- Features of the cabinet under the sink

- Pros and cons of self-mounting the sink in the countertop

- Installing an overhead sink

- Washbasin installation

- Installation of an integrated sink

- Types of sinks according to the installation method

- Overhead sink

- The main types of washbasins

- What determines the quality of our work

- What material are sinks made from?

- Installing a mortise sink

- Necessary tools and materials

- Marking and cutting a niche

- The process of installing and connecting the sink

- Two popular mounting types of kitchen sinks

- Connecting the siphon to utilities

Features of the cabinet under the sink

The kitchen is a place where the family spends a lot of time together, where neighbors, relatives and friends drop in for a cup of tea. Therefore, every detail of the interior, creating coziness and comfort, is so important. How to install a countertop sink in the kitchen? What type of equipment to choose and install so that it serves for a long time.

Start work on sink installation you need with the preparation of the structure, which is an addition to the sink. This is a module with installation features.

Both elements (cabinet and sink) are important. Place and location in the kitchen depends on: The place and location in the kitchen depends on:

The place and location in the kitchen depends on:

- layouts;

- preferences of the owners of the apartment;

- the location of other types of furniture (in the same row with them, in a straight, corner version, or separately).

The design of the countertop is the basis for the sink. Its internal area is used with maximum benefit. It is not designed for a large number of shelves, its main purpose is to place sink communications (corrugated hose, siphon) and trash bins. You can put a small shelf for detergents in it.

Surface-mounted sinks are less popular today than flush-mounted sinks.

Surface-mounted sinks are less popular today than flush-mounted sinks.

The design depends on the overhead sink and can be in the form of:

When installing, there are certain rules:

- To prevent excessive moisture, deformation of the material, open areas are treated with: special mastic; silicone sealant.

- To prevent damage to the structure from leakage, it is necessary to tighten all nuts securely using silicone sealant during installation: corrugated pipe for water drainage; siphon; mixer.

- They are installed against the wall, since pipes are located in it: for drain; supply of cold and hot water; from the washing machine. water from other equipment (filter that purifies water).

The cabinet has 3 walls, so it has insufficient rigidity. To do this, stiffeners are created (“kerchiefs”, wooden or metal corners fixed in the four corners of the cabinet from the inside). This issue can be solved by bolting the walls to other furniture or screwing them to the wall.

Cabinets are made in a variety of color characteristics, which allows you to choose them for any style of interior.

Cabinets are made in a variety of color characteristics, which allows you to choose them for any style of interior.

Pros and cons of self-mounting the sink in the countertop

When buying a new sink, the question often arises of whether to install the structure yourself or invite a professional, so you should first evaluate all the pros and cons of such actions.

Advantages of self-installation:

- Opportunity to save budget. This is the main point that encourages people to do installation without the help of specialists.

- Careful control of the work. You can do the installation of the sink slowly, only in the summary time. This will allow you to do quality work.

Of the negative aspects of self-assembly, the following can be distinguished:

- Poor installation of equipment is fraught with leakage, which will lead to damage to property.

- Not every beginner has all the necessary tools that are needed during the installation of a sink.

-

Installation of the structure by a professional eliminates the possibility of chips and cracks.

Being engaged in self-installation of the sink, you must follow the detailed instructions, then you are more likely not to make a mistake

In addition, it is important to make sure that all the necessary tools and fasteners are included with the product.

