- Plant commissioning and testing

- Preparatory stage

- Selecting the type of equipment

- Pipe selection

- Choice of accommodation

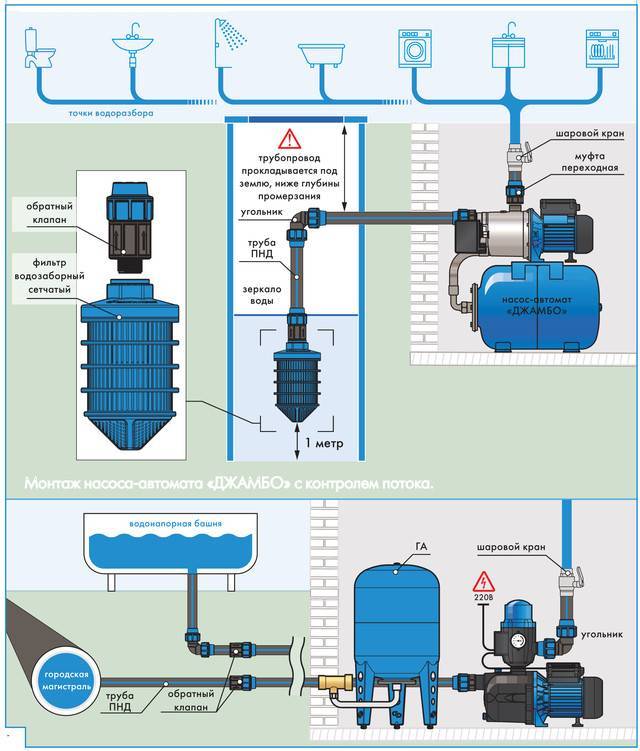

- Station connection options

- Rules for launching and configuring equipment

- First launch of the station

- Automation setting

- How to choose?

- Station Specifications

- Features of the well, well

- Connecting the deep pump to the water supply system

- Design features of the pumping unit

- Types of pumps for wells and their functions

- Types of household pumps

Plant commissioning and testing

The first start-up after installation or the restoration of the system's performance after a long "dry" period is simple, although it requires certain manipulations. Its purpose is to fill the system with water before the first connection to the network.

This is a simple procedure that does not require special skills. There is a plug on the pump that needs to be removed.

A simple funnel is inserted into the hole, through which the system is filled - it is important to fill in the supply pipe and the pump with a hydraulic accumulator. A little patience is required at this stage - it is important not to leave air bubbles. Pour water up to the neck of the cork, which is then twisted again

Then, with a simple automobile pressure gauge, the air pressure in the accumulator is checked. The system is ready to start

Pour water up to the neck of the cork, which is then twisted again. Then, with a simple automobile pressure gauge, the air pressure in the accumulator is checked. The system is ready to start.

To make it clearer how to test a pumping station, we have prepared 2 galleries for you.

Part 1:

Image gallery

Photo from

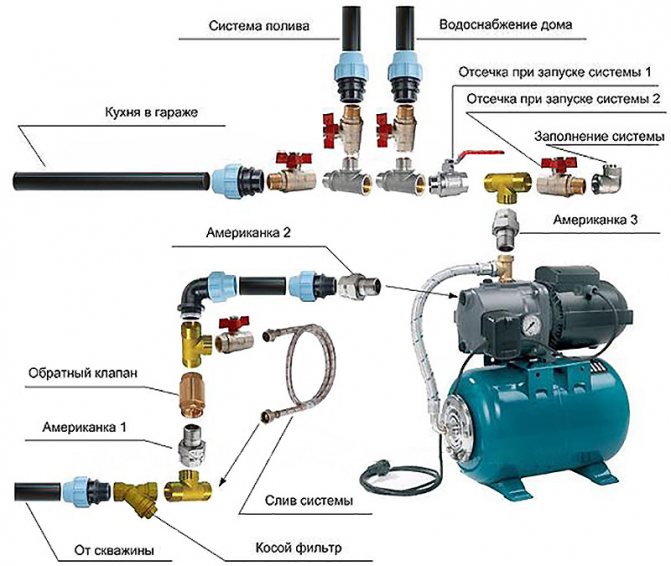

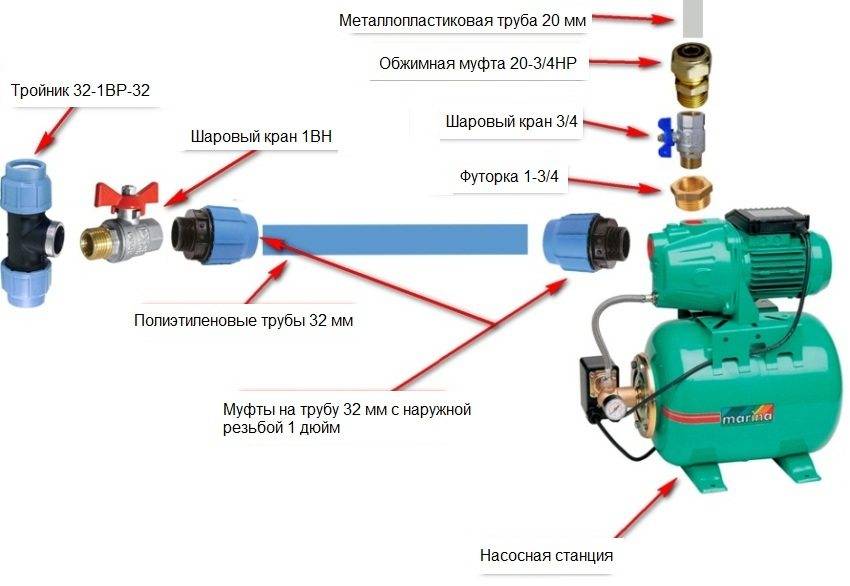

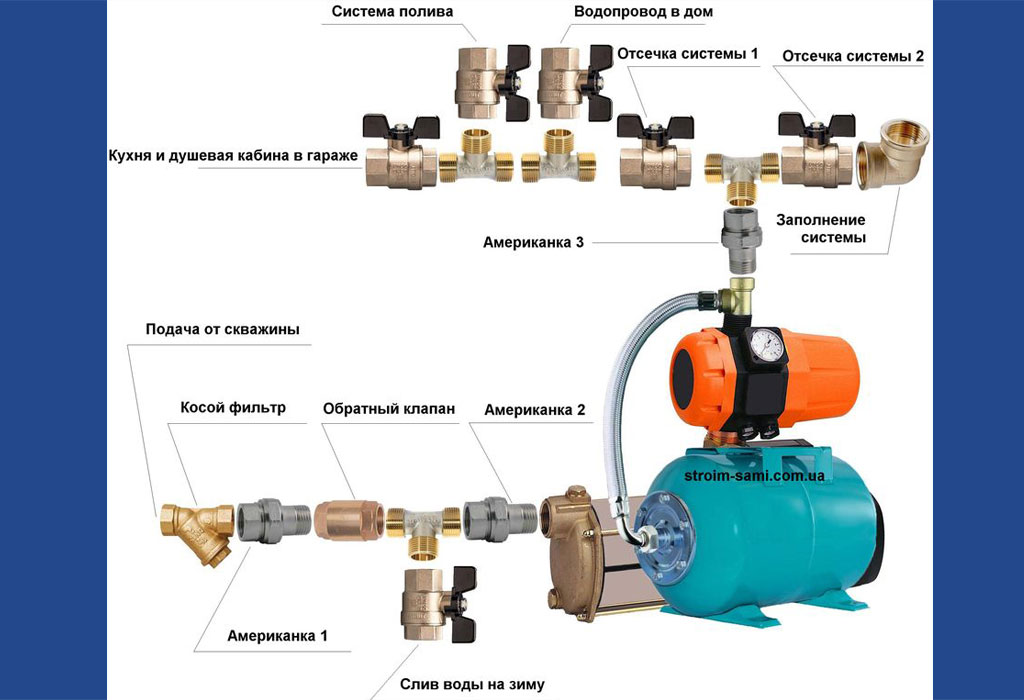

Fittings (elements for connecting water pipes or hoses to the unit) are not included in the kit, so they are purchased separately

We connect a pipe to the upper hole of the accumulator, through which water will go to the points of analysis in the house (shower, toilet, sink)

By means of a fitting, we also connect a hose or pipe for taking water from a well to the side hole

Do not forget to equip the end of the intake pipe with a check valve that ensures stable operation and the required pressure.

Before pouring water into the pipe, we check the tightness of all connections - the tightness of the fittings and the quality of the tightening of the union nuts

To test the quality of the pumping station, we fill the tank with clean water. When installing the pump at the well, we check whether the water level allows the use of the pump

Before starting work, pour 1.5-2 liters of water into the pumping equipment through a special hole

Step 1 - installation of the pumping station at the selected location

Step 2 - Installing the Water Supply Fitting

Step 3 - connecting the system that provides the house with water

Step 4 - connecting the pipe leading to the well

Step 5 - install a check valve at the end of the pipe (hose)

Step 6 - Leak Testing the Complete System

Step 7 - Filling the tank with water (or checking the water level in the well)

Step 8 - a set of water to create the desired pressure

Part 2:

Image gallery

Photo from

For the station to work, it remains to connect the power supply. We find the power cord, unwind it and plug it into a 220 V outlet

Do not forget to press the "Start" button, which is usually located on the side of the case

We turn on the pressure switch to start the pump, and wait for the pressure gauge needle to reach the desired mark

When the pressure in the accumulator reaches the desired level, it will automatically turn off.

To check the correct functioning of the pumping station, we turn on one of the taps, for example, in the bathroom or in the kitchen

We monitor the operation of the pumping station, pay attention to the speed of water supply, pressure force, performance

When the water in the tank (or in the well) runs out, the dry-running protection automatically turns on and the pump stops working.

Step 9 - Lowering the end of the hose into the water

Step 10 - connecting the station to the power supply system

Step 11 - Introduction to the working state by pressing the button

Step 12 - start the pressure switch

Step 13 - the accumulator is gaining the set pressure

Step 14 - opening the tap at the water supply point

Step 15 - Check Station Functionality

Step 16 - Automatic Dry-Run Shutdown

Preparatory stage

Before you start building a pumping station, you need to carry out several preliminary stages of work.

