- Where to put

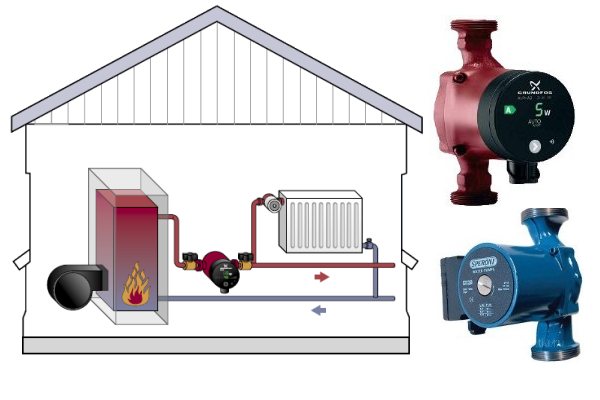

- forced circulation

- natural circulation

- Mounting Features

- Rules for connecting to the power supply

- Additional equipment for heating and hot water pumps

- Power connection

- Choice of insertion point of the device into the system

- Where can the pump be placed?

- Are there exceptions to the rules?

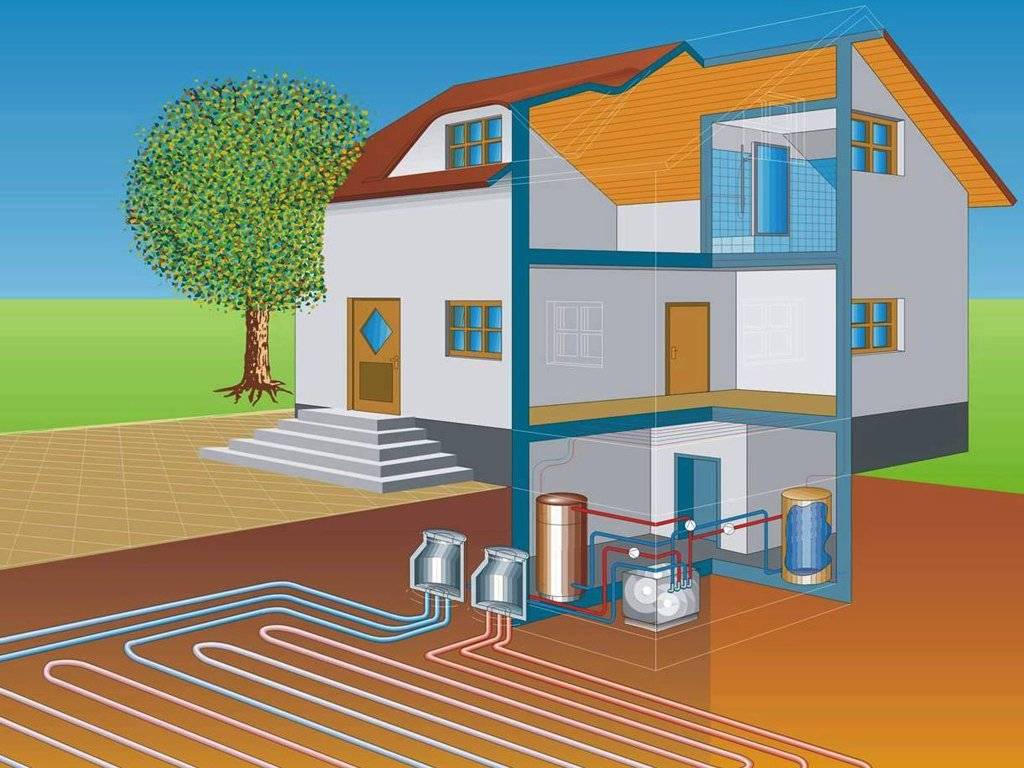

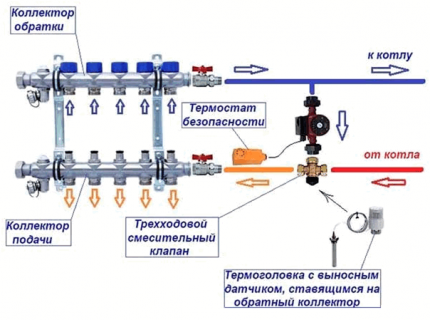

- Heating with a group of individual lines

- How the unit works

- Why do you need a circulation pump for heating

- Main technical parameters in marking

- Which manufacturers to choose

- The principle of operation of the system with coercion

- Advantages of pump heating

- Criteria for a competent choice of equipment

- The main types of pumps

- Specifications at a Glance

- Overview of models of circulation pumps of popular manufacturers

- Grundfos UPS

- Wilo Star-RS

- DAB VA

- Installation of additional equipment

- Conclusions and useful video on the topic

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it.This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

