- Boiler house at home

- Grounding gas boilers

- Connection to the gas line

- Boiler installation

- Where it is possible and where it is impossible to put a gas boiler

- Installation of exhaust and ventilation

- Rules for the device of the chimney, the conditions for its installation

- Basic rules for using a gas unit

- Chimney installation

- Documents for the boiler

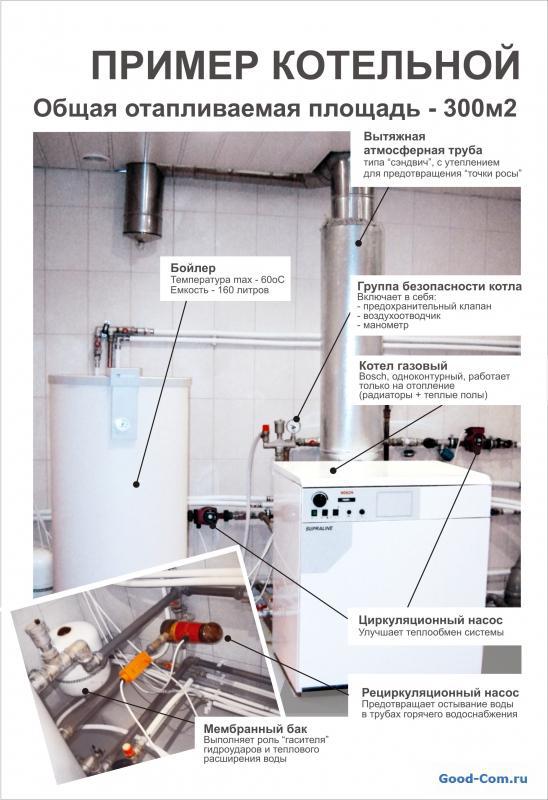

Boiler house at home

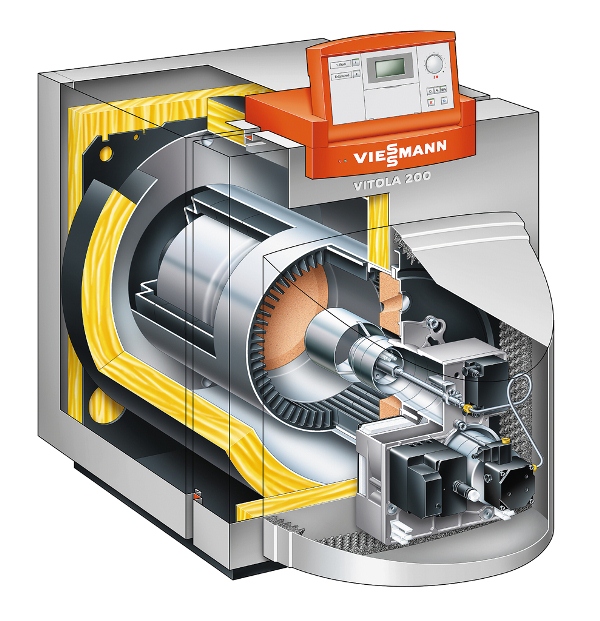

A full-fledged boiler room based on a gas boiler can be equipped in a country wooden house, in a cottage, and in an ordinary city apartment.

Its "heart" is a double-circuit boiler with automatic systems. Automation provides not only security, but also the efficiency of the operation of the entire network. It is from its work that the provision of a comfortable temperature regime and the possibility of reducing gas consumption during the operation of the device depend.

Despite all its advantages, installing a boiler with automation has one important nuance. In the event of a power outage, the unit will switch to minimum space heating mode.

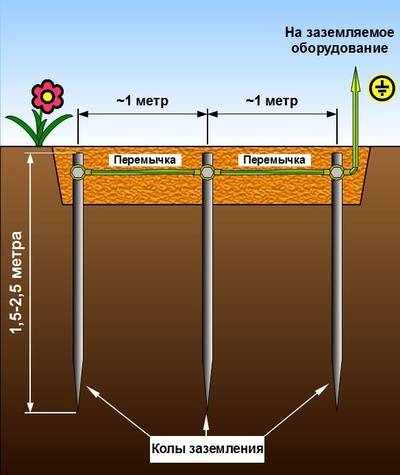

Grounding gas boilers

How to make grounding:

How to make grounding:

- It is necessary to take as a basis a contour in the form of an isosceles triangle of 3 metal rods 3 meters long.

