- Gas appliance in a private house: requirements and basic installation steps

- Boiler installation

- Video description

- Operating rules

- Video description

- Maintenance

- Norms of the room for the installation of a gas boiler, where it is better to install the device

- Standards for installing the appliance in the kitchen of wooden and other types of houses

- Requirements for a separate boiler room

- Equipment Installation Rules

- Requirements for individual rooms

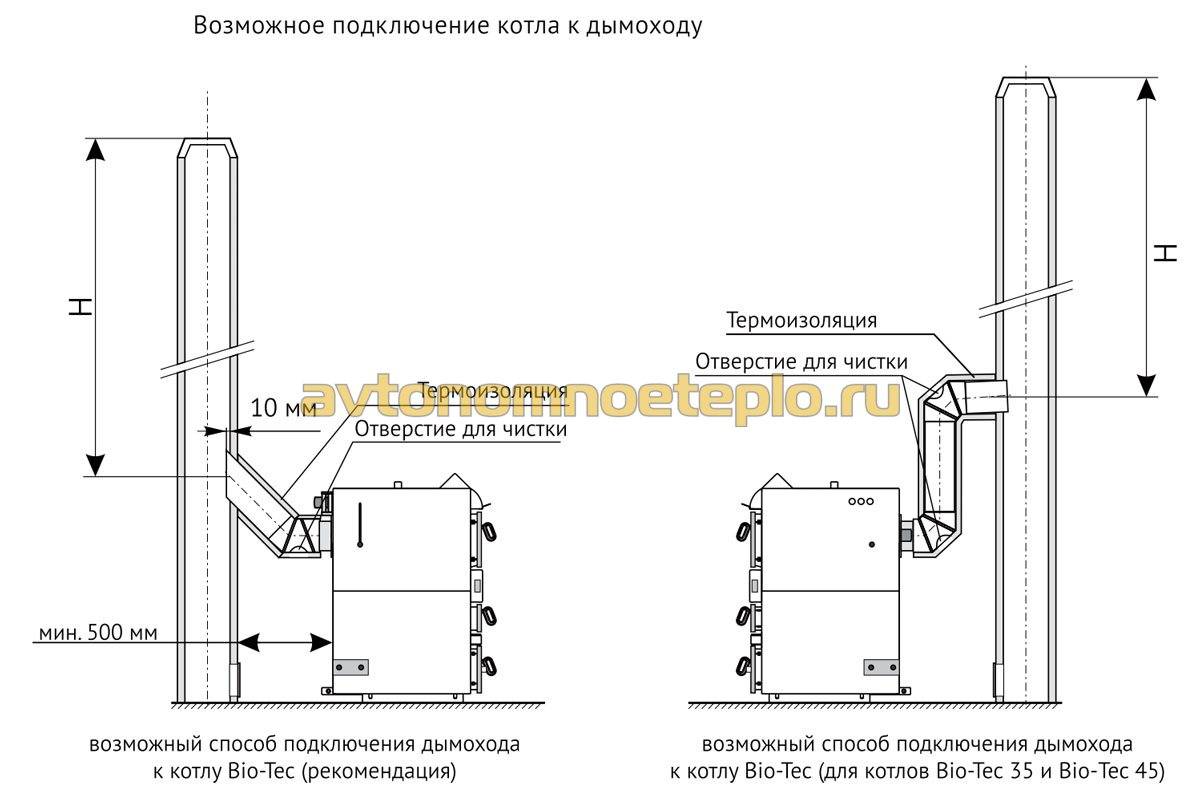

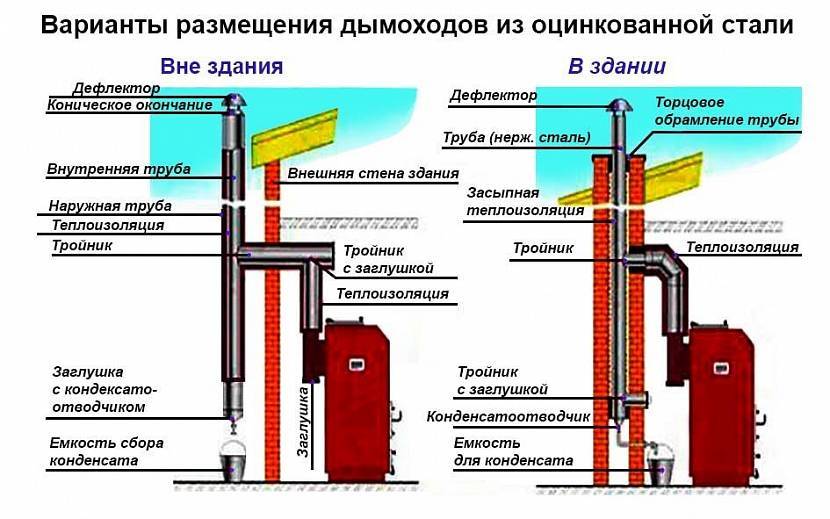

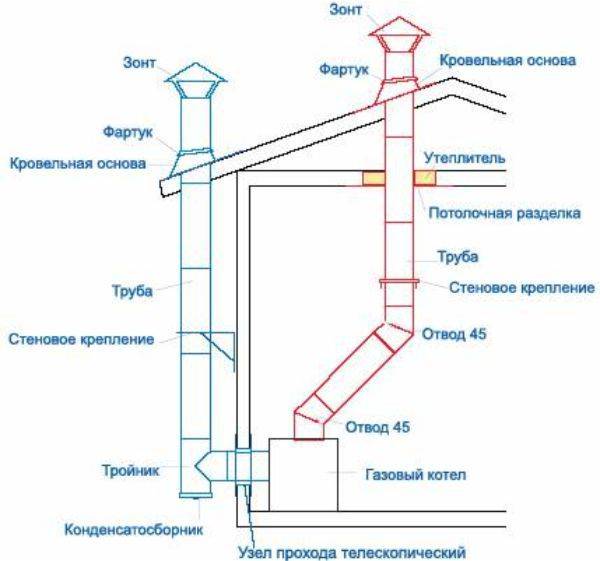

- Stage 2. Installation of the combustion products removal system

- Boiler installation - stages of work

- Pre-firebox

- Boiler location

- Chimney connection

- Fuel storage

- Boiler piping

- Location of the gas boiler

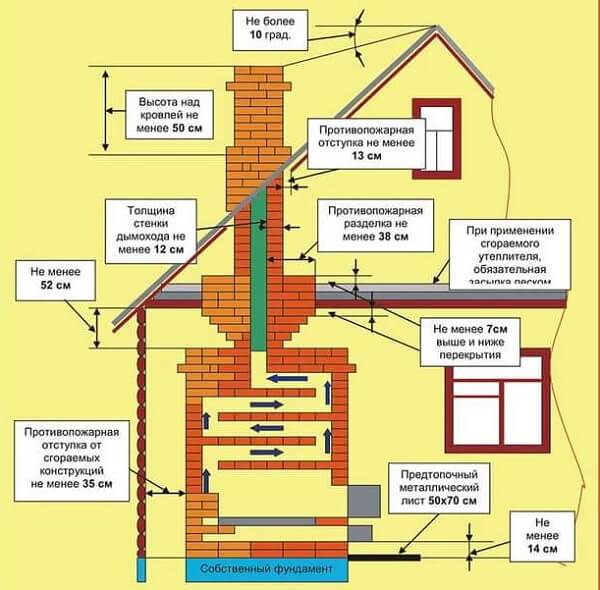

- Fire safety

- Boiler room placement

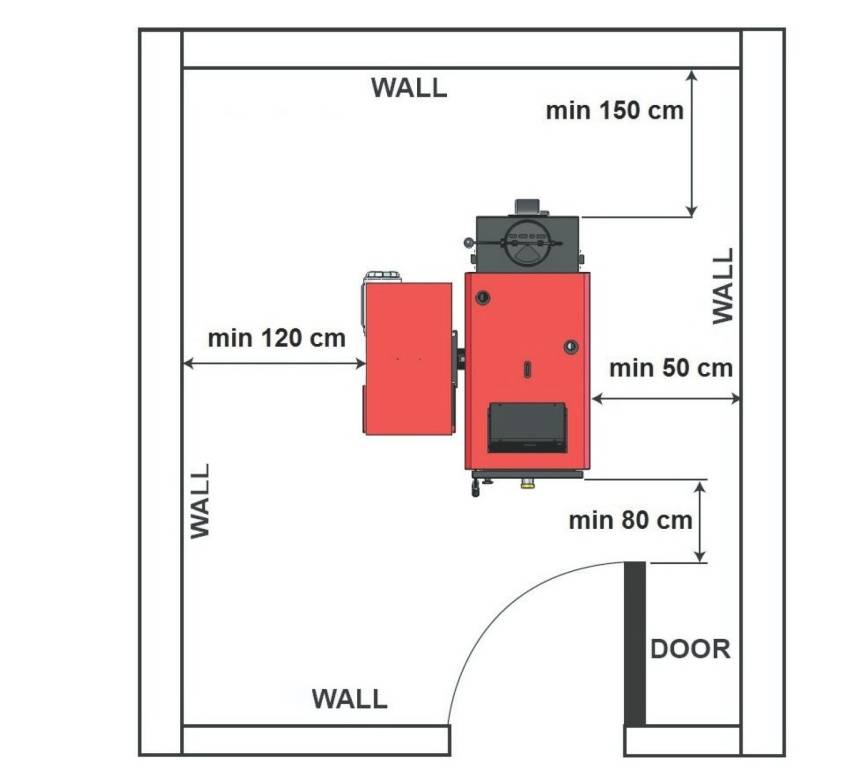

- Installing a solid fuel boiler: safety requirements and standards

- Calculation of the real power of a long-burning boiler using the example of "Kupper PRAKTIK-8"

