- Installing a pump in a heating system

- Selecting a location for the frame

- Installation sequence

- Varieties

- "Dry" pump

- "Wet" pump

- Where to put the pump - for supply or return

- Design features of a pump for heating a private house

- wet rotor

- Dry Rotor

- Recommendations for the correct installation of a circulation pump for heating in a private house.

- How to remove air from the circulation pump before starting.

- Disadvantages of heating systems with pumps

- Conclusions and useful video on the topic

Installing a pump in a heating system

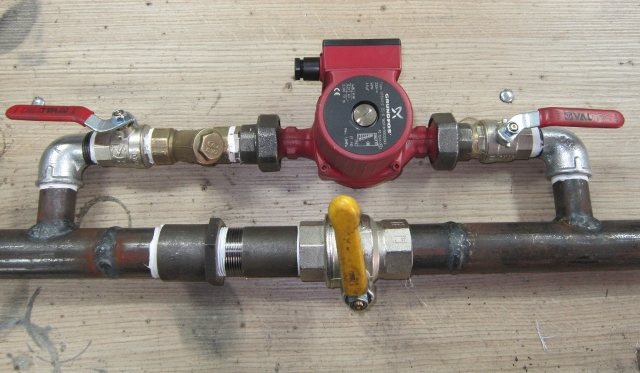

To make the pump installation process as easy as possible, experts recommend buying pumping equipment with split threads. Otherwise, you will have to select adapters yourself, which users do not always like. You should also purchase a deep filter. non-return valve, without which the full operation of the pump under pressure is impossible. You should also purchase shut-off valves of the required diameter and a bypass from a pipe segment. From the tool you will need keys. When all this is available, you can choose a place to mount the pump.

Selecting a location for the frame

The pump connection diagram must take into account the need for periodic maintenance of the device.You also need to take care of the availability of access to the mains. Although not essential, you can always extend the mains power cable to the desired installation location.

To date, the structural details of heating pumps allow them to be installed in any convenient place, while earlier they tried to install them in the place where the coolant returns.

From the target point of view of increasing the pressure at the suction point, it would be better to install the pump in the supply pipe section. Location near the entry point of the expansion tank will be a very good place. This arrangement guarantees a sufficiently high temperature in this place.

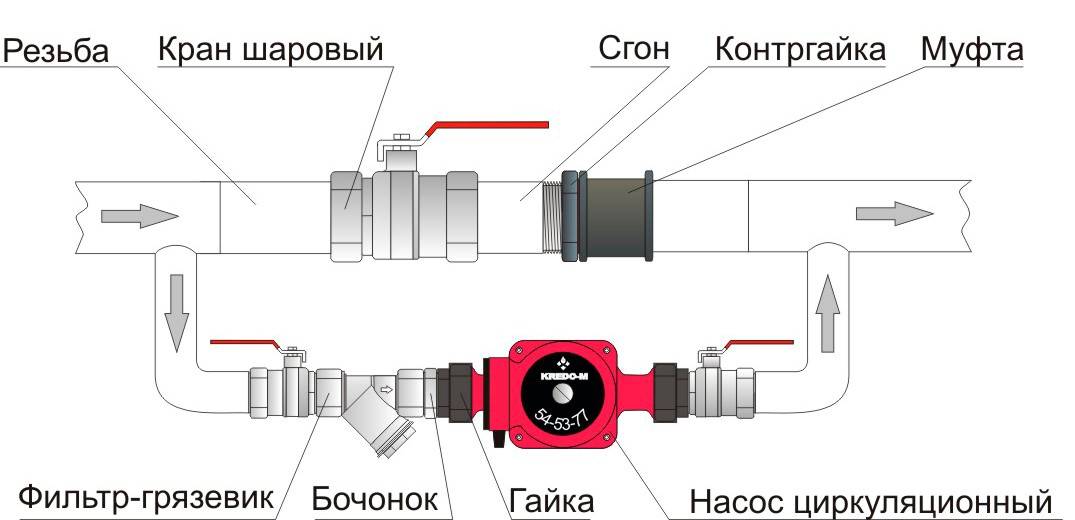

Pump connection diagram

To install the pump in a heating system with a membrane-type tank, it is advisable to place the bypass with the pump on the return line and it is also recommended to bring it as close as possible to the expansion tank. It may well be that this will complicate access to the pump in the future, then it is possible to mount it on a pipe supplying heat, but only with a mandatory tie-in check valve, which is located vertically.