Selecting the type of equipment

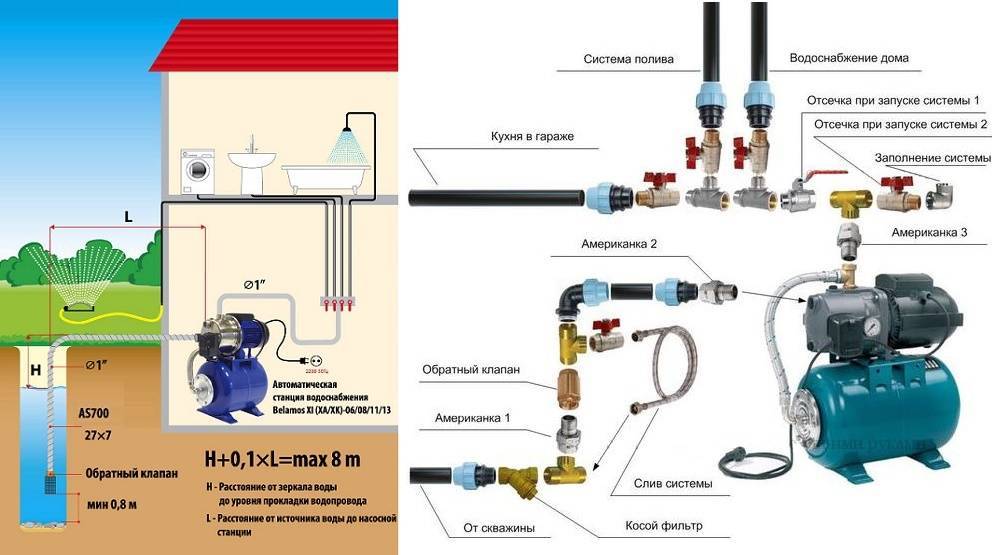

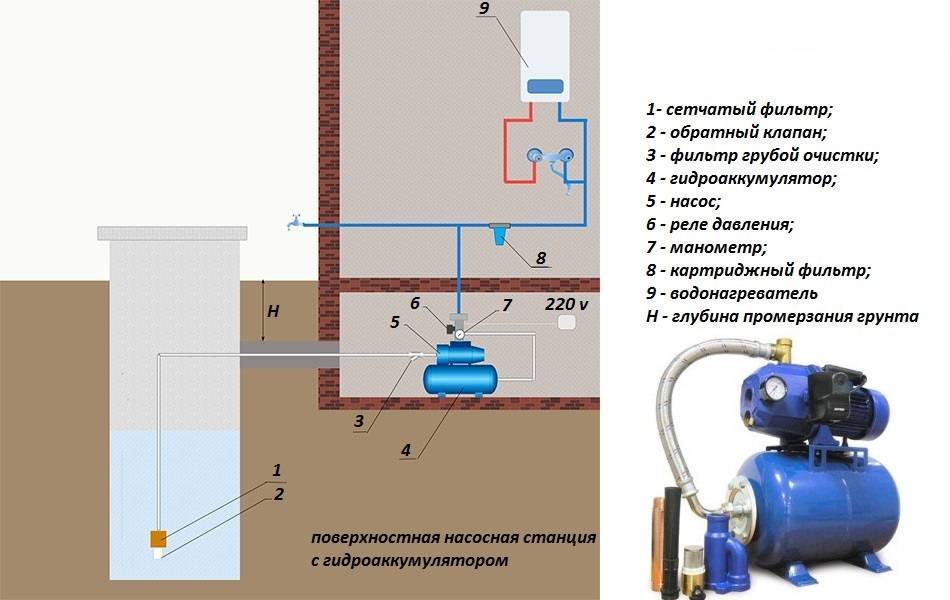

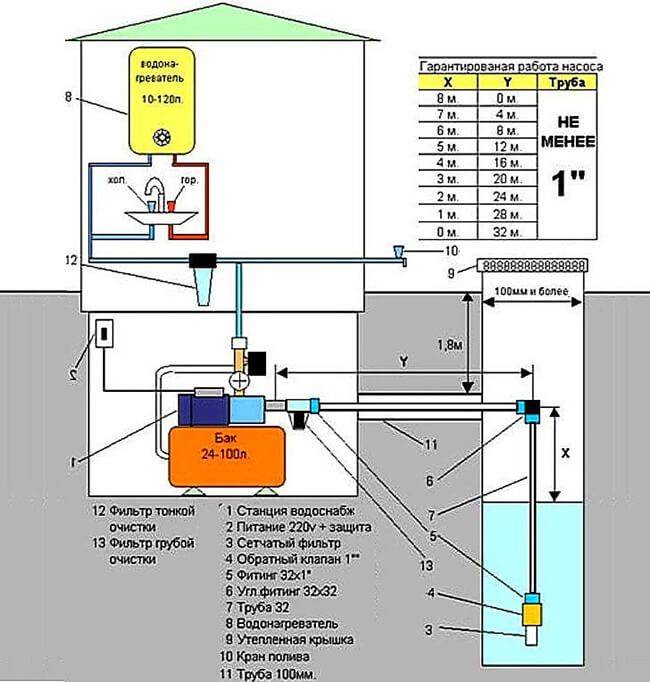

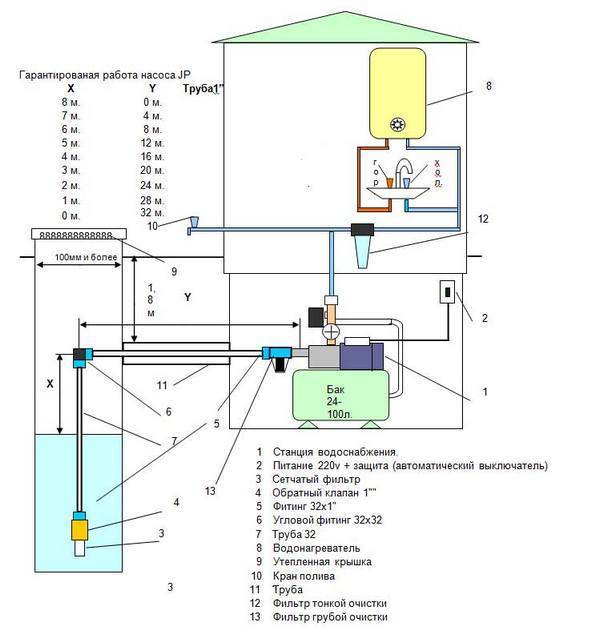

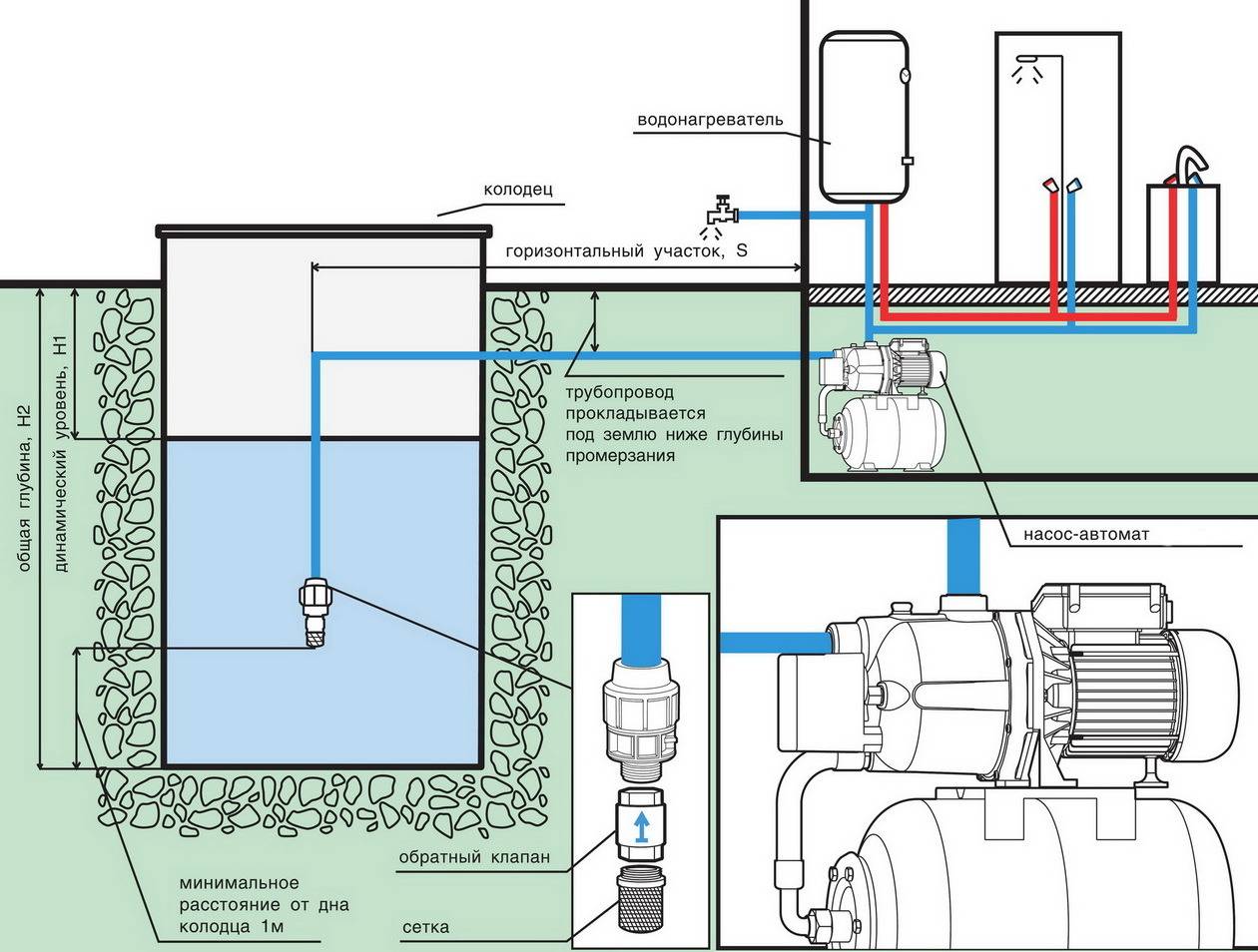

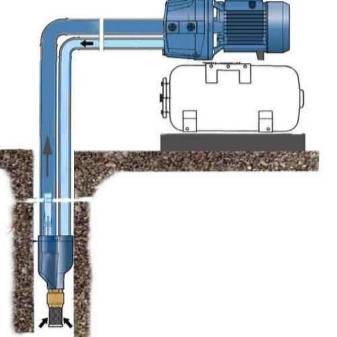

Connecting a surface ejector pump

For sand wells up to 20 meters deep, you can take a surface pump. He is able to raise water from a level of up to 9 meters. You can increase the productivity of the unit with a remote ejector. In this case, water will be taken from a depth of up to 18-20 meters, but with a lower capacity of the equipment.

For deep wells, it is worth buying a submersible pump. Deep is best. The device has the form of a flask, which is placed in the casing a meter from the bottom. The Danish pump Grundfos uses excellent characteristics, the price of which varies depending on the depth of immersion.

The rest of the equipment is selected according to the following technical parameters:

- power;

- performance;

- pressure;

- price.

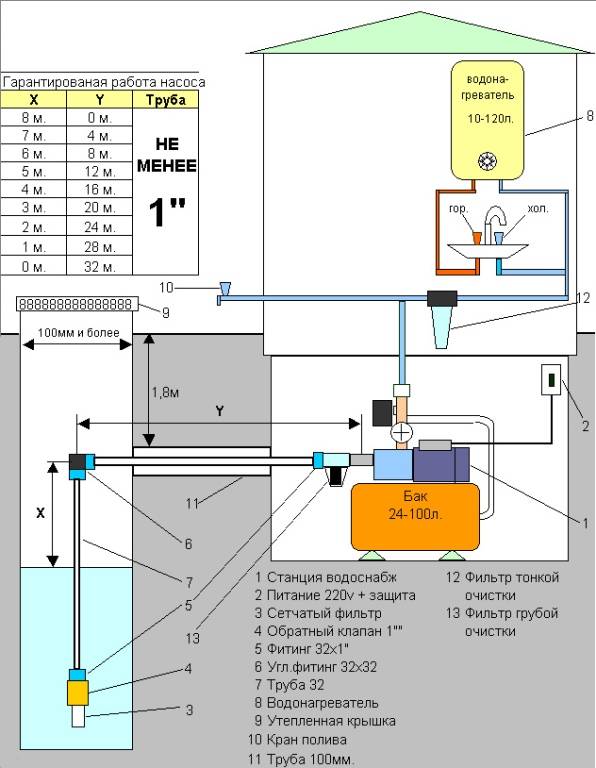

Pipe selection

Plumbing polyethylene pipes

For the installation of water supply, you need to purchase pipes for the external and internal mains. It is better to lay the outer line using HDPE products. They are not afraid of temperature changes, static and dynamic soil pressure. They have a smooth inner surface, which ensures a normal flow of water.

Inside the house it is better to lay polypropylene pipes. Their installation is carried out by soldering. As a result, the melted polymer forms a perfectly sealed joint.

Choice of accommodation

Location of pumping equipment in the downhole caisson

It is better to connect the water station to the well as close as possible to the hydraulic structure. There are several main places where you can install equipment:

Basement of a private cottage. It is always dry here, moderately warm. You do not have to spend money on the installation of a technical room and its insulation

But it is important to remember that a working pumping station makes very loud noises, which can cause discomfort to the residents of the house. You will need to soundproof the basement in order to install injection equipment in it.

Caisson

This is a special protective chamber, arranged at the very head of the well. The caisson is convenient in that it completely isolates all residents of the house from noise, protects equipment from precipitation, cold, and vandals. When installing a chamber, you can not be afraid that moisture will have a negative effect on the walls of the basement, even if we are talking about condensate.

There are several important principles that should be followed when choosing a location for installing a pumping station:

It is desirable to mount the equipment as close to the source as possible.

Access to technology should be free all year round.

It is important to ensure good ventilation of the room.

