- Documents for gas equipment

- Regulations and project documentation

- Selection and equipment of the premises for installation

- General rules for the installation of gas equipment

- Equipment Installation Requirements

- Gas boilers floor

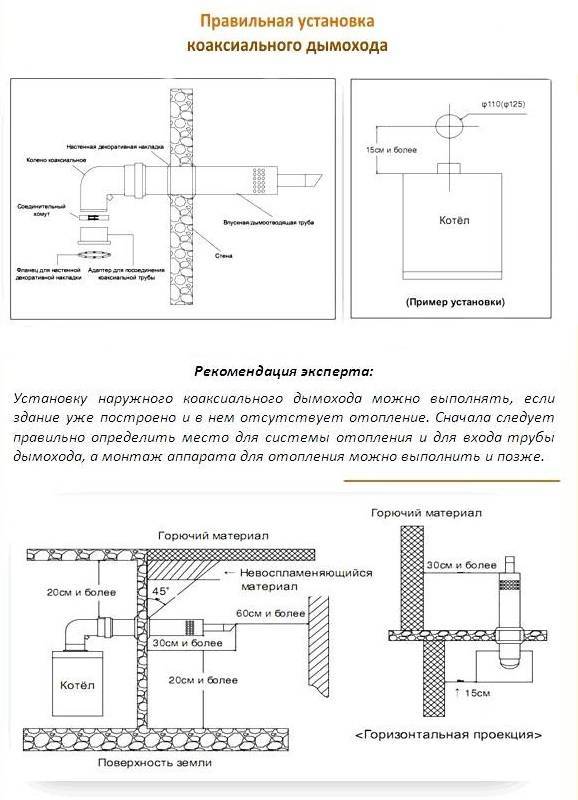

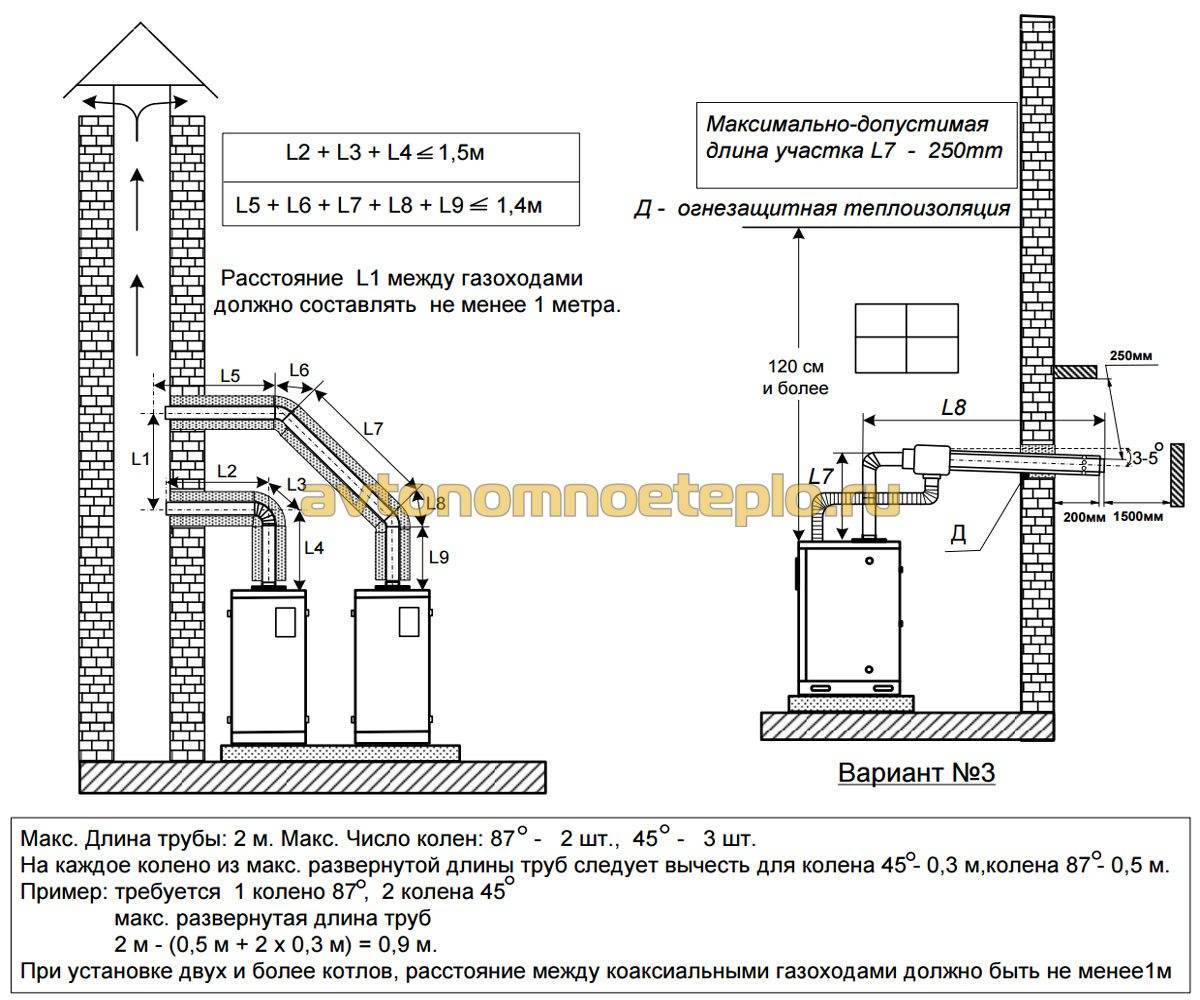

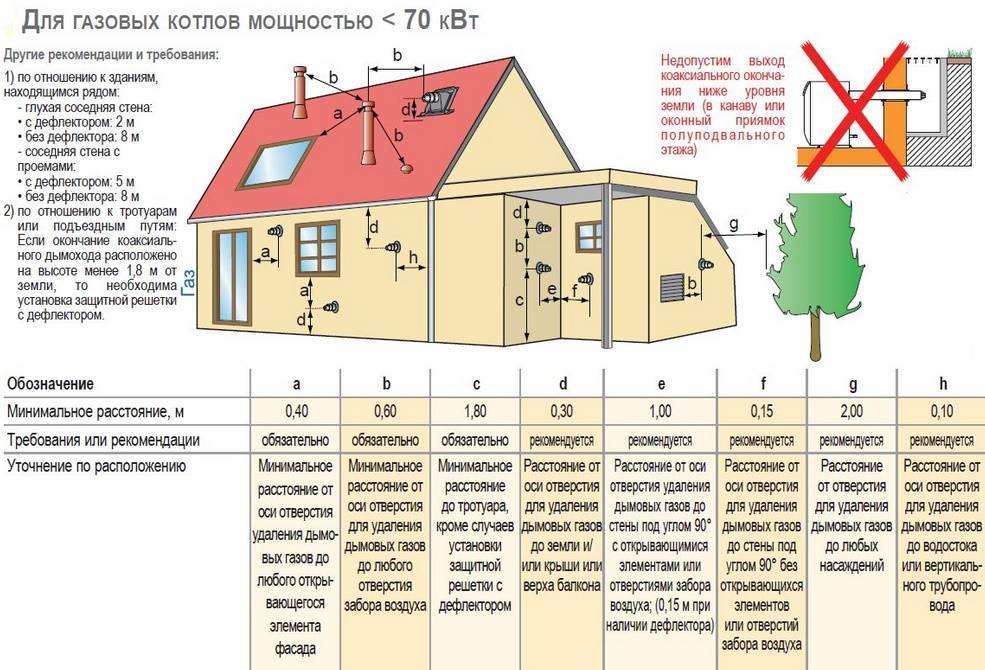

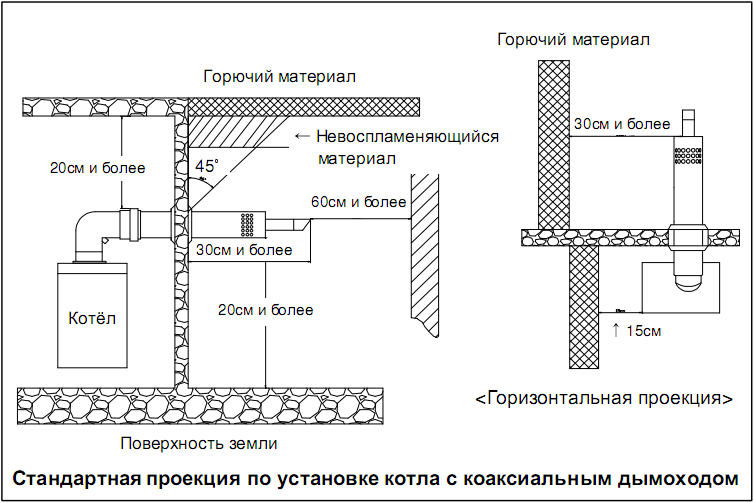

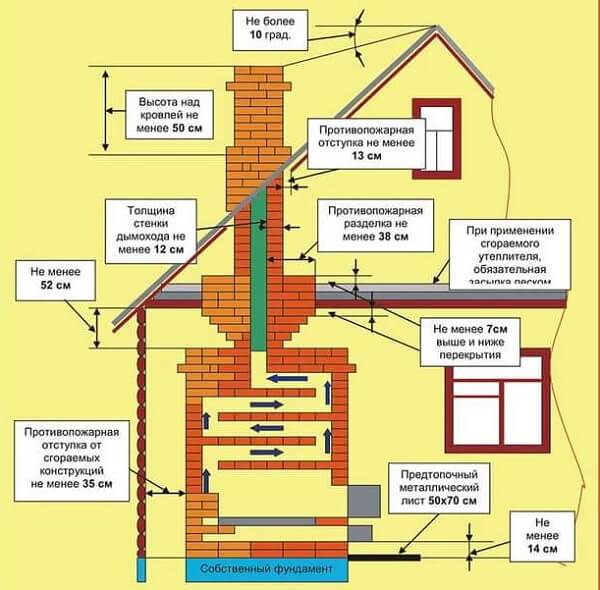

- For a chimney system, it is advisable to give general