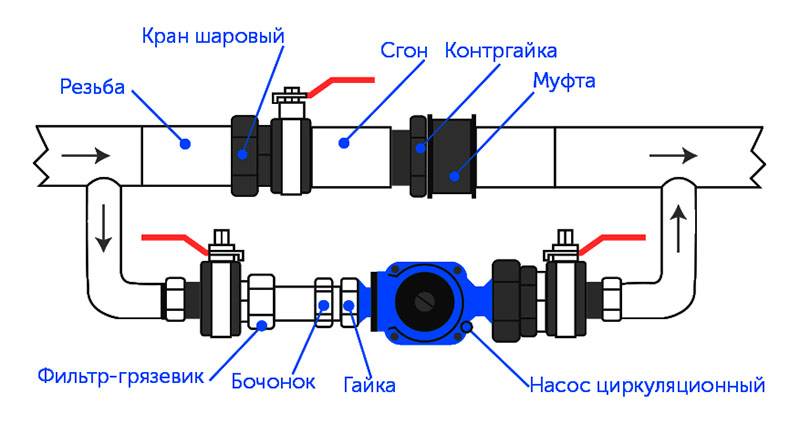

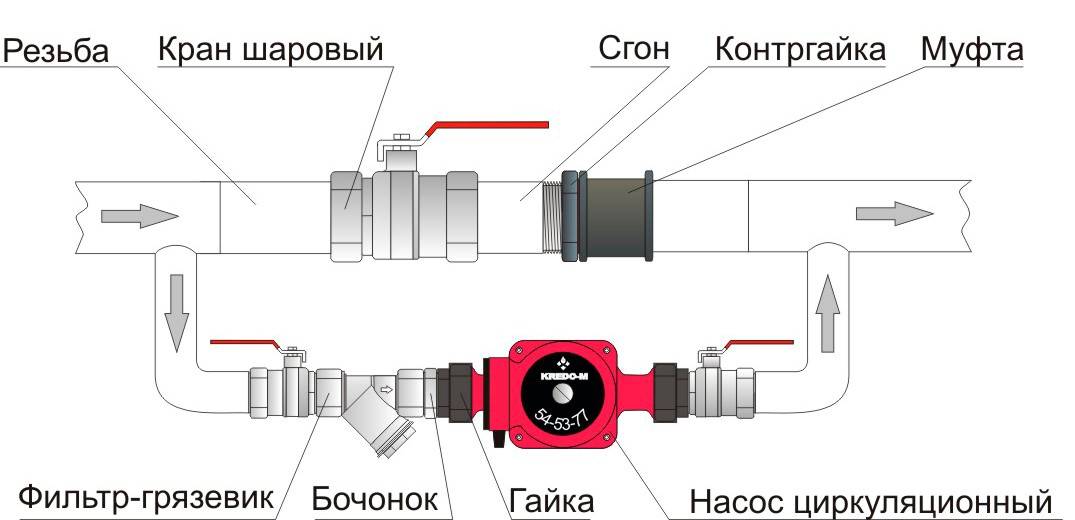

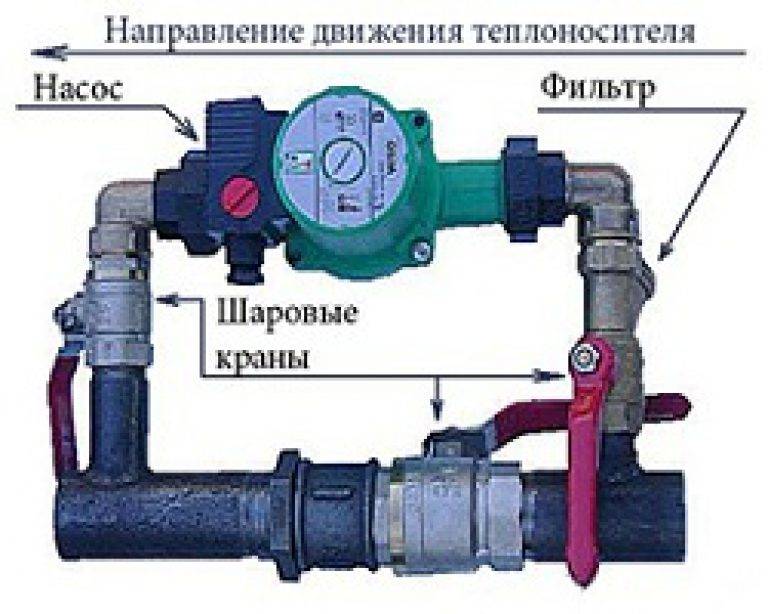

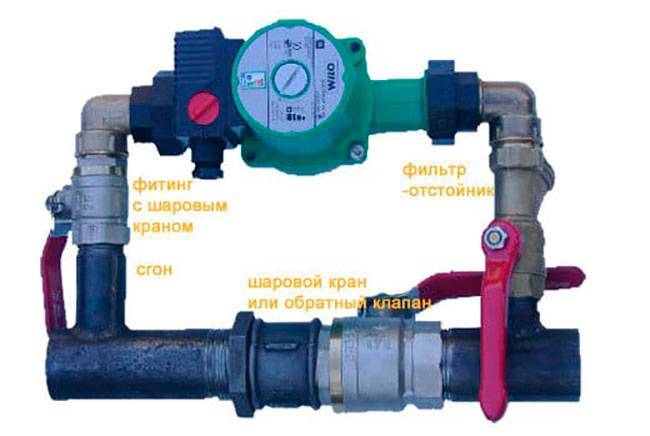

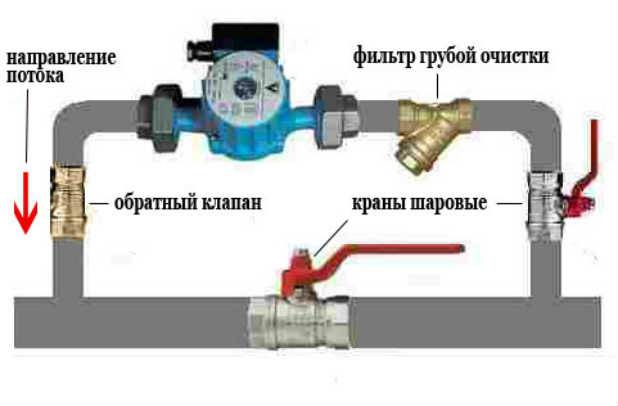

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

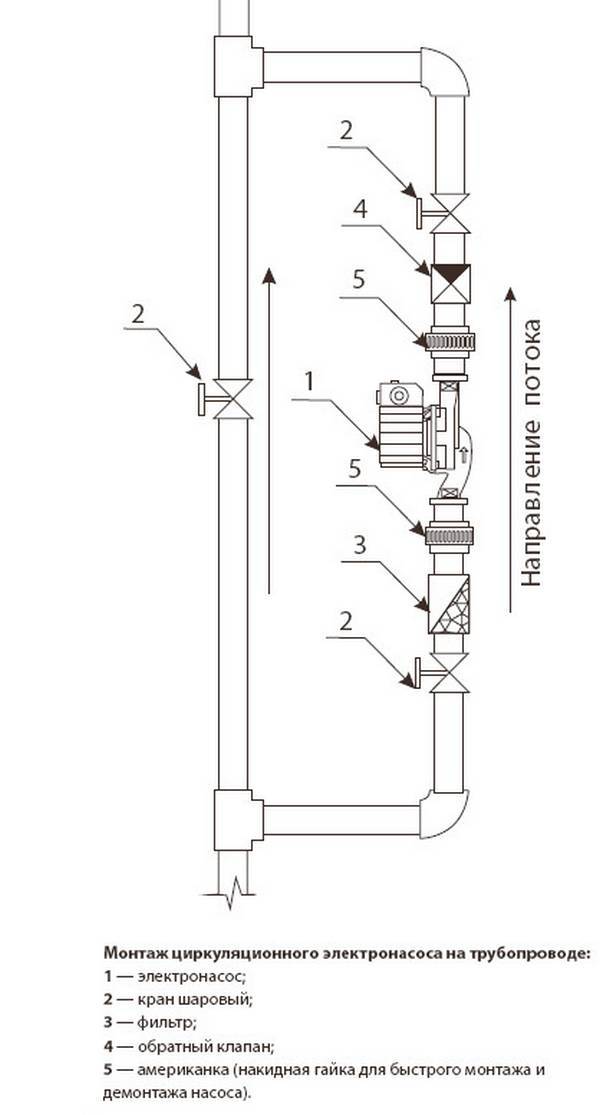

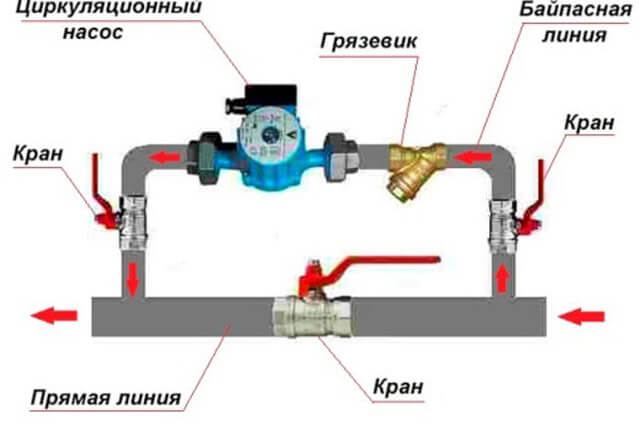

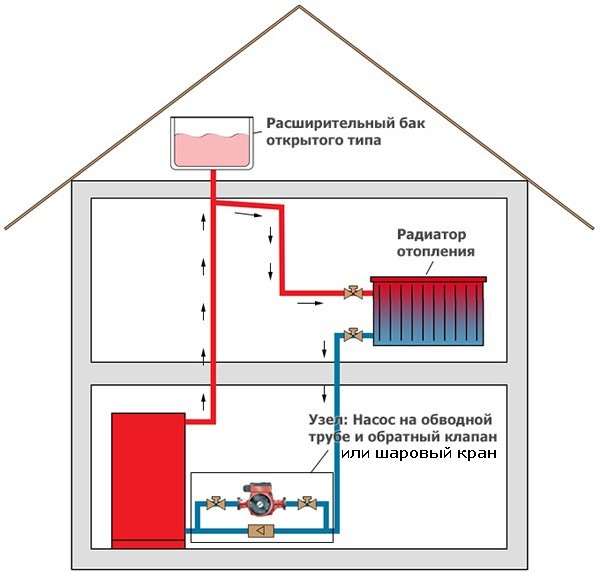

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

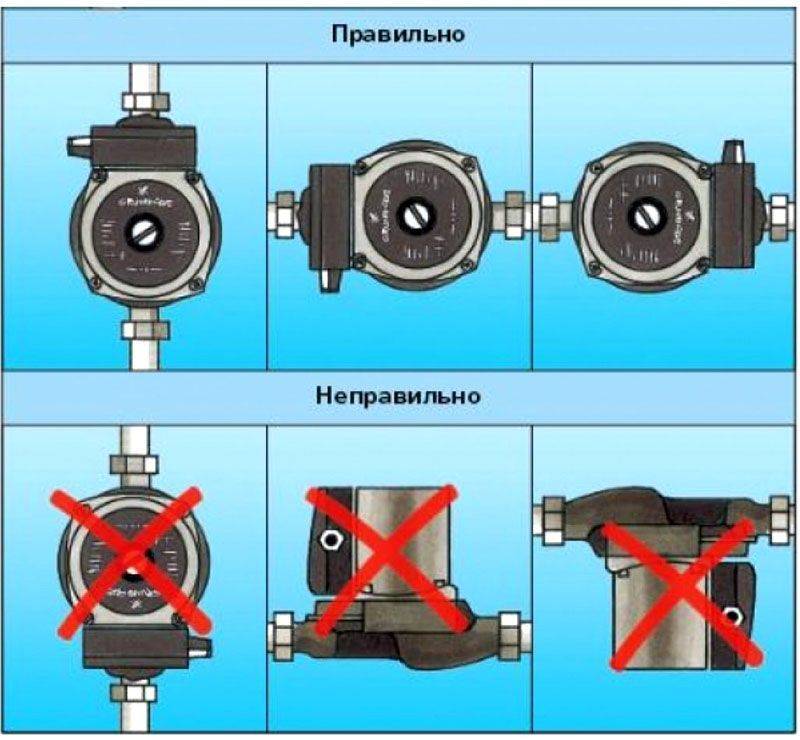

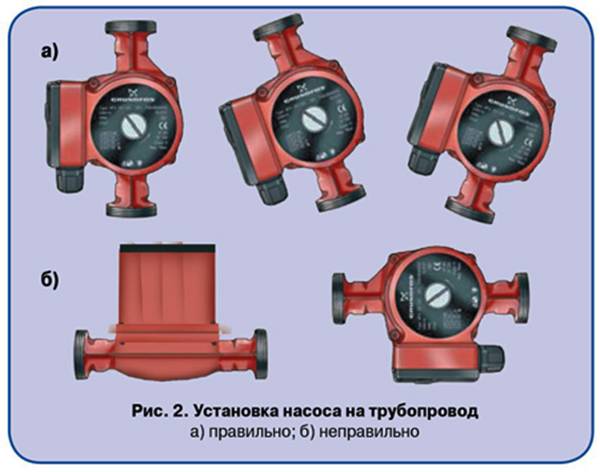

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Rules for connecting to the power supply

The circulation pump is powered by electricity. The connection is standard. It is recommended to run a separate power supply line with a surge protector.

To connect, you need to prepare 3 wires - phase, zero and ground.

You can choose any of the connection methods:

- through the device of the differential machine;

- connection to the network along with an uninterruptible power supply;

- pump power supply from the boiler automation system;

- with thermostat control.

Many people wonder why complicate, because the connection of the pump can be done by connecting the plug to the wire. This is how the pumping device is plugged into a regular outlet.

