- What should be a good pump

- Making a connection

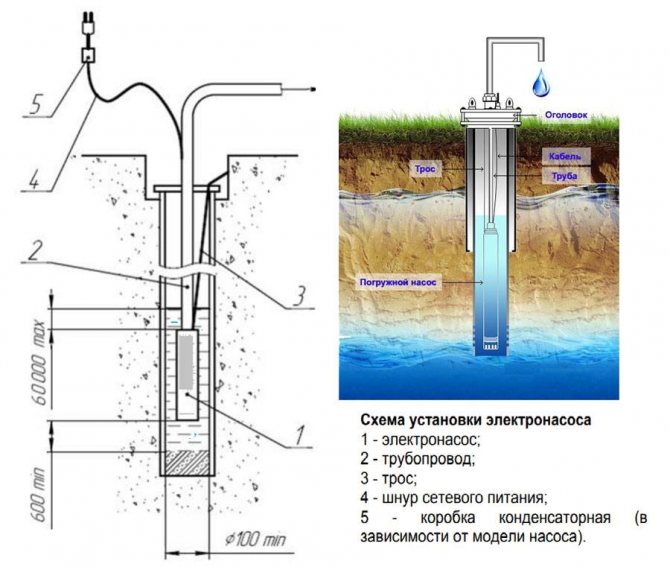

- Submersible pump installation

- Step 1: Preparing to mount the equipment

- Step 2: Submerging the pump into the well

- Step 3: Determine the duty point of the pump

- Replacing a submersible pump

- Troubleshooting

- Dismantling the deep pump

- Benefits of Hiring Qualified Professionals

- Do-it-yourself dismantling of a deep pump

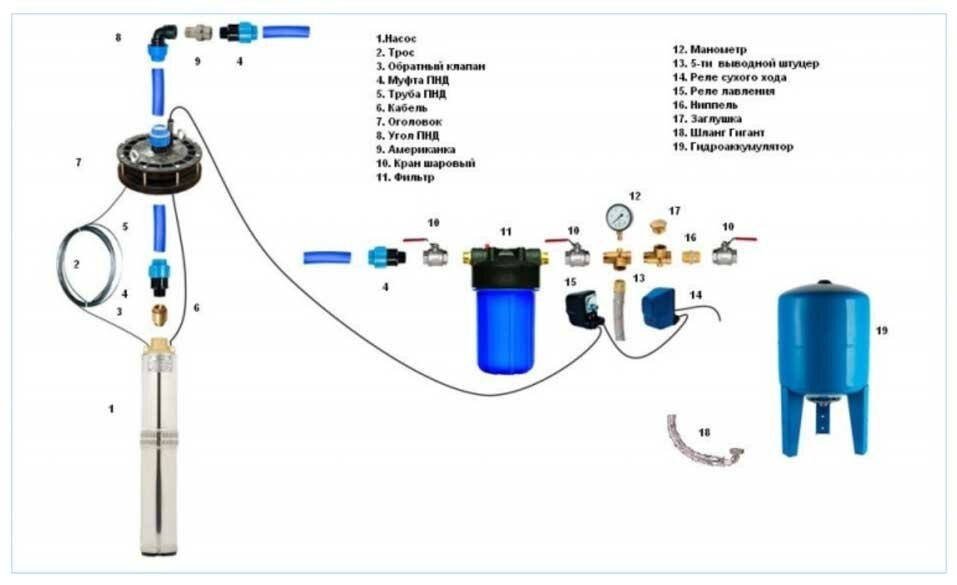

- Preparation of related installation materials

- What is a surface pump

- How to properly lower a submersible pump

- Determining the duty point of the pump

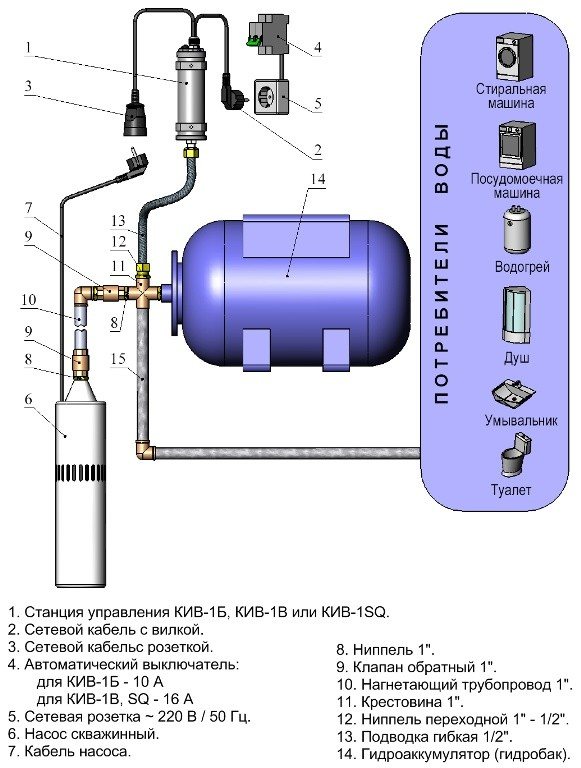

- Connection of a pumping station

- Water supply from a well for permanent residence

- Connecting the pumping station to the water supply

- Well connection

- How to replace the pump in the well in case of an accident?

- Option number 1: we call deep pump repair specialists

- Option number 2: do-it-yourself pump replacement

What should be a good pump

The flow rate of a local source is an important indicator when choosing a device. For high performance, a large power unit is required. Depth is the determining factor. A model designed for 40 m will supply water from 50 m, but will quickly fail.

The level of drilling quality should also be taken into account.If the work was carried out by a professional team, the shaft can withstand heavy loads and is resistant to external influences. For do-it-yourself pits, it is better to buy centrifugal models designed specifically for wells for installing a submersible pump.

When choosing equipment for pumping water, special attention is paid to the dimensions of the device. They must be selected in accordance with the internal section of the casing

The pump must pass freely into the pipe. If the unit is in contact with the walls, it is better to look for an option with smaller dimensions.

Finding a pump model that fits a 4" casing is easier than a 3" one. This factor must be taken into account when drawing up a plan for installing a submersible pump in a well.