Station connection options

Connecting the pump through the well adapter

There are two ways to connect the pumping station to the pipeline:

- Through borehole adapter. This is a device that is a kind of adapter between the water intake pipe in the source shaft and the water pipes outside. Thanks to the borehole adapter, it is possible to draw the line out of the hydraulic structure immediately below the freezing point of the soil and at the same time save on the construction of the caisson.

- Through the head. In this case, you will have to take care of high-quality insulation of the upper part of the source. Otherwise, ice will form here in sub-zero temperatures. The system will stop working or break in one of the places.

This is interesting: The device and principle of operation of the classical water pumping station

Rules for launching and configuring equipment

Before starting the pumping equipment for the first time, it is first necessary to prepare the accumulator, since the stability of the entire water supply system depends on the correctly selected pressure in it.A high pressure in the tank will provoke frequent turning on and off of the unit, which will not have the best effect on its durability. If there is an underpressure in the air chamber of the tank, this will lead to excessive stretching of the rubber bulb with water, and it will fail.

The hydraulic tank is prepared as follows. Before pumping air into the tank, make sure that the pear inside it is empty. Next, check the pressure in the tank with a car pressure gauge. As a rule, new tanks are filled with air at the factory. Hydraulic tanks up to 25 liters should have a pressure in the range of 1.4-1.7 bar. In containers of 50-100 liters, the air pressure should be in the range from 1.7 to 1.9 bar.

Advice! If the pressure gauge readings are lower than recommended, then you should pump air into the tank using a car pump and adjust it, referring to the pressure gauge readings.

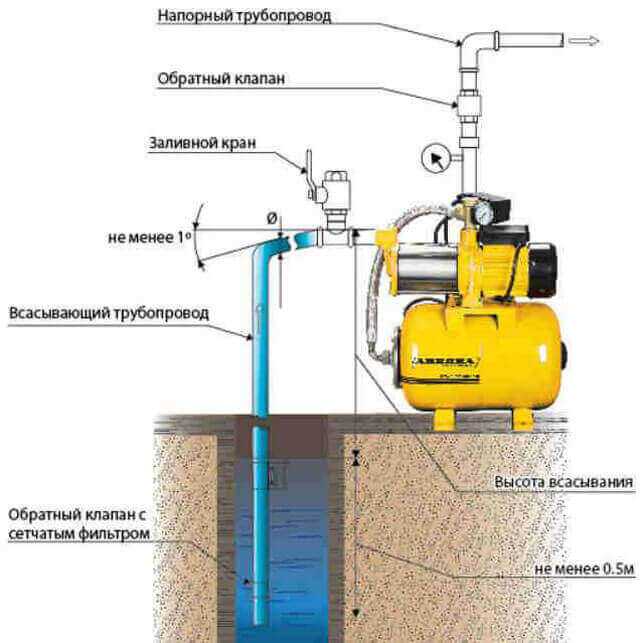

First launch of the station

To correctly start the pumping station for the first time, perform the following steps in stages.

- Unscrew the plug that closes the water hole located on the unit body. On some devices, instead of a cork, there may be a valve. It should be opened.

- Next, fill the suction pipe and pump with water. Stop pouring liquid when it starts to flow out of the fill hole.

- When the suction pipe is full, close the hole with a plug (close the valve)

- Connect the station to the mains and turn it on.

- To remove the remaining air from the equipment, slightly open the tap at the water intake point closest to the pump.

- Let the unit run for 2-3 minutes. During this time, water should flow from the tap.If this does not happen, then turn off the pump and refill the water, and then start the pumping station.

Automation setting

After a successful launch, you need to check and configure the operation of automation. The new pressure switch has factory settings for upper and lower pressure thresholds, upon reaching which it turns on or off the pump. Sometimes it becomes necessary to change these values by setting them to the desired on-off pressure.

Automation adjustment is as follows.

- Turn off the unit and drain the water from the accumulator.

- Remove the cover from the pressure switch.

- Next, you should start the pump to start collecting water in the hydraulic tank.

- When turning off the device, write down the pressure gauge readings - this will be the value of the upper shutdown threshold.

- After that, open the tap at the farthest or highest point of the water intake. As water flows out of it, the pressure in the system will begin to decrease, and the relay will turn on the pump. The readings of the pressure gauge at this moment will mean the lower switching threshold. Record this value and find the difference between the upper and lower threshold.

Normally, the cut-in pressure should be 2.7 bar, and the cut-out pressure should be 1.3 bar. Accordingly, the pressure difference is 1.4 bar. If the resulting figure is 1.4 bar, then nothing needs to be changed. If the pressure is too low, the unit will often turn on, which will provoke premature wear of its components. When overestimated, the pump will work in a more gentle mode, but the difference in pressure will be obvious: it will be unstable.

Advice! To increase the pressure difference, tighten the nut on the small spring. To reduce the difference, the nut is released.

When checking the operation of the relay, pay attention to the pressure with which water flows from the tap. If the pressure is weak, then a pressure adjustment will be required.

In this case, the pressure in the system should be higher. To raise it, turn off the device and slightly tighten the nut that presses the large pressure switch spring. To reduce the pressure, the nut must be loosened.

How to choose?

A pumping station for a summer residence or a private house must cope with its functions, so it should be chosen based on your needs

First of all, it is worth paying attention to a number of the following criteria

Station Specifications

Moreover, the performance of the device is of the greatest importance. It's best to stop your choice at the pumping station, which provides water pressure from a well that satisfies all the needs in the house and on the adjacent plot.

For a normal life of four people, a device with medium or low power is suitable. As a rule, such units are equipped with a 20-liter hydraulic accumulator. Such stations supply water from a well in the amount of 2-4 cubic meters per hour and provide a pressure of 45 meters or more. It is also worth considering the size of the station, the water level with the pump running and turned off, the type of filter, the width of the pipe.

Features of the well, well

The finished pumping station is an installation with a surface pump that draws water from a well by rarefaction. In this case, the ejector may be present in the design of the pump or be remote and must be located in the well. However, if you collect and mount pumping station on your own, you can use a borehole or submersible pump. This is especially true if it is already in stock.

