- Starting the pumping station

- Connection of a pumping station

- Water supply from a well for permanent residence

- Connecting the pumping station to the water supply

- Well connection

- Types of pumps for wells and their functions

- Types of household pumps

- Scheme how to connect with your own hands

- Mounting the safety hummock and cable

- How to install in the water supply system

- Features of operation of surface pumps

- Preparation of materials

- Installing a pump in a well

- Important criteria in the selection of water supply equipment

- What is the danger of unskilled installation of the pump in the well

- Advantages of using a pumping station

- What should be a good pump?

- Surface pump for a well 30 meters

- What should be the depth of the well to lower the pump?

- Carrying out installation work

- Technical properties of borehole pumps

Starting the pumping station

In order to put the pumping station into operation, it is necessary to completely fill it and the supply pipeline with water. For this purpose, there is a special filler hole in the body. Pour water into it until it appears. We twist the plug into place, open the tap at the outlet to consumers and start the station. At first, water goes with air - air plugs come out, which formed during the filling of the pumping station.When the water flows in an even stream without air, your system has entered the operating mode, you can operate it.

If you filled in water, and the station still does not start - the water does not pump or comes in jerks - you need to figure it out. There are several possible reasons:

- there is no non-return valve on the suction pipeline lowered into the source, or it does not work;

- somewhere on the pipe there is a leaky connection through which air is leaking;

- the resistance of the pipeline is too high - you need a pipe of a larger diameter or with smoother walls (in the case of a metal pipe);

- water mirror is too low, not enough power.

To prevent damage to the equipment itself, you can start it by lowering the short supply pipeline into some kind of container (tank of water). If everything works, check the line, suction depth and check valve.

Connection of a pumping station

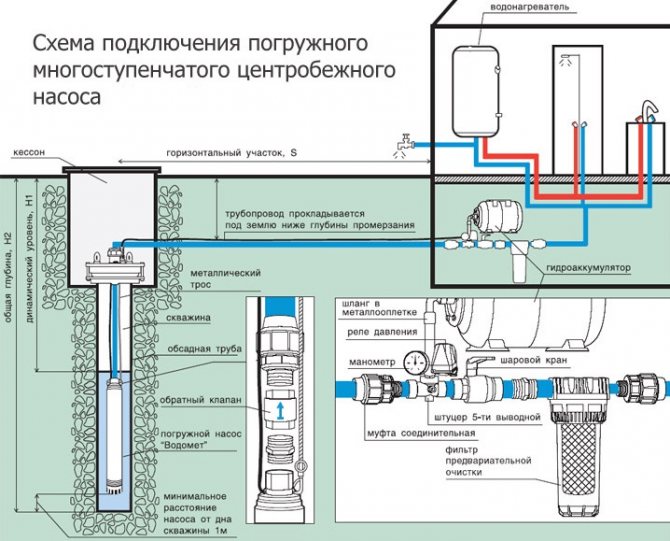

Choosing equipment and a place for installation is half the battle. You also need to correctly connect everything into a system - a water source, a station and consumers. The exact connection diagram of the pumping station depends on the chosen location. But anyway there is:

- Suction pipeline that descends into a well or well. He goes to the pumping station.

- The station itself.

- The pipeline going to consumers.

All this is true, only the strapping schemes will change depending on the circumstances. Let's consider the most common cases.

Water supply from a well for permanent residence

If the station is placed in a house or in a caisson somewhere on the way to the house, the connection scheme is the same. A filter (most often a regular mesh) is installed on the supply pipeline lowered into a well or well, a check valve is placed after it, then a pipe already goes.Why the filter - it is clear - to protect against mechanical impurities. A check valve is needed so that when the pump is turned off, water under its own weight does not flow back. Then the pump will turn on less often (it will last longer).

