- Features of installing a solid fuel boiler

- Calculations required for installation

- Operation features

- Selecting a location for the unit

- What is the difference between solid fuel boilers

- What is required to install a solid fuel boiler?

- Tying the "indirect" with the boiler

- Features of installing a solid fuel boiler

- Calculations required for installation

- Mounting Features

- Gas equipment installation technology

- Installation of a wall-mounted boiler

- Installation of a floor boiler

- Tips for Efficient Operation

- Brands of Russian-made solid fuel boilers

- Tips for Efficient Operation

- Conclusions and useful video on the topic

Features of installing a solid fuel boiler

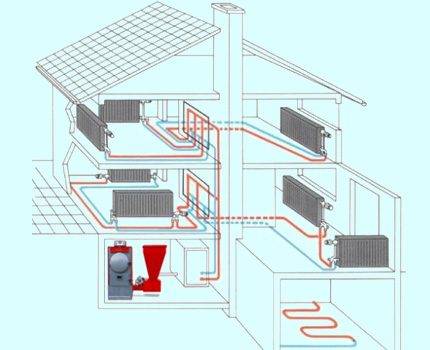

Purchasing equipment is only the initial steps. When arranging a heating system, various types of work are performed. A pipeline is laid in all rooms of the house.

Purchasing equipment is only the initial steps. When arranging a heating system, various types of work are performed. A pipeline is laid in all rooms of the house.

In accordance with all the rules, the heating unit is placed. The device is tied up and started. Installation work includes installation and connection of the device to the system.

It must be remembered that the installation of a solid fuel boiler must be carried out at a highly professional level. Indeed, the following parameters of the operation of the unit during operation depend on the quality of the installation:

- Duration of work.

- Efficiency.

- Economical fuel consumption.

Calculations required for installation

Boiler equipment is a complex modern technique, so professional advice is required before starting work on your own.

Remember that errors during installation can lead not only to inefficient operation of the unit, but also to the consequences of an emergency.

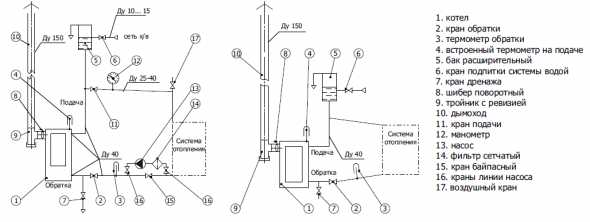

Thus, the installation work for the installation of a solid fuel boiler must be carried out by a person who has certain knowledge and skills. The work requires calculations of slopes, installation of pipes.

Remember that the chimney is not included in the package, so it becomes necessary to take into account the technical data of the equipment.

Preliminarily, the parameters of the boiler room for the boiler, as well as its power, are calculated. When choosing, they will be needed.

Operation features

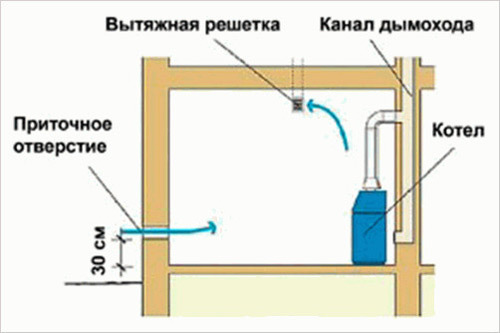

After getting acquainted with the preparation of the boiler room, foundation installation, installation of supply and exhaust ventilation and chimney installation, it is important to understand the features of installing a solid fuel boiler

