- If several convectors in a row

- Here you will learn:

- Installation and connection instructions

- Installation of water heating convectors

- Installation of electrical

- Installation depth in floor and fan

- Water heating convectors built into the floor

- Design

- Types of floor convectors

- Advantages

- Screens for heating convectors

- Short list of manufacturers

- Types of execution of water convectors

- Wall mounted water convectors

- Floor water convectors

- Floor water convectors

- Skirting water convectors

- Basement water convectors

- Autonomous heaters

- Oil radiator

- car radiator heater

- What are convectors

- Advantages and disadvantages of built-in convectors

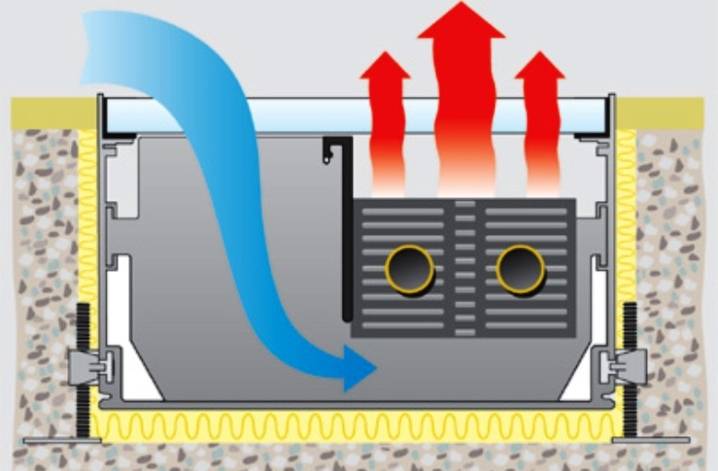

- Device and principle of operation

If several convectors in a row

The following nuance should be taken into account. In our case, 3 floor convectors for water heating were installed, each of which reaches 1800 cm in length

The equipment is equipped with its own gratings. But if necessary, you can always contact the appropriate company and order a solid grating together with the convectors, which will allow you to hide the ugly seams formed when two convectors are connected together. Such seams differ from the general lattice, which violates the overall aesthetics.

In a situation where the underfloor water heating convector is too long, the easiest way out will be to simply cut a hole in the wall of the required shape, which will allow the convector to go deep into the wall, but this is not the best way out. Of course, you can cover up the remaining cracks, but do not forget about the mobility of the grating. If it is pulled out once, a large gap will remain, which will certainly turn out to be a source of drafts, because drafts are always present behind the wall, especially if the installation was carried out in violation of the rules.

It is better to shorten the convector, it has rivets on the end, which should be disassembled and drilled. Next, the excess part of the equipment is cut off, everything inside is removed. We unscrew the rail, pull out the decorative strips, cut them off. We no longer put the rivets back, instead of them we fasten the bolts onto the nuts. We cut the lattice, we collect everything in place. If there is the necessary distance to the heat exchanger, you can shorten the equipment on either side, choose the side that is more convenient for you to work with.

In general, ideally, all dimensions should be agreed upon at the stage of choosing floor convectors or other heating equipment, so that in the future you do not have to resort to additional manipulations. Such planning will avoid the forced cutting of convectors. In order to carry out the installation of convectors correctly, you need to perform certain preparations.

In addition to size, it is also important not to make a mistake with the choice of thermal power of the equipment.

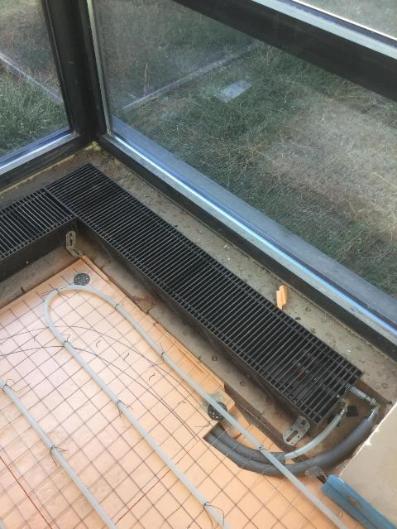

Such a procedure as making a niche in the floor requires a high level of skill and the use of special tools, as it is quite laborious.Installation of a water heating convector provides for the laying of supply and return pipes

When installing equipment, the level of finishing floor coverings is taken into account. Such works can be accompanied by a huge number of nuances that only a highly qualified master can foresee.