Deep pump mechanisms have different power supply schemes. Single and three-phase devices are allowed to be used in a water mine.

Making a connection

When a centrifugal pump is installed in a well, it is not necessary to use threaded connections when connecting. They are able to reduce the strength of pipes that are subject to corrosion. Flanged connections have a longer life span. When using them, the fixing bolt must be installed from above, while the nut is strengthened from below. This is due to the fact that a dropped bolt can cause serious accidents. On the base plate, you need to fix the discharge pipeline, or rather, its upper end. At the next stage, a check valve is mounted on it, if the pump is deprived of it.

At the same stage, the elbow, valve and pressure gauge must be connected to the water supply system. Now the suspension is strengthened to the crossbar.This is the last thing to be done before the pump is in the well. The installation of a surface pump on a well involves the process of lowering the equipment, which should not touch the walls. If such a possibility cannot be ruled out, it is recommended to protect the case with a rubber ring. To measure the water level in the well, it is necessary to mount a gas pipe string, which is installed in the hole in the base plate. It must be immersed below the dynamic level.

With a megohmmeter, it will be possible to determine the insulation resistance of the motor winding with the cable lowered. The control station should then be connected to the equipment, making sure the pump is sufficiently submerged in water. Installing a pump in a well, the price of which will be indicated below, provides for the need to assess the correct functioning of the electric motor under the load.

Submersible pump installation

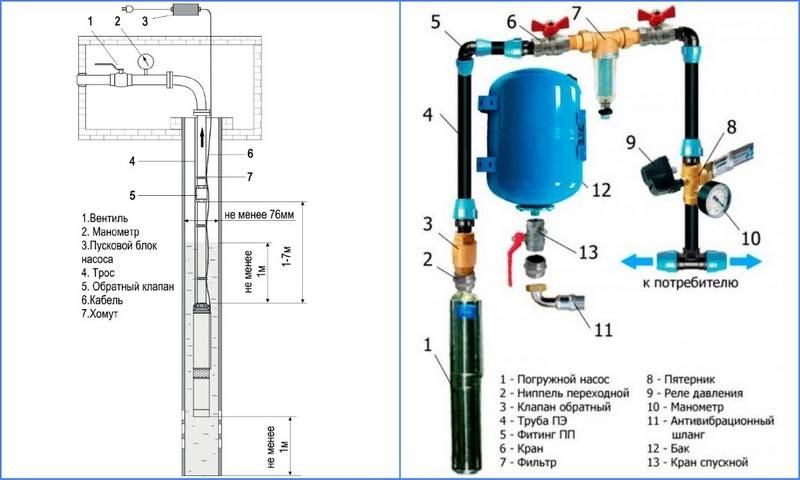

The installation of a submersible pump is carried out in a well, there is no need to separately equip a utility building or arrange a caisson. First, the unit is assembled, a cable and a pipe are attached to it, which provides water supply, a cable, after which the structure is lowered into the well.