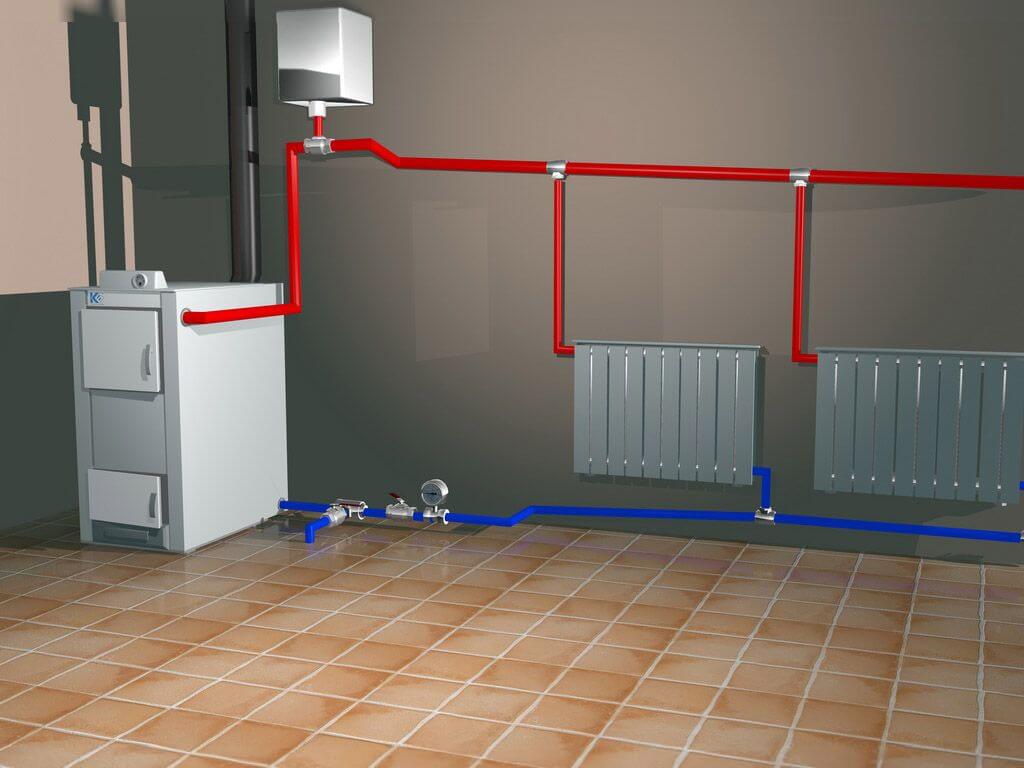

At the initial stage of work, the packaging is removed from the unit and it is assembled according to the attached instructions. The boiler is fixed on the base in such a way that its outlet coincides with the inlet of the chimney. The model is fixed on the foundation in a strictly horizontal position, for this a building level is used.

Connect the heat generator to the chimney and heating system according to the selected scheme. At the final stage of work, automation is adjusted, the fan is fixed and a circulation pump is installed.

Selecting a location for the unit

Let's figure it out in as much detail as possible, what is a solid fuel boiler? This is a thermal device equipped with an open type combustion chamber.

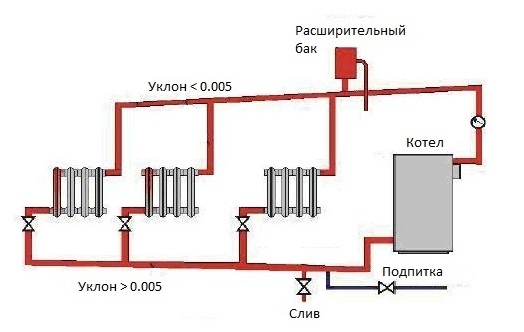

The scheme of its connection to the heating system of a private house can be based on the technical requirements for open or closed heating systems. Everything will depend on the operating conditions.

Requirements for open systems are:

- connecting the solid fuel combustion products output system to the chimney, in which the draft will be carried out naturally;

- installation of an expansion tank at the highest point of the heating circuit, through which the heat carrier will be connected to the atmosphere;

- constant supply of the heating system with water necessary to maintain it in working condition.

Although the owners of private houses often install closed heating systems, rather than open ones.

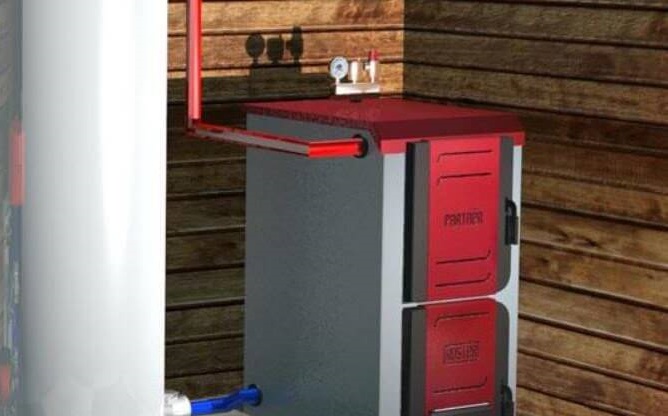

All solid fuel boilers have quite impressive dimensions. Therefore, they are made exclusively in a design that provides for floor placement.

Installing a solid fuel boiler provides for a considerable scope of work:

- determination of the premises for the placement of a solid fuel heat generator;

- preparatory work in the boiler room;

- installation of a ventilation system of supply and exhaust type;

- installation of a boiler and a chimney system;

- boiler piping;

- test run of the heating system.

Only if such an algorithm of actions is observed, problems can be avoided during the installation of a solid fuel unit, as well as during its further operation.

Items 1-3 of the above order of work are preparatory work.But this does not mean that their implementation should be approached less scrupulously than directly to the installation work.

In the event of an incorrect choice of premises for the installation of a thermal unit and errors in the installation of the ventilation system, problems with the operation of the heating system of a private house will not be long in coming. And the solution will have to be sought at the height of the heating season, in the cold season.

Therefore, it is better to immediately correctly install both the heating equipment in a private house and the solid fuel boiler itself. To do this, it is necessary to develop a detailed scheme for its installation in advance, given that the installation of some types of solid fuel boilers may provide for power supply from the mains.

