- Which pumps are suitable for residential installations

- Circulation pumping units - device and principle of operation

- Video: manual for installation and connection of the device

- Why do you need a pump in the heating system

- The principle of operation of the circulation pump

- Varieties of circulation pumps

- The need to install an additional circulation pump

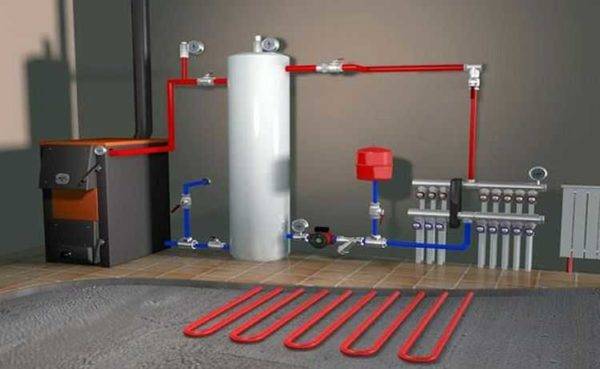

- hydraulic separator

- Functionality

- Where to put the second device in the house

- The optimal installation location for the circulation pump

- Where to put

- forced circulation

- natural circulation

- Mounting Features

Which pumps are suitable for residential installations

Installation of a circulation pump.

The optimal temperature of the heating system of a country house is achieved using built-in thermal valves. If the set temperature parameters of the heating system are exceeded, this may lead to the fact that the valve will be closed, and the hydraulic resistance and pressure will increase.

Using pumps with an electronic control system helps to prevent noise, as the devices will automatically follow all changes in water volumes. The pumps will provide smooth adjustment of pressure drops.

To automate the operation of the pump, a model of an automatic type unit is used. This helps protect it from misuse.

The pumps used may differ according to the type of application. For example, dry ones do not come into contact with the coolant during operation. Wet pumps pump water when they are submerged. Dry types of pumps are noisy, and the installation scheme of the pump in the heating system is more suitable for enterprises rather than residential premises.

For country houses and cottages, pumps designed to work in water, having special bronze or brass cases, are suitable. The parts used in the housings are stainless, so the system will not be damaged by water. Thus, these structures are protected from moisture, high and low temperatures. Installation of such a design is possible on the return and supply pipelines. The whole system will require a certain approach in its maintenance.

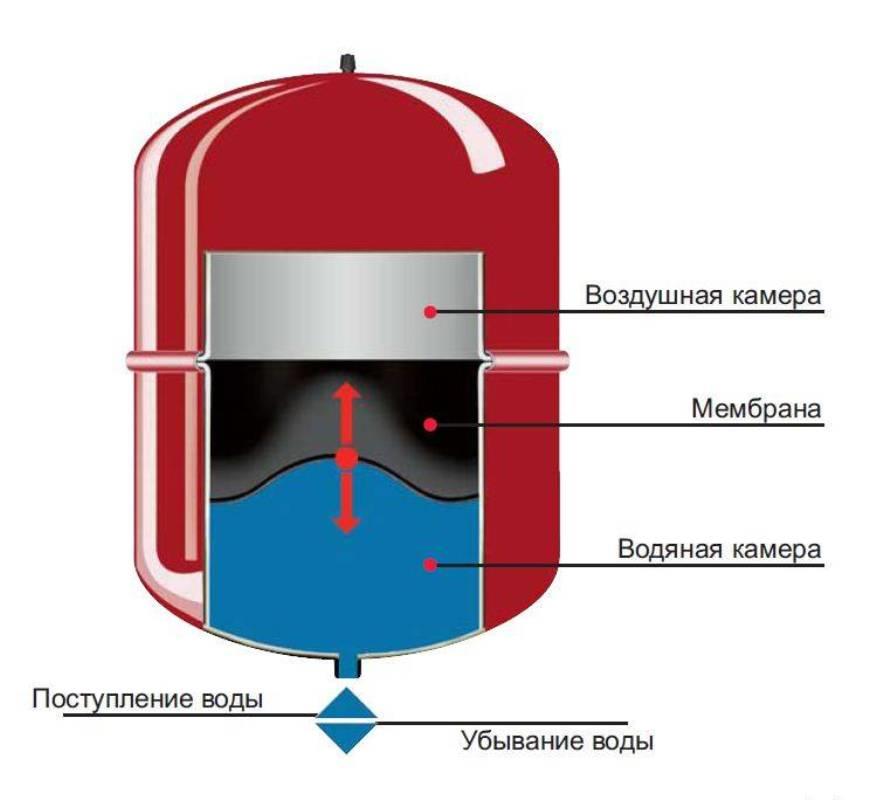

In order to increase the degree of pressure attributable to the suction section, you can install the pump so that the expansion tank is nearby. The heating piping must be descending at the point where the unit is to be connected. It will be necessary to make sure that the pump can withstand strong pressures of hot water.