- Requirements for installing a boiler in an apartment

- Required documents

- boiler room requirements

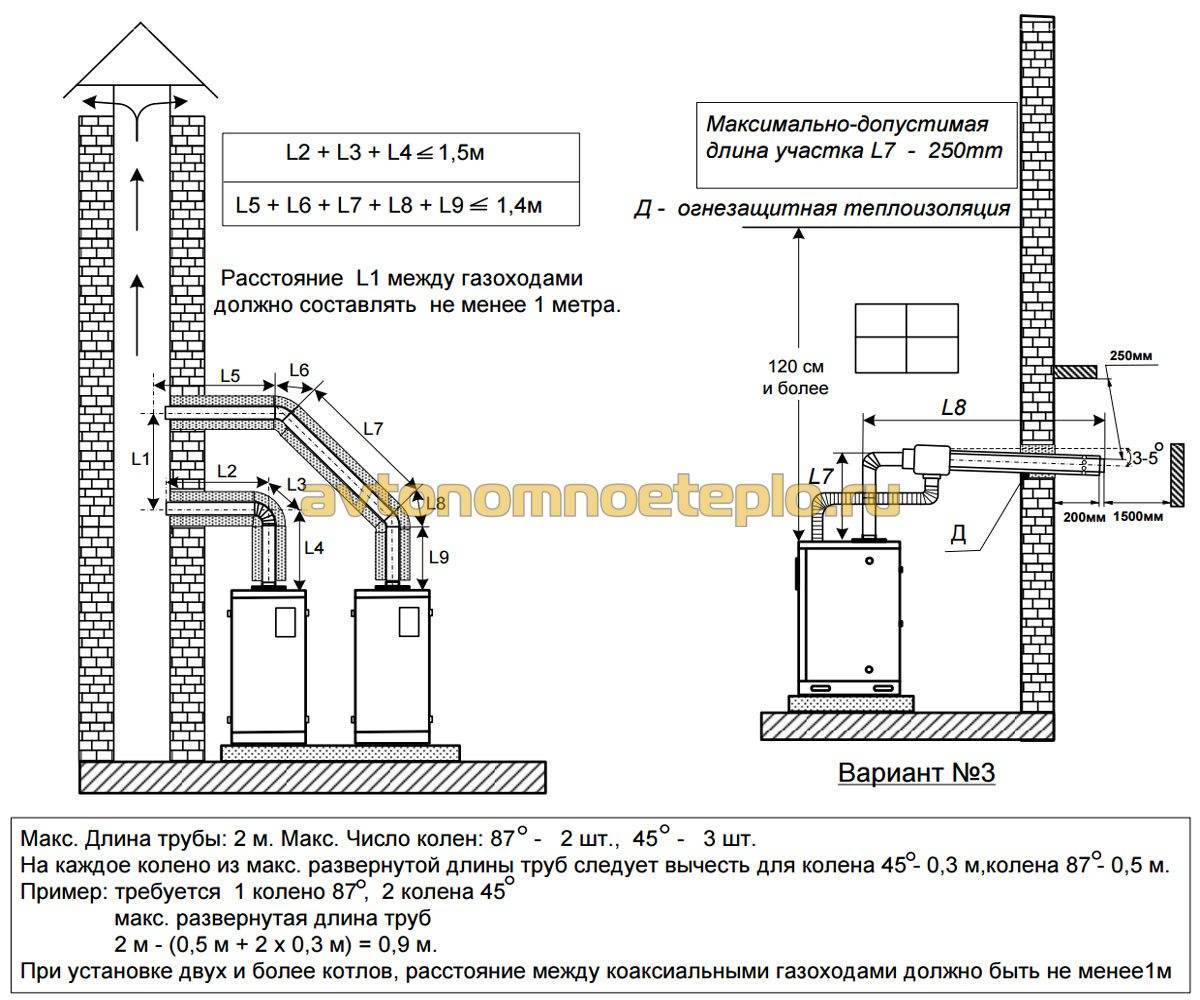

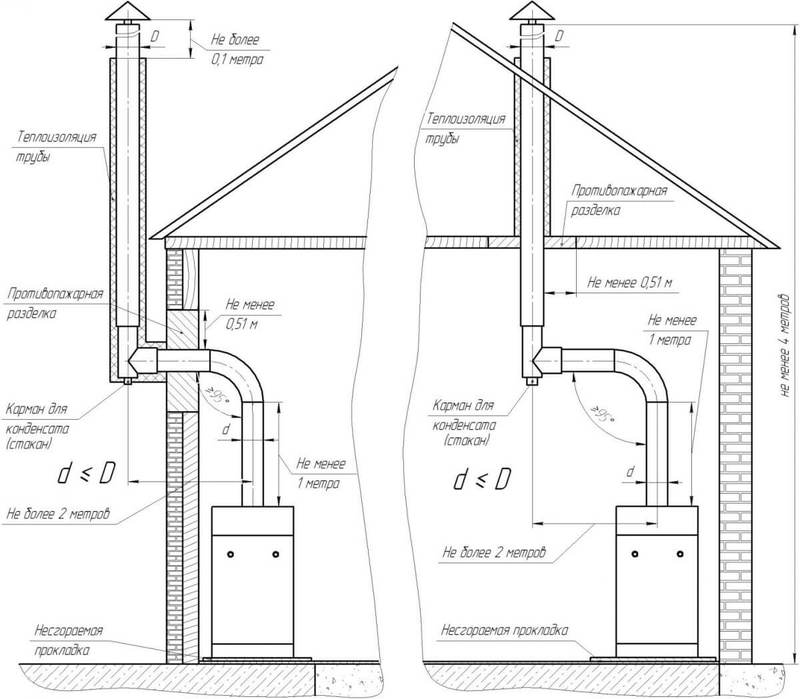

- Chimney installation

- Switching to individual heating: advantages and disadvantages

- Requirements for the boiler room in the house and apartment

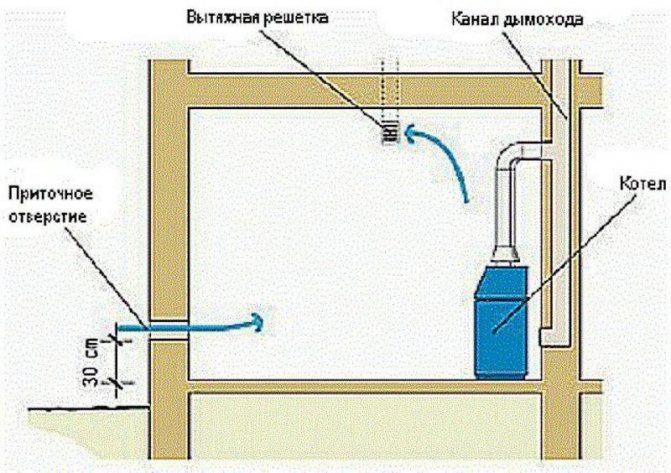

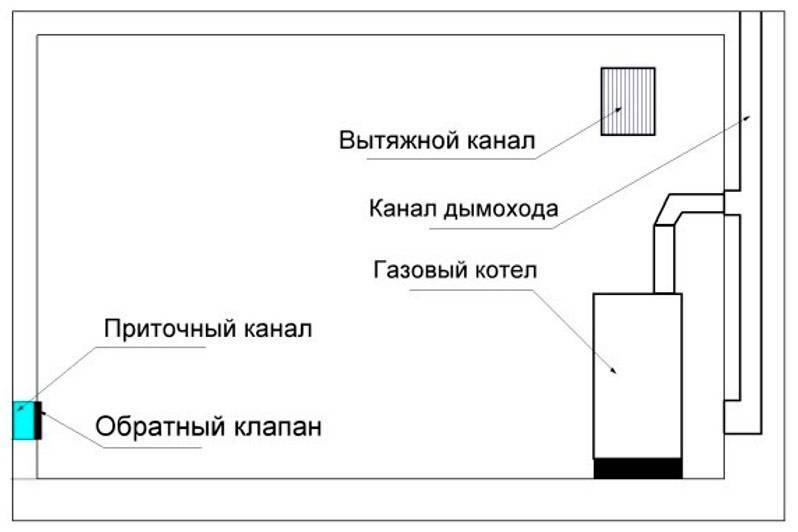

- How to properly install the supply and exhaust ventilation

- Requirements for a room for installing a gas boiler

- Stage 1. Preparation of the base

Gas appliance in a private house: requirements and basic installation steps

For proper installation of the unit, you first need to study the regulatory documentation and the rules for performing these works. They talk about the features of installing gas appliances for the installation of a heating system.

What kind of boiler would not have to be installed, it is imperative to comply with the requirements of certain norms and rules, such as:

- SNiP 41-01-2003 on heating, ventilation and air conditioning.

- SNiP 42-01-2002 on the gas distribution system.

- SNiP 21-01-97 on fire safety.

- SNiP 2.04.08-87 on the arrangement of boiler rooms.

The provisions of SNiP contain all the necessary information for the installation and start-up of a gas boiler

With regard to these conditions, in order to install a gas boiler in a house, you must first obtain a regulatory act that gives permission to carry out work on connecting gas appliances. And in order to purchase technical specifications, it is necessary to submit an application to the local gas service, which must be answered within a month.

Boiler installation

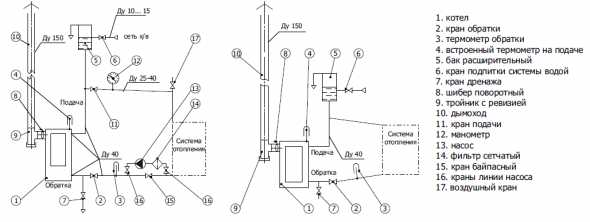