In the issue of installation, one has to focus on the basic norms of SNiP "Heating and ventilation" and some provisions of SNiP 31-02-2001 "Single-family houses" (for the Russian Federation).

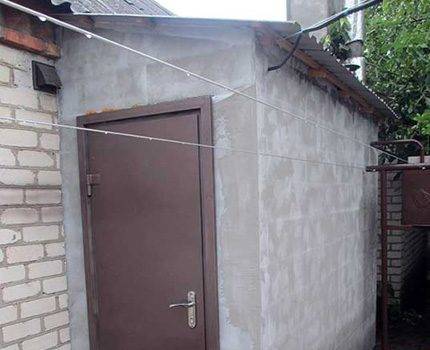

The combustion of solid fuels leads to an increase in the level of dust in the room, and during the combustion of wood or coal, different amounts of smoke can seep into the room.

Therefore, it is undesirable to install the boiler in the immediate vicinity of residential premises. Although, according to regulatory documents, the installation of a solid fuel boiler is allowed in the kitchen, corridor and other non-residential rooms.

The best places to install the boiler is a separate specialized room, preferably separated from the house. As an option, a technical room attached to the house and properly equipped is suitable.

Also a good option would be to place the thermal unit in the basement or in the garage. You can also install it in the corridor, but subject to the availability of sufficient space and good ventilation of the room.

What is the difference between solid fuel boilers

In addition to the fact that these heat sources produce heat energy by burning various types of solid fuels, they have a number of other differences from other heat generators. These differences are precisely the result of burning wood, they must be taken for granted and always taken into account when connecting the boiler to a water heating system. Features are as follows:

- High inertia. At the moment, there are no ways to abruptly extinguish a burning solid fuel in a combustion chamber.

- Formation of condensate in the firebox. The peculiarity manifests itself when a heat carrier with a low temperature (below 50 °C) enters the boiler tank.

Note. The phenomenon of inertia is absent only in one type of solid fuel units - pellet boilers. They have a burner, where wood pellets are dosed, after the supply is stopped, the flame goes out almost immediately.

The danger of inertia lies in the possible overheating of the water jacket of the heater, as a result of which the coolant boils in it. Steam is formed, which creates high pressure, tearing the body of the unit and part of the supply pipeline. As a result, there is a lot of water in the furnace room, a lot of steam and a solid fuel boiler unsuitable for further operation.

A similar situation may arise when the heat generator is connected incorrectly. After all, in fact, the normal mode of operation of wood-burning boilers is the maximum, it is at this time that the unit reaches its passport efficiency. When the thermostat responds to the heat carrier reaching a temperature of 85 ° C and closes the air damper, combustion and smoldering in the furnace still continues.The temperature of the water rises by another 2-4°C, or even more, before its growth stops.

In order to avoid excess pressure and a subsequent accident, an important element is always involved in the piping of a solid fuel boiler - a safety group, more about it will be discussed below.

Another unpleasant feature of the operation of the unit on wood is the appearance of condensate on the inner walls of the firebox due to the passage of an unheated coolant through the water jacket. This condensate is not God's dew at all, since it is an aggressive liquid, from which the steel walls of the combustion chamber quickly corrode. Then, having mixed with the ash, the condensate turns into a sticky substance, it is not so easy to tear it off the surface. The problem is solved by installing a mixing unit in the piping circuit of a solid fuel boiler.

Such a deposit serves as a heat insulator and reduces the efficiency of a solid fuel boiler.

It is too early for owners of heat generators with cast-iron heat exchangers that are not afraid of corrosion to breathe a sigh of relief. They can expect another misfortune - the possibility of destruction of cast iron from temperature shock. Imagine that in a private house the electricity was turned off for 20-30 minutes and the circulation pump, which drives water through a solid fuel boiler, stopped. During this time, the water in the radiators has time to cool down, and in the heat exchanger - to heat up (due to the same inertia).

Electricity appears, the pump turns on and sends the cooled coolant from the closed heating system to the heated boiler. From a sharp temperature drop, a temperature shock occurs at the heat exchanger, the cast-iron section cracks, water runs to the floor. It is very difficult to repair, it is not always possible to replace the section.So even in this scenario, the mixing unit will prevent an accident, which will be discussed later.

Emergencies and their consequences are not described in order to scare users of solid fuel boilers or encourage them to purchase unnecessary elements of piping circuits. The description is based on practical experience, which must always be taken into account. With the correct connection of the thermal unit, the likelihood of such consequences is extremely low, almost the same as for heat generators using other types of fuel.

What is required to install a solid fuel boiler?

So: how to install a solid fuel boiler, what is required for installation? Here I would like to immediately note that the competent creation of a heating system is a long and meticulous task, the implementation of which requires experience and a special tool. Whether it is a long burning wood boiler or some other type. Therefore, doing this on your own is highly discouraged. Before installing the system, it is necessary to calculate the parameters of the boiler room, based on the peculiarities of the principle of operation of the boiler, to consider slopes. Then make the wiring of pipes with a coolant and soldering the connecting elements, not to mention membrane expansion tanks for heating, boilers and so on. All this requires special equipment, a special soldering iron for plastic pipes, or a welding machine, pipe cutters and much more.