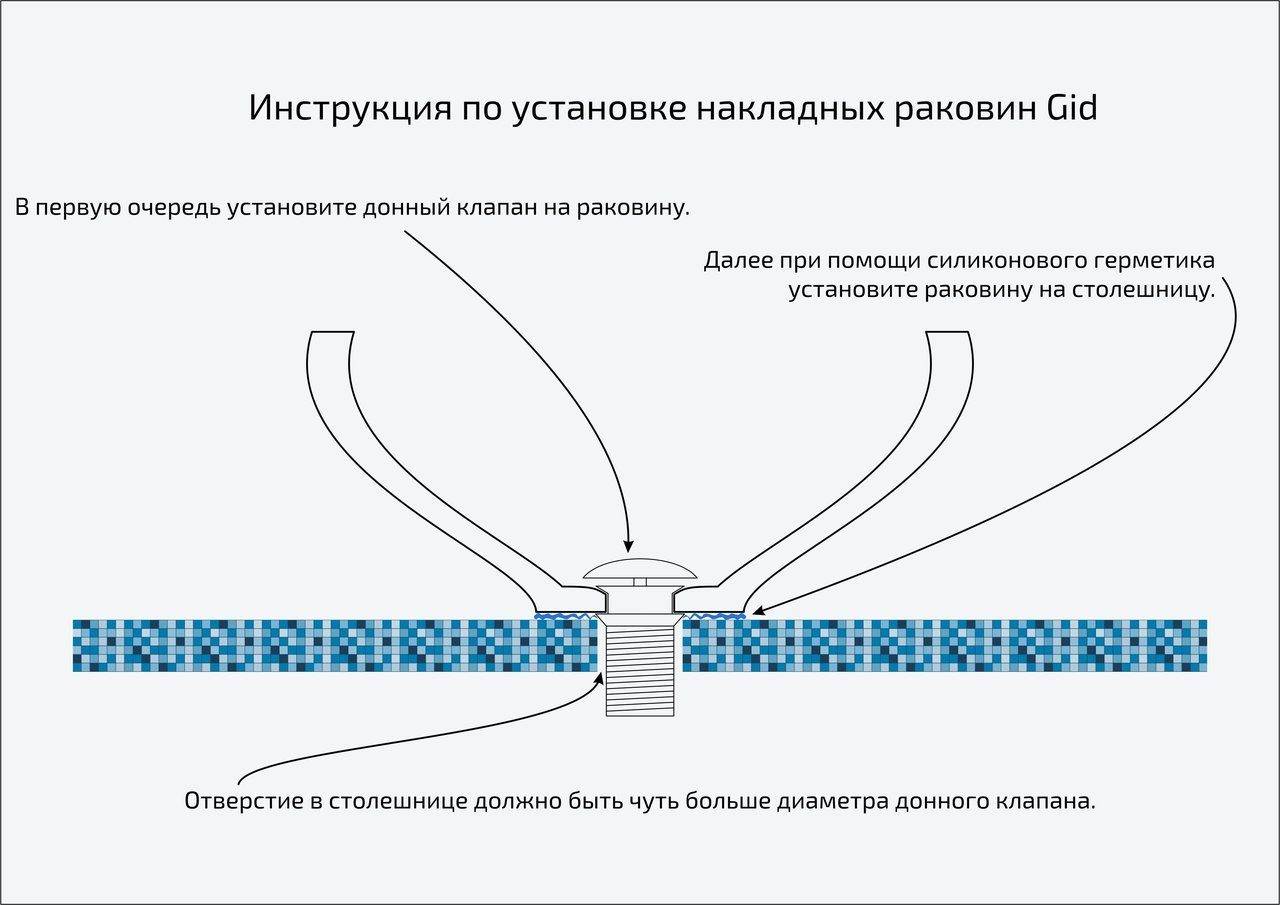

Installing an overhead sink

It is relatively easy to install an overhead sink, since it does not require additional insertion and additional fasteners. As you can see in the figure provided as an example, overhead structures really seem to be superimposed on the surface and are located above any plane. Accordingly, the most essential requirement is the presence of some foundation on which the element is actually installed.

Equally common for this variety is the installation of sinks in the bathroom and in the kitchen.In every room, the element looks quite attractive and is functional, although of course, some features of the models should be taken into account and, for example, for kitchens where splash minimization is required, choose models with higher and even sides, and for bathtubs it is quite possible to use more original options. , where the sides may have curved shapes.

The connection method is mainly a hole with a drain, but such methods as additional sizing with specialized mixtures or the use of dowels at the base, which are fixed under the sink, can also be used. On the portal you can find the installation of the sink in the countertop video, which describes in detail the features of the installation of overhead structures. Given the clarity of this process, here we confine ourselves to the instructions.

- To begin with, the surface is cleared, in which a hole is prepared according to the stencil.

- Under the hole, drain communications are connected.

- The lower part is fixed in the sink and the part is installed on a plane, after which the fasteners on screws can be additionally used from the lower part of the countertop, the structure is pulled together.

In this version, the mixer is connected separately. Holes for water supply, as a rule, are located under the mixer.

