- 2 We study general recommendations for installation - 3 points for analysis

- Types of water heaters and features of their connection

- Types of instantaneous water heaters

- What can you do yourself

- Peculiarities

- Power selection

- Required capacity

- Do-it-yourself boiler installation

- How to install a tankless water heater

- Rules for installing a storage boiler

- Mistakes and Solutions

- Uninsulated hot water pipes

- Heating not supported

- Heater not programmed

- Choosing a place to install equipment

- Schemes of connection to water of a wall-mounted storage water heater

- Location selection

- Electrical supply to the storage heater

- Water heater installation

- Mounting Features

2 We study general recommendations for installation - 3 points for analysis

Self-installation of the described units allows you to save money on calling a specialist (his services are not cheap), and also allows the home master to gain indispensable skills in maintaining such equipment. But let's say right away - if you do not have the slightest experience in plumbing, it is better to give up trying to install the heater yourself. The consequences can be deplorable, up to the flooding of the neighbors from below and the failure of the electrical wiring and network in your apartment.

Wiring diagram

If you are sure that you can install the water heater yourself, be sure to pay attention to the following points:

- 1. Assess the condition of the wiring in the home. Old cables that have been in operation for decades should be replaced with more modern ones. Even the most modest power electric instantaneous heater consumes 2–2.5 kW. Soviet wiring may not withstand such a load.

- 2. Choose a place to install the device. The storage water heater, as we have already said, is a fairly massive unit. If you plan to mount it on a wall, you need to make sure in advance that it can withstand the weight of a large volume device. In addition, during the entire period of operation of the water heater, free passage must be ensured to it.

- 3. Analyze the condition of the water risers and pipes. In their deplorable condition, it is desirable to replace the highways. And only after that proceed with the installation of the heater.

It is also required to prepare tools and special materials in advance. We will need: metal-plastic pipes, fittings, pliers, a grinder, screwdrivers, a puncher, wire cutters, wrenches (wrench and adjustable), fluoroplastic tape or threads (linen), connecting hoses. For the installation of a storage device, we purchase three plumbing tees and three stopcocks, for a flow-through device, two units of these devices each.

If it is necessary to replace the wiring, you will have to purchase an automatic fuse, the required amount of a three-core cable and a socket for connecting a water heater. Take wires with a cross section of 4–6 square meters. mm., automatic - at 32–40 A.Recommended cable types for connecting the unit are 3X8 and 3X6.

Types of water heaters and features of their connection

All types of devices used in residential and public buildings for heating water (not for heating!) Can be divided into groups according to:

- method of operation - storage (most models) and flow;

- the type of energy used - electric, gas, wood, combined;

- volume of heated water. For storage devices, this parameter is determined by the volume of the internal container, where the liquid is collected with subsequent heating. For flowing - the amount of water passed by the heater per minute with heating to the desired temperature;

- mounting method - wall-mounted (strictly vertical arrangement, with a choice of horizontal or vertical placement), floor, built-in.

Gas, wood and combined water heaters are usually part of an individual heating system and have their own connection and installation nuances, so in this article we will only consider electrical devices.

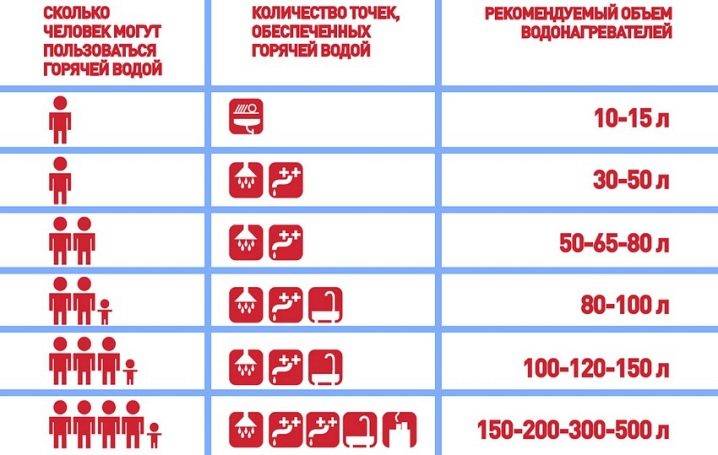

If hot water is required on the farm all the time and you need a lot of it, the storage tank will be the best choice. Flow models are suitable for limited flow and local water intake. The table below will help determine the approximate need for hot water.

Naturally, the required amount of water must be provided by the throughput of the water supply. Therefore, for housing where water is supplied manually (from a well, a column), we usually do not talk about an electric water heater. In extreme cases, this device is supplied with water from a separate storage tank and is turned on only as needed.

If the choice is nevertheless made in favor of an instantaneous water heater, it is necessary to immediately determine the possibility of connecting the device to the house electrical network - some models require too much electricity, the wiring simply cannot withstand the current.

The vertical or horizontal position of the tank has little effect on the way the water heater is installed in the apartment; here it is only necessary to take into account the actual ability of the product to work in the selected position and correctly place all the elements of the supply and discharge water supply.

Types of instantaneous water heaters

Instantaneous water heaters are divided according to the type of energy that is used for heating. Therefore, they can be divided into the following types:

- Electric, in which the passing water is heated by a heating element (tubular electric heater) or a metal tube, which is affected by an alternating magnetic field (inductor). Therefore, they are divided into two types: induction and heating elements. This type of water heater consumes electrical energy, therefore it is not suitable for places where it is impossible to connect to the mains;

- Water, working from the heating system. These devices do not require an electrical connection, so they can be used even in non-electric homes. However, dependence on the heating system does not allow their use in the summer;

- Solar, receiving heat from the luminary. They do not depend on the heating system or electricity, so they can be used in summer cottages. However, these devices heat water only on warm sunny days;

- Gas, powered by liquefied or main gas. Such devices are used only in houses and apartments connected to the central gas pipeline.

This device heats the flow of water passing through it.