Step 1: Preparing to mount the equipment

In this case, a non-return valve is needed to prevent water from draining. A filter is installed on it, resembling a bowl in shape and not allowing small particles of sludge to pass through.

Behind the valve, a pipe / discharge hose is installed

For a fixed pipe, it is important that it is even. Power cable is straightened and aligned

Reliable waterproofing is made for all connections.

Step 2: Submerging the pump into the well

Scheme of a submerged well pump.

After connecting the structures described above, the preparatory part is considered completed and you can start for pump installation.

It is lowered or immersed as follows:

- put on a gasket made of rubber on the casing;

- mount the head;

- the unit is dragged through the hole in the head and smoothly lowered down.

You can not do this, but then the immersion of the pump will require more accuracy. The design weighs a lot, and smooth movement is not easy to ensure, but it is necessary.

Even if the owner of the site mounts the heating system with his own hands, then he will need the help of at least 2 more people to lower the unit into the well or well. This is necessary so that two people can hold the unit on weight, and the third should gradually lower the cable without strong jerks.

When installing equipment, care must be taken to ensure that foreign parts do not get into the well, which would then become an obstacle. As a standard, there is a very small gap between the walls of the pipe and the pump, and even an object no larger than a nut can create a problem.

Installation depth of the submersible pump.

The pump is fixed at such a height that it is below the dynamic water level, then it will be constantly covered with it. At the same time, it should not be installed too low, since the closer it is to the bottom, the higher the risk of sand or silt being sucked in.

In addition, the installation depth for the selected equipment model, which is indicated in the technical documentation, is taken into account. On average, for most units it is 10 m, but for ejector pumps more - up to 15-20 m. There are also special devices designed for a depth of 25-40 m.

The best option is to place the pump at a distance of 1-2 m from the bottom of the well. After installation, the cable is fixed on a special bracket located on the outside.

Step 3: Determine the duty point of the pump

After completing the installation work, it is necessary to determine the performance of the unit under the existing load. The data sheet indicates average information, practical indicators may differ from them.

The owner must conduct tests during which he will measure such an indicator as water consumption per unit of time. To do this, he needs to check the rate of filling with liquid of a given volume.

At the same time, using a manometer, it is necessary to measure the pressure created in the water supply system during the operation of the equipment. After that, you should check the electrical part. To do this, special tongs that conduct current must be connected to the pump. This will help to measure the current strength and energy consumption during operation of the device.

Replacing a submersible pump

In rare cases, it is necessary to replace the device. This can be caused by incorrect installation or an emergency situation. The easiest way to replace it is to call specialists. So, experienced craftsmen will be able to assess the situation, identify the main causes and eliminate them. In some cases, it turns out that the problem was caused exclusively by automation, and the pump is still functioning. The benefit of using professional services is the contractor's guarantee. Naturally, you will have to pay for this.

In rare cases, it is necessary to replace the device. This can be caused by incorrect installation or an emergency situation. The easiest way to replace it is to call specialists. So, experienced craftsmen will be able to assess the situation, identify the main causes and eliminate them. In some cases, it turns out that the problem was caused exclusively by automation, and the pump is still functioning. The benefit of using professional services is the contractor's guarantee. Naturally, you will have to pay for this.

With experience and relevant knowledge, you can replace the centrifugal pump yourself. Of course, this applies to those cases when you know exactly the cause of the malfunction.

Replacement is performed as follows.

- First, you should prepare a soldering iron, a metalwork tool, a heat-shrink sleeve, as well as the necessary consumables.

- After that, the pipeline is disconnected from the highway that goes to the house. The power cable is also disconnected.

- Then it is necessary to unscrew the tightening elements and lift the pump. It is disconnected from the highway.

- If the equipment is not damaged, it is enough to replace the connecting mechanism, as well as the check valve and coupling. In the event that the well pump is faulty, it must be replaced.

- Next, the line is connected to the pump, after which the power cable should be soldered, taking care of the tightness.

- Then the head is tightened, the fittings are connected and the automation is adjusted. If everything is done correctly, it remains only to return the pump to its place.

When organizing the water supply of a country house, wells are often used. For their operation, a deep pump is required. Such equipment will ensure the supply of clean water and irrigation of the garden. You can install or replace such a unit yourself, but you must follow the technology so that the downhole equipment does not fail.

Troubleshooting

When the pump is immersed in the well, certain requirements must be met, if violated, the motor may break.