After the development of project documentation and receipt of an act with permission to install a gas boiler, it is installed, which is carried out in several stages:

- Preparation of a solid foundation. A concrete screed is poured onto the floor, or a sheet of metal is placed. The boiler must be installed strictly parallel to the floor.

- Chimney connection and draft check.

- Connecting the pipes of the heating system. In this case, a fine filter must be installed, which is usually placed in the return pipeline before the boiler. And on both sides of the filter element put ball valves.

- When installing a double-circuit gas boiler in a private house, it is necessary to connect it to the water supply.It is desirable to insert the supply pipe from above, and the outgoing line - from below.

- Connection to the gas pipeline. This can only be done by a gas service specialist.

Video description

The installation of a gas boiler is clearly shown in the video:

Operating rules

For the safe use of gas, the connection scheme for a gas boiler in a private house must be observed. In addition, the following conditions must be met:

- For putting the boiler into operation only at normal humidity.

- Control of the technical condition by specialists of the gas service at least once a year.

- Installation of a fine filter on the return pipe of the heating system.

- Natural or artificial ventilation in the boiler room.

- Compliance of draft in the chimney pipe with the requirements (10-20 m / s).

In the event of a leak, notify the emergency gas service promptly.

Video description

About the features of the operation of gas boilers, see the video:

Maintenance

Preventive measures for routine inspection of gas boilers include the following types of work:

- Checking the valves of the external and internal gas pipeline (disassembly, lubrication).