The basis of an electric water heater is nichrome wire, which has a high resistance, wound on a ceramic frame. The induction heater works on a different principle. A thick copper bus is wound around a metal pipe, then high-frequency (up to 100 kilohertz) voltage is applied. The alternating magnetic field heats the metal pipe, and the pipe, in turn, heats the water. There are flow heaters that are built into boilers or heat accumulators filled with water. That is why they are called water. The best option for a summer cottage is a solar instantaneous water heater. It runs on solar energy and heats the water to 38-45 degrees, which is enough to take a shower. Gas instantaneous water heaters appeared in the student environment out of desperation caused by a broken column or other similar factors. They are a copper tube twisted into a spiral, located above the fire of a kitchen gas stove.

What can you do yourself

Before choosing a specific type of water heater, you need to determine what tools, materials and skills are available to you. If you know how to work well with a welding machine, you can make an electric water heater. If you already have a working heating system with a heat accumulator and you know how to use a welding inverter, you can make a water heater. If you do not have such talents or you do not have electricity or water heating, then a solar water heater is quite capable of you.

Gas instantaneous water heaters are a means of increased danger.To work with any gas devices, you must undergo special training, otherwise it is likely that instead of a tankless water heater you will get a time bomb that will explode one day. If the concentration of gas in the room is 2–15%, then an explosion will occur from any spark. Therefore, in this article there are no instructions with which you can create a gas instantaneous water heater.

To create most water heaters, you will have to learn how to use welding

Peculiarities

The advantage of electrical systems used for hot water heating is the low installation cost associated with their installation. It is also true that they can be more expensive to run (although this is not always the case). But in general, they can be an interesting alternative to ensure the comfort of bathing in a bath in hot water streams. There is no need to light a fire, and then carry away the ashes from the hearth of wood-burning stoves.

In these devices, water is heated in a tank to a certain temperature and stored in it until it is used. When the water cools down, the heater will turn on and the set water temperature will be the same. This allows you to efficiently use hot water at the right temperature and at the right jet pressure. Tanks, thanks to thermal insulation, maintain the highest temperature for several hours after heating. There are two types of storage heaters.

- Working under pressure, they have a large stainless steel tank up to 200 liters. All faucets in the house can be connected to them.

- Working without pressure, they are characterized by a small reservoir up to 10-15 liters. Only one point can be connected to them.

Low power single point units have low efficiency so they can only heat the small amount of water they contain. They are installed next to the tap to which hot water is supplied. These are often very small units that can be installed directly above or below the sink.

On sale there is equipment equipped with its own battery and even a shower. Such a heater can be, for example, an ideal solution in a toilet that is far from other sanitary facilities. Those with a power below 6 kW supply no more than 3 liters of water per minute at 40 ° C.

Space must be provided for the heater. The longer the water is heated, the larger the volume should have a heater. If a single tank heater is connected, from which hot water will flow to all inlet points, circulation must be ensured to ensure the movement of water in the pipes and prevent it from stopping. Thanks to the circulation at a time when the water is not in use, it does not cool down in the pipes.

After unscrewing the tap, the water in the pipes first flows out of it, and not from the heater. If there is no circulation in the installation, the water is usually cooled. Hot water pipes must be thermally insulated.

Connecting a heating element with an upper connection to a double-circuit boiler and electricity in an apartment or a private house with your own hands is a very simple matter if you follow all our recommendations. The height of the device and its appearance is selected individually in each case. This can be taken into account in the budget.

Power selection

The criterion for choosing a DHW cylinder is how long it takes to fill the tank with water. Depending on the requirements of the household members, one of the heater options should have enough water for one or two baths. For a family of four, it is worth buying a heater with a capacity of 180-200 liters.

Required capacity

The capacity of the tank must be adjusted to the amount of water used in the house and depends on the number of people. It is assumed that with economical use, a person uses up to 30 liters of hot water. In houses where no attention is paid to water consumption, a boiler is needed that can hold up to 60 liters per person. A family of four can plan to purchase a heater with a capacity of up to 240 liters.

Do-it-yourself boiler installation

You need to install a water heater with your own hands in accordance with existing rules and requirements, depending on its type. So, the features of installing a flow device will be somewhat different from installing a storage device. Let's consider both one and the second case.

How to install a tankless water heater

One of the key features of instantaneous water heaters is their compactness, which allows you to put them in the kitchen or bathroom right under the sink. The liquid in such devices is heated in a special metal pipe, which contains powerful heating elements.

Such design features of the device require that the electrical wiring in the house or apartment work properly and be able to withstand heavy loads. It is advisable to install a separate machine for a flow-type heater, and connect a wire with a large cross section to it.

After you finish working with the electrical connection, you can install the boiler itself. It is installed according to a temporary or stationary scheme.

The temporary scheme provides that an additional tee is cut into the pipe with cold water, which will be connected to the water heater through a special valve. To do this, you need to apply voltage to the water heater and open the tap that supplies hot water.

But the stationary scheme assumes that the supply and intake of water in the pipes will be carried out in parallel with the general water supply system. To install the structure according to the stationary scheme, tees for hot and cold water cut into the pipes. Then you need to put stopcocks and seal them with a simple tow or fum tape.

The next steps are:

- connect the boiler inlet pipe to the pipe that supplies cold water;

- connect the outlet to the hot water tap ;

- supply water to the pipes and make sure that all connections are tight when turning on the water in the tap and shower;

- during normal operation of the system, you can supply electricity to the water heater, then hot water should flow from the desired tap;

- to increase the safety level of the entire plumbing system and the water heater, immediately install a safety valve with it.

You can see clearly the installation process of the flow apparatus in the video.

Rules for installing a storage boiler

If you plan to install a storage device with your own hands, then the requirements for the state of the wiring will not be as strict as in the previous case. And storage heaters are somewhat cheaper than flow heaters.In addition, their popularity is explained by the fact that very often they are covered by a scheme in which you can simultaneously supply water to the tap and shower.