There are several main troubleshooting methods:

- Seek qualified help from craftsmen who specialize in the repair of submersible pumps, who can easily determine the nature of the malfunction and eliminate it as soon as possible.Such measures can be resorted to in a situation where the owner of the plot has no idea about the functional features of submersible pumps. In some situations, it is enough to simply adjust the automated pump station unit. The services of qualified specialists require certain financial costs.

- If the malfunction of the submersible pump is quite obvious, you can repair it yourself with certain skills. Such work is carried out with great difficulty alone, since the total mass of the elements of the pumping station immersed in the well often reaches 250 kg. The pipe connected to the pump must be separated from the water supply system, and the pumping station will also need to be de-energized. Check valve, fittings, couplings, other mechanisms require close attention. Some parts wear out faster than others, so they need to be replaced in a timely manner.

After verification and repair, if necessary, the device is assembled and reinstalled.

Dismantling the deep pump

The need for dismantling due to pump failure can arise for a number of reasons, the most common of which are:

- improper installation of a submersible pump in the well;

- improperly selected elements of automatic control of pumping equipment;

- wrong choice of the hydraulic machine itself according to its power.

So, if a pump, originally designed to service wells with a depth of no more than 50 m, is used to lift water to a height of about 80 m, then repairs to such equipment may be required after a few months of its operation.The automation of this pump, set to a certain pressure of the pumped liquid medium, simply will not periodically turn off the device, as a result of which it will work with constant overloads and, accordingly, will quickly fail.

Downhole pump retrieved from the well

When a broken downhole pump requires dismantling, it is better to invite qualified specialists to carry out this procedure. If you have studied the theoretical material on this topic and watched the videos shared on the Internet by users of submersible pumping devices, you can do the dismantling yourself.

Benefits of Hiring Qualified Professionals

The main and most important advantage of attracting qualified specialists for the maintenance and dismantling of a submersible pump is that they have the necessary knowledge, skills and experience in working with hydraulic machines. This will allow such specialists to quickly diagnose faulty equipment, determine the cause of its failure or incorrect operation, promptly eliminate it and perform commissioning.

In addition, serious companies involved in the installation and repair of pumping equipment serving a well or well provide guarantees for all the work they perform.

Do-it-yourself dismantling of a deep pump

Taking on the independent dismantling of submersible pumping equipment, if necessary, should only be done if you are sure that you can cope with such a difficult procedure.

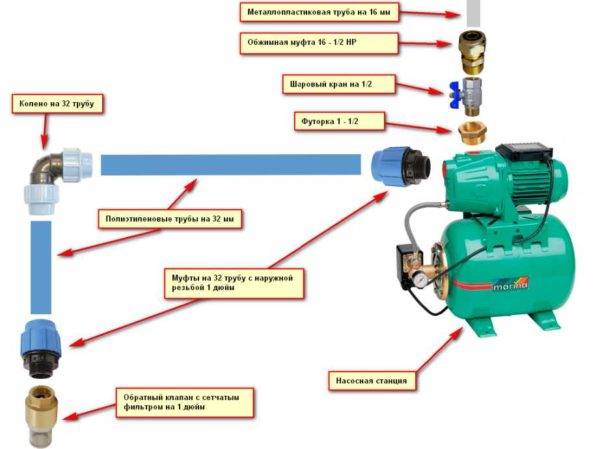

Preparation of related installation materials

The cable has the following requirements:

- reliability and strength, expressed by the ability to withstand loads that are 5 times the weight of the suspended equipment;

- resistance to the damaging effects of dampness, since certain parts of the product are under water.

It is allowed to use improvised materials to damp vibrations. A piece of medical tourniquet or elastic hose will do. Hanging the mechanism on a metal cable or wire is not worth it because of the likelihood of damage to the mount.

The next element that allows you to properly install a deep-well pump into a well is a cable for supplying equipment with power. It is better to take a wire with a small margin in length.

Water is supplied from an autonomous source to consumption points in the house through a water main. The best option is polymer pipes with a cross section of 32 mm or more. With a smaller diameter, it is impossible to provide sufficient pressure.

It is allowed to use a metal pipeline when installing a borehole pump. At the same time, threaded connections must be sealed with FUM tape, flax fiber or a special Tangit tool. To further strengthen the linen winding, a silicone-based sealant is used.

In addition, before installing the pump on the well, you need to prepare the following materials:

- manometer;

- attachment point made of durable steel;

- fittings for fixing the electric cable on the pipe line (clamps can be used);

- check valve;

- shut-off valve that shuts off the water supply, etc.