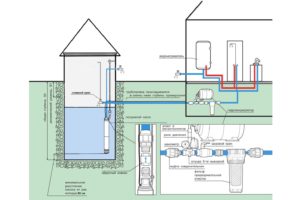

Scheme of installing a pumping station in a house

The pipe is brought out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into the trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay sheets of polystyrene foam on top, and then fill it with sand, and then with soil).

Passage option not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the place of passage should also be insulated), in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as bring the pipeline out / in through the walls, and also in the fact that it is difficult to localize damage when a leak occurs. To minimize the chances of a leak, take proven quality pipes, lay a whole piece without joints. If there is a connection, it is desirable to make a manhole.

Detailed scheme of piping a pumping station when connected to a well or well

There is also a way to reduce the volume of earthworks: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the site has a high level of groundwater.

There is another important point - the well cover must be insulated, as well as the rings on the outside to the freezing depth. It's just that the section of the pipeline from the water mirror to the outlet to the wall should not freeze. For this, insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system with centralized water supply. In this case, a water pipe is connected to the station inlet (also through a filter and a check valve), and the outlet goes to consumers.

Scheme of connecting the pumping station to the water supply

It is advisable to put a shut-off valve (ball) at the inlet so that if necessary you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - in order to cut off consumers if necessary and not drain water from the pipes.

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Unless the pipeline exits at the point where the casing pipe ends. A caisson pit is usually arranged here, and a pumping station can be installed right there.

Pumping station installation: well connection diagram

As in all previous schemes, a filter and a check valve are installed at the end of the pipe. At the entrance, you can put a filler tap through a tee. You will need it for the first start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth).If the pumping station is installed in the country, it's okay, the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

Types of pumps for wells and their functions

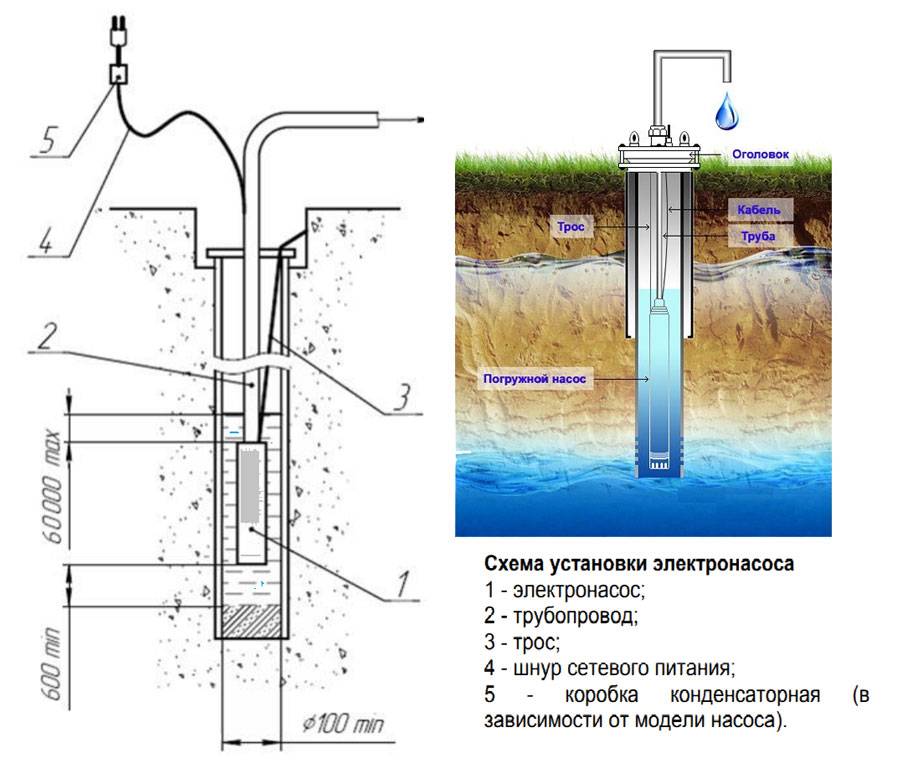

Well water pumps can be submerged into narrow wells to great depths or mounted on the surface. The principle of operation of the device and its installation is as follows:

- Its main elements are impellers mounted on a single shaft.

