- Connection according to the type of toilet outlet

- Vertical

- Horizontal

- oblique

- Rules for connecting the toilet to the water supply

- When to install a corrugated connector

- Types of connecting elements

- Corrugated connection

- Mounting procedure

- Sewer pipe preparation

- Corrugation installation

- What is important to consider when installing

- Fixing the toilet to the floor

- The procedure for connecting the toilet with corrugations

- Features and purpose of corrugations

- The procedure for connecting the toilet with corrugations

Connection according to the type of toilet outlet

Note that the connection of the toilet bowl to the sewer should be carried out, taking into account the type of outlet of the toilet bowl. And it comes in three types: vertical, horizontal and oblique. We will discuss each type in more detail below.

Vertical

Many people are wondering how to connect the toilet to the sewer if it has a vertical drain? It is popular to install such models of toilet bowls in the bathrooms of country cottages and old multi-storey buildings. They have a certain feature: a siphon and a branch pipe are a constructive part of such devices, and after installation it will not be possible to see them.

Such a toilet can be installed close to the wall, because in this case you do not need to worry about space for the location of pipeline fittings. Installation of this kind of plumbing is carried out after dismantling the previous model and removing the old solution from the surface of the site. To do this, mark up for future fasteners, and then install a screw-type flange with a retainer and a hole for docking into the floor. At the end of the work, you need to check the coincidence of all holes and joints, and then turn the toilet.

Note that all flanges have the same dimensions, and vertical models of toilet bowls almost always include accessories for tight connection with flanges. That is why it is not difficult to do the work of installing them with your own hands and without the help of a professional plumber.

Initial stage of work

Initial stage of work

Flange installation

Flange installation

Horizontal

Connecting a toilet bowl to a horizontal sewer to a riser is quite simple. To do this, the product is installed at a short distance from the pipe socket, which must be taken into account when planning a bathroom.

If we are talking about an apartment in a high-rise building, then it is unreasonable to create a sewerage wiring with a horizontal outlet in it. The fact is that it is extremely problematic to build a 110 mm pipe into the floor or hide it in a decorative box.

In this case, qualified specialists recommend connecting the device to a vertical riser using a sealing cuff or corrugation. Qualified specialists recommend that the created connection be treated with liquid silicone. This will help prevent leaks or unpleasant odors in the bathroom.

If it is necessary to shift the center of the outlet in relation to the socket of the sewer system, then a corrugation or a corner with a short pipe should be used to connect the elements.Plumbing is connected to the sewer by using a rubber cuff, which allows you to complete the work quite quickly.

Connection with a downpipe

Connection with a downpipe

oblique

If you need to make a reliable connection of the toilet bowl with an oblique sewer, you will need to prepare a cement mortar. With it, you should dock the oblique outlet with a socket made of cast iron. But first, a layer of a mixture of minium and drying oil is applied to the release of the product. Next, you need to take a resin strand and carefully wind several layers of material, leaving one end hanging freely. Then, the outlet should again be smeared with red lead and mounted in the sewer socket. Remember, the plumbing product must be clearly fixed.

You can also use another method to perform this operation. It is less hassle and more efficient. To do this, you will need to use a rubber cuff, which is put on the outlet pipe, and then it is connected to the central sewer pipe.

For maximum resistance to stress, durability of the created connection, you must first very carefully clean off the remnants of the solution from the socket. If the toilet needs to be moved away from the opening of the sewer system, you will need to use corrugated pipes.

Rules for connecting the toilet to the water supply

In order for this plumbing product to work properly, it is necessary to not only connect it to the sewer, but also connect the toilet bowl to the water supply system. This operation is performed only after the entire installation of the toilet bowl is completed, including connecting it to the sewer.

Typically, the rules for connecting a toilet to the water supply are as follows:

- The water supply to the toilet should be carried out carefully, since in the event of any mistake, water can constantly flow into the tank, which sooner or later will lead to a flood first of your apartment, and then of your neighbors.

- There are 2 types of eyeliner - it can be performed from the bottom of the tank and requires more thorough sealing, and there is a side one, which is most often found in toilet bowls of older designs.

- The toilet cistern is connected to the water supply using a flexible hose.