A nipple adapter is installed on the outlet pipe of the pump. In the absence of a pumping unit in the factory, this device is purchased separately.

During the initial pumping of the well, a large volume of heavily contaminated fluid is removed from it. For the procedure, it is recommended to use powerful models that can pump dirty water. After that, you can proceed with the installation of a standard borehole pump for further operation.

What is a surface pump

There are two types of pumps - submersible and surface. Their differences can be guessed by the name, but for a better understanding of the difference between these devices, you need to know their important characteristics. We will not understand the design, but only discuss the most important differences.

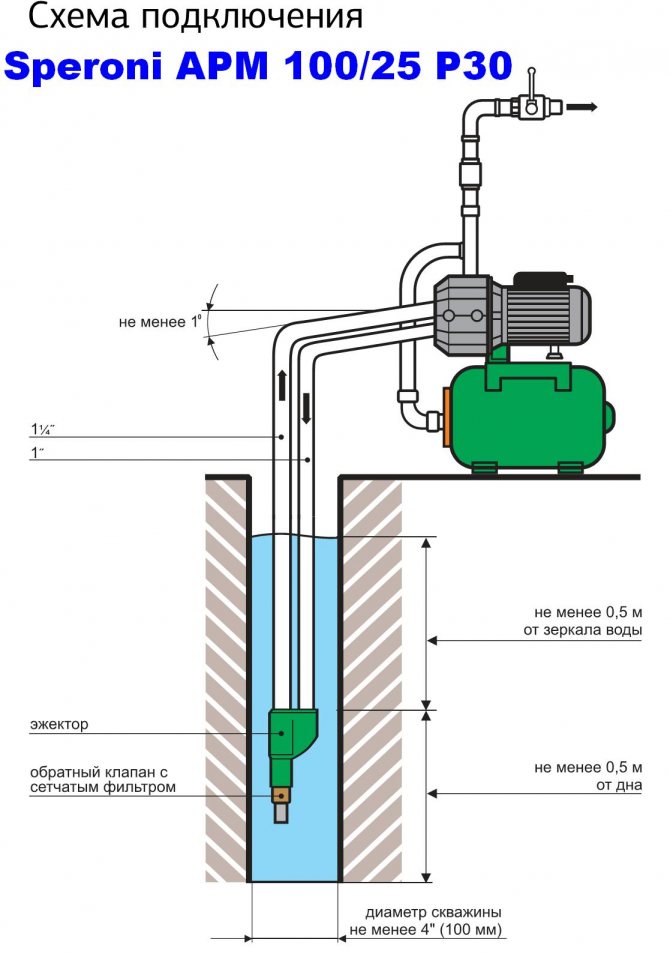

Of course, 8 meters for the extraction of high-quality drinking water is not enough, therefore, such equipment is supplemented with remote ejectors - devices that help increase the lifting depth to 40 meters.

The average performance of a surface pump is not at a very high level - from 1 to 4 cubic meters per hour, but this is enough to meet all the household needs of even a large family.

The working pressure that the equipment creates also differs greatly from model to model. Simple devices have an indicator of about 2 bar, while more powerful ones can reach up to 5, which is equal to 20 and 50 meters of water column, respectively.

Submersible pumps go straight to the bottom of the well and are controlled by a remote unit. They do not draw water, but push it into the pipeline system, which makes it possible to use such equipment even in very deep wells. 200 meters is not the limit for them, but this applies to industrial equipment.For domestic use, you simply select the model of the required power, according to the depth of your well.

Such equipment can provide a very high water consumption - an average capacity of about 10-15 cubic meters.

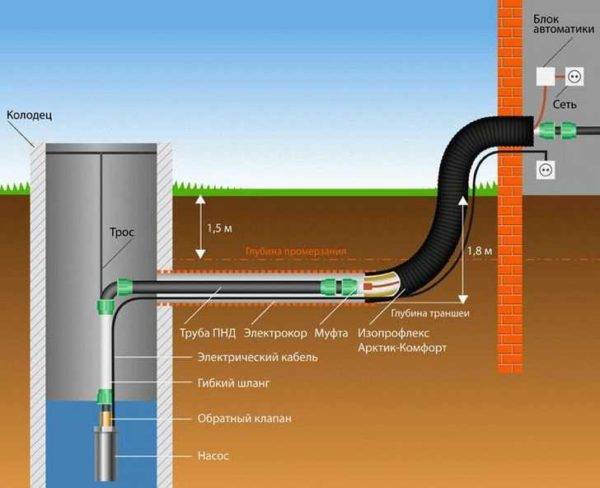

How to properly lower a submersible pump

Installing the pump in the well with your own hands is carried out after studying the instructions with the drawings for installing the pump and gaining practical experience in the video clips below.