- Their rotation occurs in diffusers, which ensures the movement of liquid.

- After passing the liquid through all the wheels, it exits the device through a special discharge valve.

- The movement of the liquid occurs due to pressure drops, which are summed up on all impellers.

There are several types of such equipment:

- Centrifugal. Such a pump allows the supply of clean water to be provided without major contaminants.

- Screw. This is the most common device, capable of pumping liquid with an admixture of particles per cubic meter no more than 300 grams.

- Vortex. Transfers only purified water.

Despite the differences, all types of pumps serve to perform similar functions:

- Supply groundwater to private houses and cottages.

- Participate in the organization of irrigation systems.

- Pump liquid into tanks and containers.

- Provide comprehensive water supply in automatic mode.

When choosing a pump for a site, the following criteria are taken into account:

- The original dimensions of the equipment. They must be taken into account to ensure certain technological tolerances when placing the pump in the well.

- Power source of electricity. Borehole pumps are made single- and three-phase.

- Device power. This parameter must be determined in advance based on the calculated pressure and water consumption.

- Pump cost. In this case, it is necessary that the price-quality ratio of the equipment is chosen correctly.

Types of household pumps

Pumps for wells are divided into submersible and surface. Such units have some advantages over the rest:

- Large water intake depth, which is not available for pumps of any other type.

- Ease of installation.

- No moving parts.

- Low noise level.

- Long service life.

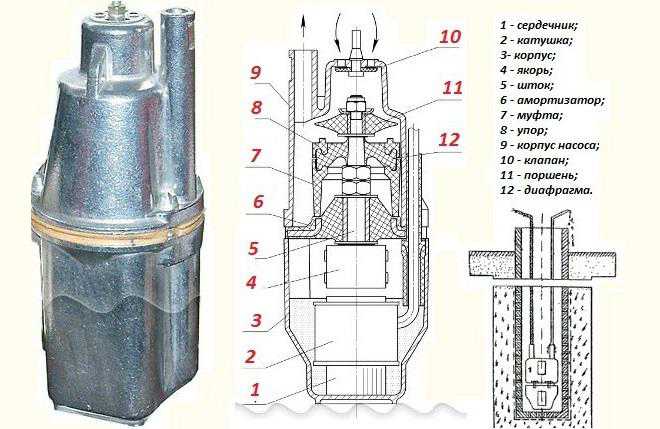

The photo shows the types of submersible borehole pumps.

Submersible borehole pumps

Tip: It is very important to follow the competent and proper arrangement of equipment, use only high-quality materials. Violation of installation technology or the use of poor materials can lead to:. Violation of installation technology or the use of poor materials can lead to:

Violation of installation technology or the use of poor materials can lead to:

- Breakage of the pump.

- its premature failure.

- When dismantling, the impossibility of lifting the pump.

Scheme how to connect with your own hands

The equipment installed in the technical room of the house includes:

- Hydraulic accumulator. The membrane tank is used to maintain pressure in the water supply system, which should be at the level of 3.5 atmospheres. With a full hydraulic tank, water is consumed within 3-4 hours, preventing frequent switching on of the well pump. It protects the water supply system from water hammer that can break pipes.

- In the body of the product there is a chamber made of hygienic rubber for water with a pressure valve, and the rest of the tank is filled with air, which creates pressure through the pneumatic valve with the help of a compressor. A line from a submersible pump is connected to the hydraulic tank, through which water enters the water chamber.

- The principle of operation is based on maintaining the pressure in the water chamber with the help of air. With the flow of water and a decrease in pressure in the system, the downhole unit is turned on, and water is supplied to the chamber.