Pumping stations with a built-in ejector allow you to raise water only from a depth of no more than 8 meters. However, they provide good pressure, which exceeds 40 meters. Such installations are not afraid of air ingress, so it is not necessary to fill them with water before starting work. They calmly pump air first, and then water.

Among the positive differences, one can also note high reliability and performance. Of course, there are also disadvantages. One of them is a lot of noise, so these stations are mounted in the house, only in utility rooms with good sound insulation.

Stations with an external ejector are required to draw water from a depth of 20 meters or more. In this case, the ejector is placed in a well or well, becoming part of the intake assembly. Pressure and suction (vacuum) hoses go to it from the installation. Through the pressure hose, water enters the ejector and a rarefaction area is formed in the suction chamber, and through the suction hose, water rises up from the well.

Pumping stations with a submersible pump are also practically not noisy. They can take water from any depth and even at a significant distance from the source of water from the building. At the same time, they are not afraid of air leakage and small leaks in the pipeline. However, clean water is important for them, which means that you will need a powerful filtration system and regular cleaning. Of the minuses, it is also worth noting the high cost of such pumps and possible difficulties in repair and maintenance.

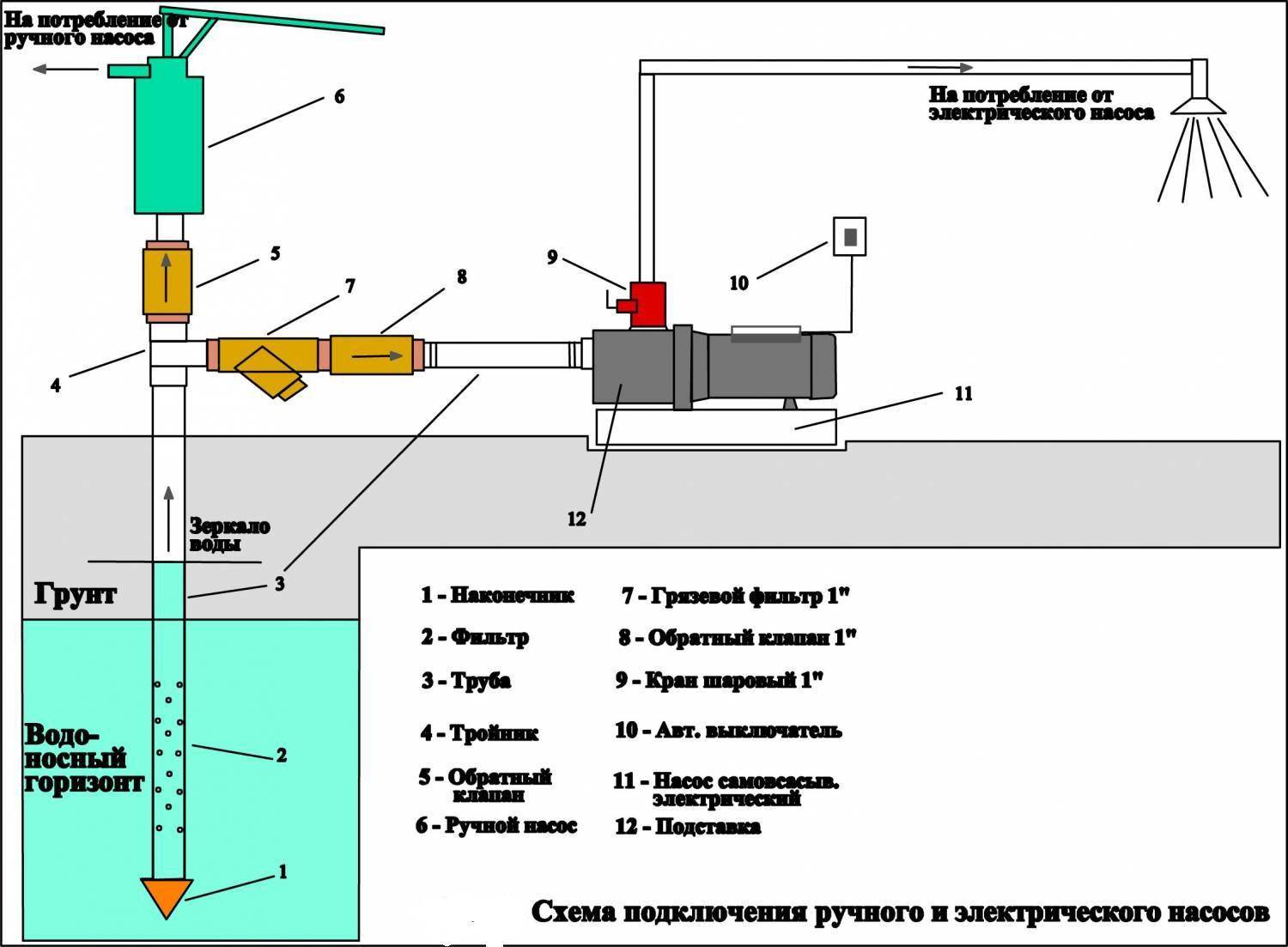

Connecting the deep pump to the water supply system

When constructing an individual water supply system, even at the stage of drilling operations, one should know the diameter and material of the pipeline, the depth of the water line, and the operating pressure in the system for which the equipment is designed. When installing and turning on the water supply, the following recommendations are guided:

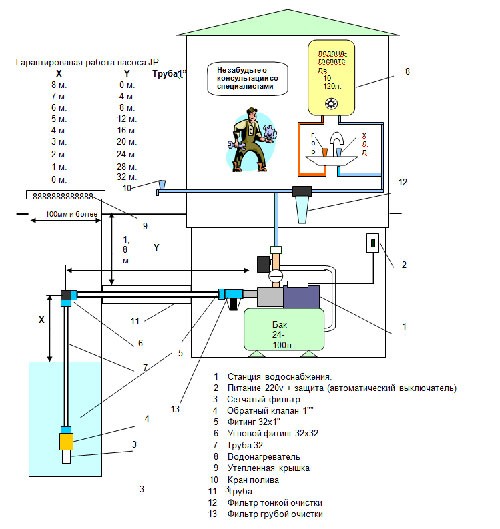

When using the plumbing system in winter, you will have to take measures to protect it from the cold. Typically, pipes are laid underground and they must come out of the head of the well, so a caisson pit will be needed to install and maintain equipment. To make it more convenient and reduce the depth, the water line is insulated and heated with an electric cable.