rules for installing gas equipment:

- Wall boilers

- Gas stoves

- Forbidden

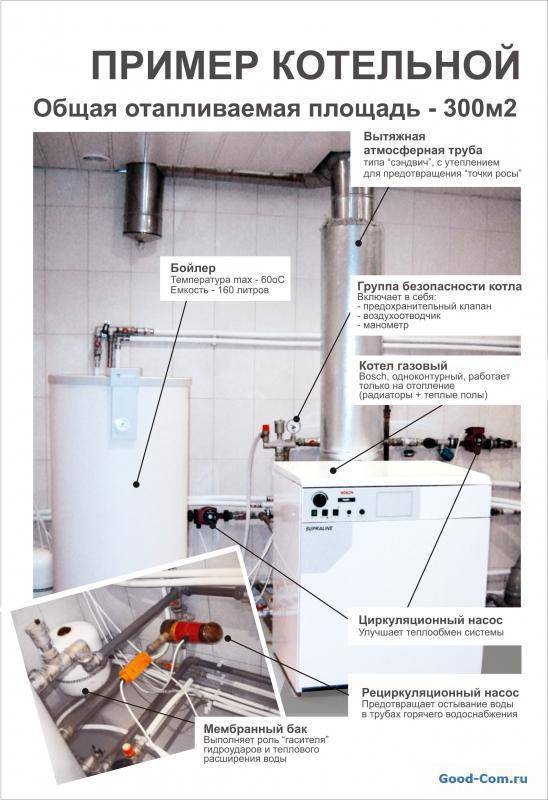

- Arrangement of a room for a boiler

- Recommendations for the installation of gas equipment

- Is self-installation possible?