- Inspection of thermostats on floor boilers.

- Flushing or replacing filter elements.

- Revision of injectors, check of the tightness of the door, the operation of the igniter on floor-standing appliances.

- Chimney draft control.

- Checking in winter ice at the coaxial pipe of wall-mounted boilers.

All components that have been worn out during operation must be replaced.

A competent preventive inspection will not only increase the life of the equipment in operation, but also reduce gas consumption.

Repair and maintenance of gas equipment

At first glance, the installation of gas boilers in a private house is not the most difficult, the requirements for compliance with standards and safety are high. Installation of a heating system with a gas boiler requires knowledge of the relevant rules and regulations, and the final check and connection should be carried out exclusively by gas service specialists. Trust the professionals and then the gas boiler will serve you faithfully and provide warmth and comfort in your home.

Norms of the room for the installation of a gas boiler, where it is better to install the device

The most stringent requirements are imposed on the premises where the installation of a gas unit is planned.

According to current regulations, it is allowed to carry out their installation in non-residential premises, equipped with high-quality ventilation.

In addition to the presence of ventilation, the area of \u200b\u200bthe room must correspond to the power of the unit and the design of the combustion chamber. When the boiler and gas column are installed together, their capacities are summed up.

Important! According to existing standards, it is allowed to install two gas devices in one room. The following standards have been established: The following standards have been established:

The following standards have been established:

- gas boilers with a power of less than 30 kW are allowed to be installed in rooms with a volume of at least 7.5 m³;

- boilers with a capacity of 30-60 kW require a space of more than 13.5 m³;

- for the installation of more efficient boiler equipment, the minimum volume is from 15 m³.

Standards for installing the appliance in the kitchen of wooden and other types of houses

For homeowners planning to place equipment in the kitchen, it is important to know that there are special regulations for this room:

- The area is more than 15 m².

- The height of the walls is at least 2.2 m.

- A window that opens outward, equipped with a window leaf.There should be 0.03 m² of window area per 1 m³ of the volume of the room.

Photo 1. Gas boiler located in the kitchen. The device is installed in a special cabinet, which is closed with a lattice door.

- If the building is wooden, then the wall adjacent to the boiler is covered with a fireproof shield. The size of the shield is determined so that it protrudes 10 cm beyond the boiler at the bottom and on the sides, and covers 80 cm of the wall from above.

- When choosing a floor model, a base made of fire-resistant material (brick, ceramic tile) is installed under it, protruding 10 cm on all sides of the boiler.

- In addition to the presence of exhaust ventilation, a gap is provided at the bottom of the door for fresh air to enter. It ensures constant air circulation.

- When installing the heating unit, a certain distance between the wall and the boiler must be observed (more than 10 cm).

Requirements for a separate boiler room

When erecting, for the placement of boiler equipment, an extension to the main building, the following conditions must be observed:

- the foundation of the extension is carried out separately from the main building;

- the design is made of fire-resistant materials, the same requirements are imposed on interior decoration;

- mortar is kneaded on sand;

- the foundation for installing the boiler is poured separately, after the completion of the extension;

- the base intended for the installation of equipment is 15-20 cm above the floor surface.

Further requirements correspond to the conditions for the installation of boilers in non-residential premises:

- a ventilation system that provides three air changes within an hour;

- the distance between the floor and the ceiling is at least 2.5 meters;

- the volume of the boiler room is more than 15 m³, a larger volume ensures the comfort of servicing all elements of the equipment;

- water is necessarily carried out, and a drain is arranged in the floor;

- all electrical outlets available in the room are grounded;

- daylight;

- when placing the boiler plant, a free approach to the unit is provided.

Photo 2. Boiler room with two gas boilers. The devices are installed on a special pedestal, access to sunlight is provided.

Certain requirements are also imposed on the equipment used in the operation of the boiler:

- gas pipelines are used only metal;

- the device is grounded using a separate ground loop;

- without a gas meter, an automatic valve that shuts off the gas supply in case of leakage, and a gas analyzer, the equipment is not accepted for operation.

Reference. Modern gas units are equipped with protective automation of varying complexity, which turns off the gas supply in case of malfunctions.

Equipment Installation Rules

Strictly follow all the rules and regulations of SNiP "Gas distribution systems" without deviating from them.

Any attempt to improvise or change classical technology may be noticed by the inspectors.

And if this causes an accident or losses to other residents of the house, the owner faces administrative, and, in some cases, criminal penalties.

- If the boiler is wall-mounted, the floor under it must be perfectly level, as the pump pumping water can cause vibration and displacement of the boiler. If the vibration is strong, the gas pipes or water supply may become disconnected from the boiler, causing gas leakage or flooding.

- If it is possible to make a stand for the boiler, this will secure the structure and increase the strength of adhesion to the floor.

- If you install the boiler near a stove, boiler or other heating elements, then the total power of the thermal field between them will be higher than the sensors show, since they measure this only inside the system itself. This rule is not specified in SNiP, but is often the cause of premature wear of the mechanism or failure.

Requirements for individual rooms

Boiler rooms, equipped in separate rooms, must meet a number of requirements that are very similar to the previous ones:

- The ceiling must be at a height of over 2.5 m;

- The area and volume of the room are selected depending on individual preferences, but the minimum allowable volume is 15 m3;

- Each wall of the boiler room must have a fire resistance of 0.75 hours and no flame propagation (this requirement corresponds to brick, concrete and building blocks);

- The requirements for ventilation are the same as when installing a boiler in the kitchen - three times the outflow and the same amount of air intake, increased by the amount of oxygen consumed during the combustion process;

- The room must have at least one window with a glazing area of 0.03 m2 per 1 m3 of the volume of the room.

When installing gas boilers with a power of over 150 kW, it should be possible to exit the boiler room directly to the street. Placing a gas boiler in an individual residential building suggests that the equipment cannot be adjacent to living rooms. In any case, the boiler room must be equipped exclusively with fire doors.