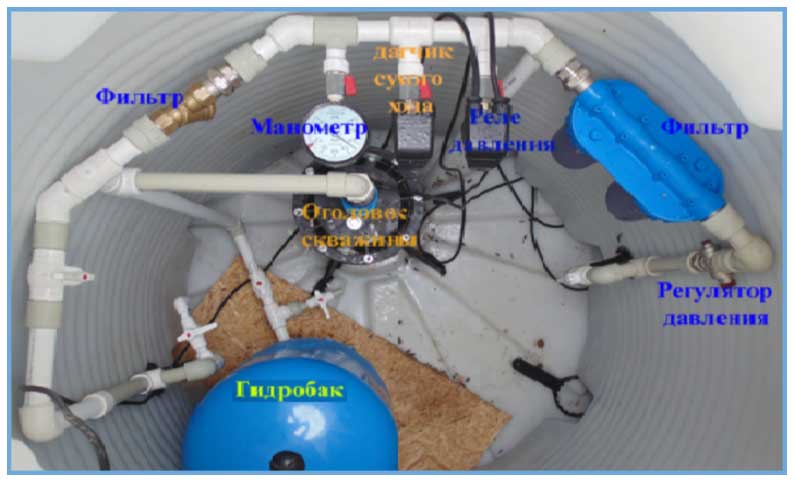

Rice. 6 Assembly of the pump room do-it-yourself stations - main steps

- When determining the immersion depth of the electric pump, set the dynamic level with the equipment turned on and hang the unit 2 meters below the set mark, the minimum distance to the bottom for deep models is 1 meter.

- When using sand wells, it is mandatory to install sand or coarse filters in the water line before the equipment.

- Electric pumps change their pumping efficiency when the supply voltage changes, so for stable operation it is better to purchase a voltage stabilizer and connect equipment to it.

- For ease of operation and maintenance, a do-it-yourself pumping station is often assembled. A pressure gauge and a pressure switch are mounted on the accumulator using a standard five-inlet fitting, but since there is no branch pipe for attaching a dry-running relay, it will have to be installed on an additional tee.

- Often electric pumps have a short power cable, not long enough to connect to the mains. It is extended by soldering, similar to the further insulation of the connection point with a heat shrink sleeve.

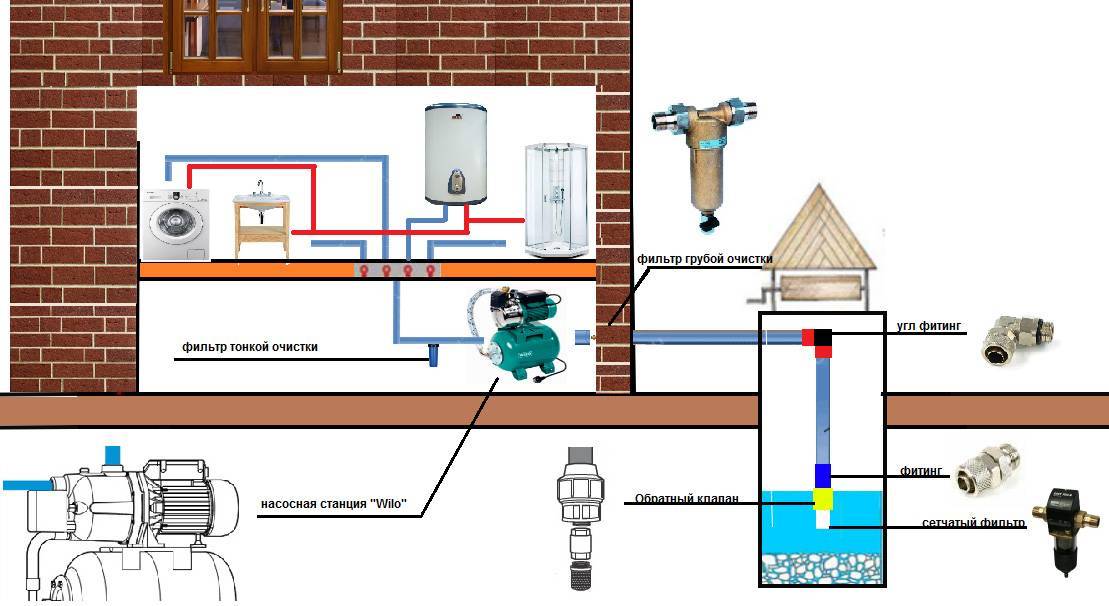

- The presence of coarse and fine filters in the plumbing system is mandatory. They must be placed before the automation of the control system, otherwise the ingress of sand and dirt will lead to their incorrect operation and breakdowns.