However, experts do not recommend using this method because of the danger of unforeseen situations: there is no grounding and safety machine.

The circuit with a differential automaton is used for the so-called wet groups.The heating system built in this way provides a high degree of safety for wiring, equipment and people.

The circuit with a differential automaton is used for the so-called wet groups.The heating system built in this way provides a high degree of safety for wiring, equipment and people.

The first option is not difficult to self-assemble. It is necessary to install a differential machine for 8 A. The wire cross section is selected based on the rating of the device.

In the standard scheme, power is supplied to the upper sockets - they are marked with odd numbers, the load - to the lower ones (even numbers). Both phase and zero will be connected to the machine, so the connectors for the latter are denoted by the letter N.

To automate the process of stopping the circulation of the heat carrier when it cools to a certain temperature, an electrical circuit for connecting a pump and a thermostat is used. The second is mounted in the supply line.

At the moment when the water temperature drops to the specified value, the device disconnects the power supply circuit.

In order for the thermostat to turn off the circulation process at the right time, it is installed on the metal section of the pipeline line. Due to the poor conduction of heat by polymers, mounting on a plastic pipe will cause incorrect operation of the device

There are no difficulties in supplying electricity through an uninterruptible power supply, for this it has special connectors. A heat generator is also connected to them when there is a need to provide electricity.

If you choose the method of connecting the pump to the boiler control panel or automation, you will need good knowledge in the power supply system or the help of a professional.

Additional equipment for heating and hot water pumps

In hot water systems, models equipped with timers and thermostats are often used.This is necessary to normalize the operation of indirect heating boilers. The thermostat controls the water temperature. If it is below the norm, then the device gives a signal to reduce the water supply, if it is higher, to increase it.