The latter option is simpler, and is also possible with the help of a hard liner, which is hidden in the wall. Despite the different types of connection, be sure to use a tap that shuts off the water. The tap is necessary to shut off the water in case of repair work, as well as according to safety rules, for example, in order to shut off the water in the event of a long absence of a person in the apartment.

Floor drain requires additional connecting elements, as well as certain toilet bowls designed for this type. If other types of drain are used, then it is necessary to use different adapters, special corrugations and other fittings that allow you to connect the toilet to the sewer.

When to install a corrugated connector

It is permissible to install such a pipe when other options cannot be used:

- corrugation is used as a temporary measure, at the construction stage or in the event of an existing pipe leak, and it takes more time to select, purchase and deliver a new one;

- changing the existing layout of plumbing fixtures in the bathroom: the toilet bowl is shifted relative to the sewer riser, the floor level becomes higher;

- discrepancy between the diameters of the toilet drain and the pipe pipe of the sewerage system;

- the plumbing fixture was replaced, and when buying a new one, the type of outlet was not taken into account: straight or oblique.

The reason may be the repair. In this case, the cladding is often mounted on top of the old coating. The bathroom also has household appliances, such as a washing machine. Often problems arise when installing communications when you need to install a new plumbing fixture in a bathroom where pipes have not changed for a long time.

Types of connecting elements

If it is impossible to directly connect the toilet bowl to the sewer due to the design features, auxiliary materials are used - connecting pipes. In most cases, the following types are used:

- corrugation;

- eccentric cuffs;

- corners and bends made of plastic;

- pipes of various materials, but preferably plastic.

The disadvantages of using corrugations to connect the toilet to the sewer include a large minimum length. If the distance between the nozzles is about 12 cm, it's better to choose on other connecting components.

These data will allow you to choose the most suitable cuff model in the store. The disadvantage of the eccentric part is its small length, which implies the possibility of installation only with a small distance between the nozzles (up to 12 cm).

Elbows and corners are installed in cases where the corrugation cannot be used for any reason. Their advantage compared to corrugations is that they have a smooth wall from the inside, which significantly reduces the risk of blockages.

The main disadvantage is rigidity, which leads to leakage even with a small skew. Plastic products can be cut to fit the required size, unlike cast iron.

In most cases, steel pipes are used when there is a danger of the hydraulic lock mechanism breaking (find out what it is water trap for sewerage, its principles of operation, what types there are, etc.). If the throughput of the riser is insufficient, liquid from the siphon will be drawn into it.

As a result, the water seal does not work, and the stench from the sewer enters the room. In such a situation, a tubular product with an automatic valve is connected to a riser or pipe connected to the toilet. When draining, a special valve opens and air enters, which prevents the disruption of the water seal.

However, to implement such a function, it is not necessary to use steel pipes. There are also eccentrics and adapters that give the pipeline similar properties. To ensure the reliability of the connection, it is recommended to use a sealant when using any type of connecting elements.

For these purposes, it is advisable to purchase a special waterproof product designed for plumbing fixtures. By loosening the rubber sealing collar, the sealant will prevent leakage.

Corrugated connection

Brief algorithm of actions:

- Lubricate the joint with silicone and insert the corrugation with a sealant into the opening of the pipeline. It is advisable not to move it until the silicone-based product has completely dried.

- Put the toilet, check its stability. If the product wobbles, level the floor or install special stands.

- Insert the corrugation into the toilet pipe, nothing is required to lubricate the connection.

- Pour a few liters of liquid, wait 1 minute, then check for leaks. If the connection is leaking, you need to disconnect the corrugation, check the correct position of the seals and carefully reinstall it.

- If there are no leaks, you can mark the attachment points of the plumbing fixture with a pencil or marker.

- Fix the product so that it does not swing.

- Connect to sewer.

- After 2 hours, test by making several drains. Wait 5 minutes, if the pipe does not leak, you can proceed with the installation of the tank and other elements.

- Lubricate the joint with sealant from the outside to prevent leaks in the future.

If a small leak (a few drops) was detected during the last test, it is necessary to completely remove all liquid and remove the corrugation. Then again apply silicone to the elastic of the product and install it on the toilet pipe.