- A cabinet with electronic and relay control and equipment protection devices, which, through the supplied sensors, control the operation of autonomous water supply.

- In the pump, the installed mini-blocks control the pump and, when the load of the low level of the aquifer increases and the single-phase motor heats up, the unit is switched off through the relay.

- Sensors located in the pipeline monitor the nominal pressure of the fluid. When it decreases through the electronic system, the device turns on, filling the chamber with water.

- If the pressure is not set to the standard, it is necessary to adjust the relay.

Mounting the safety hummock and cable

We connect the electric cable and the water pipe together with our own hands by tying

Now we proceed to fastening and installing the safety cable and electrical cable according to the further scheme. And if everything is clear with the wire (it is connected to the pump), then we attach the safety cable, selected in accordance with the parameters of the well, to the base of the pump and fix it with special steel clamps. In this case, the clamps themselves and the end of the steel cable must be insulated with a special adhesive tape (duct tape).

We connect the electric cable and the water pipe together with our own hands using the strapping method.To do this, you can use plastic clamps or just electrical tape.

It is important to avoid strong cable tension or sagging. This method of mounting the wire and pipe will prevent the formation of a loop around the pump during its operation.

And this, in turn, will insure against jamming of the pump in the well when it is lifted.

We attach a safety cable to the pipe and cable in the same way with clamps. It can be fastened with a simple duct tape with a large step.

How to install in the water supply system

Scheme of installation of a deep pump. (Click to enlarge)

Scheme of installation of a deep pump. (Click to enlarge)

It is better to entrust the installation of the pump to specialists. They will be able to tell you which type of unit is better and carry out its installation with high quality.

But, if you wish, you can do all the installation work on your own.

In this case, the installation is carried out in an already prepared well. When performing work, you must follow the established rules.

To perform installation work, you must have available:

- the unit itself;

- kapron cable;

- hoses for water intake;

- pipes and other accessories.

Before proceeding with direct installation, it is necessary to check the well for curvature and narrowing. Such defects can significantly complicate the installation of the unit and reduce its service life. The pump is selected in accordance with the technical characteristics of the pump.

The cord is tied so that the knot is at least 10 cm from the device. This will prevent the cord from entering the unit when water is sucked in.

If the unit is installed at a shallow depth, then the mount is supplemented with a spring suspension. With the help of such an element, the vibration that occurs during the operation of the unit is repaid.

An important point: it is forbidden to use steel wire or cable for fastening. Under the influence of vibration, such materials lead to the destruction of the fastening, which is located on the pump housing.

Before lowering the pump, a special rubber ring is put on its body. With its help, the pump is prevented from hitting the walls of the well. Otherwise, such mechanical action leads to damage or complete destruction of the body.