Using the timer, you can set the optimal time for the boiler to work, which allows you to turn off the pump and save resources at night when hot water is not used. To adjust the flow rate of the coolant, frequency converters are installed that change the speed of rotation of the pump impeller.

Power connection

Circulation pumps operate from a 220 V network. The connection is standard, a separate power line with a circuit breaker is desirable. Three wires are required for connection - phase, zero and ground.

Electrical connection diagram of the circulation pump

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power cable. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing a few bolts, we find three connectors. They are usually signed (pictograms are applied N - neutral wire, L - phase, and "earth" has an international designation), it is difficult to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - put a stabilizer with connected batteries.With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pull” electricity to a maximum of 250-300 watts. But when organizing, you need to calculate everything and select the capacity of the batteries. The disadvantage of such a system is the need to ensure that the batteries are not discharged.

How to connect a circulator to electricity through a stabilizer

Hello. My situation is that a 25 x 60 pump stands right after the 6 kW electric boiler, then the line from the 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, the branch goes up, then 4 m, down, rings the house of 50 sq. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bath branch 40 mm up, leaves the bath, enters the 2nd floor of the house 40 sq. m. (there are two cast-iron radiators) and returns to the bath in the return line; the heat did not go to the second floor; the idea to install a second pump in the bath for supply after a branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Choice of insertion point of the device into the system

The installation of a circulation pump is supposed to be in the area immediately after the heat generator, not reaching the first branching line. The selected pipeline does not matter - it can be either a supply or a return line.

Where can the pump be placed?

Modern models of household heating units made of high quality materials can withstand temperatures up to a maximum of 100 ° C. However, most systems are not designed for higher heating of the coolant.

The temperature indicator of the coolant in the personal heating network rarely even reaches 70 ° C. The boiler also does not heat water above 90 degrees.

Its performance will be equally effective both on the supply and on the return branch.

And that's why:

- The density of water when heated to 50 ° C is 987 kg / m3, and at 70 degrees - 977.9 kg / m3;

- The heating unit is capable of generating hydrostatic pressure of 4-6 m of water column and pumping almost 1 ton of coolant per hour.

From this we can conclude: an insignificant difference of 9 kg / m3 between the static pressure of the moving coolant and the return does not affect the quality of space heating.

Are there exceptions to the rules?

As an exception, inexpensive solid fuel boilers with a direct type of combustion can serve. Their device does not provide for automation, therefore, at the moment of overheating, the coolant begins to boil.

Installation collector wiring in the heating systemusing a solid fuel boiler is considered the most effective. However, this type of heating of a private house is one of the most difficult to perform.

Problems begin to arise if the electric pump installed in the supply line begins to fill with hot water with steam.

The heat carrier penetrates through the housing with the impeller and the following occurs:

- Due to the action of gases on the impeller of the pumping device, the efficiency of the unit decreases. As a result, the coefficient of the circulation rate of the heat carrier is significantly reduced.

- Insufficient amount of cold liquid enters the expansion tank, located near the suction pipe. The overheating of the mechanism increases and even more steam is formed.

- A large amount of steam, when it enters the impeller, completely stops the movement of warm water along the line. Due to the increase in pressure, the safety valve is triggered. Steam is released directly into the boiler room. An emergency is being created.

- If the firewood is not extinguished at this moment, the valve will not be able to cope with the load and an explosion will occur.

In practice, from the initial moment of overheating to the operation of the safety valve, no more than 5 minutes pass. If you mount the circulation mechanism on the return branch, then the length of time for which steam enters the device increases to 30 minutes. This gap will be enough to eliminate the heat supply.

In inexpensive heat generators made of low quality metal, the pressure of the safety valve is 2 bar. In high-quality solid fuel boilers - this indicator is 3 Bar

From this we can conclude that it is impractical and even dangerous to install a circulation device on the supply line. Pumps for solid fuel heat generators are best mounted in the return pipeline. However, this requirement does not apply to automated systems.

Heating with a group of individual lines

If the heating system is divided into two separate lines that heat the right and left sides of the cottage or several floors, it will be more practical to install an individual pump for each of the branches.

When installing a separate device for the heating line of the second floor, it becomes possible to save money by adjusting the required mode of operation. Due to the fact that heat has the ability to rise, it will always be warmer on the second floor.This will reduce the rate of circulation of the coolant.

The tie-in of the pump is carried out in a similar way - in the area located immediately after the heat generator to the first branch in this heating circuit. Usually, when installing two units in a two-story house, the fuel consumption for servicing the upper floor will be significantly less.

How the unit works

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant due to the capture of liquid from one side and forcing it into the pipeline from the other side

The principle of operation of the circulation unit is very similar to the operation of the drainage pump. If this device is installed in the heating system, then it will cause the movement of the coolant by capturing the liquid from one side and forcing it into the pipeline from the other side. All this happens due to the centrifugal force, which is formed during the rotation of the wheel with the blades. During the operation of the device, the pressure in the expansion tank does not change. If you want to increase the level of coolant in the heating system, install a booster pump. The circulation unit only helps to overcome the resistance force with water.

The installation scheme of the device looks like this:

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- A check valve is mounted on the section of the pipeline between the pumping equipment and the heater.