Installing the pump requires the person being mounted to follow certain rules:

- Ball valves should be fixed on the sides of the pump. If you need to dismantle the pump, then with their help the possibility of the coolant exiting the system is excluded.

- A filter is inserted directly in front of the pump. This will protect the pump from various kinds of particles present in the coolant.

- The top of the bypass must be equipped with a manual or automatic air valve. With its help, it is possible to remove accumulated air in the system.

- On the body of the pumping device there is an arrow that indicates the direction of movement of the coolant.

- All threaded connections must be made with sealant and gaskets to avoid leakage in the system.

It should be remembered that for complete safety of using the pump, it should only be connected to a grounded outlet.

Installation sequence

- If the installation is carried out in an existing network, then the coolant must first be drained. It will even be useful - after all, at the same time you can clean the entire system from accumulated pollution.

- The installation of a functional chain of fittings and a pump is carried out in full accordance with the rules described above.

- After completion of the entire installation cycle of the pump and related fittings, the heating system must be filled with coolant.

- The final step is to open the central screw located on the housing cover to remove excess air from the pump. The escaping water will notify about its complete removal.

In conclusion, it remains to add that the installation of a circulation pump unit is worth it. Already after the first days of using the system with an embedded pump, everyone notices positive changes - fuel economy, rapid heating of the coolant and, as a result, all heated rooms.

Varieties

"Dry" pump

Traffic rings relative to each other friend initiates the start of the equipment. Perfectly polished parts, in contact with each other, form thin water film. The difference in pressure levels between the outdoor space and the atmosphere of the heating system creates a sealing connection. Thanks to the springs, the rings are pressed towards each other, and as a result of wear of the parts, they are adjusted to each other without outside help.

The period of operation of the sealing rings is at least three years, while the gland packing is less durable and needs constant lubrication and cooling. The main feature of the operation of this unit is a high noise level, which implies its installation in a separate room. The efficiency is 80 percent.

When using a "dry" circulation unit with sliding end rings, one should exercise control the presence of suspension in the pumped liquid and the general degree of dustiness of the room. This is due to the fact that during the operation of a pump with a dry type of rotor, air turbulences are created that attract dust particles. Getting into the coolant, small debris damages the surface of the sealing rings and violates the tightness. The operation of a "dry" pump is characterized by the gradual destruction of the end rings, so they need a water layer between the working surfaces. The water layer acts as a lubricant.

In its turn, "Dry" pumps are divided into:

- vertical;

- Horizontal;

- Block.

Horizontal pumps

Otherwise, they are also called console. The front part of the shaft is equipped with a suction pipe, and the body with a discharge pipe. The electric motor is installed horizontally.

Vertical pumps

Branch pipes have the same diameter and are located on the same axis. The electric motor is mounted in a vertical position.

Block pumps

The coolant enters in the axial direction, and is discharged in the radial direction.

"Wet" pump

Ceramics are used to produce the rotor, while bearings are made from graphite or ceramic. The body of the equipment is made of brass, bronze or cast iron. The main feature of the "wet" type is low noise level, durability, simple settings and repairs.

The efficiency index of a "wet" pump is lower than that of a "dry" unit by about 30 percent, and is 50 percent. This is due to the fact that it is impossible to seal the metal sleeve, which separates the stator from the heat carrier, with a rather large diameter of the rotor. However, for domestic use, where there is no need for water circulation in heating systems of great length, it is advisable to use such equipment.

The design of "wet" pumps includes:

- Equipment body;

- Electric motor with stator;

- Box with terminal blocks;

- Working wheel;

- Cartridge consisting of a shaft with bearings and a rotor.

The modular assembly of the "wet" pump allows you to replace the broken part of the unit with a new one.

In "wet" circulating units, one- or three-phase electric motors are installed. The equipment is fastened to the pipeline of the heating system by a threaded or flanged connection - the type of fastening is affected by the power and performance of the pump.

Due to the strictly horizontal position of the shaft, water access to bearingswhich is used as a lubricant. Therefore, in order for the operation of the equipment to be uninterrupted and continuous, this rule must be observed.