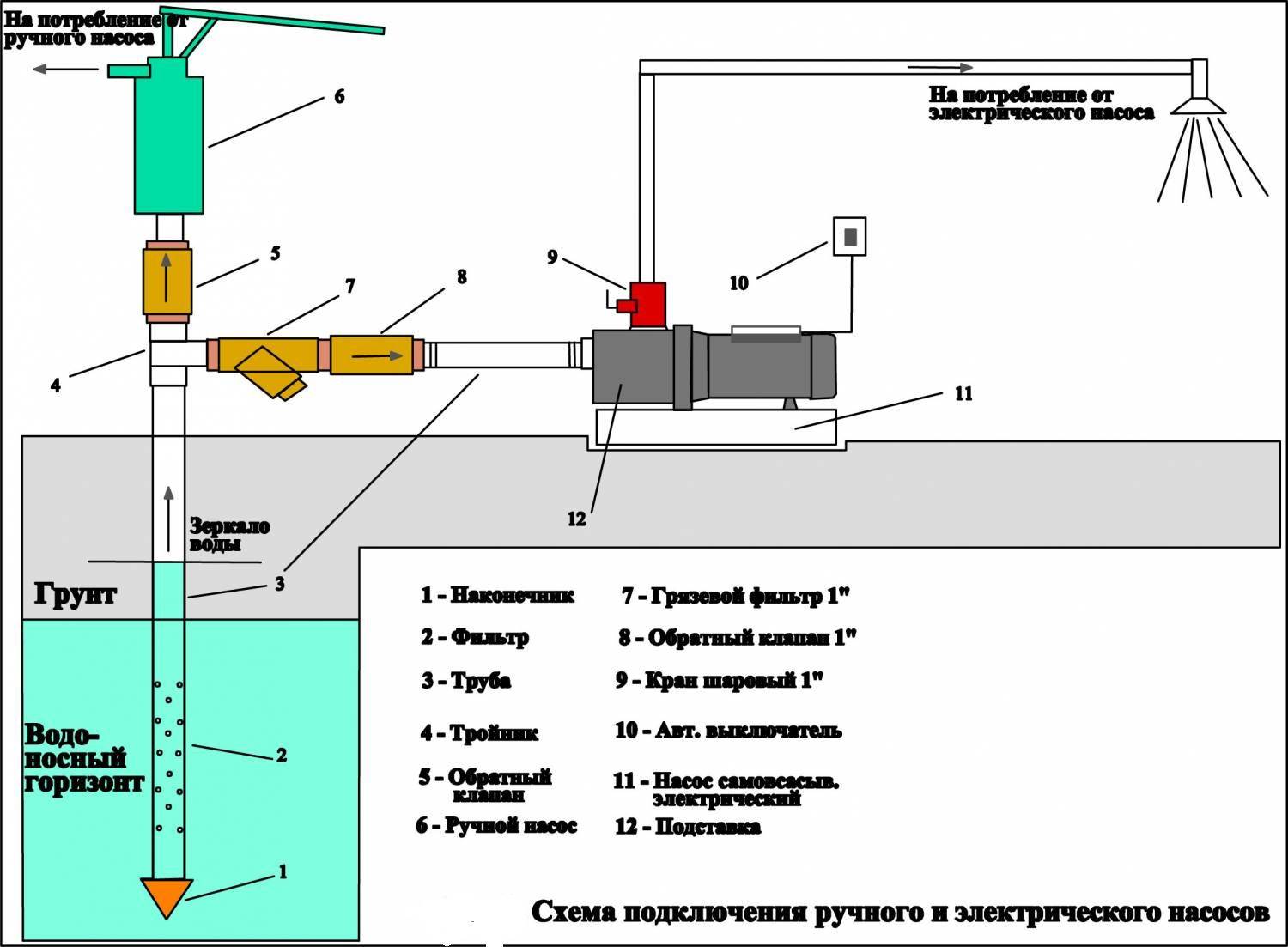

Features of operation of surface pumps

Surface pumps, as the name implies, are installed on the surface. These are relatively inexpensive and quite reliable devices, although they are not suitable for very deep wells.

You will rarely find a surface pump that can deliver water from a depth of more than 10 meters. And this is only in the presence of an ejector, without it, the performance is even lower.

Surface pumping stations have an extensive scope, they pump water from various sources with a depth of no more than 10 m

If the cottage has a well or a well of suitable depth, you can safely choose a surface pump for the site.

You can take a model with a relatively low productivity for irrigation or a more powerful device that will effectively provide water to a private house. The convenience of surface pumps is obvious: first of all, it is free access for adjustment, maintenance and repair.

In addition, the installation of such a pump at first glance looks very simple. The pump must be installed in a suitable place, lower the hose into the water, and then connect the device to the power supply.If the pump is needed only for irrigation, you can purchase and install it without any additional elements.

To optimize the operation of the device, it is recommended to take care of an automated control device. Such systems can turn off the pump when a dangerous situation arises, for example, if water does not enter it.

“Dry running” is not recommended for almost all models of surface pumps. You can also automate the shutdown of the pump if the watering time is over, the required volume is filled, etc.