Tying the "indirect" with the boiler

First of all, the unit must be installed on the floor or securely attached to a main wall made of brick or concrete. If the partition is built of porous materials (foam block, aerated concrete), it is better to refrain from wall mounting.When installing on the floor, keep a distance of 50 cm from the nearest structure - clearance is necessary for servicing the boiler.

Recommended technological indents from the floor boiler to the nearest walls

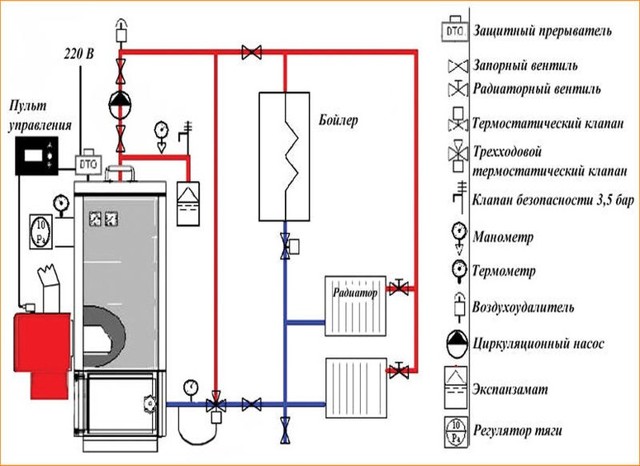

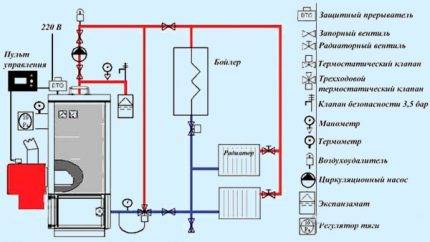

Connecting the boiler to a solid fuel or gas boiler that is not equipped with an electronic control unit is carried out according to the diagram below.

We list the main elements of the boiler circuit and indicate their functions:

- an automatic air vent is placed at the top of the supply line and discharges air bubbles that accumulate in the pipeline;

- the circulation pump provides the coolant flow through the loading circuit and the coil;

- a thermostat with an immersion sensor stops the pump when the set temperature inside the tank is reached;

- check valve eliminates the occurrence of parasitic flow from the main line to the boiler heat exchanger;

- the diagram conventionally does not show shut-off valves with American women, designed to turn off and service the apparatus.

When starting the boiler “cold”, it is better to stop the circulation pump of the boiler until the heat generator warms up

Similarly, the heater is connected to more complex systems with several boilers and heating circuits. The only condition: the boiler must receive the hottest coolant, therefore it crashes into the main line first, and it is connected directly to the hydraulic arrow distribution manifold, without a three-way valve. An example is shown in the primary/secondary ring tying diagram.

The general diagram conventionally does not show the non-return valve and boiler thermostat

When it is required to connect a tank-in-tank boiler, the manufacturer recommends using an expansion tank and a safety group connected to the coolant outlet. Rationale: when the internal DHW tank expands, the volume of the water jacket decreases, there is nowhere for the liquid to go. Applied equipment and fittings are shown in the figure.

When connecting tank-in-tank water heaters, the manufacturer recommends installing an expansion tank on the side of the heating system

The easiest way is to connect an indirect heating boiler to wall-mounted boilers, which have a special fitting. The remaining heat generators, equipped with electronics, are connected to the water heater via a motorized three-way diverter valve controlled by the boiler controller. The algorithm is this:

- When the temperature in the tank drops, the thermostat signals the boiler control unit.

- The controller gives a command to the three-way valve, which transfers the entire coolant to the loading of the DHW tank. The circulation through the coil is provided by the built-in boiler pump.

- Upon reaching the set temperature, the electronics receives a signal from the boiler temperature sensor and switches the three-way valve to its original position. The coolant goes back to the heating network.

The connection of the solar collector to the second boiler coil is shown in the following diagram. The solar system is a full-fledged closed circuit with its own expansion tank, pump and safety group. Here you can not do without a separate unit that controls the operation of the collector according to the signals of two temperature sensors.

Heating water from the solar collector must be controlled by a separate electronic unit

Features of installing a solid fuel boiler

In accordance with all the rules, the heating unit is placed. The device is tied up and started. Installation work includes installation and connection of the device to the system.

It must be remembered that the installation of a solid fuel boiler must be carried out at a highly professional level. Indeed, the following parameters of the operation of the unit during operation depend on the quality of the installation:

- Duration of work.

- Efficiency.

- Economical fuel consumption.

Calculations required for installation

Boiler equipment is a complex modern technique, so professional advice is required before starting work on your own.

Remember that errors during installation can lead not only to inefficient operation of the unit, but also to the consequences of an emergency.