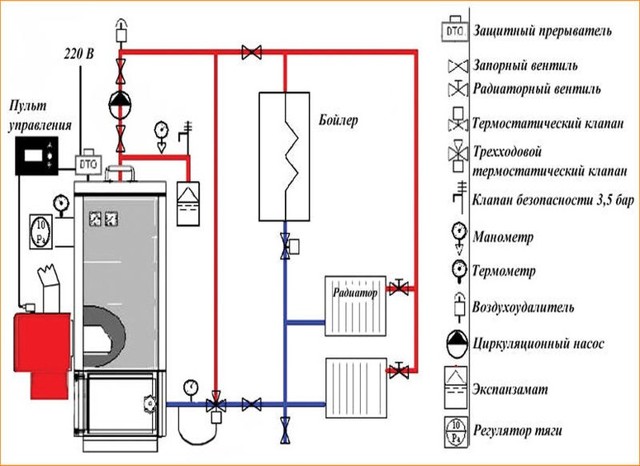

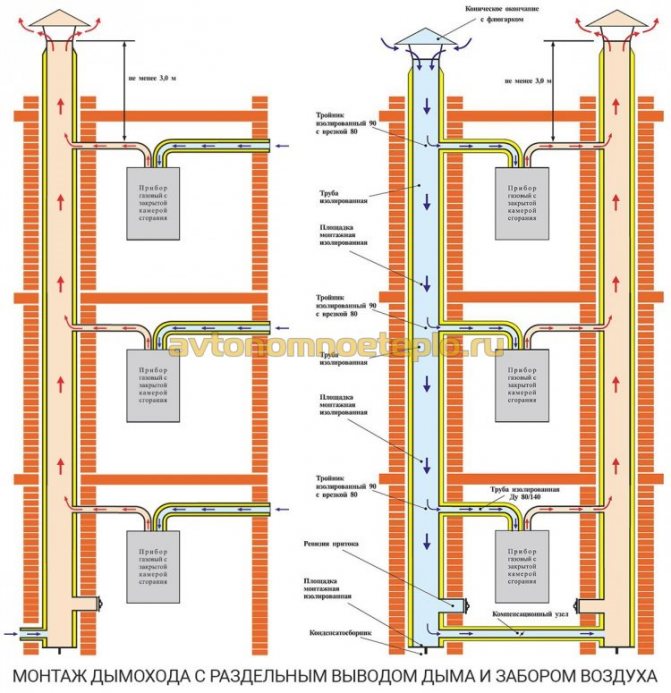

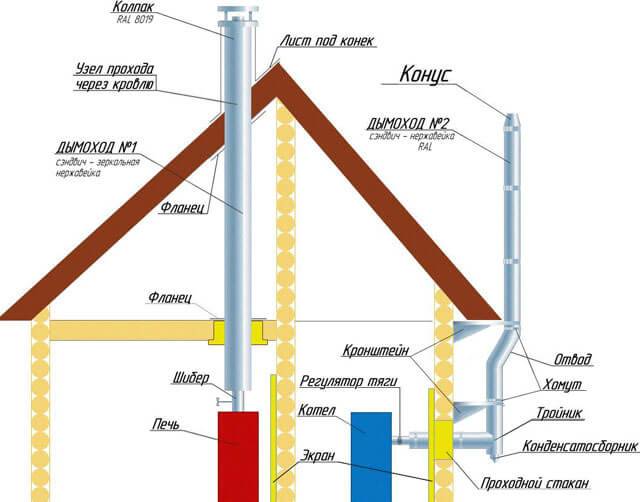

Stage 2. Installation of the combustion products removal system

The arrangement of the chimney can be called the most important point in the process of installing any heating equipment, including the installation of a wall-mounted gas boiler in a private house. It is possible to install a heating boiler on your own only if the system responsible for removing gases and products of combustion of fuel from the furnace is properly equipped. The chimney must be led outside. As for the dimensions of the pipe and its configuration, the recommendations of the manufacturer should be taken into account here. The chimney must fully comply with the parameters of the installed equipment.

Boiler installation - stages of work

Where to start, how to install a solid fuel boiler. to comply with all rules and regulations? Let's watch together.

Pre-firebox

Firstly, after you have brought the heat generator from a service center or store, you need to make a control heating on the street. Boiler equipment at the end of the production cycle is coated with paint, oil and other preservatives. When fired, all these substances give out such a smell and fumes that it is just right to suffocate. That is why the first furnace is always on the street.

It is enough to install one or two pipe segments on the flue pipe so that a small draft appears. It is enough to carry out the pre-heating procedure.

Boiler location

Next, you should have a place ready for the installation of a solid fuel boiler. Naturally, the installation of solid fuel boilers is prohibited in premises unsuitable for this. You can not put the boiler in the kitchen or in the hallway. And although there is such a requirement, our fellow citizens manage to violate it regularly.

I had to see TT boilers installed in the corridors, kitchens and even just under the wooden stairs to the second floor. After this, it becomes a little pity that the installation of solid fuel boilers is not regulated as strictly as the installation of gas boilers.

The requirements for the installation site of the TT boiler are the same as for the installation of a fireplace or stove. The same standards for distances to enclosing structures made of combustible materials and for their protection.

Chimney connection

Connecting a solid fuel boiler to a chimney is carried out in the same way as a conventional wood-burning stove or fireplace.

The only difference is that if you use coal as fuel, then you cannot deviate from the manufacturer's requirements or replace any parts of the chimney with less heat-resistant ones.

The same applies to the details of the boiler, especially grate and pipe protection in tubular heat exchangers.

Connecting a solid fuel boiler to a chimney is shown in the diagram:

One moment. If you put a long-burning boiler, then be prepared for a fairly large amount of condensate in the chimney. To remove it, it is worthwhile to provide a drain valve in the tee with a direct outlet to the sewer.

Fuel storage

This issue also has its own characteristics. For example, installing a solid fuel boiler on pellets will require space for a bunker, which can be located either next to the heat generator or on top of it.

You will also need a place to store fuel in the house if you are heating your TT boiler with wood or briquettes. The amount of fuel for 1-2 fireboxes should always be at hand.

But in any case, coal or sawdust will be brought into the boiler room from the outside immediately in front of the firebox.And this will require a thoughtful approach to organizing the space in front of the furnace door or boiler hatch.

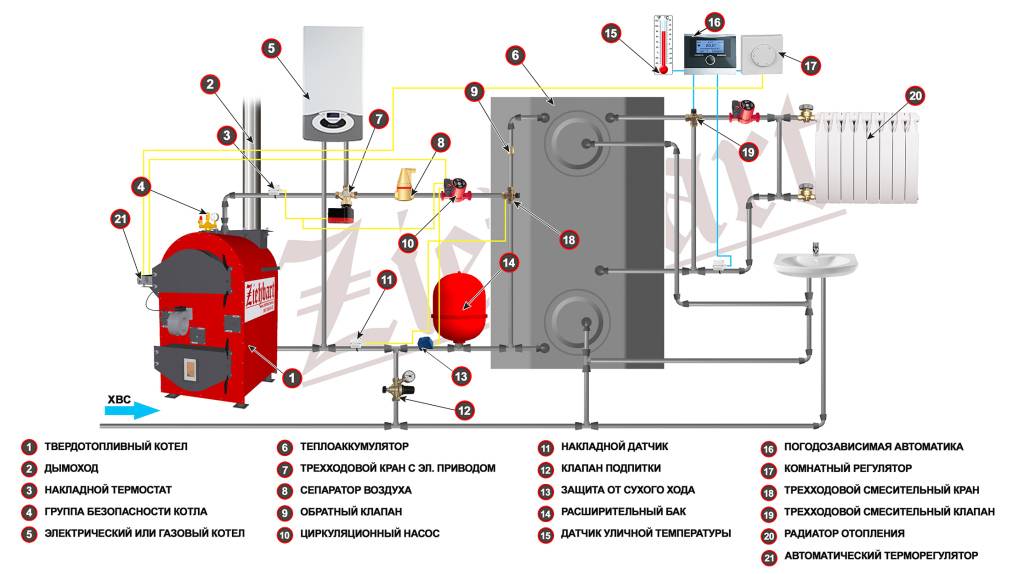

Scheme of installation of a solid fuel heating boiler in a boiler room:

As you can see, the installation scheme for a solid fuel heating boiler implies not only the actual installation of a thermal unit, but also all its service additions - fuel bins, a piping unit, a boiler safety group and automatic boiler controls.