Where to put the pump - for supply or return

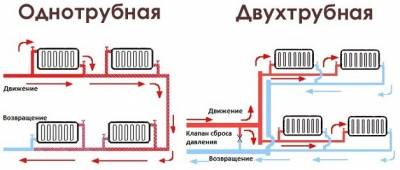

Despite the abundance of information on the Internet, it is rather difficult for the user to understand how to properly install the pump for heating in order to ensure the forced circulation of water in the system of their own home.The reason is the inconsistency of this information, which causes constant disputes on thematic forums. Most of the so-called specialists claim that the unit is placed only on the return pipeline, citing the following conclusions:

- the temperature of the coolant at the supply is much higher than at the return, so the pump will not last long;

- the density of hot water in the supply line is less, so it is more difficult to pump;

- the static pressure in the return pipe is higher, which makes the pump easier to operate.

Interesting fact. Sometimes a person accidentally gets into a boiler room that provides central heating for apartments, and sees the units there, embedded in the return line. After that, he considers such a decision to be the only correct one, although he does not know that in other boiler rooms centrifugal pumps can also be installed on the supply pipe.

We answer the following statements point by point:

- Domestic circulation pumps are designed for a maximum coolant temperature of 110 °C. In a home heating network, it rarely rises above 70 degrees, and the boiler will not heat water more than 90 ° C.

- The density of water at 50 degrees is 988 kg / m³, and at 70 ° C - 977.8 kg / m³. For a unit that develops a pressure of 4-6 m of water column and is capable of pumping about a ton of coolant in 1 hour, the difference in the density of the transported medium of 10 kg / m³ (the volume of a ten-liter canister) is simply negligible.

- In practice, the difference between the static pressures of the coolant in the supply and return lines is just as insignificant.

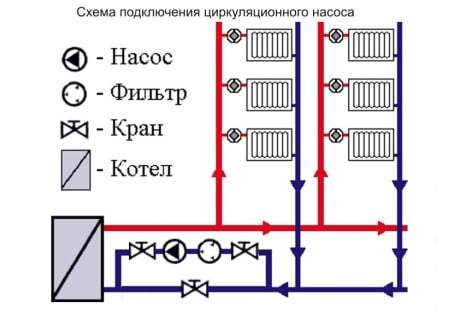

Hence a simple conclusion: circulation pumps for heating can be inserted into both the return and supply pipelines of the heating system of a private house.This factor will not affect the performance of the unit or the heating efficiency of the building.

Boiler room made by our expert Vladimir Sukhorukov. There is convenient access to all equipment, including pumps.

The exception is cheap direct combustion solid fuel boilers that are not equipped with automation. When overheated, the coolant boils in them, since burning firewood cannot be extinguished at once. If the circulation pump is installed on the supply, then the resulting steam mixed with water enters the housing with the impeller. The further process looks like this:

- The impeller of the pumping device is not designed to move gases. Therefore, the performance of the apparatus is sharply reduced, and the flow rate of the coolant drops.

- Less cooling water enters the boiler tank, which causes overheating and even more steam.

- An increase in the amount of steam and its entry into the impeller leads to a complete stop of the movement of the coolant in the system. An emergency situation arises and as a result of an increase in pressure, a safety valve is activated, ejecting steam directly into the boiler room.

- If measures are not taken to extinguish the firewood, then the valve cannot cope with the release of pressure and an explosion occurs with the destruction of the boiler shell.

For reference. In cheap heat generators made of thin metal, the safety valve threshold is 2 bar. In higher quality TT boilers, this threshold is provided at 3 bar.

Practice shows that no more than 5 minutes pass from the beginning of the overheating process to the valve actuation.If you install a circulation pump on the return pipe, then steam will not get into it and the time interval before the accident will increase to 20 minutes. That is, mounting the unit on the return line will not prevent the explosion, but will delay it, which will give more time to fix the problem. Hence the recommendation: it is better to install pumps for wood-fired and coal-fired boilers on the return pipeline.

For well-automated pellet heaters, the installation location does not matter. You will learn more information on the topic from the video of our expert:

Design features of a pump for heating a private house

In principle, a circulation pump for heating is no different from other types of water pumps.

It has two main elements: an impeller on a shaft and an electric motor that rotates this shaft. Everything is enclosed in a sealed case.