- How to hide a gas boiler indoors

- Rules for installing a wall-mounted gas boiler

- Safety regulations

- Room for the installation of a gas boiler

- boiler room requirements

- Requirements for the room for the installation of a turbocharged unit

- Requirements for a room for installing a gas boiler

Documents for gas equipment

Let's assume that the room for the boiler is already equipped in compliance with the requirements. Before purchasing a boiler, you should check the availability of documents:

- Signed contract for the supply of gas, subject to the installation of a heating boiler. If you are a sub-consumer, it will be possible to install only a water heater.

- All papers on the gas meter. In any case, the installation of a gas boiler is prohibited without a meter. If it is missing, then you will have to draw up and install.

- Only after checking the documents, you can start choosing a boiler. However, even after the purchase, it is too early to start installing it. Before that, the following is still needed:

- Carry out an agreement at the BTI on a change in the data sheet.

- Make an application in the gas section for the creation of a project and technical conditions. Among the required documents from the applicant must be, among other things, a passport for the boiler.

- Install the boiler, but do not mount the gas section. During the development of the project, this can be done, provided that the premises have already been agreed.

- Make an application for the departure of a specialist to connect the gas part.

- Submit an application for admission.

- Wait for a gas worker. He must double-check all points and issue permission to start the equipment.

Pay attention! A permit for the installation of a gas boiler for individuals is not issued. To connect the gas you need to call specialists

You can do without it, but later you will have to solve this problem with the inspector when commissioning takes place. Usually the first decision costs much less than negotiating with the inspector.

Regulations and project documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of specifications. The presence of this document entitles the applicant to begin installation and connection of heating equipment to the central gas main.The application is made in the gas service, where it is considered by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water circuit and used in central Russia, the fuel consumption is 7-12 m3 / day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flowing gas heater (gear) consumes 0.5 m³ / day.

For a number of reasons, after consideration by the gas service of an application for a connection permit, a refusal may be given. At the same time, the responsible authority is obliged to issue a document to the owner of a private house, which officially indicates all the reasons for the refusal. After their elimination, the application is submitted again.

2. The next step after receiving the technical specifications is an even longer, but necessary process - the creation of a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in the preparation of the project. He must have permission to do this work. It is not possible to develop a project on your own. In any case, the gas service will not take into consideration a document prepared by a non-specialist.

After drafting the project, it must be submitted for approval.This is done by the department of the gas service, which controls the gas supply in a particular settlement or area. As a rule, it takes up to 90 days to agree on a project, and only after receiving a positive response can work begin on the arrangement of the boiler room and the installation of the heating unit.

Together with the project and the application for its consideration, the following documents must be attached:

- technical passport (available with the equipment);

- official instruction manual (you can copy);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with the specialist who drafted the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, similarly to the receipt of technical specifications, may end in failure. At the same time, the owner is issued a prescription in which errors, shortcomings or inconsistencies that need to be eliminated are indicated. After corrections, the application is submitted and considered again.

Selection and equipment of the premises for installation

In many ways, the choice of equipment and accessories depends on SNiP 42-01-2002 "Gas distribution systems". This significantly narrows the range of choice, since a particular boiler may not be suitable for the selected room due to a discrepancy between area and power density.

IMPORTANT! SNiPs are regularly updated, and current laws amend them. It is necessary to check the legal framework immediately before installation ..Previously, for example, it was impossible to install a boiler in the basement of a house, but now it is possible if the house is single-family

Previously, for example, it was impossible to install a boiler in the basement of a house, but now it is possible if the house is single-family.

General requirements:

- The room should be well ventilated;

- The room should have window openings;

- The area is greater, the greater the power of the boiler.