If it is required to install floor convectors in a room with a finished floor, the procedure becomes much more complicated. After all, it is necessary to carry out the installation with minimal damage to the existing finish.

Many call water convectors the best devices in the heating system. The most striking advantage is the use of the principle of convection. Heat is distributed by heating the air, not the case. The convector is quite economical. You can not be afraid that a small child will be burned about it. Thanks to this device, condensation does not appear on the glazed surface, the product is not susceptible to corrosion. Water convectors are characterized by heat transfer power. At the same time, the air does not dry out, and the room warms up evenly. As you can see, water-type floor convectors have numerous advantages over other heating devices. Devices surprise with their high quality and wide possibilities.

Here you will learn:

Floor convectors are actively used for heating rooms in which there are large heat losses due to large windows and doors. They are mounted in special niches organized in the draft floors. The procedure is not very simple, but not very complicated either. Let's see how the floor convectors are installed with their own hands. We will also consider some of the features of caring for these heaters.

Installation and connection instructions

The installation of a floor convector is justified if there are elements in the room that form significant heat losses. Such areas can be represented by floor-to-ceiling glass doors, entrance areas to the loggia and exits to the terrace, as well as panoramic or stained-glass windows.

Installation of water heating convectors

To perform the correct installation and efficient operation of the installed device, you must adhere to several recommendations:

- a niche or channel is made with a depth of 1.0–2.0 cm from the total height of the device, and also approximately 5–10 cm more in width and depth;

- the indent from the window is 5-15 cm, and to the left and right of the wall - about 15-30 cm;

- additional protective insulation and sound absorption increase the efficiency of the device;

- it is optimal to connect using flexible hoses, which helps to easily and quickly align the joints;

- rigid connection with a supply valve in the form of a manual radiator valve, ball valve, thermostatic valve is more reliable;

- on the "return" it is necessary to install reliable shut-off valves.

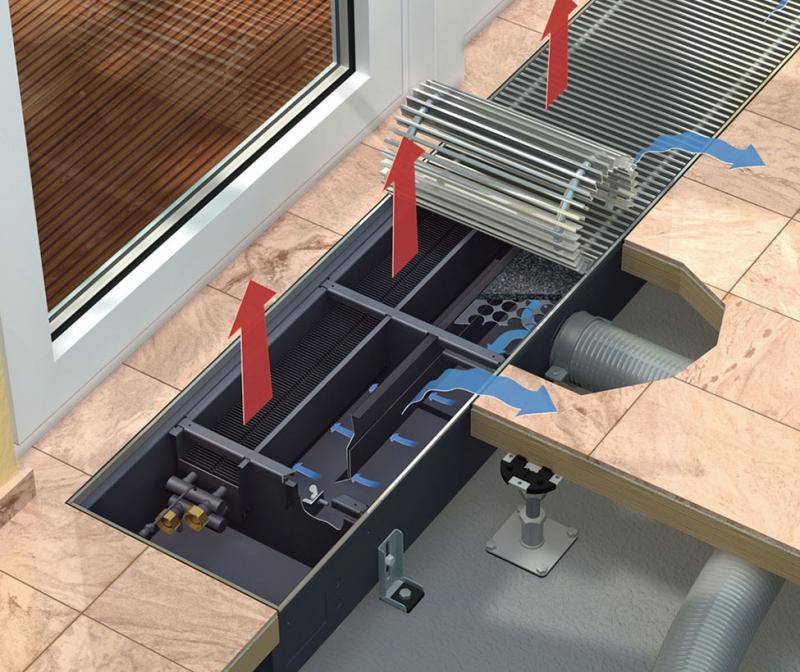

The most difficult to install is a water underfloor heating system with a forced type of ventilation:

-

Lay the supply lines for the heat carrier and electric cable in accordance with the installation diagram supplied by the manufacturer.

-

Fill the floor in accordance with the dimensions of the channel allocated for the installation of the installed device.

-

Install the equipment in the prepared channel, level it horizontally using the adjusting bolts.

-

Fix the convector inside the channel, insulate and seal the space around the device.

-

Install a clean floor covering.

-

Connect the supply of the thermal carrier and the electrical cable.

-

Fill all gaps with silicone sealant or finishing sealant.

-

Perform a test run of the installed equipment and fix the decorative grille.