Boiler piping

With regard to this issue, the piping of a solid fuel boiler is elementary and practically does not differ from the same work when installing other heat generators.

Location of the gas boiler

A gas boiler in an apartment is usually placed in the kitchen, which is due to the presence of all necessary communications, and the distance from the gas pipe to the boiler is maintained without problems. As a rule, wall-mounted boilers are used for apartments, which are attached to the walls using special brackets that come with the equipment.

If the house has a staircase leading to the upper floor, the owners have a desire to install a boiler under it. As a rule, there is enough space under the stairs for the boiler, but there are problems with ventilation, so it has to be equipped separately, using large diameter pipes.

Fire safety

The furnace area must be kept clean, and there must be sufficient artificial lighting inside to provide good illumination of work and public areas. It is prohibited to store any flammable materials in such premises. If the pipes freeze, they can only be heated with steam or hot water. The use of open flames is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems, they must be checked and cleaned at intervals:

- Annually in August - cleaning the smoke channels from soot pollution, checking the draft.

- Quarterly - cleaning of brick chimneys.

- Annually inspect the integrity of the ventilation ducts.

Entrance doors of the furnace should open outwards. Windows are required to have easily removable packages. A protective solenoid valve, a fire alarm and room gas sensors are installed at the gas pipeline inlet to the furnace.

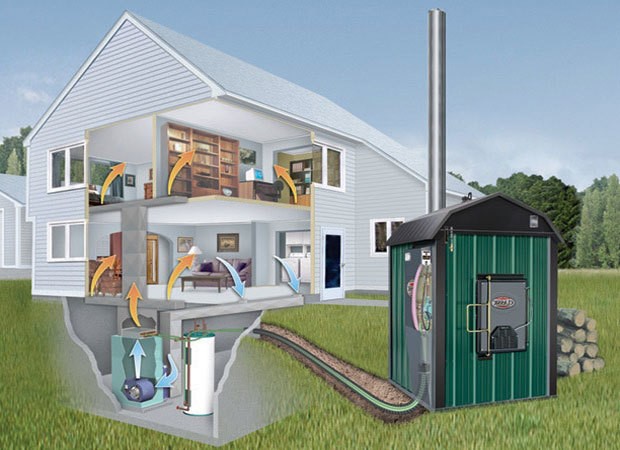

Boiler room placement

Autonomous heating allows the operation of boilers operating on various types of fuel. This includes equipment that generates heat from the processing of gas, solid fuels, electricity or combined systems. The location of the boiler room directly depends on the type of boiler chosen. The most stringent regulatory requirements apply to boilers operating on natural or liquefied gas. This is due to the high degree of their explosiveness.

A step below are boiler houses that use liquid and solid fuels. A lower level of explosion hazard does not cancel the regulatory requirements for the equipment of a separate boiler room, properly equipped with ventilation and having an individual channel for the removal of gas waste.

The most simplified requirements apply when installing an electric boiler. The presence of an isolated area is not required here, however, there are other regulatory restrictions on the safe operation of electrical equipment (selection of the cable section, organization of grounding, etc.).

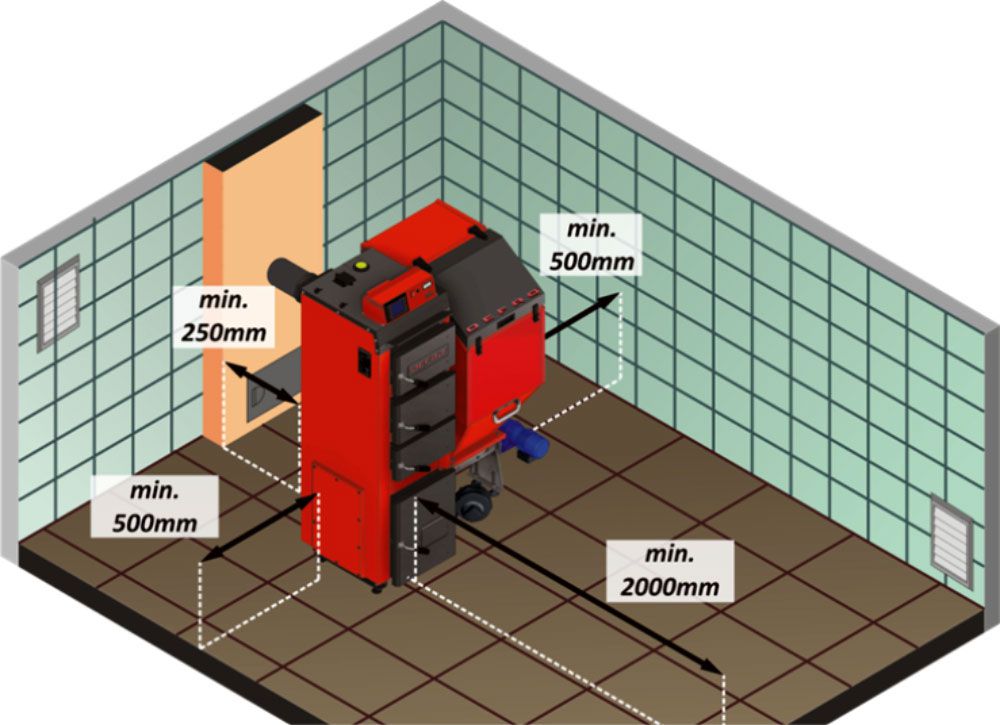

Installing a solid fuel boiler: safety requirements and standards

The main disadvantage of any solid fuel boilers is their fire safety - first of all, these are sparks that can fly out of the furnace when its door is opened, and secondly, this is the high temperature pumped by the boiler in the room in which it is installed. It is on the basis of this that the requirements appeared, to comply with which in the process of installing a solid fuel boiler with your own hands in your own interests. There are not many of them and almost all of them relate to the boiler room.

- As you already understood, the most important thing is that a solid fuel boiler needs its own room. So to say, a furnace room, in which, apart from the necessary equipment, nothing else will be installed - the minimum area of \u200b\u200bthis room is 7 square meters.

- The furnace room must be equipped with forced ventilation - unfortunately, a boiler that needs oxygen in large quantities to burn fuel cannot do without it. There is one requirement for ventilation - the diameter of the inlet and outlet should not be less than 100mm.

- Finishing. Walls, floors, ceiling - all these surfaces of the furnace must be finished with non-combustible materials. Cement floor screed, tiled, and plaster walls and ceiling, maximum puttying and painting.