Thus, the installation work for the installation of a solid fuel boiler must be carried out by a person who has certain knowledge and skills. The work requires calculations of slopes, installation of pipes.

Remember that the chimney is not included in the package, so it becomes necessary to take into account the technical data of the equipment.

Preliminarily, the parameters of the boiler room for the boiler, as well as its power, are calculated. When choosing, they will be needed.

Mounting Features

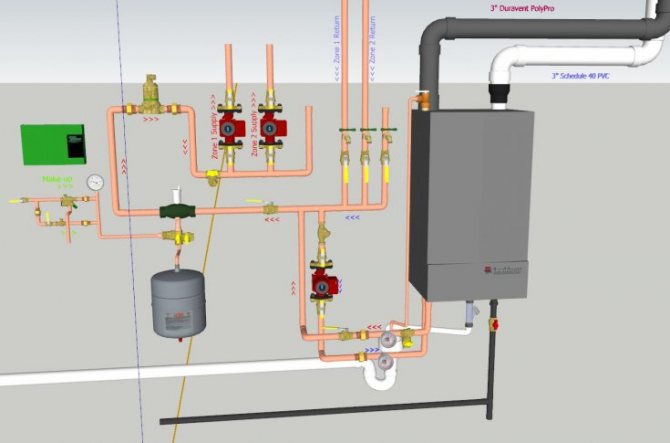

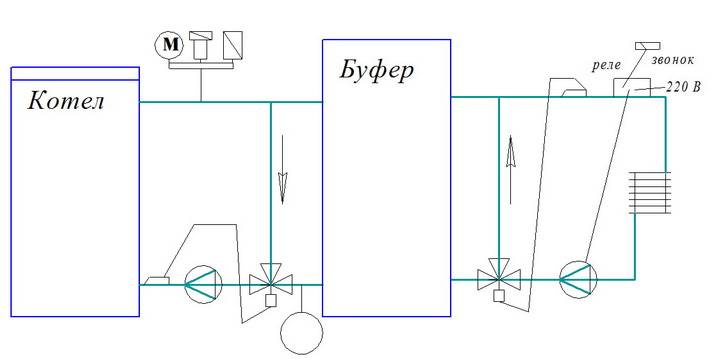

Installation of a solid fuel boiler with a pump can only be carried out in a closed system. Forced circulation has the following advantages:

- 1. The room will warm up evenly, the coolant moves at high speed.

- 2. There is no need to use large pipes. It is best to use products made of polypropylene, not plastic.

- 3. Installation is made as simple as possible, no need to place pipes under a slope.

The installation of such a circuit does not exclude the possibility of switching to a self-current mode in case of a pump malfunction or a power failure. The circulation pump is connected in parallel and with shut-off valves on the bypass.

Usually the pump is installed in the pipeline in the area of the return pipe near the boiler, as this is where the temperature is lowest. This approach saves device resources. In addition, it is the safest, because when placed on the supply pipe, the vapors will block the circulation if the liquid boils in the boiler. A filter is placed in front of the pump in the return area.

2.1

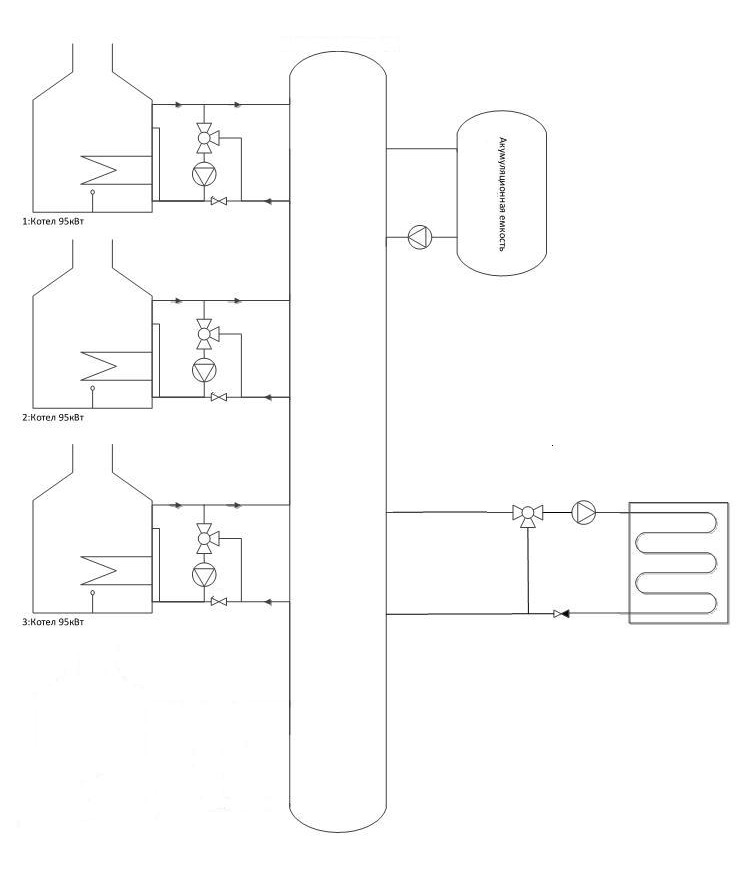

Collector wiring

In a branched pipeline with a long length, a single pump may not be enough. In such a situation, several devices are mounted, sometimes they can even put one on each circuit (separately on a warm floor, hot water supply, radiators). The warm floor has a temperature of about 50 degrees, so the pump can be installed at the inlet to the circuit.