In the process of designing a heating system, it is very important to correctly position the pipes for supply and return, provide for the drainage of water and the possibility of pumping if air enters the interior. Underfloor water heating convectors with a forced convection option require a mandatory connection to a 220 W electrical network

Installation of electrical

For self-installation of the device, you should purchase an electrical cable and select the optimal connection scheme.

Standard scheme of installation of floor electric convector:

- 1 - devices with the property of convection;

- 2 - electrical wiring;

- 3 - power supply for 220 V;

- 4 - module;

- 5 - thermostat.

The device is connected to the power supply using electrical wiring.

The main stages of installation of electrical models:

- Mount the convector in the niche of the subfloor.

- Fix the device with corners, screws and dowels provided in the kit.

- Align the device with the help of technological bolts.

- Connect electrical cables to the installed convector.

- Lay heat-insulating materials, which are most often used polystyrene foam sheets.

The last stage is quite difficult and requires effort. Thermal insulation consists of the following parts:

- concreting;

- thermal insulation;

- the floor is seamless;

- fixing pad;

- height adjustment;

- soundproofing;

- coupler;

- finishing flooring;

- eyeliner;

- raised floors;

- seals.

An obligatory stage in the installation of an electric convector is the laying of thermal insulation

At the final stage, the performance of the installed heating system is tested, the floor is poured and the final floor covering is laid, as well as the decorative lattice element is screwed on.

Installation depth in floor and fan

Now consider the situation when in your apartment the collector wiring and heating is done on the floor.

First, do not take the word of sales managers. Absolutely all floor convectors heat very poorly. And the smaller the depth of their installation, the worse they do it.

In fact, in central Russia, only the most powerful models with an installation depth of 120mm work normally. And then, if they have an additional fan.

That is, specimens with a depth of 80 and 100 mm in latitudes with a cold temperature practically do not work.

From such work, you will get misted windows, and the temperature in the room is no more than 17 degrees.

Sometimes there is even mold on the walls and ceiling.

But still there are those that more or less work (with a fan and a depth of 12cm). Let's take a look at them.

Let's start with the fact that the presence of a fan is:

additional troubles with electrics on the floor

additional problems with its inclusion-disabling

extra electricity bills

and most importantly, the constant noise from his work

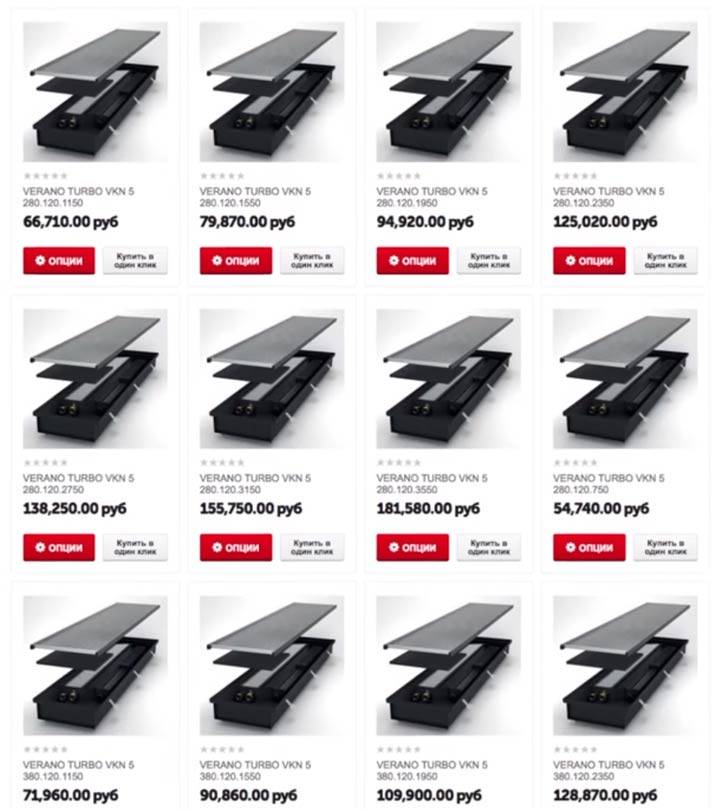

If you want a silent and quiet fan, don't be surprised by the price. It starts from 50 thousand for such models. rubles and reaches 200 thousand.

If we take for comparison the same ordinary radiator battery, then with the same heat transfer parameters, all your costs will be limited to 5 thousand.

At the same time, the fan itself is a very short-lived thing. No manufacturer of convectors gives a guarantee for more than 1 year.