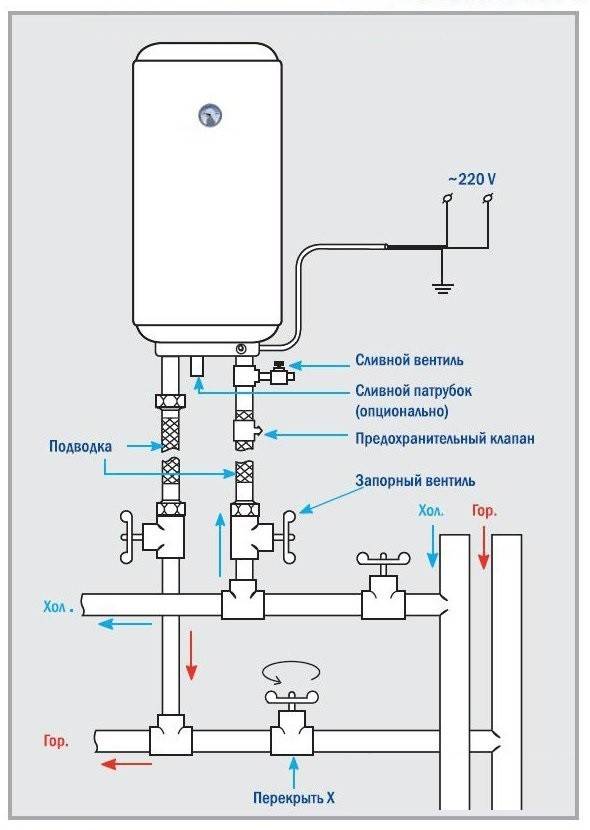

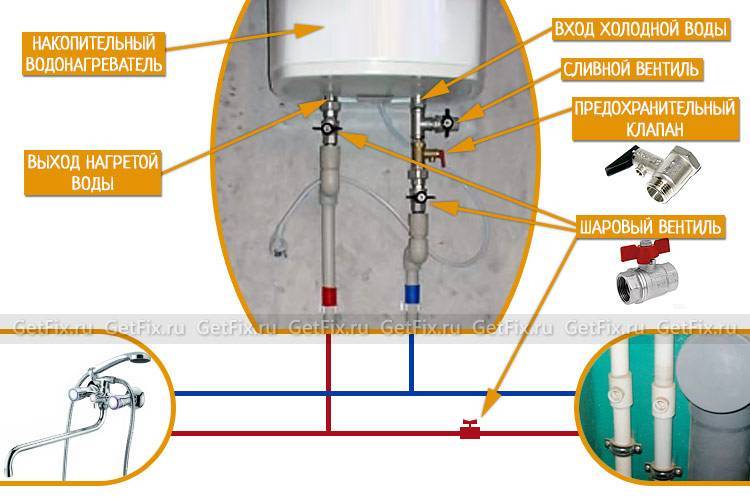

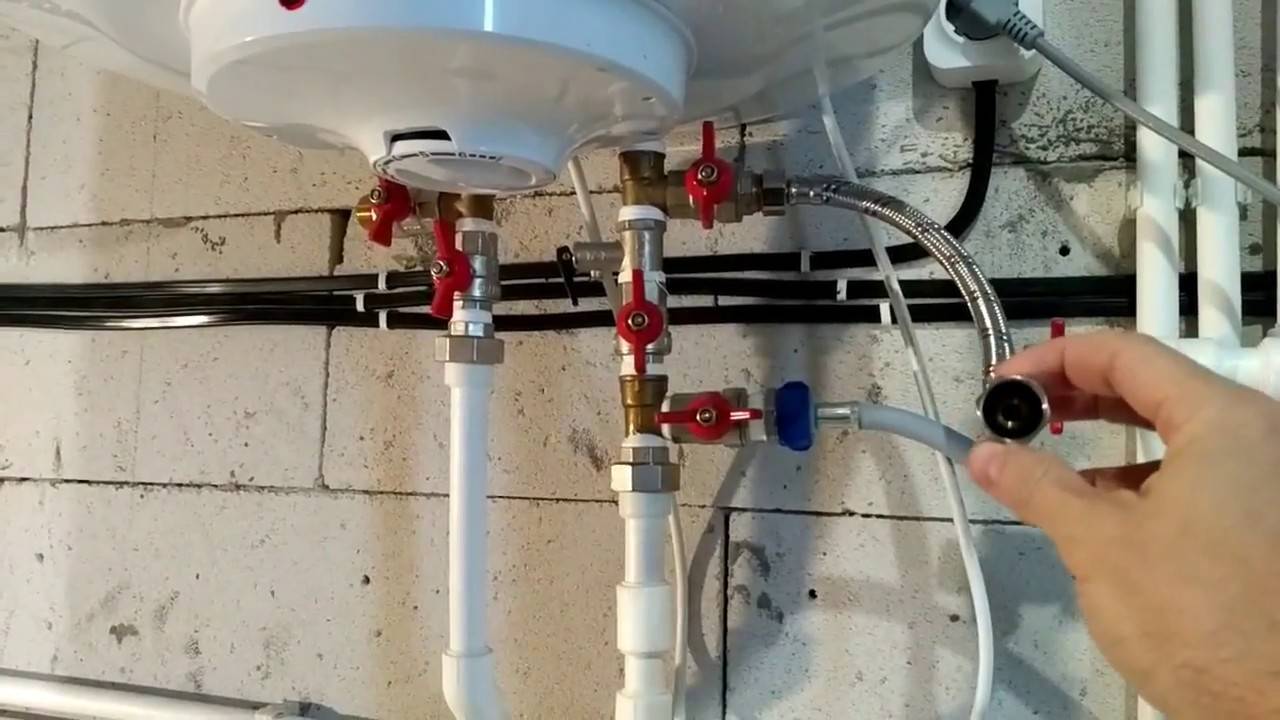

You can install such a unit with tools and materials quickly, while the work itself will not seem too complicated, it consists of the following actions:

- eliminate faults in the electrical wiring or plumbing system, if any, check their condition;

- make markings on the wall for the structure and put the necessary fasteners for its installation;

- fix the water heater on the wall and attach the safety valve;

- after installing the boiler on the wall, connect it to the water supply;

- lead the pipes through the valve to the corresponding inlets and outlets on the body;

- first install and connect cold water, and the safety valve must be closed at this time;

- also, with the valve closed, install pipes for hot water;

- connect the structure to the electrical network and check how it works.