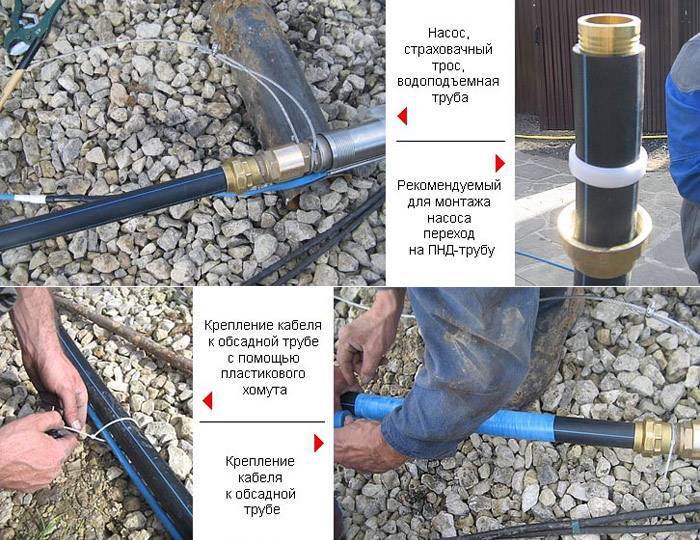

In accordance with the passport data for the development, the depth of immersion, the downhole unit and materials are selected. When assembling the structure and in the installation work, two or three people are involved, sequentially, step by step, performing the following operations:

- We check the complete set of the project and lay out the submersible pump, pressure hose, control cable, cable and fasteners for assembly.

- We begin the assembly by installing a check valve in the outlet on the pump using a transition fitting. At the same time, we take into account the direction of fluid movement indicated by the arrow on the body.

- We cut off the end of the pressure pipe at an angle of 90 degrees to the axis, put a plastic sleeve with a sealing ring on the hose and insert it into the body of the transition fitting screwed into the valve. Tighten the coupling nut, securing the connection.

- Using a heat-shrink sleeve, we connect the control cable to the engine, and fill the place where the wires enter the unit body with waterproofing glue.

- We insert a safety cable into the eyes on the body of the device, bend the threaded end into a loop and connect it to the main part of the rope using a special lock and a pressure washer.

- So that when lowering into the shaft, the cable and cable do not touch the column, we connect it together with the hose into a single whip using plastic clamps.In a meter from the pump, we fix the screed after 20 cm, and then to the top of the casing - after a meter.

- We cut off the casing pipe to the bottom of the caisson with the help of a grinder and install a head on the end. The cover serves to protect the well from debris, and it has holes for the pressure hose, cable and safety cable.

- We pass a hose, cable and cable through the holes on the head. We cut off the pressure pipe at the level of the cover and insert an angle fitting into it to connect to the water main laid in the trench to the house. We fix the safety rope on the casing string carabiner. The cable is laid in a trench and brought into the technical room.

- If the well is drilled no further than 5–7 meters from the house, the connection is simplified, the caisson is not installed. The pressure pipe is cut off at ground level and, together with the cable, is led through the head into the technical room in an insulated tray. To prevent the water from freezing in winter, a heating wire is inserted into the main hose, and a check valve is not installed on the pump. After injection, the liquid flows back, and the HDPE pipe remains dry.

When installing a water conduit into a house below the freezing point of the earth, a trench is dug to this level. In the casing, at the bottom of the ditch, a hole is drilled in which the adapter is fixed. Through the adapter, a pressure hose and a control cable are brought into the house along the trench.

Determining the duty point of the pump

Proper installation of a deep-well pump requires clarification of its characteristics during operation in standard mode. To do this, you need to determine the flow of water for a single period of time.

After measurements are taken, the indicators are compared with information from the technical documentation.If the actual data exceeds those recommended by the manufacturer, the unit valve should be slightly shifted. Due to the additional resistance, the parameters are normalized.