Circulation pumping units - device and principle of operation

In closed heating systems require forced circulation hot water. This function is performed by circulation pumps, which consist of a metal motor or a rotor attached to a housing, most often made of stainless steel. The ejection of the coolant is provided by the impeller. It is located on the rotor shaft.The entire system is driven by an electric motor.

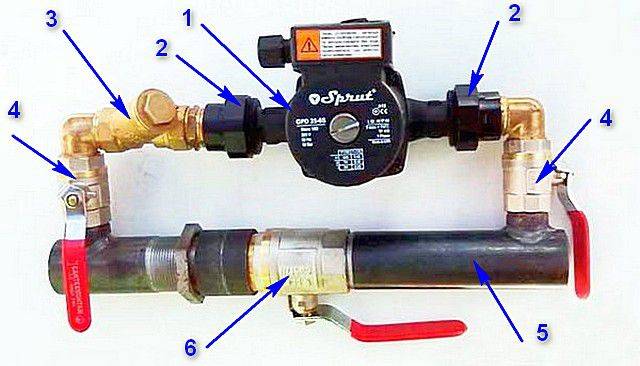

Circulation pump

Also in the design of the described installations there are the following elements:

- shut-off and check valves;

- the flow part (usually it is made of a bronze alloy);

- thermostat (it protects the pump from overheating and ensures the economical operation of the device);

- work timer;

- connector (male).

The pump, when installed in a heating system, draws in water, and then supplies it to the pipeline due to centrifugal force. The specified force is generated when the impeller produces rotational movements. The circulation pump will work efficiently only if the pressure it creates can easily cope with the resistance (hydraulic) of the various components of the heating system (radiator, pipeline itself).

Video: manual for installation and connection of the device

Of course, every owner wants to do most of the work on their own. But when it comes to improving the heating system and inserting new communications, it’s better not to risk it. Turning to specialists in the field of installation of heating pumping equipment is a wise decision that you will not have to regret.

Masters of their craft will carry out all the work in the "full cycle" mode: from choosing the optimal pump model to launching the already installed equipment and the entire network. In this case, the entire responsibility for the literacy and timeliness of the installation lies with them. The owners just have to wait for a pleasant moment when they can fully enjoy the long-awaited warmth in their own home.

Why do you need a pump in the heating system

Circulation pumps for heating private houses are designed to create a forced movement of the coolant in the water circuit. After the installation of the equipment, the natural circulation of the liquid in the system becomes impossible, the pumps will operate continuously. For this reason, high demands are placed on circulation equipment regarding:

- performance.

- Noise isolation.

- Reliability.

- Long service life.

A circulation pump is needed for "water floors", as well as two- and one-pipe heating systems. In large buildings it is used for hot water systems.

As practice shows, if you install the station in any system with natural circulation of the coolant, the heating efficiency and uniform heating along the entire length of the water circuit increase.

The only disadvantage of such a solution is the dependence of the operation of pumping equipment on electricity, but the problem is usually solved by connecting an uninterruptible power supply.

Installing a pump in the heating system of a private house is justified both when creating a new one and when modifying an existing heating system.

The principle of operation of the circulation pump

The operation of circulation pumps may differ slightly, depending on the type of construction, but the operating principle remains unchanged. Manufacturers offer more than a hundred models of equipment, with various performance and control options. According to the characteristics of pumps, stations can be divided into several groups:

- According to the type of rotor - to enhance the circulation of the coolant, models with a dry and wet rotor can be used.The designs differ in the location of the impeller and moving mechanisms in the housing. So, in models with a dry rotor, only the flywheel, which creates pressure, comes into contact with the coolant fluid. "Dry" models have high performance, but have several drawbacks: a high level of noise is generated from the operation of the pump, regular maintenance is required. For domestic use, it is better to use modules with a wet rotor. All moving parts, including bearings, are completely encased in a coolant medium that serves as a lubricant for the parts that bear the greatest load. The service life of the "wet" type water pump in the heating system is at least 7 years. There is no need for maintenance.