If all the steps have been performed correctly, then hot water should flow from the corresponding tap. At this time, all pipes and connections of the boiler must be well sealed, and the wires must not overheat.

Of course, if you are not confident in your abilities and even visual training material in video format cannot help you learn the features of a step-by-step installation of a boiler with your own hands, then do not risk it, but invite a specialist. Incorrect installation of the heater can cause it to fail prematurely and cause leaks and other problems.Therefore, take on an independent installation only when you are confident in your abilities and know that everything will be done efficiently and correctly.

Mistakes and Solutions

In order for newly installed hot water devices to work properly, the installation rules. Equally important are systematic checks and programming of the operation of the device.

Uninsulated hot water pipes

Many users do not know how much heating costs are due to the fact that warm water pipes are not insulated. The water in them cools down very quickly.

Solution: When deciding to install a new heater, the pipes must be insulated. In order for heat loss to be effectively reduced, the new regulations require thermal protection to be adequately thick. For example, for pipes up to 22 mm in diameter, 20 mm thick insulation should be used, provided that its thermal conductivity coefficient is 0.035 W / mK. With an increased diameter of 22-35 mm, this thickness increases to 30 mm.

Heating not supported

Sometimes users complain that after several years of operation of the water heater, rusty water flows from it.

Solution: Most tanks are made of steel covered with several layers of enamel. In addition, they are protected by a magnesium anode placed inside. It creates a low voltage that counteracts tank corrosion. After a while, it works out, so every 2-3 years it needs to be changed.

For this reason, regular maintenance of the tank is very important. According to the rules, it should be held at least once a year

There are heaters on the market that are protected by anodes to increase the service life (magnesium-titanium or titanium). However, the most expensive boilers are made of stainless steel.

Heater not programmed

It happens that users who use the second, cheaper tariff every day at a certain time turn the electric storage heater on and off to reduce the cost of preparing hot water for washing. Such maintenance is very cumbersome.

Solution: This can be avoided by installing a programmer (it's easy). It is equipped with a timer, so you can choose the operating hours of the device. At the right time, the programmer will automatically turn off the power supply.

It is important to occasionally check the time for which the timer is set. This is due to the fact that when there is no power, most controllers stop working, and the clock starts only after power is restored, which throws off the correct time.

As a result, the programmer turns on the heating at a different time than during hours when cheaper electricity can be used.

When using an electric water heater, it must be remembered that there must be water in the tank at all times when it is connected. Even a small amount of air entering the boiler can damage the heating element and, therefore, it will need to be changed. Therefore, when working on the water supply system or during a break in the water supply, the power supply must be turned off. After the water flow is restored, all air must first be expelled by opening the hot water faucet until water flows out of it.

For an overview and connection of storage water heaters, see the following video.

Choosing a place to install equipment

Before installing the device, choose the place where it will be located. Storage water heaters are quite large in size, which must be taken into account when placing them. There are three types of devices:

- Wall-mounted, the capacity of which does not exceed 200 liters.

- Floor standing, from 200 to 1000 l.

- Built-in, having a different capacity.

In addition, devices of vertical and horizontal types are distinguished. Depending on this type, the device should be located.

Incorrect placement hinders the operation of the equipment and quickly disables it. All these factors must be taken into account when choosing a location for a water heater.

In addition, a number of other requirements must be met. The device must be mounted in a place protected from the cold so that the water does not freeze. It should be located close to water points.

At the same time, it is desirable that the length of the water pipes be minimal.

To install a massive floor storage water heater, you will need a solid, even base, in some cases it may be a special stand

To install a massive floor storage water heater, you will need a solid, even base, in some cases it may be a special stand

If the water pipes are too far apart, it is worth considering installing several water heaters. It is desirable to choose a place for the device so that pipelines with cold and hot water are located close enough and are easily accessible.

It is also important to examine the condition of the wiring

Particular attention should be paid to its cross section and the ability to withstand additional power. Wiring must be replaced if necessary.

Another important issue is the availability of equipment.Sufficient space must be available at the place of installation of the device for unhindered installation work, subsequent maintenance and possible dismantling.

Based on this, it is necessary to provide a free distance from the nearest surface to the protective cover of the apparatus. It cannot be less than 50 cm.

If the water heater is planned to be installed in the bathroom, it must be taken into account that there are zones with different levels of humidity. In some of them, the installation of electrical equipment is strictly prohibited.

When fixing wall appliances, it is very important to determine the strength of the wall. Brick and concrete partitions, even if ventilation shafts pass behind them, can withstand the device up to 100 l

Equipment up to 200 liters can only be hung on load-bearing walls.

If there are serious doubts about the strength of the wall, you should not hang a device with a capacity of more than 50 liters on it. In this case, you will have to install a special supporting frame made of metal.

The place for built-in water heaters is chosen in strict accordance with the recommendations of the manufacturers.