- Wires need to be connected.

- Using an ohmmeter, measure the resistance inside the circuit (should be close to 4 ohms).If the value is higher, one more element can be added to the outline.

- You need to continue until the port is as close as possible to 4 ohms.

For grounding, rods and tubes are used, which are connected by metal strips. They are installed vertically in the ground so that the system works even in winter. It is recommended to coat the metal elements with an anti-corrosion solution.

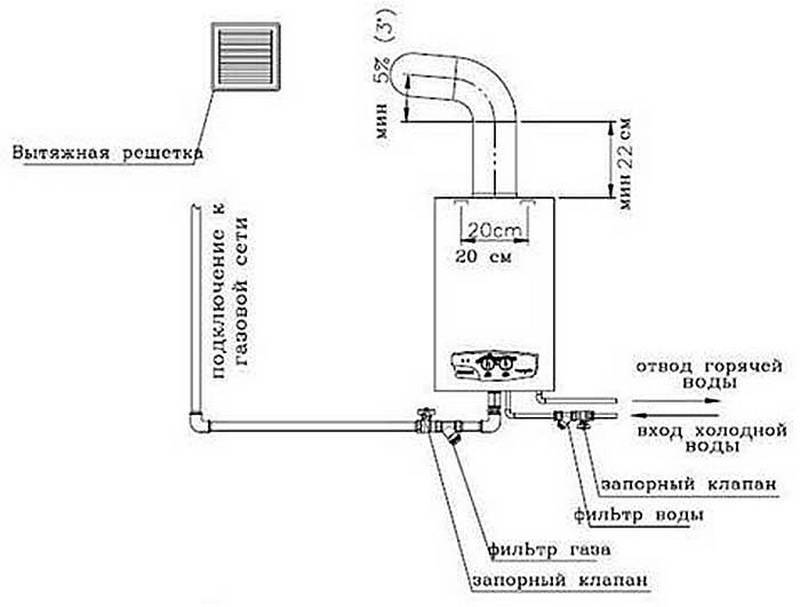

Connection to the gas line

You need to know that according to the installation standards for gas floor boilers, only a specialist with a permit can perform this operation. You can do the work yourself, but an invited professional will, after all, carry out the assembly check and make the first start.

Connection work is carried out with the utmost care and precision. They start by connecting the gas pipe with the corresponding element of the heating boiler.

Only tow can be used as a sealant. No other material will give the required tightness of the connection. It is obligatory to install a shut-off valve, which is additionally equipped with a filter.

For connection, it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses

In any case, special attention should be paid to the quality of the sealing of the joints. Since gas tends to seep from loose connections and accumulate in the room, which is fraught with the creation of an explosive situation

Behind the filter there must be a flexible connection, which can only be made with a corrugated hose. Rubber parts are strictly prohibited as they develop cracks over time, creating channels for gas to escape.

Corrugated parts are fixed on the boiler nozzle with a cap nut. A mandatory element of such a connection is a paronite gasket.

After installing and connecting the gas heating unit, it is necessary to check the quality of the connections and assemblies. The simplest control method is to apply a soapy solution to the joint. If it bubbles, then there is a leak.