Preparation of materials

Before starting work, you need to purchase the necessary materials. A special moment of installation is the lowering of the pump into the casing. To do this, you need the original rope. The factory equipment of some models of submersible units includes a polymer cord. If it is not available, you should purchase a device for lowering the mechanism into the pipe separately.

The cable has the following requirements:

- reliability and strength, expressed by the ability to withstand loads that are 5 times the weight of the suspended equipment;

- resistance to the damaging effects of dampness, since certain parts of the product are under water.

It is allowed to use improvised materials to damp vibrations. A piece of medical tourniquet or elastic hose will do. Hanging the mechanism on a metal cable or wire is not worth it because of the likelihood of damage to the mount.

The next element that allows you to properly install a deep-well pump into a well is a cable for supplying equipment with power. It is better to take a wire with a small margin in length.

Water is supplied from an autonomous source to consumption points in the house through a water main.The best option is polymer pipes with a cross section of 32 mm or more. With a smaller diameter, it is impossible to provide sufficient pressure.

It is allowed to use a metal pipeline when installing a borehole pump. At the same time, threaded connections must be sealed with FUM tape, flax fiber or a special Tangit tool. To further strengthen the linen winding, a silicone-based sealant is used.

In addition, before installing the pump on the well, you need to prepare the following materials:

- manometer;

- attachment point made of durable steel;

- fittings for fixing the electric cable on the pipe line (clamps can be used);

- check valve;

- shut-off valve that shuts off the water supply, etc.

A nipple adapter is installed on the outlet pipe of the pump. In the absence of a pumping unit in the factory, this device is purchased separately.

During the initial pumping of the well, a large volume of heavily contaminated fluid is removed from it. For the procedure, it is recommended to use powerful models that can pump dirty water. After that, you can proceed with the installation of a standard borehole pump for further operation.

Installing a pump in a well

An important point during the work on the water supply of a country house is the competent installation of the pump in the well. If the equipment is installed correctly, this is a guarantee of its long and trouble-free operation.

Despite the fact that there is nothing complicated in installing a pump in a well, there are also some nuances here that should be taken into account even before work begins.

Important criteria in the selection of water supply equipment

If the water supply equipment was chosen incorrectly, installing a well pump can be a rather difficult task. The parameters that must be considered when choosing pumping equipment include the following:

- Dynamic and static level of a water artesian well. You can find this information in the installation passport. If you do not have such data, for example, due to the loss of documents, you should not panic - this information is restored empirically;

- To calculate the required volume of water to be provided by the installed equipment, count the number of water consumption points. These include a sink, bathtub, shower, toilet, washing machine and dishwasher, etc.;

- The distance between the house and the water shaft.

What is the danger of unskilled installation of the pump in the well

If mistakes were made during the installation of downhole equipment or poor-quality materials were used, this can cause a number of negative consequences. There are frequent cases when work performed by non-professionals leads to breaks in water-lifting products, the impossibility of dismantling if replacement is necessary, as well as premature breakdowns of pumps.

The first two scenarios, when the old equipment cannot be removed from the well, jeopardize the possibility of its subsequent use. Because of this, all work has to be done anew: another well is drilled, a new caisson is installed, since the use of the old one is impractical, and new equipment is installed.

Advantages of using a pumping station

The device of autonomous water supply in your home provides independence and comfort.

The pumping station provides the following benefits:

- Increases the efficiency of the water supply system.

- Increases the safety of operation of equipment and pipelines.

- Provides some (depending on the capacity of the hydraulic tank) supply of water and its supply even when the power supply is turned off.

- Maintains constant water pressure and stability.

- Increases the durability of appliances and household appliances connected to the water supply system.

- Automatic mode of operation (timely switching on and off the pumping unit) reduces equipment wear and energy costs.

- Possibility to choose the installation location of the unit.