But there are two varieties of this equipment, which differ from each other in the location of the rotor. More precisely, whether the rotating part is in contact with the coolant or not. Hence the names of the models: with a wet rotor and dry. In this case, we mean the rotor of the electric motor.

wet rotor

Structurally, this type of water pump has an electric motor in which the rotor and stator (with windings) are separated by a sealed glass. The stator is located in a dry compartment, where water never penetrates, the rotor is located in the coolant. The latter cools the rotating parts of the device: the rotor, impeller and bearings. Water in this case acts for bearings, and as a lubricant.

This design makes the pumps quiet, because the coolant absorbs the vibration of the rotating parts. A serious drawback: low efficiency, not exceeding 50% of the nominal value.Therefore, pumping equipment with a wet rotor is installed on heating networks of small length. For a small private house, even 2-3 floors, this would be a good choice.

The advantages of wet rotor pumps, in addition to silent operation, include:

- small overall dimensions and weight;

- economical consumption of electric current;

- long and uninterrupted work;

- Easy to adjust rotation speed.

Photo 1. Scheme of the device of a circulation pump with a dry rotor. Arrows indicate parts of the structure.

The disadvantage is the impossibility of repair. If any part is out of order, then the old pump is dismantled, installing a new one. There is no model range in terms of design possibilities for pumps with a wet rotor. All of them are produced of the same type: vertical execution, when the electric motor is located with the shaft down. The outlet and inlet pipes are on the same horizontal axis, so the device is installed only on a horizontal section of the pipeline.

Important! When filling the heating system, the air pushed out by water penetrates into all voids, including the rotor compartment. To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover. To bleed the air plug, you must use a special bleed hole located in the upper part of the electric motor and closed with a sealed rotating cover

To bleed the air plug, you must use a special bleed hole located at the top of the motor and closed with a sealed rotating cover.

Preventive measures for "wet" circulation pumps are not required. There are no rubbing parts in the design, cuffs and gaskets are installed only on fixed joints. They fail due to the fact that the material has simply grown old. The main requirement for their operation is not to leave the structure dry.

Dry Rotor

Pumps of this type do not have a separation of the rotor and stator. This is a normal standard electric motor. In the design of the pump itself, sealing rings are installed that block the access of the coolant to the compartment where the elements of the engine are located. It turns out that the impeller is mounted on the rotor shaft, but is in the compartment with water. And the entire electric motor is located in another part, separated from the first by seals.

Photo 2. A circulation pump with a dry rotor. There is a fan at the back to cool the device.

These design features have made dry rotor pumps powerful. The efficiency reaches 80%, which is quite a serious indicator for equipment of this type. Disadvantage: the noise emitted by the rotating parts of the device.

Circulation pumps are represented by two models:

- Vertical design, as in the case of a wet rotor device.

- Cantilever - this is a horizontal version of the structure, where the device rests on the paws. That is, the pump itself does not press on the pipeline with its weight, and the latter is not a support for it. Therefore, a strong and even slab (metal, concrete) must be laid under this type.

Attention! O-rings often fail, becoming thin, which creates conditions for the penetration of the coolant into the compartment where the electrical part of the electric motor is located. Therefore, once every two or three years, they carry out preventive maintenance of the device, inspecting, first of all, the seals

Recommendations for the correct installation of a circulation pump for heating in a private house.

How to remove air from the circulation pump before starting.

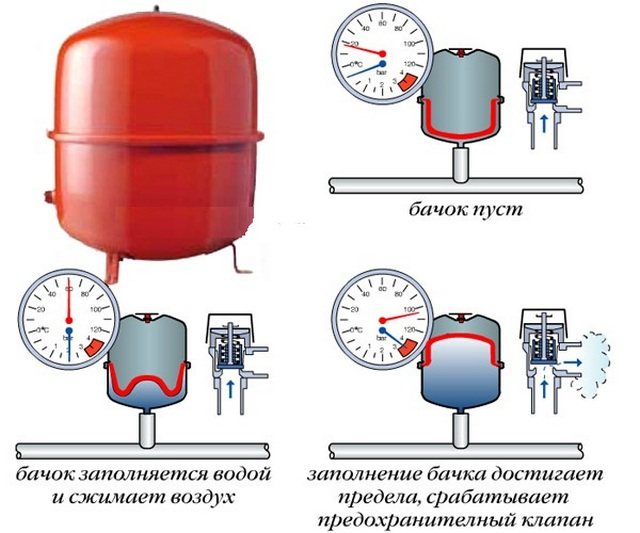

Circulation pumps installed in closed heating systems with a membrane tank must be installed on the return pipeline in the boiler room, next to the boiler.