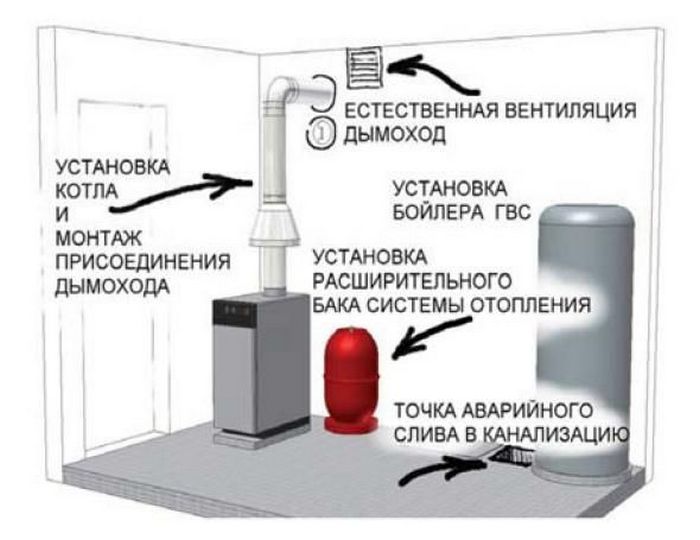

Boiler installation

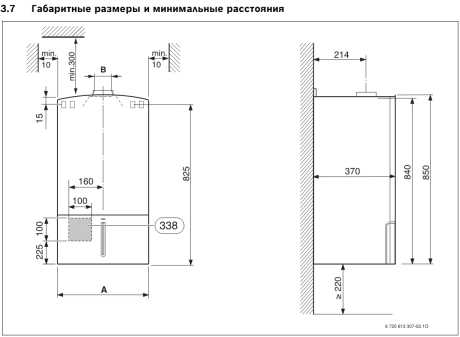

Adjacency of the boiler body close to any of the walls is unacceptable; it is forbidden. After installing the boiler in place, it is tied up - connecting three systems: gas, hydraulic and electric. Gas piping should be done by a gas specialist as indicated, and lastly, when everything else is already connected.

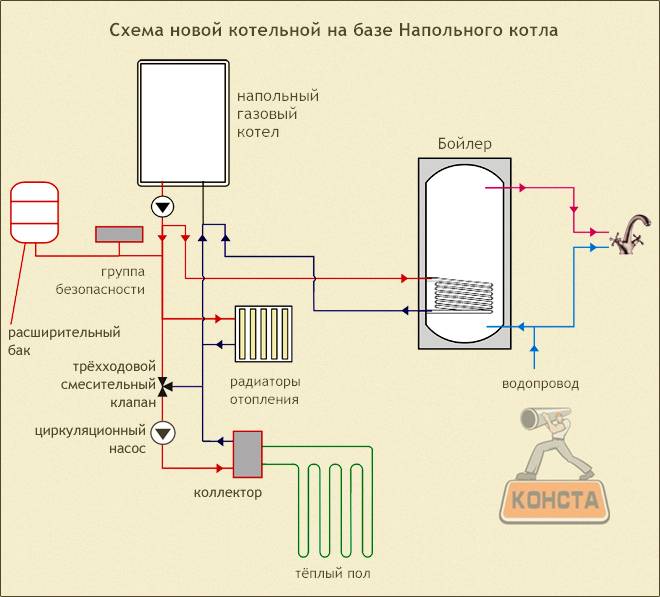

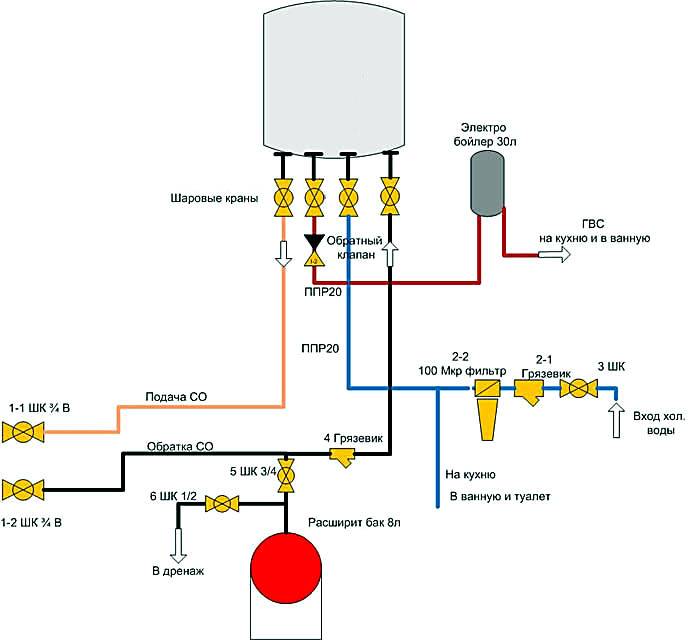

Scheme of hydraulic piping of a gas boiler

Electrical and hydraulic piping can be done independently. Here the main guiding document is the instructions for the boiler. A typical boiler hydraulic piping diagram is shown in the figure. For any boiler, the following conditions must be strictly observed:

Water and hot gases in the boiler heat exchanger must go countercurrent, otherwise it can simply explode with any automation

Therefore, it is extremely important not to confuse, through negligence or for the sake of ease of installation, cold and hot pipes. After hydrobinding, inspect the entire system carefully again, then rest for an hour, and inspect again.

If antifreeze has been poured into the heating system, drain it completely and flush the system twice with clean water

The admixture of antifreeze in the water entering the heat exchanger is also explosive.

Do not neglect the "mud filters" - coarse water filters. They should be located at the lowest points in the system. The accumulation of dirt between the thin fins of the heat exchanger also creates a dangerous situation, not to mention exorbitant gas consumption. At the beginning and at the end of the heating season, drain the sediment through the sumps, check their condition and, if necessary, flush the system.

If the boiler has a built-in expansion tank and a de-airing system, remove the old expansion tank, and close the old air cock tightly, after checking its condition beforehand: air leakage will also create a dangerous situation.

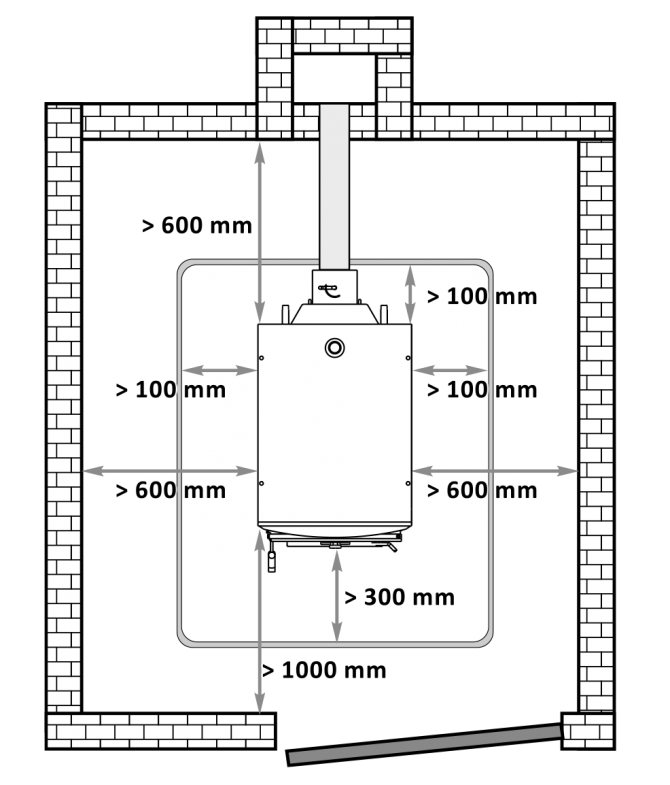

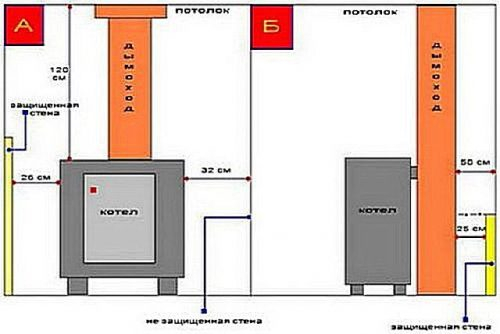

Where it is possible and where it is impossible to put a gas boiler

The rules for installing a gas boiler provide for the following requirements for installing a HEATING boiler, regardless of whether it also provides domestic hot water or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications of the admissibility of a ceiling of 2 m. This is not true. 8 cubes is the minimum free volume.

- The furnace must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with combustible materials, the presence of a false ceiling or raised floor in it is unacceptable.