Washbasin installation

A democratic overhead (built-in) sink is made of stainless steel. It is mounted on a separate module and covers its entire upper part. The installation is very simple here - special L-shaped elements with an oblique slot are used for fastening. About 4-5 such fasteners are provided for one sink.

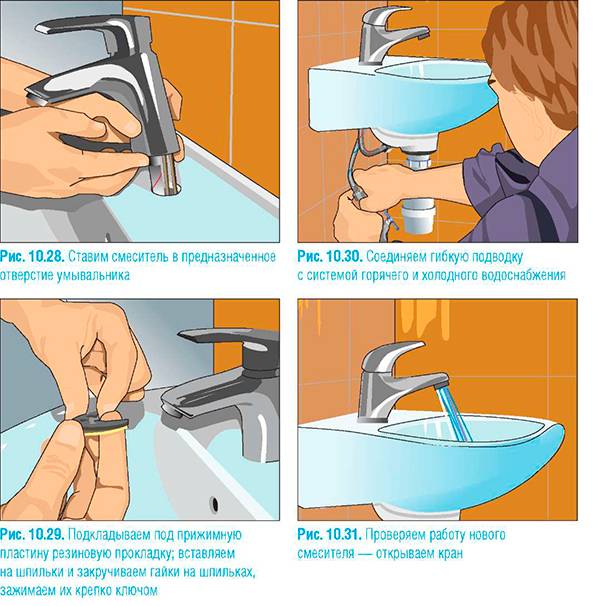

Advice! The connection of the mixer is carried out before the stage of installing the sink (the sink is already installed with the installed equipment) - otherwise it will be inconvenient to do all this at subsequent stages.

How to fix a surface sink with your own hands:

It is necessary to attach L-shaped fasteners to the cabinet from the inside and make notes;

Screw in the marked places with self-tapping screws

It is important to choose short 15 mm self-tapping screws and screw them in so that 5 mm remains above the mark, no less;

Cover the end of the box with a sealant - it will protect the furniture and additionally glue the sink;

After that, the sink is installed on self-tapping screws screwed into the cabinet and moves until it fits completely;

Then the fasteners are fixed, the excess sealant is erased, you can start connecting the sink to the water supply and sewerage

Installation of an integrated sink

A sink purchased for installation by cutting into a countertop should be selected with a template included in the kit. Otherwise, marking and cutting the hole for the sink can be difficult and not accurate enough, which will lead to the penetration of moisture under the sink and ruin the wooden countertop.

Making a hole for a sink in an artificial stone countertop will have to be entrusted to a specialist. It is quite difficult to do this with your own hands without the necessary tools for processing such material.

Tools for work:

- jigsaw and drill;

- wrench or gas wrench - for the installation of communications.