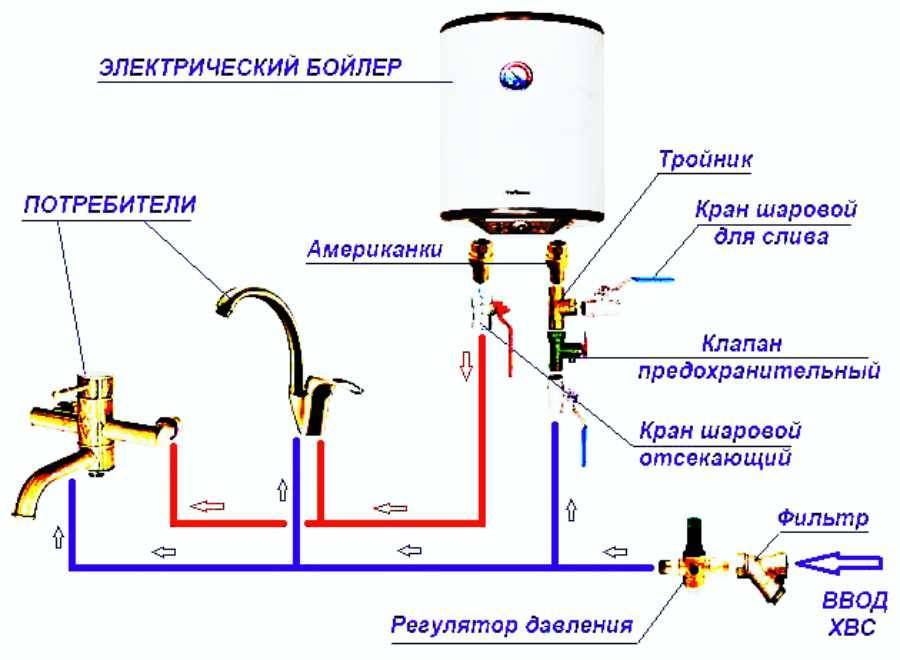

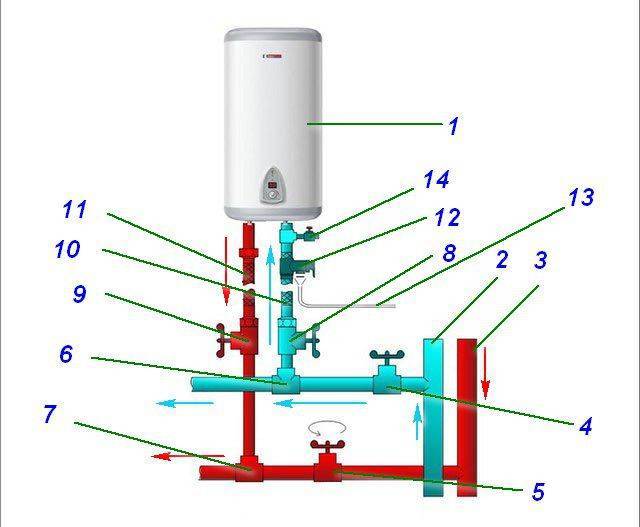

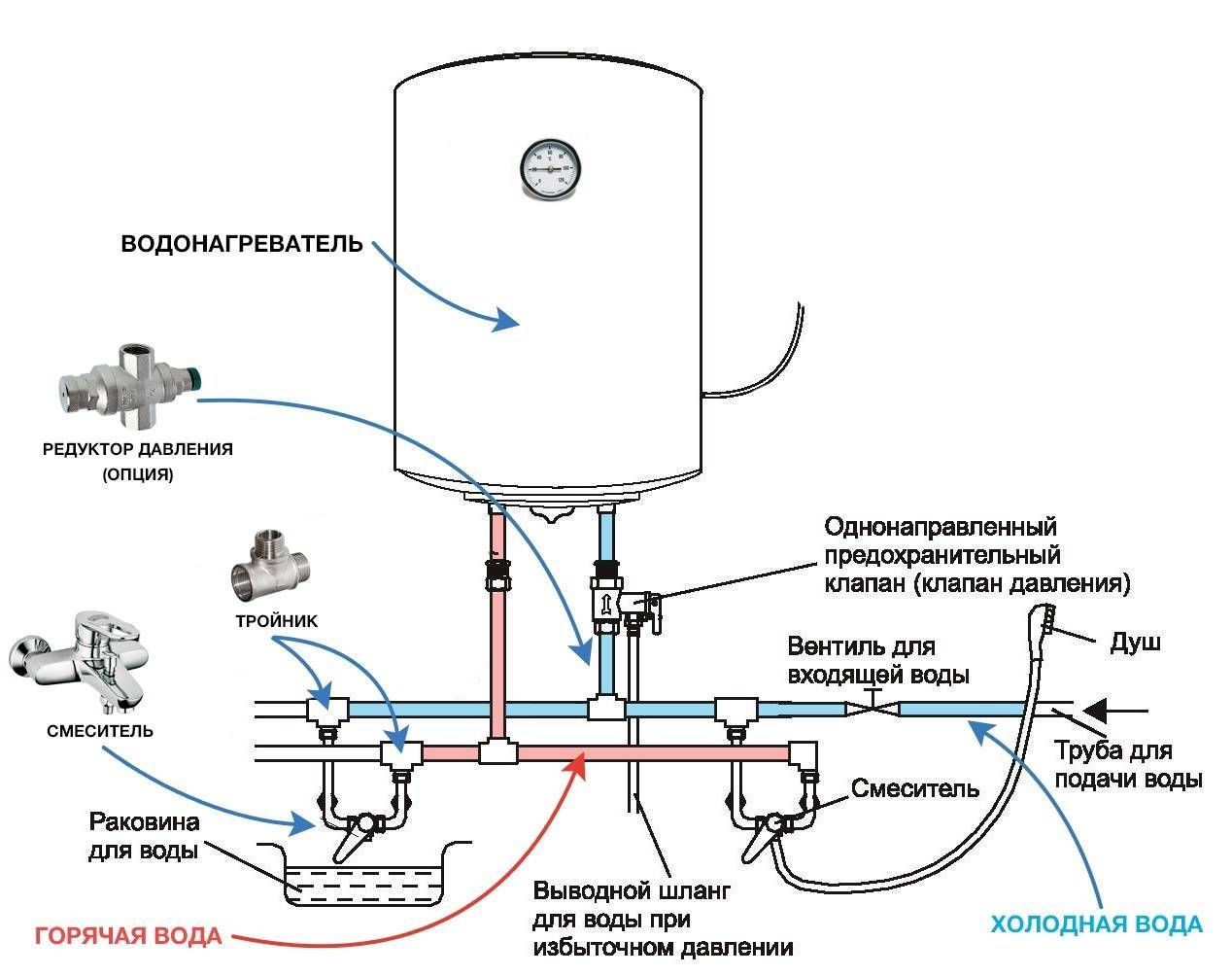

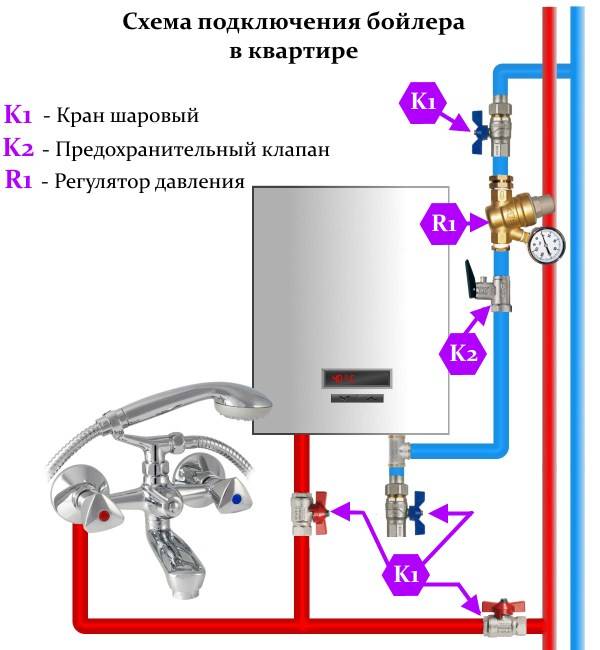

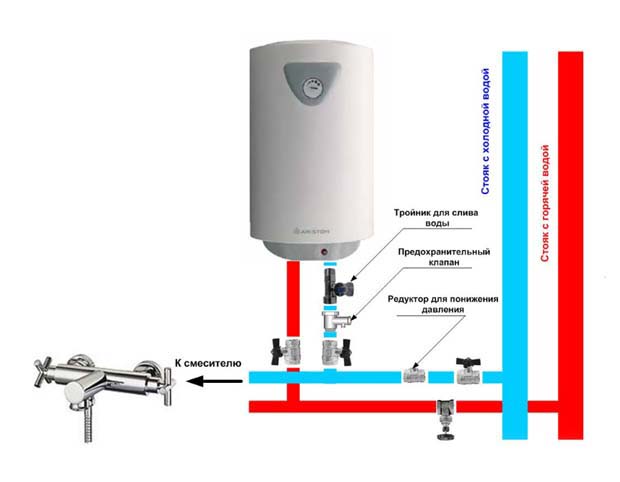

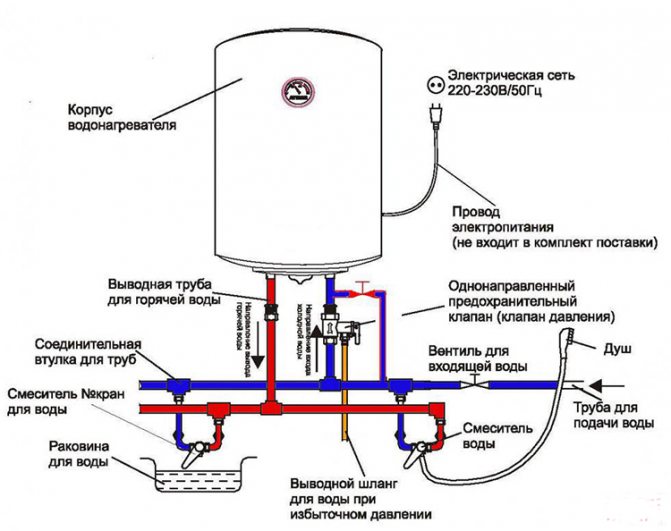

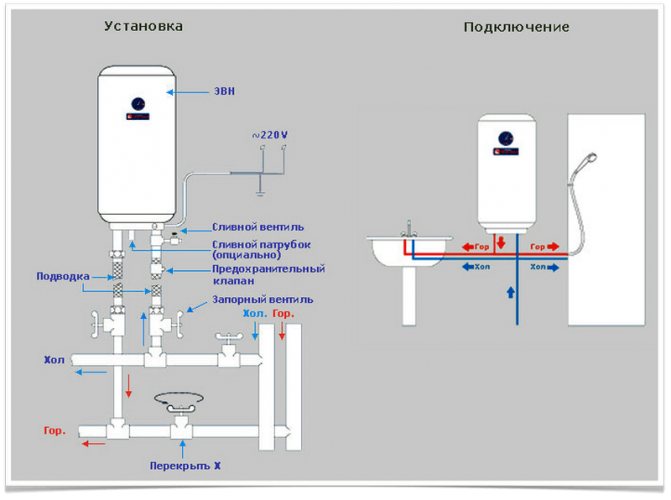

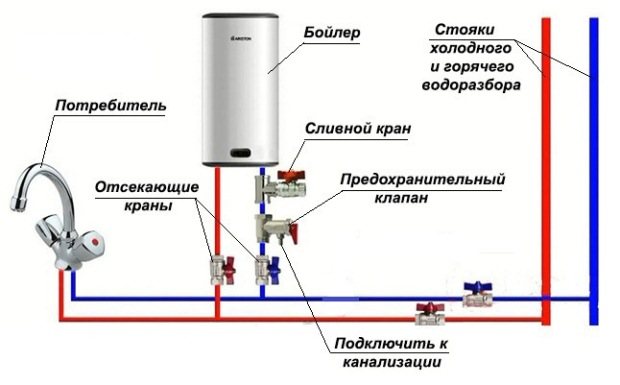

Schemes of connection to water of a wall-mounted storage water heater

The fittings for supplying cold and discharging hot water are located at the bottom of the wall-mounted boiler, and are marked in blue and red, respectively. The connection to the trunk can be made in two ways:

- no security group;

- with the security team.

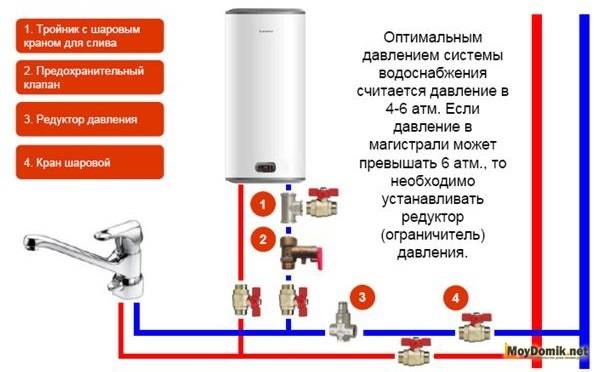

Schemes without a safety group can be used when connecting a water heater designed for pressure exceeding the pressure in the main cold water supply, if this pressure is stable.In case of unstable, strong pressure in the line, preference should be given to connecting through a security group.