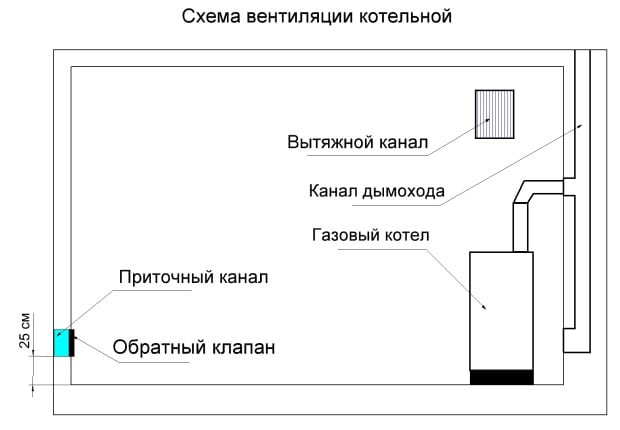

- Air must be supplied to the furnace through a through, non-closable vent with a cross section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly referred to as a chimney); the use of ventilation ducts for this is unacceptable - life-threatening combustion products can get to neighbors or other rooms.

- The length of the horizontal part of the flue must not exceed 3 m within the furnace and have no more than 3 angles of rotation.

- The outlet of the flue must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since the products of combustion form chemically aggressive substances during cooling, the chimney must be made of heat- and chemical-resistant solid materials. The use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest branch pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A strong fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- The room should not have cavities in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment / house:

- The slope of the horizontal pipe sections must be positive, but not more than 5 mm per linear meter in terms of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler in which everything is provided for: rules are rules.

- The condition of the heating system must allow it to be pressure tested at a pressure of 1.8 atm.

The requirements, as we see, are tough, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a hot water boiler, if:

- You live in a block Khrushchev or other apartment building without a main flue.

- If you have a false ceiling in your kitchen, which you do not want to clean, or a capital mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which, in principle, can be removed, and then there will be no mezzanine, gas workers look through their fingers.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment that only the owner can do.

In all other cases, you can put a hot water boiler in the apartment; heating wall is possible, and floor - very problematic.

In a private house, any boiler can be installed: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside under the furnace, then the authorities will only have fewer reasons for nit-picking. In it, you can put a floor gas boiler of high power for heating not only the mansion, but also office space.

For private housing of the middle class, the optimal solution is a wall-mounted boiler; under it is not required, as for the floor, to arrange a brick or concrete pallet with sides of half a meter.Installing a wall-mounted gas boiler in a private house also does without technical and organizational difficulties: a fireproof closet for a furnace can always be shielded, at least in the attic.