-

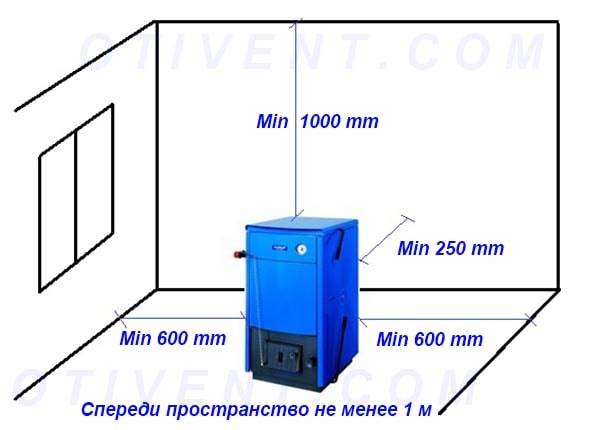

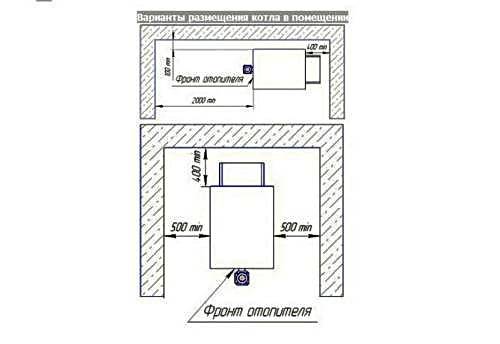

The very place of installation of a solid fuel boiler in the furnace. It is necessary to position the boiler in the room so that there is at least half a meter of free space around it. This is necessary both for convenient maintenance and to increase the level of fire safety.

Of the basic requirements, this is probably all.On my own behalf, I want to add one common truth - when approaching the solution of the question of how to install a solid fuel boiler with your own hands, it should be understood that all responsibility for its safe operation lies with you. It is for this reason that the word “safety” should be firmly ingrained in your mind and pop up to the surface every time you make a decision. In general, the question of whether what I'm doing will be safe should be the most important.

Calculation of the real power of a long-burning boiler using the example of "Kupper PRAKTIK-8"

Q = 0.1 × S × k1 × k2 × k3 × k4 × k5 × k6 × k7

- 0.1 kW - the rate of required heat per 1 m².

- S is the area of the room to be heated.

- k1 shows the heat that is lost due to the structure of the windows, and has the following indicators:

- 1.27 - the window has a single glass

- 1.00 - double-glazed window

- 0.85 - the window has triple glass

- k2 shows how much heat is lost due to the area of the window (Sw). Sw refers to the floor area Sf. Its stats are as follows:

- 0.8 - at Sw/Sf = 0.1;

- 0.9 - at Sw/Sf = 0.2;

- 1.0 – at Sw/Sf = 0.3;

- 1.1 - at Sw/Sf = 0.4;

- 1.2 - at Sw/Sf = 0.5.

- k3 shows heat leakage through walls. Could be the following:

- 1.27 - poor-quality thermal insulation

- 1 - the wall of the house has a thickness of 2 bricks or insulation 15 cm thick

- 0.854 - good thermal insulation

- k4 shows the amount of heat lost due to the temperature outside the building. Has the following stats:

- 0.7 when tz = -10 °С;

- 0.9 for tz = -15 °С;

- 1.1 for tz = -20 °С;

- 1.3 for tz = -25 °С;

- 1.5 for tz = -30 °С.

- k5 shows how much heat is lost due to the outside walls. Has the following meanings:

- 1.1 in building 1 external wall

- 1.2 in the building 2 external walls

- 1.3 in the building 3 external walls

- 1.4 in the building 4 external walls

- k6 shows the amount of heat that is needed additionally and depends on the height of the ceiling (H):

- 1 - for a ceiling height of 2.5 m;

- 1.05 - for for a ceiling height of 3.0 m;

- 1.1 - for a ceiling height of 3.5 m;

- 1.15 - for a ceiling height of 4.0 m;

- 1.2 - for for a ceiling height of 4.5 m.

- k7 shows how much heat has been lost. Depends on the type of building that is located above the heated room. Has the following stats:

- 0.8 heated room;

- 0.9 warm attic;

- 1 cold attic.

As an example, let's take the same initial conditions, except for the parameter of windows that have triple glazing and make up 30% of the floor area. The building has 4 outer walls, and above it is a cold attic.

We suggest you familiarize yourself with where the split system takes air to cool the room

Q = 0.1 × 200 × 0.85 × 1 × 0.854 × 1.3 × 1.4 × 1.05 × 1 = 27.74 kWh

This indicator must be increased, for this you need to independently add the amount of heat that is required for hot water supply, if it is connected to the boiler.

The above methods are very useful when it is necessary to calculate the power of a heating boiler.

Requirements for installing a boiler in an apartment

How to install a double-circuit gas boiler in an apartment? Often the installation of such equipment is difficult for a number of reasons (lack of a central gas pipeline, difficulties in obtaining permission, lack of conditions, etc.). To register, knowledge of the laws and basic rules is required. In case of unauthorized installation of a gas heating boiler, you will have to pay a large fine and dismantle the boiler. You need to start by getting permission.

Required documents

To mount the boiler in an apartment with existing central heating, you need to collect a package of documents and go through several authorities in stages:

- After submitting an application to the state supervision authorities, if the conditions for installation and maintenance of the heating device are met, technical specifications are issued, which are a permit for the installation of equipment.

- After receiving the conditions, a project is created. It can be performed by an organization that has a license for this type of activity. The best choice would be a gas company.

- Obtaining permission to enter the boiler. It is issued by inspectors of companies that check ventilation. During the inspection, an act will be drawn up with instructions that need to be eliminated.

- After collecting all the documents, the design documentation for the installation of the boiler in a separate apartment is coordinated. Within 1-3 months, employees of state supervision must complete the coordination of installation. If no violations are found during the collection and preparation of documents, the consumer receives a final license for the installation.

- Documents for refusal of service are submitted to the company providing heat supply services.

You can't break the rules. Only the fulfillment of all conditions will allow obtaining permission to install gas equipment.

boiler room requirements

The room in which the boiler is installed must meet the following requirements:

- Gas equipment can only be installed in non-residential premises with tightly closed doors. For installation, do not use the bedroom, utility rooms, kitchens and toilets.

- It is best to install a gas meter in the kitchen. In this case, an additional pipe is introduced into the room.

- All surfaces (walls and ceiling) in the room must be lined with refractory materials. It is advisable to use ceramic tiles or gypsum fiber sheets.

- The area of the room for installation must be at least 4 m2. It is required to provide access to all nodes of the gas boiler for high-quality maintenance of the system.

Chimney installation

Installation of heating on gas in apartments is allowed only with normally functioning ventilation and a system for removing combustion products. Therefore, it would be optimal to use a boiler with a closed combustion chamber, which is connected to a horizontal pipe for smoke removal. In this case, it will not be necessary to carry out several pipes for ventilation and smoke removal.

If several owners in the house want to switch to individual heating at the same time, the chimneys are combined into a single cluster. One vertical pipe is attached outside, to which the horizontal pipes coming from the apartments are connected.