Some authors recommend installing an expansion membrane tank on the return pipeline (return) as close as possible to the pump. In principle, this can somewhat soften the operation of the pump, but there is no need for this, you can install an expansion membrane tank in any convenient place, preferably on the return line and closer to the boiler. The main thing is to properly prepare (pre-inflate to a certain pressure) the expansion tank of the heating system for operation. Read about this in the article "How to choose the right expansion tank."

When installing a circulation pump in a heating system, mistakes are often made that, at best, reduce the service life, and at worst, disable it. The most common installation error is installing the pump in a non-horizontal position as shown in the figure. As you remember from the last article, wet rotor pumps are installed in the heating systems of private houses.In such pumps, the impeller must float in the working medium, due to which natural lubrication and smooth running of the impeller occur, and cooling of the pump motor. The branded block of the pump must be placed on top or facing you.

How to remove air from the circulation pump before starting.

How to remove air from the circulation pump before starting.

The heating system must be flushed before start-up to remove solid particles that could jam the impeller. Before starting a wet rotor pump, it is essential to bleed it by slightly loosening the shiny screw in the center of the pump motor. Air is vented until water flows out from under the released screw without air bubbles. The air removal operation must be repeated several times after 5-10 minutes of operation. In this case, the pump does not need to be stopped. After a long summer downtime, in order to avoid jamming of the pump and its burnout, before starting, be sure to completely unscrew the same screw, having previously closed the taps before and after the pump, and turn the rotor with a screwdriver (on some pumps, a hexagon).

As you can see for yourself, the selection, installation and start-up of the pump in the heating system of a private house is a rather complicated procedure. Therefore, if you are still not confident in your abilities, it is better to invite a professional specialist. And use our recommendations in everyday maintenance and for general development, if, God forbid, you come across a grief - a professional, and such are found at every step, you can avoid unnecessary financial costs.

Disadvantages of heating systems with pumps

- large amounts of electricity bills.The use of a circulation pump powered by electricity means additional cash costs. How large they will be depends on the power of the device;

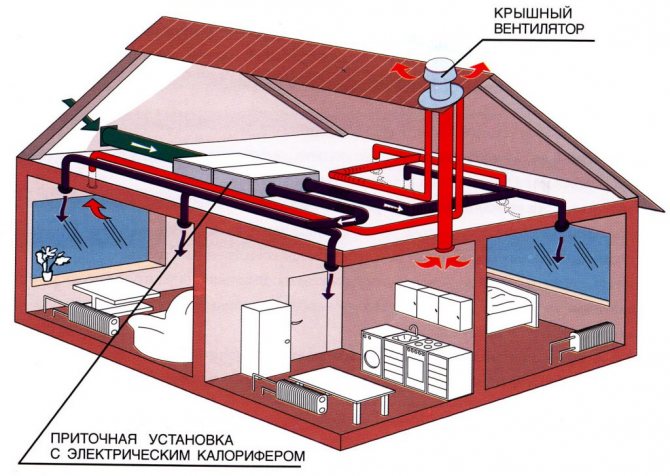

- the operation of the device depends on the supply of electricity, but this problem with frequent power outages can be solved by purchasing a diesel generator designed for the pumping group. It is also possible to make the device of a circulation pump for heating with the necessary slope and then the system will be able to function for some time with natural circulation in the event of a lack of electricity;

- equipment requires additional costs, and more specifically, you will need to purchase a pump, taps, filters and additional pipes for arranging a bypass. The cost of these elements will increase the price of the system;

- the cost of installing a circulation pump when the heating system is already available. If installation is in progress

Conclusions and useful video on the topic

Details on how to properly connect a surface pump as part of a pumping station are set out in the following video:

Here is a visual representation of the procedure for connecting a surface pump for irrigation:

There are not so many “pitfalls” in installing a surface pump. Of course, you should not rely on your own instinct or the famous “maybe”.

A careful study of the manufacturer's instructions, as well as a few small consultations with experienced craftsmen, will help even a beginner to cope with this task quite satisfactorily.

Do you want to tell how you use a surface pump in the country or have a water supply system based on it? There are rationalization proposals or tricky questions? Please write comments in the block below.