It is also very difficult to find manufacturers who would sell fans separately. And this means that if it breaks, you will most likely have to buy a whole convector again.

Water heating convectors built into the floor

Convectors built into the floor are installed in apartments and private houses, in car dealerships, entertainment venues, hospitals, shops and other organizations. In rooms with a large glazing area - swimming pools, greenhouses, airport buildings, on the terraces of country houses and cottages - an underfloor heating convector will be the best choice.

The price of a floor water convector depends on the manufacturer of the device, its dimensions and type, design features and technical characteristics.

Design

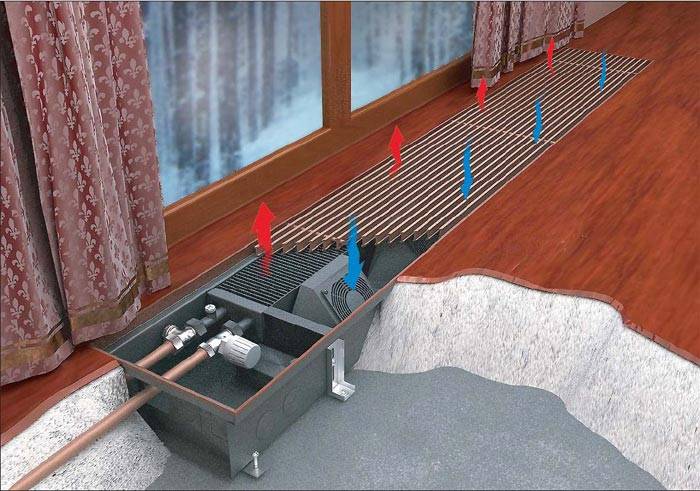

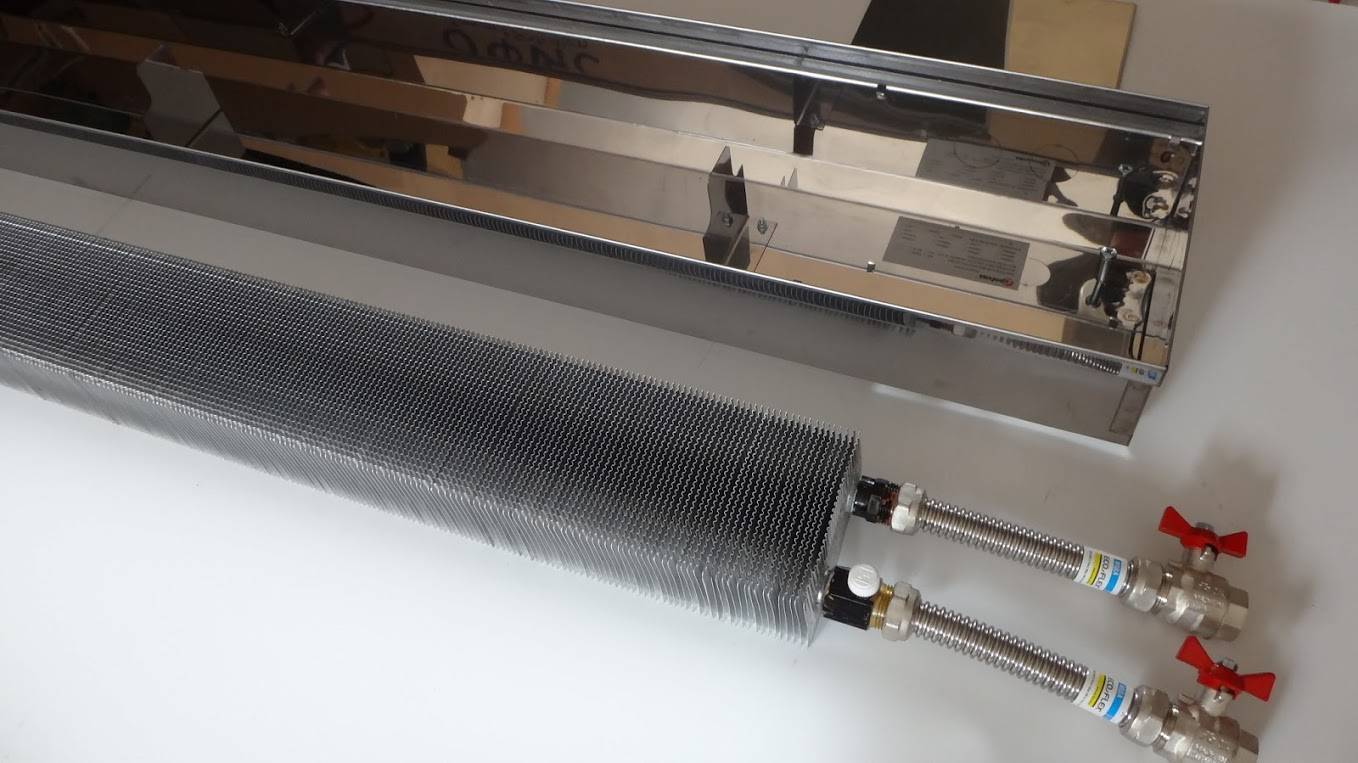

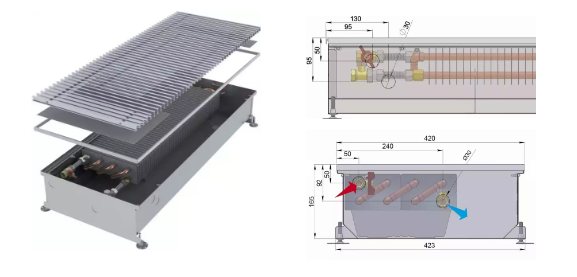

A water heating convector built into the floor is a heat exchanger placed in a special casing. The heat exchanger is a copper-aluminum heating element with high resistance to corrosion, which is connected to a hot water heating system.

The casing of a built-in convector is usually made of thick sheets of galvanized or stainless steel and provides reliable protection of the floor covering in case of possible leakage.