In any case, the connection and installation of the water supply system begins with the insertion of tees into the pipelines of cold and hot water after the taps installed at the entrance of the water supply to the apartment.

Attention! If the pipes in the house have not changed for a long time, you need to check their condition before work. It may be necessary to replace rusted steel pipes with new ones. Branches are made from the tees to connect the water heater

When the boiler is in operation, the hot water tap must be completely closed. Cold water freely flows to heating, to mixers, to the toilet bowl

Branches are made from the tees to connect the water heater. When the boiler is in operation, the hot water tap must be completely closed. Cold water freely flows to heating, to mixers, to the toilet bowl.

On the boiler, a check safety valve is screwed onto the cold water inlet. It serves as protection against thermal expansion of water in the storage tank, periodically bleeding off its excess. From the drain hole of the valve, a drainage tube is mounted, which should be directed downward and fall into the tank or sewer freely, without kinks that could prevent the draining of excess water in the tank.

Check relief valve

Shut-off valves cannot be installed between the valve and the water heater. But the tee, on the branch of which a tap is installed to empty the tank, can be installed, and is even recommended by manufacturers.The pipe or hose from it must be brought to the sewer, or connected with a tee to the cold water supply pipe to the safety valve.

At the outlet of the hot water boiler and at the inlet of cold water, immediately after the check valve, it is necessary to install taps that block this line during the period when the water heater is not working. After the taps, the pipelines through flexible plumbing hoses or rigid steel or plastic pipes must be connected to the taps from the tees on the mains.

Water supply without a safety group with a pressure reducer: 1 - shut-off valves for the water supply; 2 - water pressure reducer; 3 - shut-off valves of the water heater; 4 - check safety valve; 5 - drainage to the sewer; 6 - valve for draining water from the tank; 7 - storage water heater

If the main water supply requires pressure adjustment, then the reducer or safety group is installed at the cold water inlet after the main taps or on branches from the tees. As a rule, for household water heaters in urban areas, it is sufficient to install a pressure reducer that reduces the pressure to the permissible or recommended limits by the manufacturer.

The safety group for an electric water heater is made up of individual elements assembled locally. Not to be confused with the safety group for boilers! The order of their installation is shown in the figure.

Scheme of water supply through the safety group: 1 - pressure reducer; 2 - valve for draining the tank; 3 - security group; 4 - drain into the sewer when the water pressure is exceeded

For horizontal water heaters, the connection is made according to similar schemes.

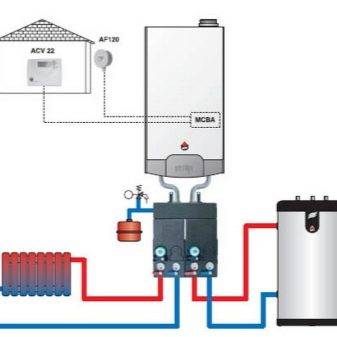

Location selection

First of all, for the operation of a flowing water heater, sufficient power is needed. They range in power from 1 to 27 kW and usually require a new network to be installed and connected to an electrical panel. In apartments, single-phase non-pressure flow devices are most often used, the power of which is up to 4-6 kW.

If you constantly do not have warm water in your apartment, then you should choose a more powerful model, preferably a pressure type, or consider buying a storage tank.

It should be said that low-power instantaneous water heaters usually have a single phase, and devices with a power of 11 kW or more are three-phase. If your housing has only one phase, then you can only install a single-phase device.

Learn how to build a cellar with ventilation, a sheepfold, a chicken coop, a veranda, an arbor, a brazier, a fence with a foundation with your own hands.

The choice of the place where the instantaneous water heater will be installed depends on its type: non-pressure or pressure. Most often, in order to ensure washing under the shower during water outages, non-pressure models are installed in the bathrooms.

Of course, they are not able to provide such a pressure of hot water, which gives a centralized supply of hot water or a pressurized water heater. But even that flow of heated water, which will provide you with a non-pressure view, is quite enough to wash.

Important! You should use exactly the shower head that comes with the non-pressure water heater - it has fewer holes. Water can barely flow from a conventional shower head. A non-pressure model is installed next to the place of consumption of the water it heats

Usually this place is above or below the washbasin, on the side. This takes into account the following aspects:

- it should not be splashed from the shower. Devices marked IP 24 and IP 25 are protected from water ingress, but it is also undesirable to place them in flood areas;

- access to management, regulation;

- ease of use of the shower (faucet) to which the connection is made;

- ease of connection to the central water supply;

- the strength of the wall to which the device will be attached. Typically, the weight of such water heaters is small, but the wall must ensure its reliable fastening. Brick, concrete, wooden walls are usually not in doubt, but drywall may not be suitable;

- evenness of the wall. On very curved surfaces, it is sometimes difficult to position the instrument correctly.

Learn how to get rid of old paint, stick wallpaper, insulate windows in an apartment. A pressure water heater is able to serve several points of water consumption at once. Its installation is carried out next to the riser or draw-off point. Such a device has more power than non-pressure. It can have both top and bottom connections, but to install and connect such a model, it is better to contact specialists. Flowing water heaters are gas and electric. Mostly electrical appliances are used, since for gas it is necessary that the project provides for a gas column and the presence of a gas pipeline, and the installation must be agreed with the gas service.

Did you know? One of the first methods of heating water was stones heated on fire, which were immersed in a container of water.