- The pipeline between the bypass valve and the circulation pump is connected by a bypass to the return pipeline.

Such an installation scheme implies the release of the coolant from the device only if the unit is filled with water. In order to keep the liquid in the wheel for a long time, a receiver equipped with a check valve is built at the end of the pipeline.

Circulation pumps used for domestic purposes can develop a coolant speed of up to 2 m / s, and units used in the industrial field accelerate the coolant up to 8 m / s.

Worth knowing: any kind the circulation pump is powered by the mains. This is a fairly economical equipment, since the engine power for large industrial pumps is 0.3 kW, while for household appliances it is only 85 watts.

Why do you need a circulation pump for heating

This is a household appliance for pumping liquid, in the body of which an electric motor and a working shaft are installed. When turned on, the rotor begins to rotate the impeller, which creates a reduced pressure at the inlet and an increased pressure at the outlet. The device speeds up the movement of hot water through the pipes, and the owner receives the benefit of reducing the cost of heating the house.

Main technical parameters in marking

There are designs with a dry and wet rotor. Despite the relatively low efficiency (50-60%), models of the second type are most often used, because. they are compact and do not make noise during operation. When mounting such a device, it is advisable to install a mud filter in front of the inlet so that pieces of scale from the radiators do not get inside the case and jam the impeller.

The device works from a conventional power supply with a voltage of 220 watts. Power consumption may vary depending on the model and mode of operation. Usually it is 25-100 W / h. In many models, the possibility of adjusting the speeds is provided.

When choosing, special attention should be paid to performance, pressure, diameter of the connection to the pipe. The data are indicated in the technical documentation and marking. The first digit of the marking determines the connecting size, and the second indicates the power

For example, the Grundfos UPS 25-40 model is suitable for connection to an inch (25 mm) pipe, and the water lifting height (power) is 40 dm, i.e. 0.4 atmospheres

The first digit of the marking determines the connecting size, and the second indicates the power. For example, the Grundfos UPS 25-40 model is suitable for connection to an inch (25 mm) pipe, and the water lifting height (power) is 40 dm, i.e. 0.4 atmospheres.

Which manufacturers to choose

The list of the most reliable brands is headed by Grundfos (Germany), Wilo (Germany), Pedrollo (Italy), DAB (Italy). The equipment of the German company Grundfos is always high quality, functionality, long service life. The company's products rarely cause inconvenience to the owners, the percentage of marriage is minimal. Wilo pumps are slightly inferior in quality to Grundfos, but they are cheaper. "Italians" Pedrollo, DAB also please with high quality, good performance, durability. Devices of these brands can be bought without fear.

The principle of operation of the system with coercion

The circulation pump is a small electrical device that is extremely simple in design. Inside the housing there is an impeller, it rotates and gives the coolant circulating through the system the necessary acceleration. The electric motor that provides rotation consumes very little electricity, only 60-100 watts.

The presence of such a device in the system greatly simplifies its design and installation.Forced circulation of the coolant allows the use of heating pipes of small diameter, expands the possibilities when choosing a heating boiler and radiators.

Very often, a system originally created with the expectation of natural circulation does not work satisfactorily due to the low speed of the coolant through the pipes, i.e. low circulation pressure. In this case, installing a pump will help solve the problem.

However, one should not get too carried away with the speed of the water in the pipes, since it should not be excessively high. Otherwise, over time, the structure may simply not withstand additional pressure for which it was not designed.

If in systems with natural circulation of the coolant it is possible to use an open expansion tank, then in forced circuits, preference should be given to a closed sealed container

For residential premises, the following limiting norms for the speed of movement of the coolant are recommended:

- with a nominal pipe diameter of 10 mm - up to 1.5 m / s;

- with a nominal pipe diameter of 15 mm - up to 1.2 m / s;

- with a nominal pipe diameter of 20 mm or more - up to 1.0 m / s;

- for utility rooms of residential buildings - up to 1.5 m / s;

- for auxiliary buildings - up to 2.0 m/s.

In systems with natural circulation, the expansion tank is usually placed on the supply. But if the design is supplemented with a circulation pump, it is usually recommended to move the drive to the return line.

The device of the circulation pump is very simple, the task of this device is to give the coolant an acceleration sufficient to overcome the hydrostatic resistance of the system

In addition, instead of an open tank, a closed one should be put.Only in a small apartment, where the heating system has a small length and a simple device, you can do without such a rearrangement and use the old expansion tank.

Advantages of pump heating

Not so long ago, almost all private houses were equipped with steam heating, which was powered by a gas boiler or a conventional wood-burning stove. The coolant in such systems circulated inside the pipes and batteries by gravity. Only centralized heating systems were completed with pumps for pumping water. After the appearance of more compact devices, they were also used in private housing construction.

This solution provided a number of advantages:

- The coolant circulation rate has increased. The water heated in the boilers was able to flow much faster to the radiators and heat the premises.

- Significantly reduced the time for heating homes.

- The increase in the flow rate resulted in an increase in the throughput of the circuit. This means that smaller pipes can be used to deliver the same amount of heat to the destination. On average, the pipelines were reduced by half, which was facilitated by the forced circulation of water from an embedded pump. This made the systems cheaper and more practical.