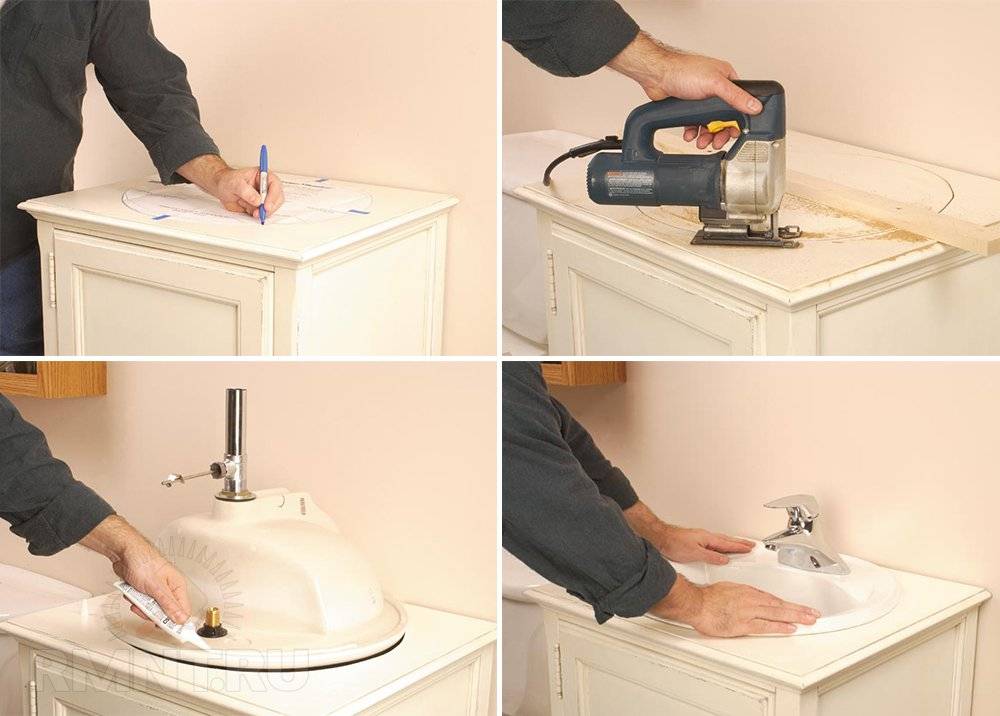

- Step 1. Carefully cut out the template for the outline. Determine a place on the countertop where the elements located under the countertop will not interfere.Place the template on the countertop and carefully align it parallel to the edge, secure and trace around the contour with a pencil.

- Step 2. Paste the surface of the countertop along the contour with masking tape. This is done in order to protect its surfaces from damage by the jigsaw body when cutting a hole.

- Step 3. Drill a hole for the jigsaw blade with a drill. Cut the hole exactly along the contour. This must be done without pressure on the jigsaw, otherwise its blade will bend, and the cut will be uneven or oblique, deviate from the contour line. In any case, this will require additional refinement of the cut with a sherhebel, file, etc. Cut a hole for the sewer outlet and water pipes, if necessary.

- Step 4. Carefully treat the cut surfaces with silicone sealant. Allow the time required for curing. Try on a sink.

- Step 5. Install a siphon of the selected design on the sink. Install a drinking water faucet on the countertop (if necessary). Using the template, mark the holes on the sink panel for installing the faucet. Drill holes. Fasten the faucet with the flexible hose connected to the sink. Install the sink fixtures included in the product kit. With their lack of reliability. you can make a mount with your own hands from a metal mounting tape by threading it into the holes of the mounts.

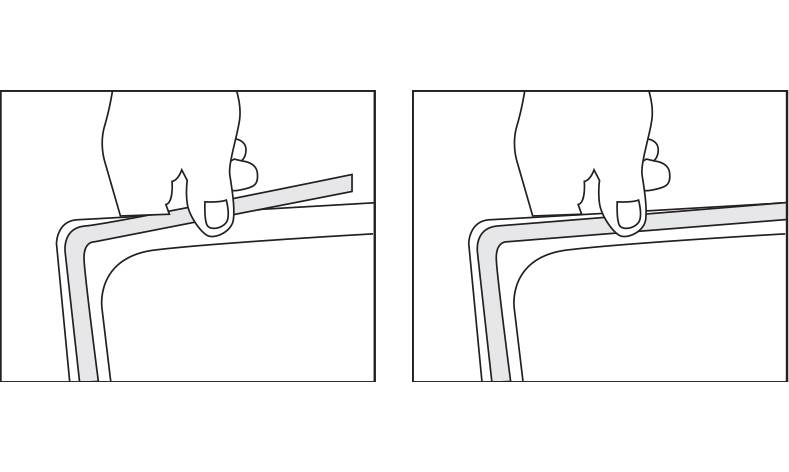

- Step 6 Glue the edge of the countertop with a rubber seal or apply a layer of sealant. Install the sink panel. From the bottom side, inside the pedestal, fasten the mounting tape with tension using self-tapping screws to the details of the pedestal. Apply a layer of transparent sealant around the perimeter of the installed panel (its excess can be cut off after hardening).

- Step 7. Connect communications inside the cabinet.

A more difficult option for installing a mortise sink in the kitchen with your own hands is to install a panel under the countertop. To do this, after cutting the hole according to the template, an additional groove is made along the perimeter of the cutout on the reverse side of the tabletop.

- Step 1. Make a template that will repeat the dimensions and contour of the surfaces of the sink and the “wing” of the panel that should be opened. Draw a contour according to the template on the top side of the countertop.

- Step 2. Cut a hole along the contour, file the rough edge of the countertop with a file, and sand it. Flip the tabletop.

- Step 3. On the reverse side, select the groove so that the tabletop panel freely enters there.