- By type of control - the traditional model of pumping equipment, most often installed in domestic premises of a small area, has a mechanical regulator with three fixed speeds. It is quite inconvenient to regulate the temperature in the house using a mechanical circulation pump. The modules are distinguished by high power consumption. The optimal pump has an electronic control unit. A room thermostat is built into the housing. Automation independently analyzes the temperature indicators in the room, automatically changing the selected mode. At the same time, electricity consumption is reduced by 2-3 times.

There are other parameters that distinguish circulation equipment. But to choose a suitable model, it will be enough to know about the above nuances.

Varieties of circulation pumps

The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine

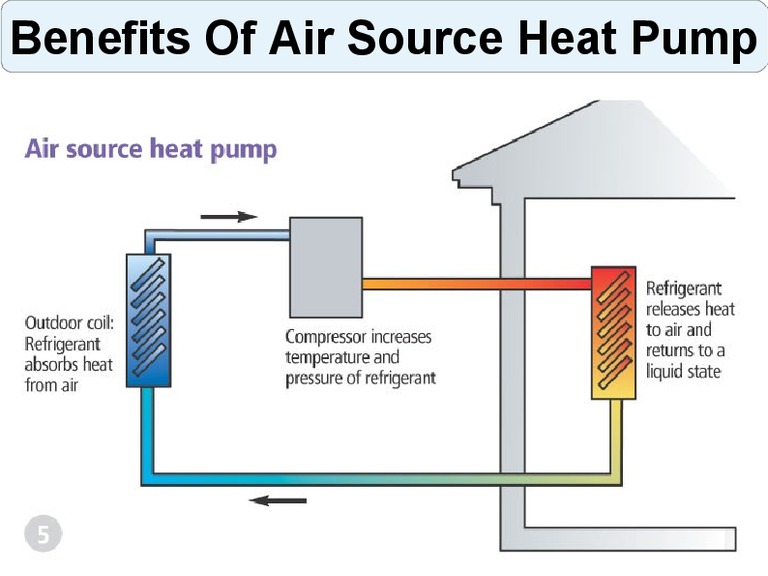

To understand how this device works, you need to know the differences between the two types of circulation pumping equipment. Although the fundamental scheme of the heating system based on a heat pump does not change, two types of such units differ in their operation features:

- The wet rotor pump is available in stainless steel, cast iron, bronze or aluminium. Inside is a ceramic or steel engine. The technopolymer impeller is mounted on the rotor shaft. When the impeller blades rotate, the water in the system is set in motion. This water simultaneously acts as an engine cooler and lubricant for the working elements of the device. Since the “wet” device circuit does not provide for the use of a fan, the operation of the unit is almost silent. Such equipment only works in a horizontal position, otherwise the device will simply overheat and fail. The main advantages of the wet pump are that it is maintenance-free and has excellent maintainability. However, the efficiency of the device is only 45%, which is a small drawback. But for domestic use, this unit is perfect.

- A dry rotor pump differs from its counterpart in that its motor does not come into contact with the liquid. In this regard, the unit has a lower durability. If the device will work "dry", then the risk of overheating and failure is low, but there is a threat of leakage due to abrasion of the seal.Since the efficiency of a dry circulation pump is 70%, it is advisable to use it for solving utility and industrial problems. To cool the engine, the circuit of the device provides for the use of a fan, which causes an increase in the noise level during operation, which is a disadvantage of this type of pump. Since in this unit water does not perform the function of lubricating the working elements, during the operation of the unit it is periodically necessary to carry out technical inspection and lubricate the parts.

In turn, "dry" circulating units are divided into several types according to the type of installation and connection to the engine:

- Console. In these devices, the engine and housing have their own place. They are separated and firmly fixed on it. The drive and working shaft of such a pump is connected by a coupling. To install this type of device, you will need to build a foundation, and the maintenance of this unit is quite expensive.

- Monoblock pumps can be operated for three years. The hull and engine are located separately, but are combined as a monoblock. The wheel in such a device is mounted on the rotor shaft.

- Vertical. The term of use of these devices reaches five years. These are sealed advanced units with a seal on the front side made of two polished rings. For the manufacture of seals, graphite, ceramics, stainless steel, aluminum are used. When the device is in operation, these rings rotate relative to each other.

Also on sale there are more powerful devices with two rotors. This dual circuit allows you to increase the performance of the device at maximum load. If one of the rotors exits, the second one can take over its functions.This allows not only to enhance the operation of the unit, but also to save energy, because with a decrease in heat demand, only one rotor works.

The need to install an additional circulation pump

The idea of installing a second device arises with uneven heating of the coolant. This is due to insufficient boiler power.