Mounting procedure

The first step is to prepare a sewer hole. In order for the corrugation to stand up qualitatively, it must be clean and smooth. If you are going to do installation work in a new building, then, of course, no preparation is needed, since all the pipes there are new.

But if we are talking about an old house, then, most likely, a cast-iron pipe was installed there from the toilet to the sewer. Moreover, usually the toilet outlet was built into the cast iron tightly, this was done with the help of cement mortar.

If you have just such a case, then you will have to change the entire toilet. You can read about this entire procedure in other articles on our portal, but here we will talk exclusively about working with the drain.

Sewer pipe preparation

So, we have a cast-iron knee in which the toilet is cemented. We take a hammer and just break the sanitary ware right at the pipe. Before doing this, be sure to put on safety glasses so that the fragments do not get into your eyes.

Now it is necessary to remove cement residues and various hardened deposits from the inner walls of the pipe. To do this, we again need a hammer: gently tap the cast iron on all sides with it. Do not overdo it, otherwise you can split the pipe, since old cast iron sometimes surprises with its sudden fragility.

When you get rid of all global deposits and other interference, treat the pipe from the inside with a cleaning agent such as toilet "Duckling". Let it work for about 10-15 minutes, and then thoroughly scrub the walls using a wire brush.

Finally, wipe the cleaned surface with a rag. The most important area that should be given more attention at all stages of cleaning is a piece of pipe at the very exit, about five centimeters. It is his condition that will directly affect the quality of docking with the corrugation. Therefore, this area must be properly prepared, absolutely clean and smooth.

Corrugation installation

So, the drain is prepared for docking, you can proceed directly to the installation. Please note that the corrugation should be a third longer than the distance between the outlet and the sewer hole. Therefore, before buying, do not forget to take the necessary measurements.

For installation, we need the corrugated pipe itself, rubber cuffs, seals and silicone-based sealant. The procedure is extremely simple.

- We apply a thick layer of silicone sealant to the edge of the sewer hole.

- We install a rubber cuff-seal in this place.

- We are waiting for the silicone sealant to completely dry, it usually takes about two hours. A more accurate time is indicated on the package. Until the moment of drying, try not to touch the pipe at all, so as not to disturb the reliability of the connection with the sewer.

- Now find the rubber tip located on the opposite end of the pipe. It also needs to be coated with a silicone layer.

- Pull this rubber tip over the toilet pipe and wait again until the sealant has completely cured.

Finally, test the system: draw a full tank of water several times and drain it, while carefully inspecting the corrugation for leaks. If none are found, then congratulations - you did it!

Important note: if during the installation process it turned out that the corrugated pipe needs to be stretched, do it evenly along the entire length. If you stretch any one section, then in the end you will get the very sagging that was mentioned above.

I am sure that if you follow all the nuances described in the article, you will successfully solve the problem of connecting a toilet bowl to the sewer using corrugations. Just in case, watch the video as well, so that the knowledge is definitely fixed in your head. Good luck!

What is important to consider when installing

Old houses equipped with cast iron pipes, plumbing

connected using the following workflow:

- The outlet can be inserted into the pipe hole, and the excess

the gap is smeared with a cement mixture; - Oblique outlet can be connected with a cuff;

- Corrugation is used in cases where the toilet is turned

relative to the angled flare. Except

In addition, the corrugation can be used when, after repair, the toilet is installed on

the pedestal and outlet do not match the sewer hole; - To prevent odor from entering the apartment

sewerage when installing a horizontal outlet, you should put on a cuff made of

rubber. And only after that connect to the socket.

You may notice that installing a toilet on your own is not

cause special problems for the owner of the apartment. Especially if he has at least

small skills or desire to learn new things. Any type of plumbing has

complete instructions containing the procedure. With such a document, do

toilet installation will be even easier.

If there is uncertainty, then it is easier to order a turnkey installation.

Everything useful about sewerage -

Fixing the toilet to the floor

After collecting the entire structure, you can proceed to the installation of the toilet bowl directly to the tiled floor. To do this, it is advisable to wash the tile before installation, so that the markings where the toilet will be placed can be better seen.

In addition, if for some reason it is not possible to drill holes in the tile, then sealant is also used for fastening. Even if in the future you want to change the toilet, its dismantling will not cause any difficulties, since the sealant is well cut and easily removed. Just make sure the surface is clean and dry before applying the material.