The manifold consists of at least reverse and straight combs. At their ends, the necessary lines are placed; return and straight loop pipes are connected in parallel to the fittings. A fuse and a pressure gauge are located at the inlet to the collector. On the opposite side, an air outlet is installed on the warm comb, and on the cold one - a tap designed to drain the energy carrier from the equipment. In order for the circuits to have different temperature conditions, valves are placed in the pipes for adjustment.

Another option that allows you to set different temperature conditions is a hydraulic arrow.To do this, a pipe with a large cross section is placed vertically and connected to the boiler return and a straight pipe. Circuits are connected to the body in various areas. The higher the connection, the hotter the energy carrier will be.

In small circuits, the temperature regime can be adjusted in another way. It is necessary to connect the ends of the combs to the bypass. If you open the valve, then the liquid from the return is mixed with hot water from the supply pipe.

2.2

Security group

Safety level monitors are needed to protect the pipeline from the consequences of pressure problems, prevent overheating of the TTA device and normalize the temperature. Also, the devices do not allow condensation to form. Most often this is due to an excessively high temperature fork between the return and supply. The normal temperature delta should be 20 degrees. The security group category includes the following devices:

- air outlet;

- control fittings, including thermostatic valves;

- emergency heat exchanger;

- fuse to relieve excess pressure;

- control manometer.

Gas equipment installation technology

Despite the fact that all boilers have a similar design and principle of operation, there are special rules and installation nuances for floor, wall, autonomous boilers.

Installation of a wall-mounted boiler

- Mounting of wall-mounted boilers is carried out using a special bracket, which is included with the device. The bracket material must be compatible with the wall material. If the ones in the kit are not compatible with the wall (you need to check this in the specification for the brackets), you need to purchase others.Often, a stencil is provided with the boiler for precise marking of the mount.

- The heating system can be one-pipe or two-pipe. Regardless of the number of pipes, you must first remove the plugs from the nozzles of the device. A special filter (mesh) is installed at the return feed inlet to protect against dust or dirt.

- Next, you need to seal all contact areas (both paint and silicone sealant are suitable)

- Similarly to the previous paragraph, you need to remove the plugs. Then the pipe supplying cold water must be equipped with a filter to eliminate the chance of dirt entering. Shut-off valves must have detachable connections (popularly called "Americans"). It makes the installation process much easier, and replacing the faucet is no problem. The cold water connections are on the left, and the hot water connections are on the right.

- The valve that cuts off the gas supply from the main is equipped with a special filter. Many save on this item, but in vain, because the detail is very responsible. Next, you need to securely seal the joint and check the quality with water or a gas sensor. Rubber hoses are prohibited, only corrugated ones are allowed. The boiler nozzle is attached to the hose and the union nut is tightened. Sealing in this case is guaranteed by a paranitic gasket.

- It is necessary to connect the device to the network only when the design involves a closed firebox. Most devices have a three-wire connection system. For a safe connection, you need to use a stabilizer that will save you from power surges and extend the service life.

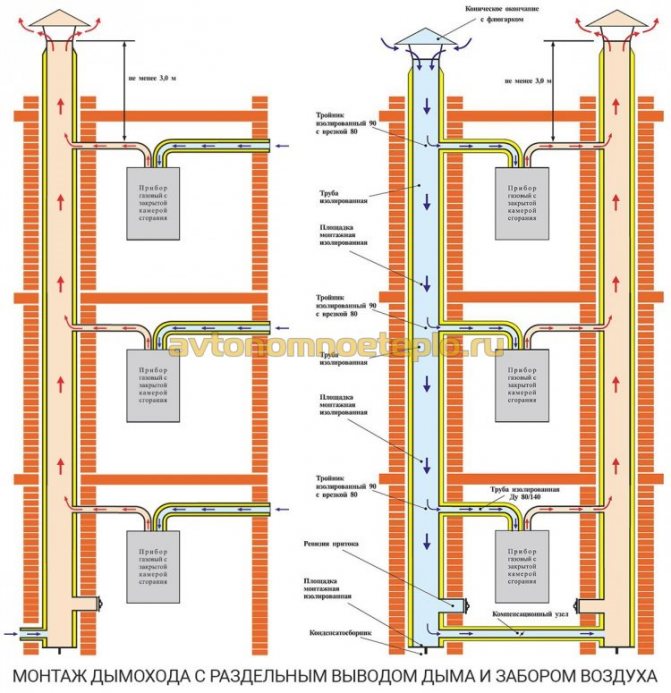

- Appliances with a closed firebox are easiest to connect to the chimney. For this, coaxial pipes are used.If there are many apartments in the house, then you need to connect to a common chimney, if the house is private, the chimney is led out through the wall. Next, you need to clean the chimney from soot and debris. The chimney must be mounted at a slight inclination relative to the boiler. At the outlet, there must be a strictly vertical pipe section, its length before the turn must be more than two pipe diameters.