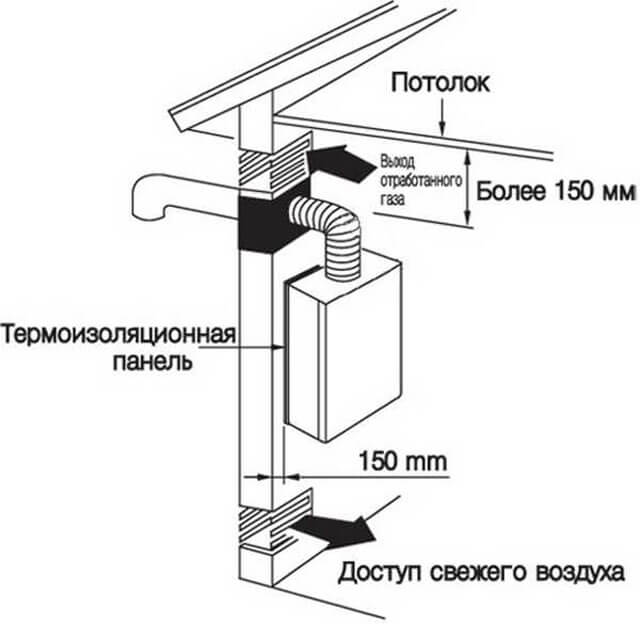

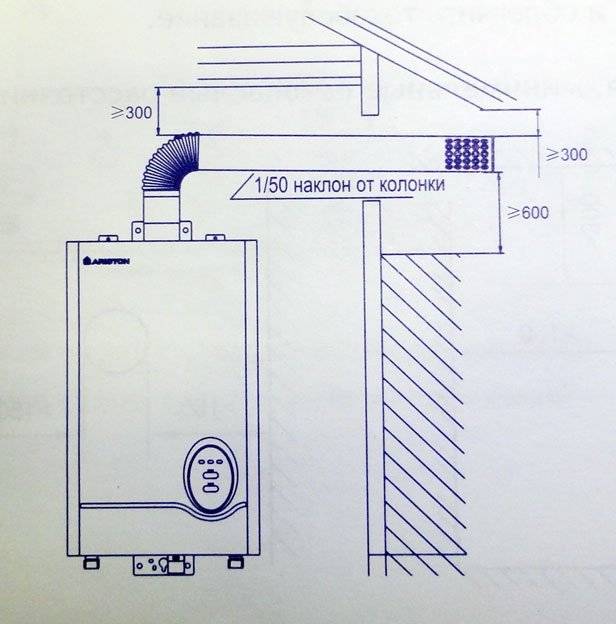

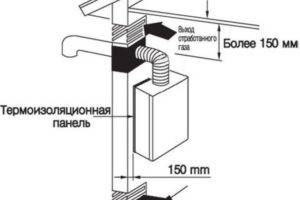

Installation of exhaust and ventilation

Safety measures require that forced ventilation be made in the room where the boiler is installed.

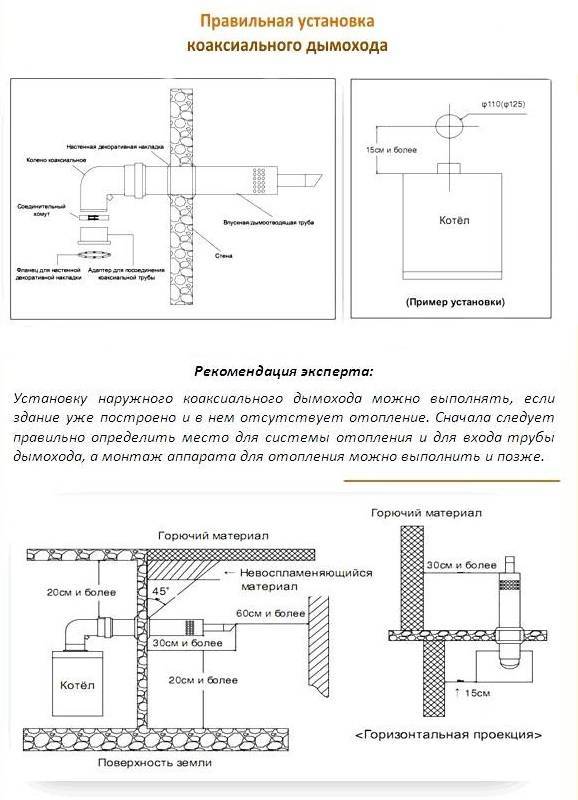

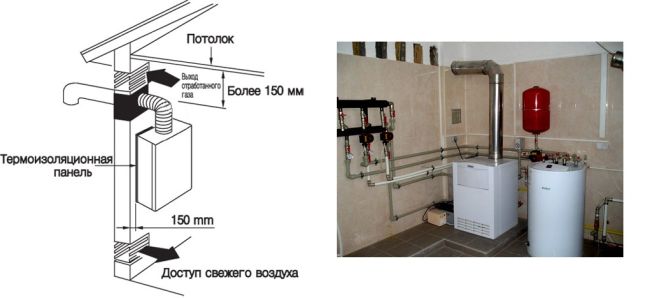

Everything is quite easy if we are talking about a device with a closed combustion chamber (and these are now the majority). By installing a coaxial chimney pipe, the owner gets two in one: both the inflow of fresh air directly into the boiler and the removal of exhaust gases.

If the hood is mounted on the roof, it is usually made in the same block as the flue, but the latter must be a meter higher.

Gas workers will periodically check the pipeline for its cleanliness and draft. Cleaning hatches and condensate collectors should be arranged.