To detect a problem, measure the temperature of the water in the boiler and pipelines. If the difference is 20°C or more, the system should be purged of air pockets.

In the event of a further malfunction, an additional circulation pump is installed. The latter is also necessary if a second heating circuit is being installed, especially in situations where the strapping length is 80 meters or more.

Reference! Invite experts to clarify the calculations. If they are incorrect, installing an additional device will result in poor performance. In rare cases, nothing will change, but the costs of buying and hosting will go to waste.

A second pump is also not needed if the heating system is balanced by special valves. Purge the pipes of air, replenish the amount of water and carry out a test run. If the devices interact normally, then it is not necessary to mount new equipment.

hydraulic separator

Used when an additional pump is required. The device is also called an anuloid.

Photo 1. Hydraulic separator model SHE156-OC, power 156 kW, manufacturer - GTM, Poland.

Such devices are used in heating, if water is heated when using long-burning boilers.The devices in question support several modes of operation of the heater, from ignition to fuel attenuation. In each of them, it is desirable to maintain the required level, which is what the hydraulic gun does.

Installing a hydraulic separator in the piping creates a balance during the operation of the coolant. Anuloid is a tube with 4 outgoing elements. Its main tasks:

- independent removal of air from heating;

- catching part of the sludge to protect pipes;

- filtration of dirt entering the harness.

Attention! Characteristics must be carefully selected. Choosing a quality device will help protect the system from problems. Because of this, the installation of a pump becomes mandatory.

Because of this, the installation of a pump becomes mandatory.

Functionality

Piping with a circulation pump performs many tasks. They must be allowed regardless of the flow of working water and possible pressure surges in the pipes. Efficiency is difficult to achieve because the fluid is taken in from a common source.

Thus, the coolant leaving the boiler will unbalance the system.

Because of this, a hydraulic separator is placed: its main goal is to create a decoupling that will solve the problem described above.

The following features are also important:

- contour matching, if several are used;

- support of the calculated flow rate in the primary piping, regardless of the secondary ones;

- continuous provision of circulation pumps;

- facilitating the operation of branched systems;

- cleaning pipes from air;

- sludge recovery;

- ease of installation when using modules.

Where to put the second device in the house

In autonomous heating, it is recommended to install a device with a wet rotor, which is self-lubricated by the working fluid. Therefore, consider the following points:

- the shaft is placed horizontally, parallel to the floor;

- the flow of water is directed in one direction with the arrow installed on the device;

- the box is placed on any side except the bottom, which protects the terminal from water ingress.

The device is mounted on the return line, where the coolant temperature is minimal.

This increases the duration of operation, although some experts disagree with this phrase. The latter is related to the rules of operation: the device must withstand heating of the working fluid up to 100-110 ° C.

Important! Placement is possible not only on the reverse, but also on the straight pipe. The main thing is to install between the boiler and the radiators, since the opposite is prohibited. It also makes maintenance of the device easier.

This also makes the device easier to maintain.

The optimal installation location for the circulation pump

Although the Internet is replete with a wealth of information on this topic, however, a simple user is not always able to determine the optimal scheme for connecting a circulation pump to a heating system. The reason lies in the inconsistency of the information provided, which is why heated discussions constantly arise on thematic forums.

Adherents of installing the apparatus exclusively on the return pipeline cite the following arguments in defense of their position:

- The higher temperature of the coolant at the supply compared to the return provokes a significant reduction in the life of the pump.

- Hot water inside the supply line is less dense, which causes additional difficulties in pumping it.

- In the return pipeline, the coolant has a high static pressure, which facilitates the operation of the pump.

Often, such a conviction also develops from an accidental contemplation of where the circulation pump is installed for heating in traditional boiler rooms: there, the pumps, indeed, are sometimes cut into the return line. At the same time, in other boiler rooms, the installation of centrifugal pumps can be carried out on the supply pipes.

Arguments against each of the above arguments in favor of installation on the return pipe are as follows:

- The resistance of household circulation pumps to the coolant temperature usually reaches +110 degrees, while inside autonomous heating systems, water rarely heats up above +70 degrees. As for the boilers, they give out a coolant temperature of about +90 degrees at the outlet.

- Water at a temperature of +50 degrees has a density of 988 kg / m³, and at +70 degrees - 977.8 kg / m³. For devices that create a pressure of 4-6 m of water column and are capable of pumping about a ton of coolant in 1 hour, such a meager difference in density of 10 kg / m³ (canister capacity of 10 liters) does not play a significant role.

- The actual difference in the static pressure of the coolant inside the supply and return is also minimal.