The casing with the heat exchanger is installed in a pre-prepared niche in the floor or directly into the cement screed and is closed with a decorative grille that makes invisible and protects the interior of floor-mounted heating radiators.

In other words, the visible part of the built-in convector is a decorative grille located on the same level with the floor covering, which can be made of various materials with a wide variety of textures, shapes and colors, and additionally painted in the required color, in accordance with the wishes of the client. .

Types of floor convectors

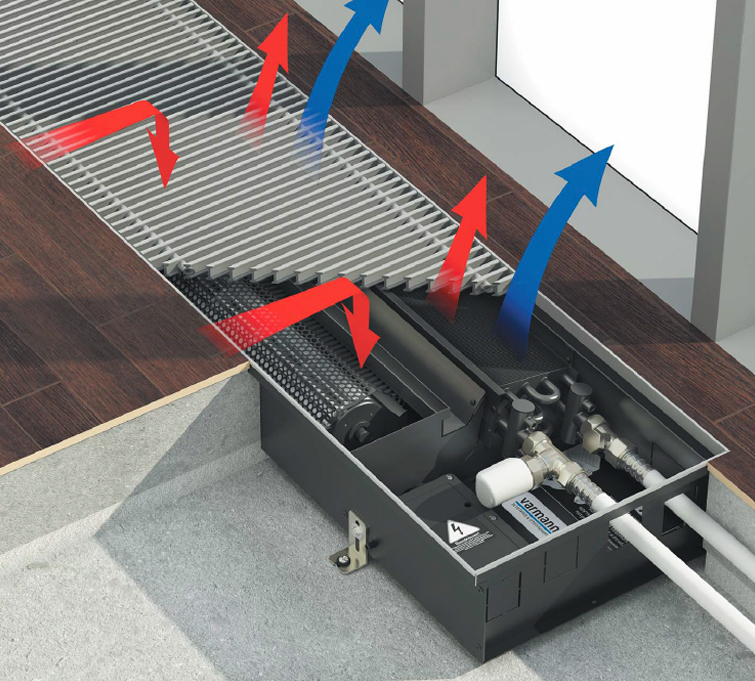

Floor convectors are divided into two types:

- convectors with natural convection;

- convectors with forced convection, with a built-in tangential fan, which contributes to a more intensive heat exchange.

As a rule, convectors with a fan are used as the main heating device in the room.

Convectors with natural convection are auxiliary heating devices. They are designed to isolate large windows and doorways from cold air and are used with underfloor heating or radiator heating systems.

A control system can be connected to floor convectors of any type.