Rules for the device of the chimney, the conditions for its installation

For the safe operation of a gas-fired heating unit, not only good ventilation in the room is required, but also the constant removal of fuel combustion products. For this purpose, chimney pipes made according to certain rules are intended.

Attention! The rules for installing a chimney indicate the inadmissibility of connecting it to a ventilation duct. The reasons for this ban are obvious.

First, ventilation is designed to ensure constant air circulation.

The reasons for this ban are obvious. First, ventilation is designed to provide constant air circulation.

Secondly, it cannot provide effective traction, thereby not allowing full use of the power of the boiler equipment.

Certain requirements are also imposed on the device of the chimney.They affect both its design and the material of its manufacture.

Regardless of the location of the chimney outlet (through the roof or through the wall), it is made of a round metal pipe. The use of pipes having a different cross section is not allowed. By production of a flue corrosion-proof or carbonaceous sheet steel is applied.

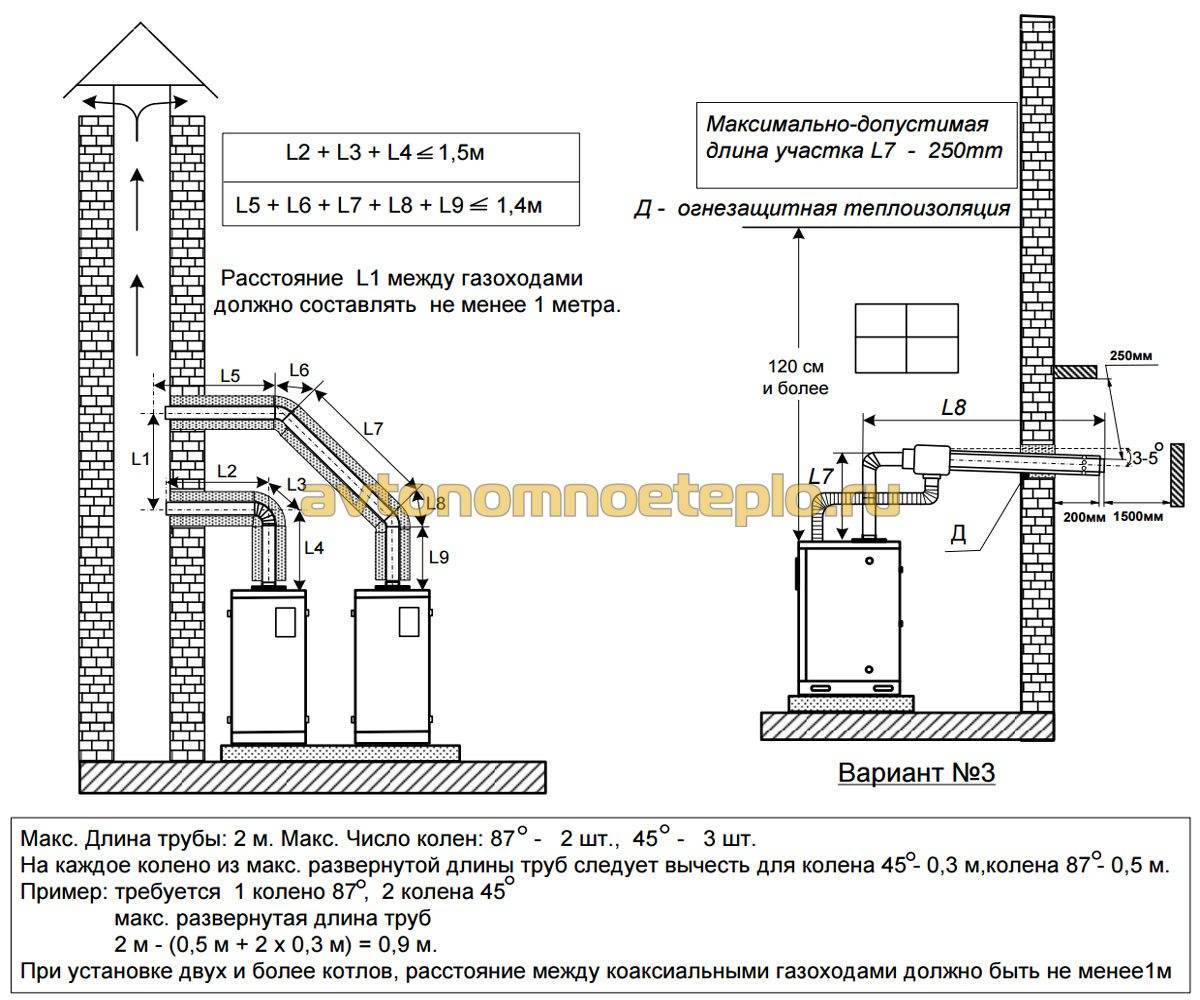

When installing a chimney, the following requirements must be observed:

- the diameter of the exhaust hole of the pipe is selected larger than that of the boiler nozzle;

- no more than three bends are allowed along the length of the chimney;

- it is allowed to supplement the metal chimney pipe with an asbestos-concrete pipe, but the permissible distance from it to the chimney pipe is at least 500 mm;

- the height of the chimney pipe depends on the shape of the roof and the place of its installation, it is determined by the established standards;

- it is forbidden to install a protective cap on the chimney.

The requirements for the installation of a classic chimney are relevant for floor models equipped with an open combustion chamber. For their installation, a separate room is most often used. Most of the problems associated with installing a chimney disappear when purchasing a wall-mounted boiler model.

For it, a more modern way of removing combustion products is used - installation of a coaxial chimney. It is mounted in an external wall and performs two tasks at the same time - it removes the waste generated during the combustion of gas and supplies the air necessary for the operation of the burner.

Photo 3. Coaxial chimney for a gas boiler. The product consists of several parts, it is located horizontally.

Basic rules for using a gas unit

It is necessary to use heating gas appliances in compliance with certain rules:

- The boiler room or other room should always be dry.

- Filters for the heat carrier should be cleaned of dirt in a timely manner in order to extend the life of the heat exchanger.