- Before the first start, you need to wait until the liquid enters the system. The optimum pressure is 2 atmospheres. While water is being collected, check the tightness.

IMPORTANT! The first start is carried out in the presence of a gasman.

Installation of a floor boiler

- First you need to prepare a refractory board or similar protective screen at the place where the boiler will be located.

- Then you need to prepare a hole in which the chimney will be located. There you need to install an adapter that will be connected to the chimney. Corrugated pipes must not be used when installing the floor standing boiler.

- Carry out the fastening of pipes and elbows. The chimney is placed at a slight angle so that condensate can easily leave the system. The structure is clamped with clamps (with a step of 2 m) and brackets (with a step of 4 m). At the end of the chimney, a cone-shaped tip is installed, which saves from water and dirt.

- The boiler is connected to the drain and the contact point of the heating system. If the boiler is single-circuit, then this stage is over, if it is double-circuit, then you need to connect it to the water supply. Connections are sealed.

- Connection to the gas system begins with the connection of the gas pipe to the boiler. The connection is sealed with tow. Be sure to install a shut-off valve for emergency gas shut-off. It is recommended to use copper pipes with a diameter of 1.5 to 3.2 cm.Be sure to seal the connection with a paronite gasket.

- Next, the boiler is started using a stabilizer, in the presence of a gas service worker.

Tips for Efficient Operation

During the operation of a boiler that consumes solid fuels, slag deposits remain in its furnace. As they accumulate, they must be periodically removed. In addition, to maintain the energy efficiency of such a boiler, certain actions should be taken periodically.

Firstly, from time to time the walls of the boiler must be cleaned of accumulated ash and soot. Due to the millimeter layer of soot on the walls, the energy efficiency of a solid fuel boiler is reduced by 3%. It must be cleaned at least once every seven days. In this case, the boiler must be turned off, and its walls cooled down.

Secondly, as the grate of grates is clogged with ash, the boiler will also gradually lose its energy capacity. If such a phenomenon has been noticed, it can be eliminated quite simply - by slightly moving the contents of the furnace.

Modern models of solid fuel boilers are equipped with a special lever for turning over the coals, besides, if necessary, it will help to dump the coals.

Thirdly, in order to improve the circulation of water along the heating circuit of the boiler, a circulation pump can be used. This will significantly increase the energy efficiency of the thermal unit, since the heat carrier will move through the system much faster, and it will return to the boiler with a higher temperature.

And this means that less thermal energy will be needed to reheat it, therefore, the energy efficiency of such a boiler will be noticeably greater.

The circulation pump can be placed in front of the boiler inlet in the water return pipe

Fourthly, it is worth monitoring the state of draft in the smoke exhaust duct. And to keep it in optimal condition, the chimney must be cleaned at least once a year. Sections of the chimney channel that run through rooms without heating must be insulated.

This must be done to prevent the formation of condensate vapors. They, in turn, are harmful in that, when accumulated, they interfere with the normal release of combustion products.

And in order for the fuel to be used most efficiently, it is necessary to set the temperature controller to the minimum performance position, but only when the room at home has warmed up well, and it has warmed up outside.

The owner of a private house can always choose the way to perform the whole range of work: with his own hands or through specialists from companies involved in the installation of boilers

Brands of Russian-made solid fuel boilers

An analysis of the technical characteristics will help to get a general idea of solid fuel boilers for long burning. Consumer reviews on independent forums give an objective assessment of domestic developments.

Table 1. Solid fuel Boilers Zota Mix and Pellet manufactured by the heating equipment and automation plant (Krasnoyarsk):

Table 1. Solid fuel boilers Zota Mix and Pellet manufactured by the heating equipment and automation plant (Krasnoyarsk)

- The efficiency of boilers of the Zota Mix model range is 80%, Pellet is 90%;

- combined steel solid fuel boilers Zota Mix operate on any type of fuel (liquefied or natural gas, electricity, liquid fuel);

- the combustion chamber and the ash box are located inside the water jacket;

- adjustable chimney damper, mechanical draft regulator and air suction by an ejector, which is installed in the furnace door, ensure complete combustion of fuel with minimal draft;

- the outer surface of the body is coated with an anti-corrosion polymer composition;

- a removable door behind the front panel provides access for cleaning the flue;

- the possibility of repair.