For normal operation of the system, it is necessary to install devices for air circulation with high throughput in the boiler room. Such ventilation should be installed separately, without contact with the general one.

Switching to individual heating: advantages and disadvantages

Switching from central heating to gas requires a lot of money and labor. It takes a lot of time to issue permits, so you need to plan and start collecting the necessary papers long before the proposed installation.

Most representatives of state structures will prevent disconnection from the central heating system. Permits are issued reluctantly.Therefore, problems with paperwork are the main drawback in the transition to gas heating.

Switching cons:

- Unsuitability of the apartment for the installation of individual heating systems. To obtain a permit, a number of steps must be completed. Partial reconstruction costs a lot.

- Heating appliances require grounding. It is difficult to do this in an apartment, since according to SNiP it is impossible to use water pipes or an electrical network for this.

The main advantage of such heating is efficiency and profitability. The cost of re-equipment pays off in a few years, and the consumer receives energy independence.

Finished construction

Requirements for the boiler room in the house and apartment

There are no special differences for a cottage or apartment in terms of installing an autonomous heating system.

There are SNiP criteria that apply to all categories of premises, and if they meet the established standards, a gas boiler can be located there.

Kitchens deserve special consideration. The architect, creating the plan of the house, has already taken into account the necessary safety requirements. But that's not all. An important role is played by the total thermal power coming from all kitchen units (cooking oven, heating element, radiators, boiler). The maximum allowable value for this indicator is 150 kW.

It is permissible to install any boiler in a country house, and there are usually no problems with the premises. But in the kitchen of a city apartment, it is allowed to install only one type of boiler - wall-mounted, equipped with a closed combustion chamber.Additionally, a barred opening is made in the front door, with an area of at least 0.02 m² - to increase air draft.

There is another difficulty. The entrance door of the boiler room leads to the street, this rule is strictly observed. The supervisory authority will require either to install such a door, or to eliminate redevelopment. Often there is only one way out - to break through a hole in the wall, which is fraught with numerous expenditures of strength, nerves and money.

In small kitchens, the volume of which is less than 7.5 m³, it is not allowed to place two water heaters - residents of old houses with the idea of a separate furnace will have to say goodbye.

Photo 1. Wall-mounted gas boiler installed in an apartment. The device must be freely accessible.

In an apartment building, in case of fire, there is a risk of the fire spreading to other premises. So those who want to equip a furnace in the kitchen should better immediately tune in to a refusal from the fire department - redevelopment will not be allowed.

Important! In all cases, the installation of a gas boiler is carried out only by a qualified specialist. Never take on this challenge!

How to properly install the supply and exhaust ventilation

There are several objective reasons why ventilation in the boiler room is necessary:

- supplying sufficient oxygen to the boiler to support the combustion process;

- removal outside the room of carbon monoxide gases that accidentally got into the room from the furnace;

- compensation of the amount of air used in the combustion process.

- Openings for the inflow and outflow of air should be located on different sides of the boiler room. The inlet is made in the lower part of the wall as close as possible to the heat generator, and the exhaust is under the ceiling.

- If the boiler is equipped with a smoke exhauster or a blower fan, you should not place an exhaust hood next to it (read: “How to choose a smoke exhauster for a solid fuel boiler - types, differences”). Otherwise, the thrust will overturn, and the exhaust opening will become an inlet.

- If the door from the residential building goes into the furnace room, then it is desirable to build in the air inlet grate in the door leaf. Warm air entering the boiler will improve the combustion process.

- The size of the exhaust opening must be smaller than the inlet, since most of the incoming air enters into a thermochemical reaction and exits through the chimney in the form of CO2.

You can calculate the required size of the hood if you multiply the boiler power by 8 - we get the hole area in cm2.

Requirements for a room for installing a gas boiler

Comprehensive information on the proper preparation of the premises is contained in one of the above documents. In particular, there are regulations on the dimensions of the boiler room, the arrangement of the front door, the height of the ceiling and other important parameters (see key requirements below).

It is immediately worth noting that if the maximum thermal power of a gas boiler is more than 30 kW, then a separate room must be allocated for its installation. Models with a lower capacity and with an appropriate location for the chimney outlet can be installed, for example, in a kitchen room. It is strictly forbidden to install a gas boiler in the bathroom.

You can not install it in the bathroom, as well as in rooms that are considered residential for their intended purpose. As an alternative, it is allowed to equip the boiler room in a separate building. At the same time, their own norms are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the basement level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

In accordance with the rules for installing a gas boiler in a private house, it must be equipped with the following criteria:

- The area is not less than 4 m2.

- One room is calculated for no more than two units of heating equipment.

- Free volume is taken from 15 m3. For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling should be 2.2 m (not less).

- The boiler is installed so that the distance from it to the front door is at least 1 m; it is recommended to equip the unit near the wall, which is located opposite the doorway.

- On the front side of the boiler, at least 1.3 m of free distance must be left for setting up, diagnosing and repairing the unit.

- The width of the front door is taken in the region of 0.8 m; it is desirable that it opens outwards.

- The room is provided with a window with a window opening outward for emergency ventilation of the room; its area must be at least 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or ignition.

- A separate power line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, with an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a top coat of absolutely non-combustible materials (ceramics, stone, concrete)

To make it easier to set the boiler, the floors are made strictly according to the level.

On a curved surface, the installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is forbidden to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not work correctly, with increased noise and vibrations.

To fill the water heating system and feed it during operation, it is necessary to enter a cold water pipeline into the boiler room. To drain the system for the period of maintenance or repair of equipment, a sewer point is equipped in the room.

There are special requirements for the chimney and ensuring air exchange in the boiler room of a private house, therefore this issue is considered in a separate subparagraph below.

If the room for the installation of a gas boiler is equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- the presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- it is allowed to install no more than two gas boilers in the same boiler room;

- the presence of a properly equipped chimney;

- it must be freely accessible for cleaning and other operations;

- for supplying piece lighting and heating equipment, a separate input with an automatic machine of the appropriate power is provided;

- the water supply must be organized so that the mains do not freeze during the cold season.

Mini-boiler room mounted near the house.

The floors, walls and ceilings of a separately equipped boiler room must also be made and finished with materials that correspond to the class of non-combustible and heat-resistant.

Stage 1. Preparation of the base

Before installing a solid fuel boiler, it is necessary to choose a place for installing the equipment. This stage is the most important when deciding how to properly install a heating boiler, so its implementation should be approached with all responsibility.

The solid fuel boiler cannot be installed in residential areas such as kitchens, bedrooms or living rooms. For this equipment, it is necessary to prepare a separate room. Another prerequisite is the presence of an effective ventilation system that will prevent harmful gases from entering the premises.

Unlike installing a wall-mounted boiler in a private house, modern solid fuel boilers require a solid, stable base 10-20 cm high. This can be a specially made podium or a reinforced cement screed. As an additional protection, a steel plate 0.6 mm thick or an asbestos sheet about 5 mm thick should be used.