You also need to remember that if you install the toilet on silicone sealant, it is better to immediately attach the main structure with the tank. This installation option will be much more convenient, because it will take a day for the silicone sealant to harden.

Be sure to put the toilet only on a clean finished surface of the tile.Otherwise, if you install the finish on an unfinished floor, then during the dismantling of the toilet bowl, you will have to remove it along with the floor covering.

After the finished toilet bowl has been fixed to the tile and to the sewerage system, they proceed to the final stage - connecting to the water supply. Usually water is connected to the tank through a flexible pipe.

The procedure for connecting the toilet with corrugations

Connecting the toilet to the sewer drain using a corrugated pipe is not difficult, but it is necessary to take into account and follow a certain procedure. To connect the corrugation to the toilet, it is best to choose the time before it is installed at a permanent place of operation.

Connecting a new device does not require additional processing, but connecting a previously used one requires stripping the exits and removing layers of sealing and cement.

In addition to the toilet outlet, it is necessary to clean the sewer entrance. If you ignore this item, then the quality installation of the corrugations will be in doubt. After the cleaning work has been carried out, it is necessary to proceed with the main installation steps for connecting the corrugation to the toilet.

We process with sealant or silicone the joining of the drain plastic pipe of the toilet bowl and the sewer. Also, the outlet must be blocked by a 60 mm outlet.

It is necessary to carry out the tension of the pipe without distortions. In order to make this easier to do, you can lubricate the rubber seal, which is located in the socket, with oil.

The pipe at one end must be inserted into the inlet of the sewer pipe, and the other end must be connected to the toilet outlet.

It is necessary to pour water into the toilet with a bucket to check the tightness of the docking of the elements.

Marking the place where the toilet bowl is attached to the floor. To do this, you need to remove the connector and mark the places where the bolts are attached, this can be done with a pencil or marker.

You need to drill holes as carefully as possible, especially if the flooring is made of tiles.

Lubricate the holes with sealant so that moisture does not get in, and perform the final installation of the toilet.

The bolts are tightened until the plumbing fixture wobbles. Do not tighten the bolts too much, so as not to split the base of the toilet.

Install the pipe and once again treat with sealant, check the tightness of the joints with water. You can simply glue the corrugation to the toilet, but then its further dismantling will be impossible without damage.

The exit at the floor toilet can be:

- vertical;

- horizontal;

- oblique.

In houses with an old layout, toilet outlets are often made vertically or obliquely, and toilet bowls with a horizontal outlet are installed in new buildings.

If the entrance to the sewer pipe is located in the floor, then you need to install the corrugation with a socket at 90 degrees. For a horizontal entry, an adapter with a socket at 45 degrees is used.

Features and purpose of corrugations

This is the name of the type of pipe. It has a wide range of applications, it is also used as a transitional element of the sewage system - when installing a toilet bowl. When installing this plumbing fixture, a large pipe is used. This is due to the significant cross-country ability of the product, the dimensions of the outlet of the toilet bowl.

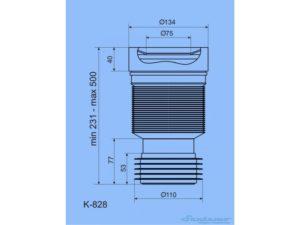

Communications of this group are made of thermoplastic.The pipe weighs little, can be installed by hand. One side has a cuff. There is a rubber seal in this area. The cuff connects to the toilet outlet and is relatively short. The length of the product varies depending on the position of the stiffening rings: from 23 to 50 cm. This allows you to change the parameters in accordance with the location of the plumbing fixture and the sewer riser in the toilet.

The outer and inner diameters differ from the standard dimensions of the pipes of the sewerage system, respectively 134 and 75 mm. However, the end of the corrugation corresponds to the cross section of the outlet of the sewer riser - 110 mm. This eliminates the need for adapters at the stage when the drain tube is being installed.

The procedure for connecting the toilet with corrugations

The work of connecting the toilet is not difficult, but a certain sequence of actions must be followed. It is more convenient to start installing the corrugation to the toilet bowl, both to the new one and the old one, even before it is fixed in a permanent place.