- For laying highways in this case, you can use the minimum slope, without fear of complex and lengthy water heating schemes. The main thing at the same time is to choose the right pump power so that it can create optimal pressure in the circuit.

- Thanks to household circulation pumps, it became possible to use underfloor heating and closed systems of high efficiency, which require increased pressure to operate.

- The new approach made it possible to get rid of a lot of pipes and risers, which did not always fit harmoniously into the interior. Forced circulation opens up opportunities for laying the circuit inside walls, under the floor and above suspended ceiling structures.

A minimum slope of 2-3 mm per 1 m of the pipeline is necessary so that in the event of repair measures, the network can be emptied by gravity. In classical systems with natural circulation, this figure reaches 5 mm/m or more. As for the disadvantages of forced systems, the most significant of them is the dependence on electrical energy. Therefore, in areas with unstable electricity supplies, circulation pump installation you must use uninterruptible power supplies or an electric generator.

You should also be prepared for an increase in bills for consumed energy (with the right selection of unit power, costs can be minimized). In addition, leading manufacturers of equipment for heating systems have developed modern modifications of circulation pumps that can operate in increased economy. For example, the Alpfa2 model from Grundfos automatically adjusts its performance, depending on the needs of the heating system. Such equipment is quite expensive.

Criteria for a competent choice of equipment

All installation efforts will be reduced to zero if you choose the wrong equipment. In order not to be mistaken, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

The main types of pumps

According to the design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet pumps. This option is suitable for private houses. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high performance - the maximum efficiency of modern models reaches 52-54%.

Circulation devices for heating networks should not be confused with similar devices for hot water supply. The heating pump does not need an anti-corrosion housing made of bronze or stainless steel and additional protection against scale - respectively, and is cheaper

Pumps with a dry rotor are productive, undemanding to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal location on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are mounted on a foundation or metal support frame.

For the installation of console, monoblock or "In-line" models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³ / h is required, that is, for servicing groups of cottages or apartment buildings.

Specifications at a Glance

When choosing a pump, be sure to study the technical specifications and compare them with the requirements of the heating system.

Important indicators are:

- head, which covers the loss of hydraulics in the circuit;

- productivity - the volume of water or supply for a certain time interval;

- operating temperature of the coolant, max and min - for modern models on average +2 ºС ... +110 ºС;

- power - taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet / outlet diameter of the nozzles. For heating systems, the average parameters are 25 mm and 32 mm.

The number of electric pumps is selected, focusing on the length of the heating main. If the total length of the circuits is up to 80 m, one device is enough, if more, additional devices will be required

An example of a unit for equipping a residential heating network with an area of 100 m² is Grundfos UPS pump with pipe connection 32 mm, capacity 62 l/s and weight 3.65 kg. A compact and low-noise cast-iron device is not audible even behind a thin partition, and its power is enough to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode, depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information about the calculation and selection of circulation heating pump featured in articles:

- How to calculate a pump for heating: examples of calculations and rules for selecting equipment

- Selection of a circulation pump: device, types and rules for choosing a pump for heating

- Circulation pump for heating: top ten models and tips for customers

Overview of models of circulation pumps of popular manufacturers

It is possible to compare injection devices not only by parameters. The choice also includes the study of information about models of well-known manufacturers.

Grundfos UPS

Quality device equipped with ceramic bearings, stainless sleeves and composite wheels.Grundofs produces mainly wet rotor models, which differ in:

- energy efficiency - consume 45-220 W;

- minimum noise level not exceeding 43 dB;

- operating temperature range from 2 to 110 degrees;

- ease of installation and maintenance;

- compactness and light weight.

Grundfos equipment cannot be called budget.

Wilo Star-RS

The series is distinguished by the reliability of components and electronic circuits. Wilo is an economical model with power control modes, a cast-iron body, and polypropylene turbines. Stainless steel is used for the shafts, metal graphite for the bearings. Features of the units:

- ease of installation;

- work at temperatures from -10 to +110 degrees;

- the presence of a protection system against voltage fluctuations.

The pumps are noisy at high speed.

DAB VA

Italian equipment should be chosen for operation in domestic conditions. Cast aluminum motor, technopolymer turbine ring, ceramic shaft and bearing. Device features:

- three modes of speed adjustment;

- quick-release mounting clamps;

- mounting dimensions 130 and 180 mm;

- noise level up to 70 dB.

Bushings are made of graphite.