Advantages

Water convectors built into the floor have undoubted advantages compared to conventional heating radiators:

- saving space, due to the fact that heating radiators are located in the floor;

- attractive appearance that does not violate the overall aesthetics of the interior and can fit into the design of any direction;

- a wide variety of standard sizes, allowing you to choose a heating device for the parameters of the room, providing the necessary heat transfer;

- reliability, efficiency and durability of devices, provided by the use of high quality corrosion-resistant materials.

Screens for heating convectors

The screen for the heating convector is a special overlay on the device that improves its aesthetic appeal. The decorative screen is made of different materials: plastic, glass, wood, metal. This panel must have holes for air circulation. They provide efficient heat transfer. With an insufficient number of holes or their small size, the heating efficiency is reduced by 50% maximum.

When choosing a screen, pay attention to the following important points:

The material the element is made of. Wooden overlays are not recommended for use in a room with high humidity, and glass screens transmit heat energy worse. When choosing a plastic lining, give preference to elements made of heat-resistant plastic that do not deform when heated. Metal panels are the most reliable and durable, but they must have a protective powder coating.

According to the method of fastening, the screens are hinged, sliding and attached. The easiest way is to install a hinged or attached structure. The hinged screen has special fasteners that allow you to hang it on the radiator from above. Attached panels are mounted on a niche in which the heating device is installed. Both types can be easily dismantled if necessary. A sliding screen is much more difficult to install because it has doors.But this model provides quick access to the heater.

There are many color options and screen configurations

It is important that the dimensions of the panel fit the dimensions of the heating unit or niche. Most often, overlays are white, but there are also models with interesting decor and different color options on sale.

If necessary, the white screen can be painted in the desired color.

When choosing the right radiator cover, keep the ease of maintenance in mind. Please note that in the kitchen, a small grate will quickly become dirty, and it is not easy to clean it from grease and soot. Plastic pads are simple and easy to use. They are inexpensive and come in a variety of colors.

Short list of manufacturers

To facilitate the choice, we suggest that you familiarize yourself with the most famous manufacturers of convectors, their products have positive reviews from numerous consumers.

| Brand Name | Technical specifications |

|

Verano | Made in Poland, can be with natural or forced convection. The thickness of the aluminum plates of the radiator is 0.22 mm, the steel box with a zinc-magnesium coating. The diameter of the main copper tubes is 15 mm, the body dimensions are from 100 × 50 mm to 200 × 100 mm. It is completed with aluminum, wooden or stainless steel gratings. |

| Kermi | They can be with or without fans, the depth of the box is 18–35 cm, the width is 9–20 cm. It is used as additional space heating, installed at the entrance doors, stained-glass windows. The low mounting height allows the devices to be mounted on thin interfloor ceilings. |

|

Mohlenhoff | German floor convectors. They can have radial and tangential fans, there are options for electric heating. Depth 7–19 cm, width 18–41 cm. A wide range of models makes it possible to increase the scope of equipment use. The maximum pressure is 16 atm., working 10 atm. Can function in one - and two-pipe systems of heating. |

|

Jaga | The box is made of galvanized steel, width 14–42 cm, depth 6–19 cm. Made in Belgium, small size significantly expands the scope of use. They can have natural or forced ventilation of the heat exchanger. Service life not less than 30 years. |

|

Kampmann | Hi-End class devices operate with forced or natural ventilation. Made in Germany, the company was founded in 1972. Depth 9–20 cm, low noise fans. The heat exchanger has aluminum fins and can withstand temperatures up to +120°C. |

|

Minib | Produced in the Czech Republic, they have a reduced height (from 5 cm), which allows you to install devices on thin floor bases. The box is made of stainless steel. Have a wide choice of decorative lattices. |

|

Heatmann | During manufacture, the most modern technologies are used, due to which the efficiency factor is significantly increased. Convectors are made in Germany, the box is made of powder-coated galvanized steel. Width 10–42 cm, depth 8–20 cm. A wide range of sizes allows consumers to choose the best option, taking into account the size of the room and the specific installation site. There are options with natural and forced ventilation of the heat exchanger. |

|

Itermic | Devices manufactured by a domestic company, galvanized steel casing, there are options with and without fans. Depth 7–19 cm, width 20–40 cm. Copper heat exchanger tubes, aluminum lamellas. The thickness of the lamellas is 0.5 mm, the diameter of the tubes is 16 mm. Are calculated on working pressure of 15 atm., pressing 25 atm. There are manual or automatic control modes of operation. |

|

Varmann | They are widely used in Europe and our country, the body is made of galvanized steel, options for the electric version of the heater are provided. They can work both for heating and for cooling rooms with natural or forced convection. Depth 9–20 cm, width 14–37 cm. |

|

Polvax | The manufacturer is a Polish company, they can have one or two heat exchangers, which increases the heat output. Housing made of alloyed sheet steel, depth 7–34 cm, width 18–38 cm. Tube diameter 22 mm, coolant temperature up to +90°С, working pressure 10 atm. |

Each company produces a wide range of equipment according to technical specifications, which makes it possible to find the most suitable convector option, taking into account the maximum number of different factors.