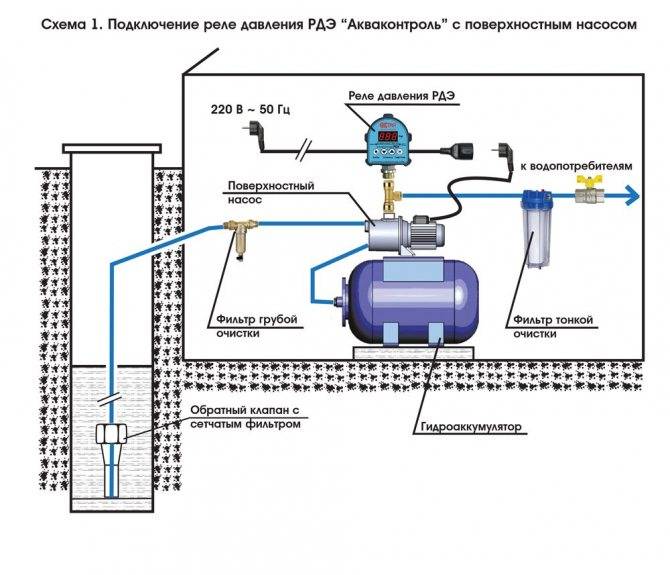

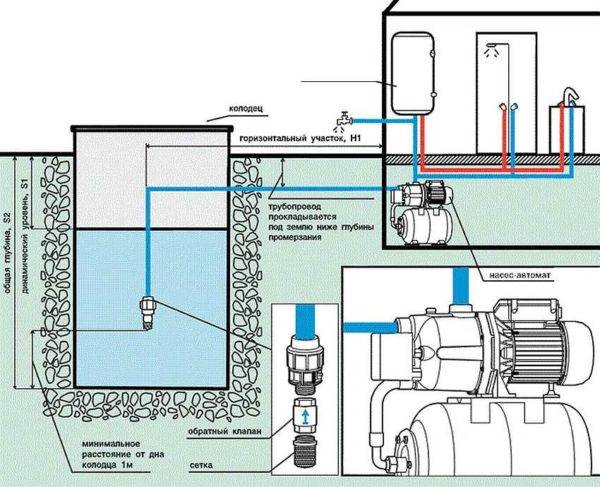

Connection of a pumping station

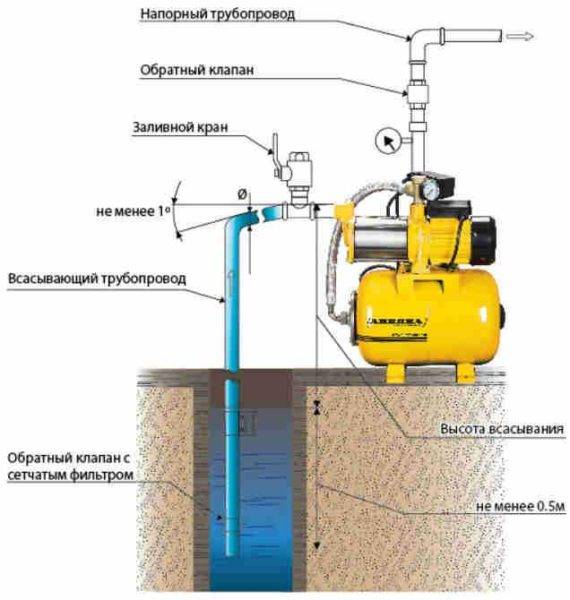

Choosing equipment and a place for installation is half the battle. You also need to correctly connect everything into a system - a water source, a station and consumers. The exact connection diagram of the pumping station depends on the chosen location. But anyway there is:

- Suction pipeline that descends into a well or well. He goes to the pumping station.

- The station itself.

- The pipeline going to consumers.

All this is true, only the strapping schemes will change depending on the circumstances. Let's consider the most common cases.

Water supply from a well for permanent residence

If the station is placed in a house or in a caisson somewhere on the way to the house, the connection scheme is the same. A filter (most often a regular mesh) is installed on the supply pipeline lowered into a well or well, a check valve is placed after it, then a pipe already goes. Why the filter - it is clear - to protect against mechanical impurities. A check valve is needed so that when the pump is turned off, water under its own weight does not flow back. Then the pump will turn on less often (it will last longer).

Scheme of installing a pumping station in a house

The pipe is brought out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into the trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay sheets of polystyrene foam on top, and then fill it with sand, and then with soil).

Passage option not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the place of passage should also be insulated), in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as bring the pipeline out / in through the walls, and also in the fact that it is difficult to localize damage when a leak occurs. To minimize the chances of a leak, take proven quality pipes, lay a whole piece without joints. If there is a connection, it is desirable to make a manhole.