As a conclusion, we can say that the connection diagram of the circulation pump may involve its installation both on the return and on the supply pipe of the heating circuit. This or that option, where to install the circulation pump in the heating system, does not significantly affect its level of performance and efficiency. An exception is the use of inexpensive solid fuel boilers of direct combustion, in which there is no automation.Since there is no way to quickly extinguish the burning fuel in such heaters, this often provokes the boiling of the coolant. If the connection of the heating pump was carried out on the supply pipe, this allows the resulting steam, together with hot water, to get inside the casing with the impeller.

Further events unfold as follows:

- The device sharply reduces its productivity, since its impeller is not able to move gases. This provokes a decrease in the circulation rate of the coolant.

- There is a decrease in the cooling water entering the boiler tank. As a result, the appliance overheats even more and steam production increases.

- After the volume of steam reaches critical values, it enters the inside of the impeller. After that, a complete stop of the circulation of the coolant occurs: an emergency occurs. The pressure in the system increases, due to which the triggered safety valve throws out puffs of steam into the boiler room.

- If you do not put out the firewood, then at some stage the valve will not cope with the increasing pressure. As a result, there is a real danger of a boiler explosion.

If the installation scheme of the circulation pump in the heating system involves its installation on the return pipe, then this protects the device from direct exposure to water vapor. As a result, the period of time before the accident is increased (by almost 15 minutes). That is, it does not prevent an explosion, but only gives additional time to take on-duty measures to eliminate the resulting system overload.Therefore, when looking for a place to put the pump on heating, in cases with the simplest wood-burning boilers, it is better to choose a return pipeline for this. Modern automated pellet heaters can be mounted on any convenient site.

Where to put

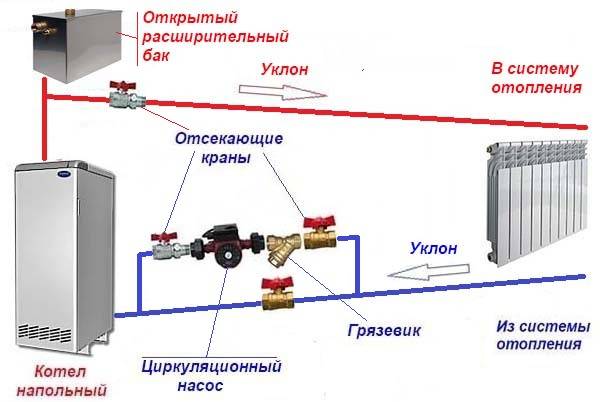

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there.If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

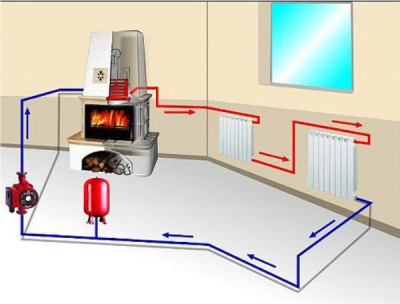

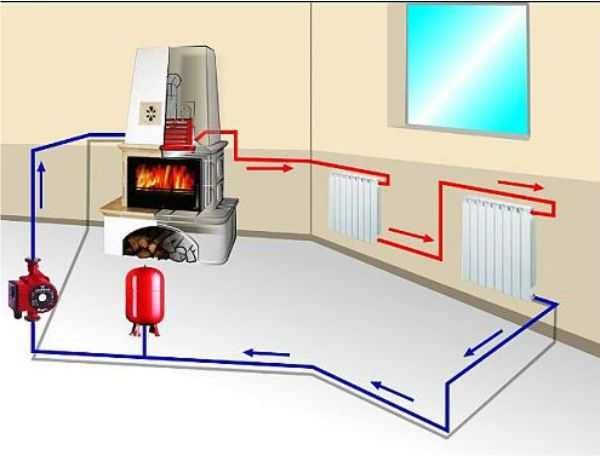

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

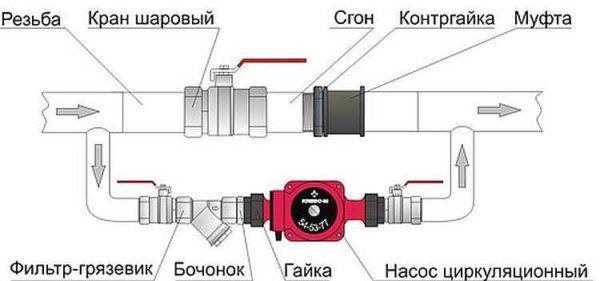

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit.Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.