- Step 4. Apply a layer of modified silane adhesive to the resulting groove and place the sink panel there (install the sink in the “upside down” position). Press the panel around the perimeter with your hands, then pull it through the substrate with clamps in several places and leave the glue to harden for 12-24 hours.

- Step 5. After the glue has hardened, the sink is additionally fixed with a two-component epoxy resin. The composition is prepared according to the instructions and poured into the gap between the panel and the countertop body. After hardening, the junction of the countertop and sink is glued with aluminum tape.

- Step 6. Turn over the countertop with the installed kitchen sink, install it on the cabinet. Carefully cut off excess glue around the sink. Make water and sewer connections.

Installing sinks in the kitchen is not as difficult as it might seem at first. The main requirements are the accurate performance of work on sealing all possible points of water penetration and the exact correspondence of the hole for mounting the mortise sink.

Types of sinks according to the installation method

Now on the market there are many models of sinks for kitchens and bathrooms. They differ not only in appearance and dimensions, but also in the installation method. To make it easier for you to understand, we presented the main characteristics of the most popular varieties in the form of a table:

| Kitchen sink type | Highlights of design and installation |

| desktop | Desktop-type products are now practically not used. In most cases, such a product is a bowl that is installed on top of the countertop and comes into contact with it only at the location of the drain hole. A small number of desktop sinks are represented by premium models, so their price will be appropriate. |

| invoice | Overhead copies are mounted on a curbstone without a top: flat areas near the bowl replace the missing countertop. In most cases, such models are made of stainless steel, and therefore they are characterized by a relatively low price. |

| mortise | Unlike the consignment note, the mortise design is “recessed” into the countertop, which greatly complicates installation. |

| Underbench | The bowl, as the name implies, is placed below the level of the countertop. In most cases, models for tables made of artificial stone have such a design. Special brackets are used to fix the product, in addition, the joint of the bowl with the bottom plane of the table top is sealed with special glue. |

| Integrated | The most expensive variety.The bowl is installed in the countertop so that the gap between them is minimal. In most cases, synthetic stone products have this design, but it is also possible to find experimental varieties made of stainless steel. |

It should be emphasized that fixing a sink to a countertop made of artificial stone or installing an integrated structure is a rather time-consuming task that should be entrusted to specialists. But fastening a surface sink to a pedestal or installing a mortise product is within the power of any master who has sufficient skill.

Overhead sink

Once this type of sink was the most common in the domestic market. A feature of the overhead sink is that it is installed on a stand-alone cabinet without a countertop. It can be square (for a single-door cabinet, the bowl is located exactly in the center) or rectangular (for a two-door cabinet, in addition to the bowl, there is a small ribbed surface for washed dishes). Moreover, the shape of the bowl can be any: square, round or oval.

As a support for the overhead sink, a profile side is provided - in the form of a channel. It simultaneously serves as a stiffener and a place of attachment to the pedestal.

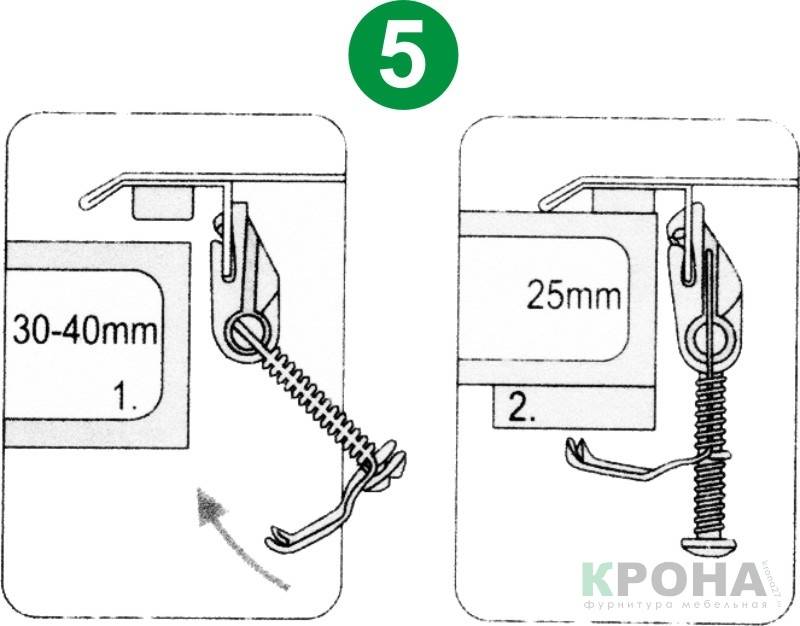

For reliable fixation of the sink to the cabinet frame, special plastic fasteners are used. They are made in the form of a corner with an oblique slot on one side.