Detailed scheme of piping a pumping station when connected to a well or well

There is also a way to reduce the volume of earthworks: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the site has a high level of groundwater.

There is another important point - the well cover must be insulated, as well as the rings on the outside to the freezing depth. It's just that the section of the pipeline from the water mirror to the outlet to the wall should not freeze. For this, insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system with centralized water supply. In this case, a water pipe is connected to the station inlet (also through a filter and a check valve), and the outlet goes to consumers.

Scheme of connecting the pumping station to the water supply

It is advisable to put a shut-off valve (ball) at the inlet so that if necessary you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - in order to cut off consumers if necessary and not drain water from the pipes.

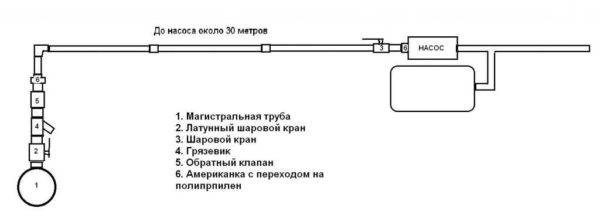

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Unless the pipeline exits at the point where the casing pipe ends. A caisson pit is usually arranged here, and a pumping station can be installed right there.

Pumping station installation: well connection diagram

As in all previous schemes, a filter and a check valve are installed at the end of the pipe. At the entrance, you can put a filler tap through a tee. You will need it for the first start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed in the country, it's okay, the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

How to replace the pump in the well in case of an accident?

The need to replace the pump rarely occurs, mainly due to the fact that the pump was installed incorrectly in the well. The cause of the accident may lie in the incorrectly selected automatic power supply, and in the low power of the pump itself. For example, if it is designed for a 50-meter dive, but in fact it is installed to a depth of 80 meters, then repairs will be needed in a few months.

The automatic power supply is set to working, and from such a depth a weak pump simply cannot lift it. As a result of constant work without shutting down, it quickly breaks down.

As in any situation, there are two ways out: we call repair specialists or we do everything ourselves.

Option number 1: we call deep pump repair specialists

First of all, this option is suitable for those who do not understand pumping equipment. Professionals can objectively assess the situation, identify the causes that led to equipment failures. Perhaps only the automatic power supply is not working properly, and the pump itself is in working condition. In this case, it is enough to properly configure it.

Another plus for those who have already decided that such repairs are beyond their power is the guarantee that the contractor gives. Also, in addition to the basic work, you will be fully configured for the entire water supply system. Of course, you need to pay for such services, and if we are talking about replacing the pump, then the amount will be impressive.

Option number 2: do-it-yourself pump replacement

On your own, the replacement of the pump in the well is carried out only if you are sure that it is malfunctioning. If in doubt, it is better to consult a specialist.

It is simply impossible to do this work alone, you will need the help of at least five more people: at a depth of 100 meters, a pump with a cable and suspension weighs about 250 kilograms.

First of all, you need to prepare a metalwork tool, an electric soldering iron, a building hair dryer, a heat-shrink sleeve, scissors and consumables.

Then we disconnect the wellhead pipeline and the pump power cable from the main line going to the house. After that, unscrew the tightening element.

When lifting the pump, be sure to use a safety rope. If the pump fails, it will be impossible to raise it, which means that the well will also be used in the future.

The pump raised to the surface is disconnected from the line. We inspect the pump, if it is still in working order, replace the connecting mechanism, coupling and check valve. The old ones, most likely, have already lost their working properties, so it is better to put in new ones. If the old pump cannot be repaired, install a new one.

- Next, we connect the main pipeline with the pump, solder the power cable, remembering the tightness of the connection and the heat shrink sleeve. We attach a safety cable, check its tension.

We prepare the new pump for diving, solder the power cable and attach the safety cable

- Installation of a deep well pump in a well must be carried out with the utmost care. It is undesirable to allow contact with the walls of the casing.

The pump must be lowered into the well very carefully - we make sure that it does not hit the wall

- We tighten the borehole head, attach the fittings to the piping and configure the automation in accordance with the specified parameters.

We set up automatic power supply in accordance with the specified working pressure parameters

The most convenient option for organizing water supply in a suburban area is a well. The submersible pump runs quietly, and if the installation and commissioning were done correctly, then next time you will have to look into the well very soon.

One of the main problems with submersible pump installation is the reluctance of the pump to go through the casing connection.

As a rule, in this connection there is a decrease in the diameter of the casing pipe. Therefore, purchasing a pump with a smaller outer diameter (3 inch pumps) is always preferable.