- It is strictly forbidden to make independent changes to the structural device of the boiler.

- Cleaning of the flue structure pipe from the combustion products deposited on its walls should be carried out in a timely manner.

- In a private household or boiler room, it is advisable to install a gas analyzer that helps to identify malfunctions in the functioning of gas equipment.

- Timely maintenance of the heating unit should not be avoided, which experts recommend to carry out before the start of the heating season and after its completion. To do this, you need to invite a master who will comprehensively check the condition and operation of the chimney, ventilation system, filters, burner and boiler as a whole.

A qualified installation and compliance with preventive measures can ensure the long and trouble-free operation of gas equipment, and, accordingly, the entire heating system of a household.

Chimney installation

If the pipe is coaxial, it is connected to the boiler, taken out of the house, the joint of the pipe with the wall is finished, and that's it.

Gas flue requirements:

- It must be a separate pipe (cannot be combined with ventilation, or two pipes from different boilers).

- The horizontal segment should not be longer than 3 meters.

- No more than three turns.

- The chimney material is heat-resistant, chemical-resistant, one-piece. Asbestos can only be used on the upper section of the pipe, no closer than 5 meters to the boiler nozzle.Stainless steel is great!

- Diameter for boilers up to 24 kW - 12 cm, up to 30 kW - 13 cm.

Whatever the power, the diameter of the flue cannot be less than 11 cm and in no way less than the diameter of the nozzle on the boiler.

Documents for the boiler

Let's say you equipped a furnace in compliance with all requirements. Buying a boiler Still early. First of all, check if the old papers have been lost for gas, and take them out into the light of day:

- Contract for the supply of gas, if the boiler is heating. Subconsumers may only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing to be done, you need to set it up and draw it up, but that’s another topic.

Now you can buy a boiler. But, having bought, it is too early to install:

- In BTI, you need to make changes to the registration certificate at home. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be applied, and clearly marked: “Furnace” or “Boiler Room”.

- Submit an application to the gas service for the project and specifications. As part of the required documents and the technical passport for the boiler, so it must have already been purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas piping.

- Submit an application to gas workers for commissioning.

- Wait for the arrival of the gas service engineer, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.