. Turns and narrowing of water lines also increase hydraulic resistance. Purchase a storage tank for irrigation, so you will create a supply of water if the daily well flow rate is low.

Video - Hand pump for a well without a foundation

One more type of pump could be considered - the compressor. It is used to lift water from a well using an airlift. The method has not found wide distribution. Submersible, semi-submersible and deep pumps are often used, but their device is more complicated, the cost and repair is also expensive. The best option for shallow wells is a surface pump.