Types of execution of water convectors

By type of execution, water convectors are very diverse, which allows you to install them in any room, as well as hide them in the finishing elements, for example, convectors are:

- wall;

- floor;

- intrafloor;

- plinth;

- basement.

The principle of operation of different types of convectors is practically the same, the difference lies only in the location of the gratings for air intake and outlet.

Types of water convectors

Wall mounted water convectors

In appearance, wall-mounted models are not much different from conventional radiators. They are attached to the wall with brackets, usually installed under the windowsill or on the outer, coldest wall.

At the same time, it is important to observe the distances to the floor and window sill indicated in the passport in order to ensure the free movement of air flows.

Wall mounted water convector

Wall models of water convectors differ in thermal power and geometric dimensions, the number of heat exchangers and the material from which they are made. Additionally, wall convectors are equipped with a Mayevsky crane, control valves and a thermostat.

Floor water convectors

The convenience of floor convectors is that they can be installed anywhere without being tied to walls. Floor models are often used to heat studio apartments without internal walls. Heating pipes are located in the floor

Air intake in floor convectors is carried out from below, so it is important not to block them with furniture

Floor convector

The original solution is a convector-bench, it is equipped with a comfortable seat made of wood, which does not interfere with the movement of warm air. Such convectors are installed in shopping centers and other public places, as well as in greenhouses and winter gardens. You can also install floor convectors in ordinary apartments, placing them on the floor under windows or at the front door - where they create a thermal curtain.

Floor water convectors

Floor-mounted models are often used to heat rooms with panoramic windows or for rooms made in a minimalist design.Floor convectors do not take up extra space, they can be placed in any convenient place. The body of the convector is built into a special niche in the floor, the pipes are also laid hidden. Pipe laying and a niche are performed at the stage of pouring the floor screed.

Floor convector

From above, the convector heater is closed with a grate made of wood, plastic or metal, the choice of material depends on the finish of the floor. The grate is installed flush with the finished floor, which facilitates movement on it. Air intake is carried out through the same grate as its outlet. Floor convectors can be used as an independent source of heating or additional - to create a thermal curtain in front of windows and doors.

Air circulation in floor convector

Skirting water convectors

Another way to successfully hide heaters is to install baseboard water convectors around the perimeter of all cold walls. Skirting convectors consist of heat exchangers connected in parallel or in series and connected to heating pipes. The heat exchangers are closed with aluminum or steel casings with an air outlet grille.

Water heating (cottage) allows you to maximally equalize the temperature in the room and normalize the humidity. The closed circuit significantly reduces heat loss. Skirting models are compact and fit well into the design of the room, in addition, they allow you to hide the heating pipes under the body.

Convector heater-baseboard

Basement water convectors

Socle models are also embedded, but the possibilities of their application are much wider.Basement convectors are mounted in wall niches, partitions, steps or interior items, which allows you to make the heating system almost invisible and bring heat to those parts of the room where it is most needed. How to install a stove with a water circuit for heating a house, you can read in our article.

The placement of basement convectors is planned at the stage of rough finishing: niches are prepared, hidden pipelines are laid, wiring and shutoff equipment are installed. At the same time, inspection hatches must be made at the location of the shut-off valves.

Basement convector built into the stairs

Autonomous heaters

What to do if there is no central heating and gas in the garage, and the frequency of your visits to the premises does not allow organizing a scheme with a solid fuel boiler?

In this case, it would be quite logical to use electricity for heating.

Oil radiator

The simplest homemade oil cooler is a welded register already familiar to us with several modifications.

- There are no welds for connecting to the piping.

- The register, as a rule, is made portable, which implies the presence of legs.

- Jumpers between sections are present on both sides. Their diameter is made somewhat larger than when assembling a register for water heating. The instruction is related to the fact that natural convection implies a minimum hydraulic pressure, and if so, the hydraulic resistance should also be minimal.