Boiler design Zota Mix

- need a supply of fuel and a place to store it;

- costs of delivery, unloading and storage of firewood, coal, briquettes;

- decrease in productivity of Zota Mix boilers when using low-quality fuel (lignite by 10÷20%, raw firewood by 60÷70%);

- for Zota Mix - manual loading of fuel, cleaning the ash pan, furnace walls, gas ducts and flue pipe;

- mandatory preparation of boiler water (hardness up to 2 mg-eq / l);

- installation in a separate room;

- for boilers of the Zota Mix line, it is necessary to install a heat accumulator, a smoke exhauster, and a boiler.

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV). Manufacturer OOO Sibteploenergomash (Novosibirsk):

Table 2. Apparatuses combined solid fuel with a water circuit (AKTV). Manufacturer Sibteploenergomash LLC (Novosibirsk)

- a budget option for solid fuel boilers with a water circuit for the home (price 11,000 ÷ 25,000 rubles);

- compact size;

- the water heat exchanger covers the furnace from all sides (except the front);

- retractable ash drawer;

- mounting socket for draft regulator;

- the ability to connect to a chimney of any configuration;

- a steel heat exchanger allows a simplified connection to the heating piping (without admixture);

- the design is adapted to work on gas and electricity.

Boilers "Karakan" from the manufacturer LLC "Sibteploenergomash"

- outdated design, primitive low-quality automation;

- the technical characteristics declared by the manufacturer (power, heated area and efficiency), according to consumer reviews, do not correspond to actual indicators.

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma):

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma)

- ensures stable combustion of fuel of any grade and degree of humidity;

- effective operation of the boiler from one tab for 8 hours;

- economical fuel consumption;

- generator compatibility with natural or forced circulation systems;

- environmentally friendly unit, the fuel goes through a cycle of complete combustion, without forming harmful emissions into the atmosphere;

- the design of the firebox provides an effective mode of operation in 40 minutes.

Solid fuel pyrolysis boilers "Bourgeois & K"

- complex installation: the connection must be made by employees of specialized enterprises licensed for this type of activity (otherwise the guarantee from the manufacturer does not apply to the unit);

- manual loading of fuel and cleaning of the combustion chamber;

- great weight.

Installation and operation of solid fuel boilers must be carried out in accordance with fire safety rules

For heating a country house. garage or greenhouse, it is possible to manufacture solid fuel boilers for long burning with your own hands. Videos with materials on this topic can be found on the Internet. But remember that the main condition for the use of heating equipment is fire safety.And only a certified manufacturer can guarantee the fulfillment of this condition under proper operating conditions and equipment installation.

Tips for Efficient Operation

During the operation of a boiler that consumes solid fuels, slag deposits remain in its furnace. As they accumulate, they must be periodically removed. In addition, to maintain the energy efficiency of such a boiler, certain actions should be taken periodically.

Firstly, from time to time the walls of the boiler must be cleaned of accumulated ash and soot. Due to the millimeter layer of soot on the walls, the energy efficiency of a solid fuel boiler is reduced by 3%. It must be cleaned at least once every seven days. In this case, the boiler must be turned off, and its walls cooled down.

Secondly, as the grate of grates is clogged with ash, the boiler will also gradually lose its energy capacity. If such a phenomenon has been noticed, it can be eliminated quite simply - by slightly moving the contents of the furnace.

Modern models of solid fuel boilers are equipped with a special lever for turning over the coals, besides, if necessary, it will help to dump the coals.

Thirdly, in order to improve the circulation of water along the heating circuit of the boiler, a circulation pump can be used. This will significantly increase the energy efficiency of the thermal unit, since the heat carrier will move through the system much faster, and it will return to the boiler with a higher temperature.

And this means that less thermal energy will be needed to reheat it, therefore, the energy efficiency of such a boiler will be noticeably greater.

The circulation pump can be placed in front of the boiler inlet in the water return pipe

Fourthly, it is worth monitoring the state of draft in the smoke exhaust duct. And to keep it in optimal condition, the chimney must be cleaned at least once a year. Sections of the chimney channel that run through rooms without heating must be insulated.

This must be done to prevent the formation of condensate vapors. They, in turn, are harmful in that, when accumulated, they interfere with the normal release of combustion products.

Conclusions and useful video on the topic

The video discusses in detail the regulatory requirements for the installation of wall-mounted gas boilers:

The video tells about the connection scheme of the wall-mounted boiler:

The video demonstrates the process of installing a wall-mounted boiler:

p> Installing a gas heating unit is a responsible and rather complicated operation, the quality of which depends on the safety of everyone who lives in the house. Therefore, representatives of gas services strongly do not recommend doing it on their own.

Yes, and manufacturers of heating appliances insist on this. Therefore, even experienced home craftsmen are better off seeking help from professionals, which guarantees long-term, and most importantly, safe operation of the device.

Please leave your comments if you have any questions about the topic of the article. Or maybe you yourself had to deal with the installation of gas wall-mounted equipment and do you have something to advise our readers?