These mounts can come with the sink, or they can be bought separately. The fastening method is simple: 1. First, a fastener is applied to the inside of the walls of the pedestal with an emphasis on the end and a line is drawn in the slot. 2. Stepping back about 5 mm up from the bottom mark, drill a small recess in the wall for the self-tapping screw. 3. Screw in a self-tapping screw. The length of the screw depends on the wall thickness. In most cases, the furniture plate for the walls has a thickness of 16 mm, so the self-tapping screw should not be larger than this size (for example, a 4x16 mm wood screw). And in order for it to press the mount well against the wall, it must have a semicircular or semi-secret head - the main thing is that it passes into the lower (largest) hole of the mount and does not slip through the rest of the slot. The self-tapping screw is not screwed in completely, leaving a gap between the head and the wall slightly larger than the thickness of the sink mount. 4. If the end of the walls is not treated with a protective edge, then a layer of sealant is applied to it. 5. The sink is installed in place and “put on” on the head of the fastening screws. In this case, the attachment angle should be turned upwards and inward relative to the pedestal, and the second “beam” of the angle should go beyond the side of the sink. 6. To pull the sink to the pedestal, the mount is knocked out from the short side of the slot to the screw. 7. After the screw becomes tightly in one of the recesses of the slot, it is finally screwed in. After that, you can mount the siphon and connect the sink to the sewer. Installation of the mixer depends on the type of water supply. If the mixer is mounted on a sink, then it can be fixed to it before installation on the cabinet.

The main types of washbasins

The technology for installing a plumbing fixture depends on the type of sink, which are suspended and overhead, and the rest of the products are related to their varieties.

Domestic and foreign manufacturers produce different models of washbasins, but the following are most in demand:

- Embedded. They are placed on the top of a table, cabinet or other flat surface. They are convenient, because the furniture doors make engineering communications completely invisible.

- Console. The suspended design of the washbasin allows you to fix it on the wall using a ready-made installation system.

- with pedestal. The product of the “tulip” type has a decorative element in the form of a pedestal, on which a massive bowl is placed. The drain fitting is located inside the support.

- With half pedestal. Such models also have a pedestal, but it rests not on the floor, but on the wall. Thanks to this, wall-mounted washbasins look more elegant. Mounting the sink makes it difficult to bring the drain to a certain height.

Built-in products can also be installed on top of the table top, fixed with sides around the perimeter of the base, or built into the structure from below. In bathrooms where it is not possible to place a countertop with a standard width, it is more convenient to use semi-embedded models.

When installing this plumbing equipment, you will need to use an improvised cabinet to hide pipes and other communications behind its walls.

Usually, cantilevered and built-in designs are preferred by property owners with small bathrooms, in which every centimeter counts.

In addition, all commercially available sinks for installation in bathrooms are distinguished by a variety of shapes and configurations, so there are models:

- round;

- oval;

- cubic.

What determines the quality of our work

Any installation of an overhead sink begins with a study of the configuration of the template.The more complex the shape of the shell, the more effort will have to be applied to cut the corresponding hole. The slightest mistake can lead to damage to the countertop.

For a good craftsman, a high-quality installation of a mortise sink does not depend on its model, shape and material from which it is made. Today in fashion:

- round sinks made of stainless steel and stone;

- double sinks with two drains from a variety of materials;

- built-in and overhead granite sinks.

One of the popular models of sinks is a bowl made of granite chips. It looks solid, washes well, lasts a long time. Its installation is more complicated than the installation of sinks made of other materials.

If there are no holes for installing such a sink, then the cut-in of a granite sink turns into a filigree work. Sometimes there are holes, but they are too small and you have to cut them out additionally.

Our masters perfectly cope with such work, using special drills with a "diamond" crown and other tools. To determine how much it costs to install a sink in the kitchen, you need to know what material the master will have to work with.