- A heating element or several parallel connected heating elements are installed at the end of the lower section.

- Oil acts as a heat carrier.Ideally - transformer, but even working out will do.

- The register is supplied with a small open expansion tank. As an option, the oil is not added a little to the top of the register, and the weld on its upper section is equipped with an automatic air vent.

car radiator heater

Another interesting solution is a homemade garage heater from a radiator.

Numbered on the diagram:

- Radiator.

- Expansion tank.

- Forced blower fan.

- A casing that protects the fan blades.

- Water pump.

- Pipe for oil supply.

- Actuator.

- Fan drive belt.

- Electric motor.

- Frame stand.

- Drain tap.

- Block of heating elements.

- Blinds to adjust the direction of the air flow.

- Partially clogged radiator tubes are not a hindrance. They will miss the oil.

- Optimum motor performance - 300 - 500 watts at 1500 rpm.

- To heat the oil, heating elements with a total capacity of up to 3 kW are used. It is better to provide for stepwise power adjustment by switching them on separately.

- Due to the small diameter of the radiator tubes, it is not worth using mining in this design. Suitable transformer oil or antifreeze A-40.

- The most efficient operation of the heater will be at an oil temperature of about 80C. The temperature is regulated by the selection of the power of the heating elements and the fan speed.

What are convectors

According to the principle of working with energy carriers, there is a wide choice of such equipment. But now most convectors sold in stores have an electric heater. There are models that run on gas - gas convectors.

Electric convectors are best suited for heating apartments, as they are compact in size.It is more profitable to operate convector heating of a summer house or a country house, creating it on the basis of gas convectors - gas is much cheaper. Of course, subject to the presence of gas in the house.

According to the installation method, convectors can be divided into:

- floor;

- Wall mounted;

- Mounted in the floor or plinth.

- Floor convectors are installed on the floor, they can have wheels for moving along the floor surface, or they can be rigidly installed, without the possibility of movement. A photo with a floor convector is just below.

- Wall convectors for heating are mounted directly on the wall using special brackets.

- The third type of convectors can be installed in the floor or in the floor plinth.

Advantages and disadvantages of built-in convectors

Underfloor water convectors have a whole range of advantages:

- Convectors heat up to the required temperature much faster than traditional radiators.

- Due to the creation of a large number of hot air flows, a room with water convectors heats up more efficiently and faster than a room of the same size with conventional batteries.

- Built-in convectors are lightweight and compact in size, so they fit perfectly into absolutely any interior, remaining almost invisible even in small rooms. This is beneficial not only from an aesthetic point of view, but also from a functional one: the appliances do not take up much space, so the space near the walls remains free - it can be used at your discretion.

The convector allows you to evenly heat the room

- If the appliance breaks down, there will be no need to destroy the flooring - just remove the grate to carry out repairs.

In fairness, it should be noted the disadvantages of built-in convectors:

Dust quickly accumulates inside the housing, which not only clogs the heat exchanger, thereby reducing its functionality, but also actively spreads throughout the room along with air flows.

Device and principle of operation

Fame for underfloor heating devices came after the popularization of panoramic window structures on the market. Standard classic heaters were not able to cope with the constant humidity and cold in modern rooms, which led to the creation of completely new floor-mounted heating devices.

Floor convectors are heating devices of the latest generation, which are designed to effectively heat rooms of any size and fit perfectly into any style solution. The most important advantage of such devices is to save free space - they are installed in an already prepared floor niche and are covered with a special decorative grille flush with the floor level.

Floor convectors that run on electricity are necessarily equipped with a tubular electric heater, or heating element. This makes their installation possible in absolutely any place with access to the electrical network. In terms of installation, such devices are much simpler than water convectors, since no extra wires are required, but they cost much more and hit the wallet harder.

Convectors built into the floor, running on water, are more appreciated for their budget price and insignificant financial costs at the time of use. Unfortunately, such units require a full-fledged heating main. The principle of operation of such a device is slightly different from convectors powered by electricity. Only convection heat flow is involved here, while radiant heat flow is also present in electrical models.

Concerning the design, water floor convectors look like this: a convection heat exchanger is placed in a metal case and is directly connected to the pipeline. The upper or outer part of the body of such a device is equipped with a special grille. The grill, in turn, is made of heat-resistant materials, made in a certain style and is able to withstand a certain external pressure (weight).