- It has compact dimensions and light weight.

- Easy to mount.

In rural areas, cottage and holiday villages, water supply communication networks often sin with low pressure and unstable pressure.

In this case, the pumping station can be connected to an existing main water supply - this will solve the problems with pressure drop and lack of pressure in the water supply.

The use of a pumping station in an autonomous water supply scheme will not only significantly increase the level of comfort of living conditions, but also significantly increase the working life of devices installed in the water supply system

What should be a good pump?

First you need to select and purchase a suitable pump, as well as a number of materials necessary for its successful installation. The pump is usually taken submersible, while it is very desirable that it be centrifugal.

Unlike centrifugal models, vibratory pumps cause dangerous vibrations in the well, which can lead to the destruction of the soil and casing.Such models are especially dangerous for sand wells, which are less stable than artesian counterparts.

The power of the pump must match the productivity of the well. In addition, the immersion depth for which a particular pump is designed should be taken into account. A model designed to work at a depth of 50 m can supply water from a depth of 60 meters, but the pump will soon break down.

A submersible centrifugal pump is the best choice for a well. Its performance, dimensions and other indicators should be correlated with the characteristics of its own water source

Another risk factor is the level of drilling quality. If an experienced team drilled, the well will be better able to withstand the destructive effect. And for wells created by one's own hands or by the efforts of “shabashniki”, it is recommended to use not just a centrifugal pump, but special models for wells.

Such devices better tolerate the loads associated with pumping water heavily polluted with sand, silt, clay particles, etc. Another important point is the diameter of the pump. It must match the dimensions of the casing

It is important to take into account the features of the power supply of the pump. For wells, both single-phase and three-phase devices are used.

For four-inch pipes, finding equipment is easier than for three-inch pipes. It is good if this moment is taken into account at the well planning stage. The greater the distance from the pipe walls to the pump housing, the better. If the pump passes into the pipe with difficulty, and not freely, you need to look for a model with a smaller diameter.

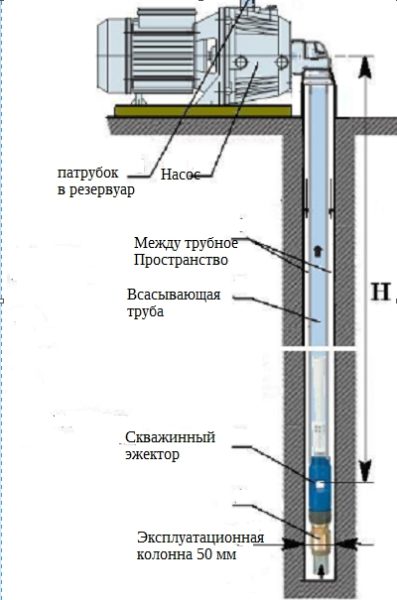

Surface pump for a well 30 meters

With increasing depth, the pressure increases, so for a static level of 30 m, you will need a pump more powerful than the DP-100.

Surface pump with remote ejector LEO AJDm110/4H

Surface pump with remote ejector LEO AJDm110/4H

The maximum suction height is 40 meters, which guarantees a certain power reserve for lifting water from a depth of 30 meters.

The manufacturer LEO launches a new type of flexible shaft pumps for deep wells.

It is installed at the wellhead. A flexible shaft is produced with a length of 25, 45 meters - the depth from which water can be pumped out. This type of pump is more semi-submersible than surface. They are mounted on a production string with a diameter of 50 mm. Can be an alternative to a hand pump.

The hydraulic part consists of 2 hoses inserted one into the other. A flexible shaft is passed inside, connected to a screw-type pump head.

screw pump

screw pump

Despite its small size, the maximum capacity is 1.8 m3/h and the head is 90 meters. The hose is lowered into the well to a predetermined depth, the flexible shaft is connected to the shaft of the electric motor gearbox. The advantage of the pump is that the electric motor is at the top. In case of clogging of the pump, the flexible shaft is disconnected, the hose is pulled out, and washed.