The sink itself is quite heavy, so installing the sink into the countertop in the kitchen is done with great care so as not to drop or break expensive plumbing. More and more people are installing a convenient and practical double sink in the kitchen. Usually it is made of stainless steel, so it is easy to clean and is not “afraid” of chips if you accidentally drop the plate into the sink.

But there are other models - marble, granite or quartz. The installation of such “stone” double sinks is similar to working with a granite sink.

Usually it is made of stainless steel, so it is easy to clean and is not “afraid” of chips if you accidentally drop the plate into the sink. But there are other models - marble, granite or quartz. The installation of such “stone” double sinks is similar to working with a granite sink.

More and more people are installing a convenient and practical double sink in the kitchen. Usually it is made of stainless steel, so it is easy to clean and is not “afraid” of chips if you accidentally drop the plate into the sink. But there are other models - marble, granite or quartz. Installing these "stone" double sinks is similar to working with a granite sink.

Unlike a conventional sink, installation of an overhead sink with a double sink includes two drains. Such a turnkey sink is mounted by our specialists and is handed over to the owners in working condition.

No less popular is the installation of a round sink in the kitchen or in the bathroom. Like other models, it can be made from a variety of materials.

The laconic geometric shape attracts attention and looks great in any interior.

The installation of any models of built-in or overhead sinks is slightly complicated by the undermount installation of the sink, because you have to work in an uncomfortable narrow space.

Before you ask how much it costs to install a kitchen sink, tell our operator which model you want to install. Having invited a specialist to install the sink, you can be sure that a qualified master will come to you.

By calling our phone and ordering any plumbing service, you will be convinced that we work not only with high quality, but also quickly. The best specialists of our company will go to fulfill your order.

What material are sinks made from?

Quite often, choosing a sink for the kitchen becomes a daunting task. Errors in operation lead to the fact that products have to be constantly changed, so you need to familiarize yourself with some of the features of each material in advance.

Table number 3. Materials for the manufacture of modern sinks

| View, illustration | Description |

|---|---|

Stainless steel | Often used in the production of sinks. Products come with a rough, matte and glossy texture. At the same time, the main advantage of the material is its low price. In addition, even a beginner can handle the installation of such a sink without fear of damaging the surface. Metal products have an aesthetic appearance, so they fit perfectly into the interior of various kitchens. In addition, stainless steel does not suffer from exposure to various chemicals. Of the shortcomings, one can single out only the possibility of scratches, dents. |

Ceramics | Washbasins of various types are often made from this material. At the same time, an attractive appearance is considered the main advantage of ceramic products. Especially such designs are suitable for a classic design kitchen. In addition, such a surface is not damaged when exposed to hot water, aggressive alkali, it rarely gets scratches. Another clear plus is the ability to install the sink yourself without the help of a master. Among the shortcomings, the fragility of ceramics can be distinguished - this means that the sink can break with a strong impact. |

Fake diamond | This is the most modern material that is actively used for the manufacture of sinks. It is based on natural and synthetic components.The first option has a higher cost, it is resistant to various damages, chemicals. One of the main advantages is the variety of colors. |

Installing a mortise sink

Kitchen furniture consists of different products, each of which performs a specific function. The countertop is one of the main elements of the kitchen. It is a work surface, and can also become a frame for the sink. The material from which it is made is important, the ability to withstand loads depends on it. Thin composite panels will hold only stainless models. Stone sinks require a massive surface, it must be made of a similar material, have a special design that includes holders.

It is quite possible to install a sink into a wooden countertop with your own hands, as for a granite one, it is better to entrust the work to professionals. Of course, you can try to make a tie-in yourself, following the recommendations for working with a specific material, but this will require a special milling cutter or waterjet, the price of which will be several times higher than the cost of the hole. Let us consider in more detail the method of installing mortise sinks.

Necessary tools and materials

Before starting work, an audit of the existing tools should be carried out, if necessary, purchased. Standard set includes:

- measuring instruments, pencil, marker, cardboard, adhesive tape;

- construction knife, glue, sealant, screws;

- adjustable, open-end wrenches, screwdriver, pliers;

- electric drill, drill, jigsaw;

- sink, faucet, siphon, hoses for water supply.