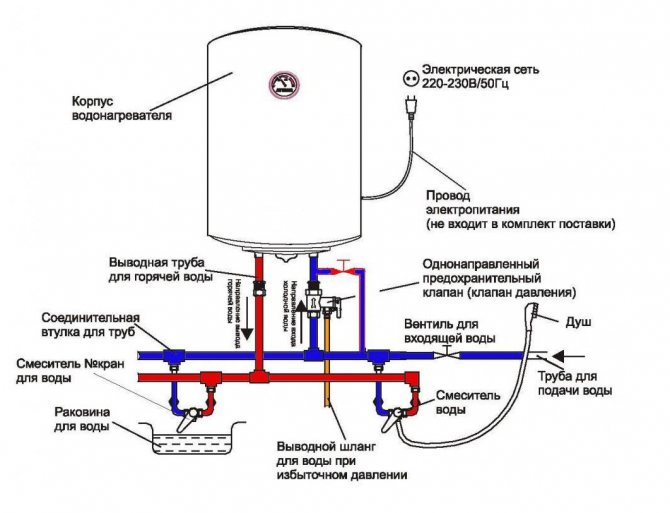

Electrical supply to the storage heater

For the correct connection of the storage water heater, there is an electrical circuit for connecting to the network. All connecting contacts are marked, with the help of which the phase and zero with grounding are immediately distinguished.

For correct connection, use the instructions that are attached to the documentation for the water heater. Consulting services in this regard can also be obtained from the store at the time of purchase of the boiler. In the event that you have correctly connected the heater to the network, the corresponding indicator on the operating panel will light up.

Water heater installation

To connect a single-phase instantaneous water heater to electricity, you will need to measure the cable length you need from the electrical panel to the place where the device is used. Usually, for such purposes, they take a three-core copper cable having a cross section of 3x2.5 mm, but the power of the water heater itself should also be taken into account. Approximate cross-section values depending on the power are provided in the table.

For the safe operation of the device (after all, it will be used in a room with high humidity), you will also need automatic protection for this connection (RCD). For the same reason, there must be grounding.

The socket should be chosen not cheap, waterproof, which can withstand a current of 25A. If there is no plug, then you should install it yourself. The plug must be selected with a grounding contact.

First, connect the cable to the turned off device through a special hole and hang the device on the wall.

Strip the ends of the wires and connect to the terminal box according to the instructions

It is very important to connect all three cores (phase, working zero and ground) to the socket intended for them.Tighten them with fixing screws.

Connect the other end of the cable to the terminals of the electrical panel through the RCD in the same way as in the device - phase to phase, zero to zero, ground to ground.

Important! The operation of such a heater gives a large load on the network, and it is undesirable to turn it on simultaneously with other devices that have high power consumption. All work on connecting to the electrical network is carried out in the absence of voltage in the network

All work on connecting to the electrical network is carried out in the absence of voltage in the network.

If you have a washing machine with a socket installed in your bathroom, which has a separate connection to the shield through an RCD, then you just need to connect a cable with a plug to this socket to the appliance.

Video: how to install instantaneous water heater

Mounting Features

When deciding how to install and connect a water heating boiler to the water supply, consider the following recommendations:

- According to the rules for installing water heaters, hot water pipes must be supplied to plumbing fixtures in thermal insulation with a shell thickness of at least 20 mm, its thermal conductivity coefficient should not exceed 0.035 W / m2. Fulfillment of this condition reduces heat losses in the line, saves electricity and, accordingly, the financial resources of the consumer.

- It is also desirable to have insulation on metal pipes made of steel, stainless steel or copper in the cold water supply line (CWS). The main purpose of thermal insulation on the cold water supply pipeline is to prevent the formation of condensate, which causes the appearance of mold and mildew, corrosion.

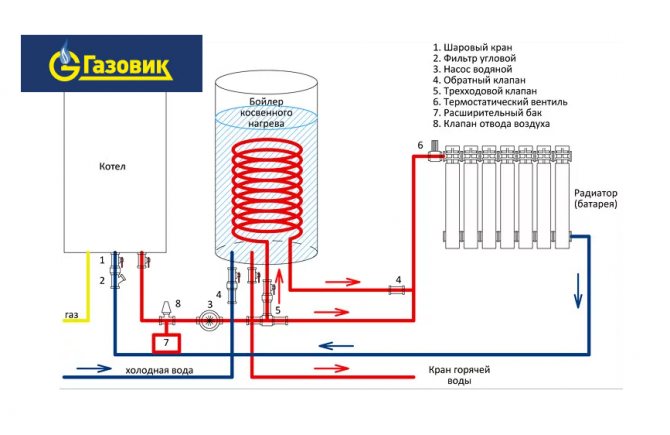

Rice. 14 Indirect heating boiler in an individual house

- A common malfunction of many boilers is water leakage through the side fitting of the safety drain valve, caused by high pressure in the water main (found on the first floors of high-rise apartment buildings). Usually, water is diverted to the sewer using a flexible piping attached to the side fitting, which is not always convenient. One option to avoid installing an interfering hose is to install an expansion tank on the broiler to compensate for pressure drops.

- As a rule, an expansion tank is placed on indirectly heated boilers or large-capacity tanks with a large amount of water, where small temperature fluctuations cause significant pressure drops.

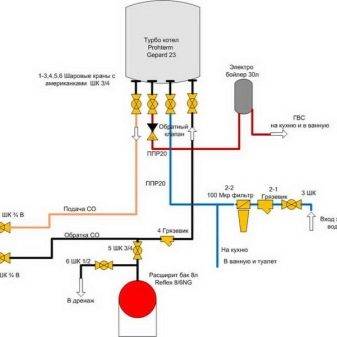

- When installing boilers, it is necessary to select a power cable with heat-resistant insulation; a ground loop is required in the electrical circuit. The power supply system of the water heater must have an RCD protective shutdown device.

- When operating powerful boilers with an energy consumption of more than 5 kW, they are fed with a three-core copper wire of large cross section (2 - 2.5 mm2) from the shield, conducting a separate electrical line, the most commonly used brands of electrical cable are VVG 3x2.5-380, PPV 3x2.5- 380.

- To increase the service life of heating elements of water heaters, a magnetic filter is installed in the water supply system, which prevents the deposition of metal salts on the surface of the heating element.

Rice. 15 Connecting a typical boiler to the electrical network