Rice. 7 Placement of automatic equipment in the caisson pit

Design features of the pumping unit

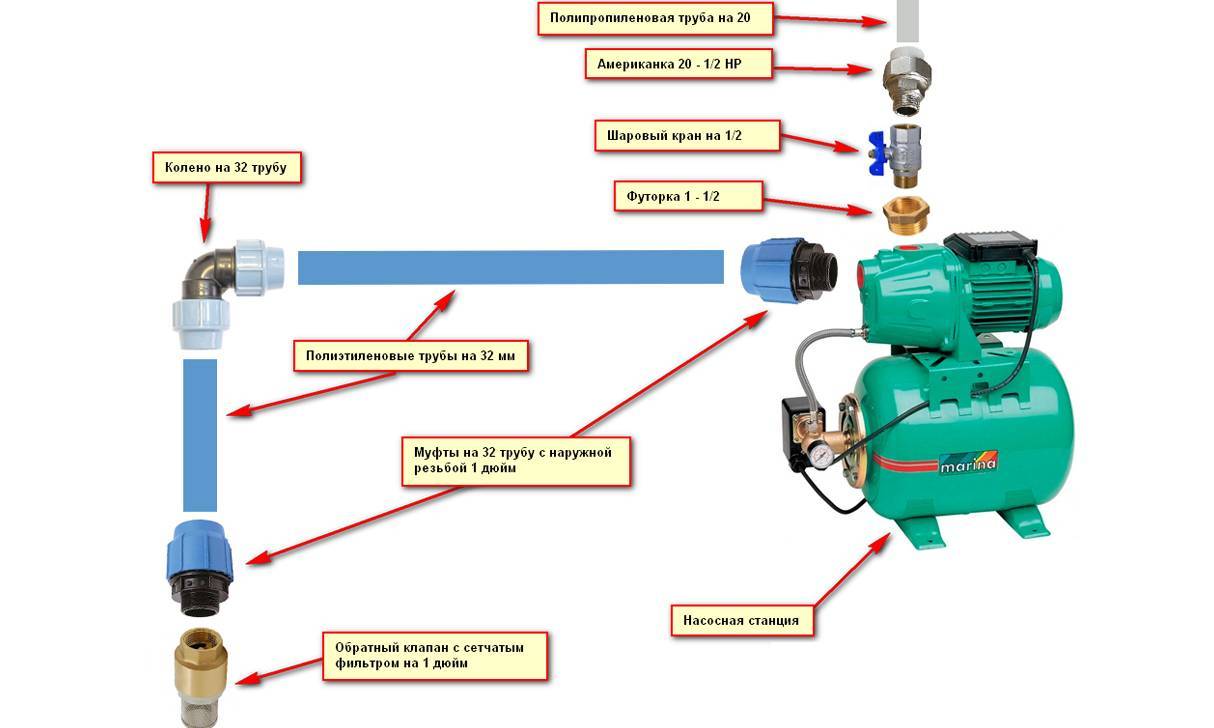

A pumping unit (station) is a whole complex of technical devices, each of which plays a role in ensuring the efficient operation of the entire system as a whole. Typical structural diagram of a pumping unit includes a number of elements.

The main parts of the pumping station

Pump

In this capacity, as a rule, surface devices of a self-priming or centrifugal type are used. They are installed together with the rest of the equipment that is part of the station on the surface of the earth, and a suction hose is lowered into the well or well, through which the liquid medium is pumped out from the underground source.

Mechanical filter

The filter is installed on the end of the hose lowered into the pumped liquid medium. The task of such a device is to prevent solid inclusions contained in the composition of water pumped out from an underground source from entering the inside of the pump.

Screen filters for wells

check valve

This element prevents the water pumped out of the well or well from moving in the opposite direction.

Hydraulic accumulator (hydraulic tank)

The hydraulic tank is a metal container, the inner part of which is divided by an elastic partition made of rubber - a membrane. Air is contained in one part of such a tank, and water is pumped into the other, raised by a pump from an underground source. The water entering the accumulator stretches the membrane, and when the pump is turned off, it begins to shrink, acting on the liquid in the other half of the tank and pushing it through the pressure pipe into the pipeline under a certain pressure.

The device of the hydraulic accumulator of the pumping station

Working according to the principle described above, the hydraulic accumulator of the pumping station provides a constant pressure of the fluid flow in the pipeline. In addition, the pumping station, the installation of which does not take much effort and money, eliminates the occurrence of hydraulic shocks that are dangerous for the water supply system.

Automation block

It controls the operation of the pumping unit. The main element of the pumping automation unit is a relay that reacts to the level of water pressure, which is filled with a hydraulic accumulator tank. In the event that the water pressure in the accumulator drops to a critical level, the relay automatically turns on the electric pump, and water begins to flow into the tank, stretching the membrane. When the fluid pressure rises to desired level, the pump is switched off.

Automation units allow you to automate the operation of the electric pump

Pumping units are also equipped with pressure gauges and pipes, which are used to tie and connect to the main circuit of the water supply system.

It should be borne in mind that a typical pumping unit, which is made on the basis of a surface pump, can be used to pump water from wells and wells, the depth of which does not exceed 10 meters. In order to raise water from deeper underground sources, you can additionally equip the pumping unit with an ejector or assemble a pumping station with a submersible pump, but such a design scheme is used quite rarely.

Installation diagram of a pump with a remote ejector

The modern market offers many pumping stations of various models and brands, the prices of which vary quite a lot. Meanwhile, you can save on the purchase of serial equipment if you buy the necessary components and assemble the pumping station with your own hands.

Types of pumps for wells and their functions

Well water pumps can be submerged into narrow wells to great depths or mounted on the surface. The principle of operation of the device and its installation is as follows:

- Its main elements are impellers mounted on a single shaft.

- Their rotation occurs in diffusers, which ensures the movement of liquid.

- After passing the liquid through all the wheels, it exits the device through a special discharge valve.

- The movement of the liquid occurs due to pressure drops, which are summed up on all impellers.

There are several types of such equipment:

- Centrifugal. Such a pump allows the supply of clean water to be provided without major contaminants.

- Screw. This is the most common device, capable of pumping liquid with an admixture of particles per cubic meter no more than 300 grams.

- Vortex.Transfers only purified water.

Despite the differences, all types of pumps serve to perform similar functions:

- Supply groundwater to private houses and cottages.

- Participate in the organization of irrigation systems.

- Pump liquid into tanks and containers.

- Provide comprehensive water supply in automatic mode.

When choosing a pump for a site, the following criteria are taken into account:

- The original dimensions of the equipment. They must be taken into account to ensure certain technological tolerances when placing the pump in the well.

- Power source of electricity. Borehole pumps are made single- and three-phase.

- Device power. This parameter must be determined in advance based on the calculated pressure and water consumption.

- Pump cost. In this case, it is necessary that the price-quality ratio of the equipment is chosen correctly.

Types of household pumps

Pumps for wells are divided into submersible and surface. Such units have some advantages over the rest:

- Large water intake depth, which is not available for pumps of any other type.

- Ease of installation.

- No moving parts.

- Low noise level.

- Long service life.

The photo shows the types of submersible borehole pumps.

Submersible borehole pumps

Tip: It is very important to follow the competent and proper arrangement of equipment, use only high-quality materials. Violation of installation technology or the use of poor materials can lead to:. Violation of installation technology or the use of poor materials can lead to:

Violation of installation technology or the use of poor materials can lead to:

- Breakage of the pump.

- its premature failure.

- When dismantling, the impossibility of lifting the pump.