Marking and cutting a niche

Having determined the location of the product, it remains to perform a number of simple steps with which the installation of the sink in the kitchen will be successful. The step by step process is as follows:

- Mortise sinks are sold complete with ready-made cardboard templates and fasteners. If there are none, you will have to cut the patterns yourself. In this case, the sink itself will become a template. A sheet of cardboard is applied to it, a silhouette is outlined along the contours, a blank is cut out.

- To determine the inner contour according to which the cut is made, the width of the rim is measured. After that, these data are transferred to the workpiece to indicate the final type of pattern.

- The drain point is indicated on the countertop. A template is applied to it, fixed with adhesive tape, a contour is outlined. In this case, the indentation from the front end of the working surface to the side of the sink should be more than 5 cm, from the rear - 2.5 cm.

- Holes are drilled along the contour of the finished marking using an electric drill. To pass the jigsaw blade, a drill diameter of 10-12 mm is sufficient. The number of holes depends on the shape of the bowl to be installed. For round - the step between them will be 7 cm, for square, rectangular - four passes of the drill in the corners are enough. Drilling and cutting work is performed from the front side of the surface. Next, using an electric jigsaw, a hole for the sink is cut. After that, the cut is cleaned of dust, polished with sandpaper.

- The edges of the saw cut are treated with a silicone-based sealant. It protects uncoated wood from swelling. Insufficient sealing can lead to rotting of the countertop at the saw cut, so it is better to apply a double layer.

The process of installing and connecting the sink

- Using a brush or spatula, a layer of transparent silicone is applied to the work surface in the area of the sink rim.

- The rim of the sink inside is treated with a sealant. It provides reliable fastening of the objects in question, does not allow liquid to pass through at the junction of the elements.

- The next step is to install the sink in the cut hole. It is superimposed from the side of the crane attachment. Gradually pressed until the moment of complete contact of objects. Remove excess sealant with a rag.

- With the help of fasteners, the sink is fixed to the countertop. They can be plastic or metal. More reliable iron clamps.

- After the installation is completed, the necessary communications are connected. Usually the sink is attached with the faucet fixed to it, and the only thing left to do is to screw the water supply hoses (hot, cold) to the water pipes.

- At the final stage, a drain is installed. The siphon outlet is inserted into the sink, and the corrugated pipe is inserted into the sewer.

Two popular mounting types of kitchen sinks

A wide range of kitchen equipment users are most familiar with two types of washing bowls - overhead and mortise.

Many overhead sinks can be attributed to the universal and inexpensive segment, however, today they are becoming less and less common. Differ in simple designs, mainly made of thin stainless steel. Their installation usually does not cause difficulties even for home masters. Often, installation is carried out on top of a separate cabinet, thus replacing the countertop with it. Not in favor of the popularity of overhead bowls are also evidenced by the facts that they:

- have a limited number of models;

- when installed, they rise above the level of the working surface to the height of the flanging, which does not look quite aesthetically pleasing;

- have a design for which it is difficult to achieve tightness of the gap under the edging flanging, where moisture then penetrates and dirt collects.

In the segment of overhead sinks, special models, for example, made of stone, began to be found. However, they cost a lot, so they are not widespread.

Mortise sink - its name speaks for itself. Under it, an opening is cut out in the common countertop (working surface), where the sanitary bowl is mounted. The edges of the opening are waterproofed, and the mating gap is carefully sealed. Due to the tight fit, as well as a slight elevation of the sink above the countertop, moisture and dirt do not accumulate. Such modern products have a significant selection of models that are precisely matched to the overall style of the kitchen set. For example, a mortise sink, in addition to the standard rectangular one, may have a round, oval, corner or a special complex shape made to order.

Connecting the siphon to utilities

When installing the sink, special attention is paid to the installation of the siphon. First you need to fix the outlet, for which a grid, a silicone or rubber gasket, and a clamping screw are placed in the drain hole

The use of a gasket is an indispensable condition, since its presence creates a tight connection.

In the process of its installation, it is necessary to control that it fits as tightly as possible and without the slightest displacement or gap fits the drain of the plumbing fixture.First you need to make sure that the gasket is installed correctly, and only then tighten the clamping screw, thereby joining the siphon and outlet.

Next, the end of the outlet pipe, made of corrugated tube or hard plastic, is joined to the sewer socket. When connecting to a sewer pipeline, they will certainly use seals, the function of which is performed by rubber gaskets or cuffs for corrugated pipes.