When nothing needs to be done with a product just brought from the store, then the outlet of the old device must be freed from deposits of cement or sealant.

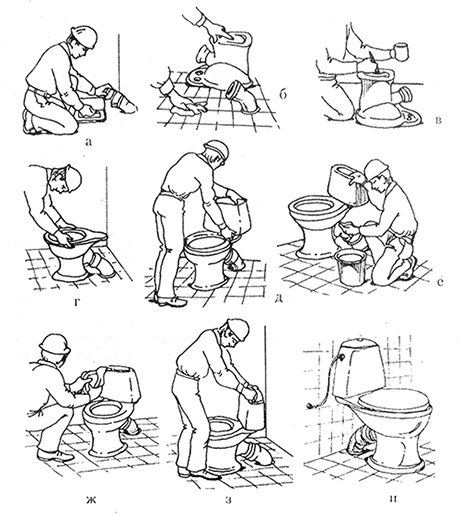

The photo shows the sequence of connecting the toilet using corrugations. Some experts believe that it is not worth sealing the connection of the corrugation with the sewer, because. silicone can destroy rubber over time

You also need to clean the socket of the sewer pipe. If this place is not freed from the remnants of materials, it will be difficult to ensure the tightness of the connection.

Then they act according to the following scheme:

- The end of the pipe, which is going to be connected to the sewer, is treated with silicone.The end of the outlet must be evenly blocked by a 50-60 mm outlet. You need to tighten with a turn, without allowing any distortions. To facilitate the process of tightening the corrugations, smear the rubber seal in the socket with soap.

- A corrugated pipe is inserted into the inlet of the system at one end, and the other end is connected to the toilet.

- Pour water into the toilet to check the joints.

- Mark the toilet attachment points on the floor by disconnecting the corrugation before that.

- Drill holes and coat with sealant.

- Attach the toilet to the floor. At the same time, the fixing bolts are attracted until the device stops staggering and becomes perpendicular to the floor. With increasing effort, you can split the base.

- Reconnect the adapter, process the joints with plumbing sealant and check them again for leaks.

- The screed is poured and the floor surface is finished.

The release form of the floor toilet can be vertical‚ horizontal‚ oblique. In each case, connecting the toilet bowl has its own characteristics. In old houses, vertical and oblique outlets are most often found, and in new ones, horizontal ones.

To connect the toilet bowl to a sewer pipe, the outlet of which is in the floor, a corrugation with a socket bent at 90⁰ is suitable. For a plumbing fixture with a horizontal outlet, a corrugation with a 45⁰ socket rotation is mainly used.

It happens that in a bathroom with a small area it is necessary to place a lot of plumbing fixtures. To do this, it is necessary that there are many branches on the sewer pipe, and this is not always realistic.

The only way out is to use a corrugated toilet bowl with a tap. It is the only alternative when the bathroom is located almost right next to the toilet.

It happens that for some reason the corrugation becomes unusable. It's easy to replace it. To do this, you don’t even have to dismantle the toilet, but you need to prepare rags and buckets.

Shut off the flow of water into the toilet drain, then disconnect the tube intended for water intake. The tank is freed from water and removed. The corrugated pipe is simply compressed and disconnected from the device. Next, take it out of the socket.

Corrugation for draining is a universal product. With its help, the toilet bowl can be connected both to the sewer, made of plastic pipes, and to old pipes made of cast iron

A new pipe is inserted into the socket, compressed, pulled over the outlet of the toilet bowl. All this can be done with a stretched corrugation. If it is extremely compressed, nothing will work. This is a nuance that must be taken into account even during the initial installation.

We have other useful articles on the site with detailed installation instructions. toilet bowls of various types and designs:

- How to install a toilet with an oblique outlet: detailed technical instructions

- Toilet with vertical outlet: how it works and works, pros and cons, step-by-step installation instructions

- Corner toilet with a cistern: pros and cons, scheme and features of installing a toilet in a corner

- How to connect a toilet to a sewer: an overview of installation technologies for all types of toilets

![[instruction] do-it-yourself toilet installation | video](https://fix.housecope.com/wp-content/uploads/e/0/5/e05c3aaa569c15a65a76abf551b1139c.jpg)