What should be the depth of the well to lower the pump?

The installation of a submersible pump in the well must be carried out in such a way that the motor can be cooled properly. To achieve a good effect, it is recommended to lower the unit to a depth of 30-40 cm below the liquid level. However, professionals say that it is most optimal to immerse the deep pump by 2-3 meters. In this case, very often the depth of the well can reach 100 meters or more.

Drilling a well is best left in the hands of experienced professionals, as they are likely to distinguish between dynamic and static water levels, which many are not aware of. After drilling, a measurement is taken from the ground to the surface of the water, and the result is called a static level. Further, the installed pump pumps out water and again the depth to the water surface in its calm state is measured, as a result of which the dynamic level becomes known.

Scheme of installing a pump in a well

The water level in the well is measured after the installation of the gas pipe string, which is submerged below the dynamic level. The insulation resistance of the motor winding with the electrical wire lowered must be determined with a megohmmeter, after which it is already possible to connect the station to the device and evaluate the correctness of the actions taken.

Carrying out installation work

There are many rules and recommendations regarding the installation of a submersible borehole pump, including do-it-yourself ones. The regulations state that this device must not come into contact with the bottom of the intake well, and at the same time the device must be submerged more than a meter under water. The filling of the well is not constant. It may vary depending on the time of year and the intensity of the fence.

There are many rules and recommendations regarding the installation of a submersible borehole pump, including do-it-yourself ones. The regulations state that this device must not come into contact with the bottom of the intake well, and at the same time the device must be submerged more than a meter under water. The filling of the well is not constant. It may vary depending on the time of year and the intensity of the fence.

- The higher the performance parameters of the unit indicated in the passport, the greater should be the immersion depth. The best way to determine the location, which is most often used in practice: the device is lowered on a safety cable to the bottom of a water well, and then raised by 2.5-3 m and temporarily secured, launched. If the equipment operates without deviations from the norm, it is fixed in this position.

-

This method is used when installing units in wells up to 16 m; for deep wells, the calculation is done differently. From the total depth of the source from the tip to the bottom, the distance from the mouth to the water table (dynamic level) is subtracted. The resulting difference is the magnitude of the location of the water during the active operation of the well. According to the norms, this gap is reduced by 300 mm from below and 100 mm from above. In the remaining segment, the apparatus should be located.

- Before lowering the pump into the well, you need to check the casing yourself for the presence of bumps, narrowing or curvature. They can affect the quality of the equipment and cause the unit to fail. Preliminary flushing and cleaning of the mine will make it possible to save the main components of the structure. The steps of this process can be seen in the video.

- Before lowering the unit, a head is put on the pipe through the sealing ring. If the preparatory work is done correctly, there should be no problems at this stage. However, if the pump stops and does not go, then there are foreign objects in the well.

Technical properties of borehole pumps

The main characteristic properties of submersible pumping equipment are as follows:

- the possibility of creating a water pressure at the level at which its optimal extraction from the well and supply to the water supply system is ensured;

- high duration of uninterrupted operation;

- the cylindrical shape of the body, which provides a certain convenience during the installation process;

- some models are able to pump out from a well that has impurities in the form of sand and clay; such devices are made from materials that have high wear resistance.

Types of pumps for wells

Deep pumping equipment is distinguished by good workmanship and a high degree of reliability. These qualities have allowed these devices to gain high popularity and become in demand among the owners of country houses and summer cottages.

The use of these pumping systems has become a popular way to organize autonomous water supply for country cottages and private houses.

The main advantages of submersible pumps:

- large depth of water intake;

- low technical complexity of the installation;

- lack of rubbing elements, which increases the overall service life and increases wear resistance;

- low noise level;

- long service life.

Due to the reliability of this equipment, maintenance and replacement of a submersible pump in the well are very rare.