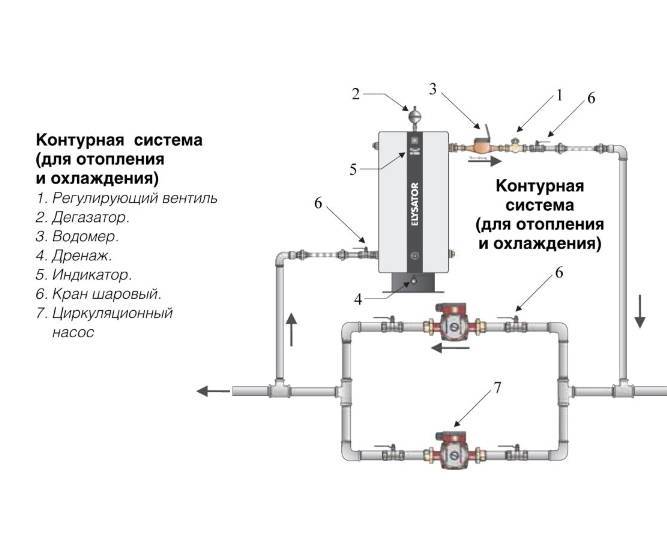

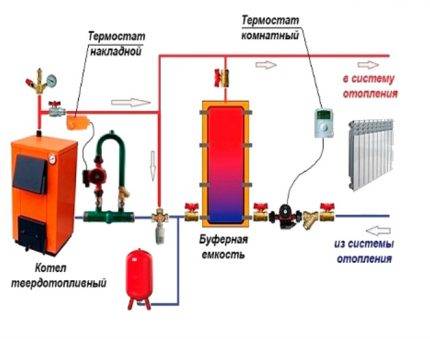

Installation of additional equipment

Regardless of the type of heating circuit used, where one boiler serves as a heat producer, it will be enough to install a single pumping device.

If the system is structurally more complex, it is possible to use additional devices that provide forced circulation of the liquid.

An example of a joint piping scheme for a solid fuel boiler paired with an electric one. This heating system has two pumping devices

An example of a joint piping scheme for a solid fuel boiler paired with an electric one. This heating system has two pumping devices

The need for this appears in the following cases:

- when heating a house, more than one boiler unit is involved;

- if there is a buffer capacity in the strapping scheme;

- the heating system diverges into several branches, for example, maintenance of an indirect boiler, several floors, etc.;

- when using a hydraulic separator;

- when the length of the pipeline is more than 80 meters;

- when organizing the movement of water in the floor heating circuits.

To perform the correct piping of several boilers operating on different fuels, it is necessary to install backup pumps.

For a circuit with a heat accumulator, it is also necessary to install an additional circulation pump. In this case, the line consists of two circuits - heating and boiler.

The buffer tank separates the system into two circuits, although in practice there may be more

The buffer tank separates the system into two circuits, although in practice there may be more

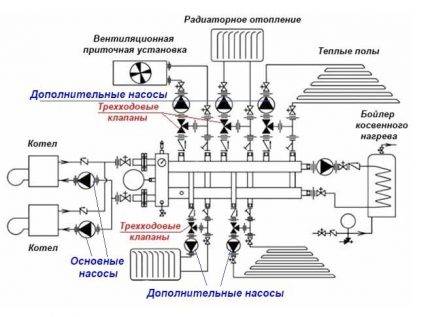

A more complex heating scheme is implemented in large houses on 2-3 floors. Due to the branching of the system into several lines, pumps for pumping coolant are used from 2 or more.

They are responsible for supplying the coolant to each of the floors to various heating devices.

Regardless of the number of pumping devices, they are installed on the bypass. In the off-season, the heating system can work without a pump, which is closed using ball valves

Regardless of the number of pumping devices, they are installed on the bypass. In the off-season, the heating system can work without a pump, which is closed using ball valves

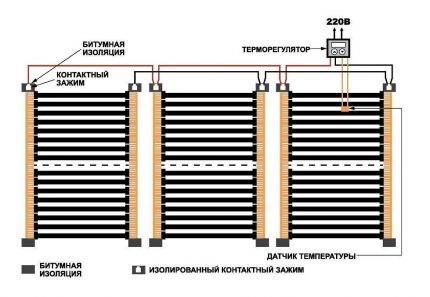

If it is planned to organize heated floors in the house, then it is advisable to install two circulation pumps.

In the complex, the pumping and mixing unit is responsible for the preparation of the coolant, i.e. keeping the temperature at 30-40 ° C.

In order for the power of the main pumping device to be enough to overcome the local hydraulic resistance of the floor contours, the length of the line should not exceed 50 m.Otherwise, the heating of the floors will become uneven, respectively, and the premises

In order for the power of the main pumping device to be enough to overcome the local hydraulic resistance of the floor contours, the length of the line should not exceed 50 m.Otherwise, the heating of the floors will become uneven, respectively, and the premises

In some cases, the installation of pumping units is not required at all. Many models of wall-mounted electric and gas generators already have built-in circulation devices.

Conclusions and useful video on the topic

Rules for installing heating equipment in the video:

The video explains the features of a two-pipe heating system and demonstrates different installation schemes for devices:

Features of connecting the heat accumulator to the heating system in the video:

p> If you know all the connection rules, there will be no difficulties with the installation of the circulation pump, as well as when connecting it to the power supply at home.

The most difficult task is to insert a pumping device into a steel pipeline. However, using a set of lerok for creating threads on pipes, you can independently arrange the arrangement of the pumping unit.

Do you want to supplement the information presented in the article with recommendations from personal experience? Or maybe you saw inaccuracies or errors in the reviewed material? Please write to us about it in the comments block.

Or have you successfully installed the pump and want to share your success with other users? Tell us about it, add a photo of your pump - your experience will be useful to many readers.