General rules for the installation of gas equipment

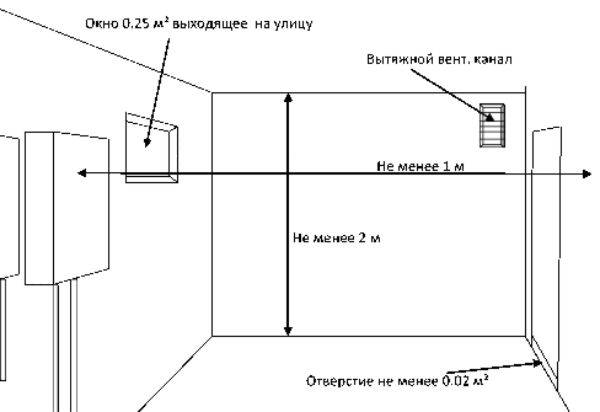

- Gas equipment is installed only in rooms that are suitable in terms of area (in accordance with the specifications for the device) and ventilation efficiency.

- If this is a private house, then the mini-boiler room must have a window, the dimensions of which meet the requirement - a numerical expression of the area ˃ 0.02 "cubic capacity" of the room in which gas equipment is located (all requirements for the boiler room are described here).

- The window frame must open and ensure the safety of the household in case of a possible gas explosion. The shock wave must be directed outward. For this purpose, the glazing of rooms with gas appliances is made “light”, single, without the installation of double-glazed windows or massive frames with 2 glasses in the furnace (boiler room).

- Cylinders and other gas equipment located outside a private house are placed in a special cage against the wall. Access to it should be free (for ease of control and maintenance).

- All work on the installation and connection of gas equipment is carried out by specialists of a resource supplying or other organization certified for this type of activity. Self-installation is fraught not only with problems with the normal functioning of the product, but also with the cancellation of the manufacturer's warranty.

Equipment Installation Requirements

They are detailed in the instructions for each gas appliance. Compliance with them is a guarantee not only of safety, but also of the fact that in the event of equipment failure, the user will be able to count on a free replacement of both an individual unit (component) and the entire installation within a specified period. Therefore, the technical specifications for the boiler (stove or other gas equipment) are one of the fundamental documents in the installation order.

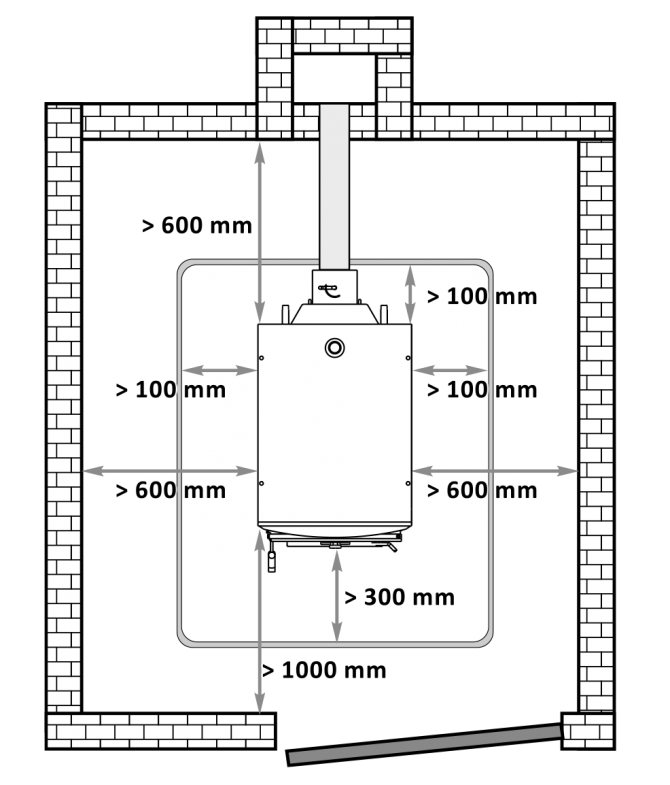

Gas boilers floor

- The base for the equipment is fire resistant. As an option - a specially mounted pedestal (brickwork, concrete platform) to a height of up to 20 cm.

- Minimum distances from structures: combustible - 50 cm, non-combustible - 100 cm.

- For the convenience of inspections, maintenance and repair of gas equipment, there should be a free zone along its perimeter (within 1 m on each side).

- The area of a mini-boiler room in a private house is from 4 "squares" with a ceiling height of at least 2.5 m. At the same time, a minimum free space in the room with a volume of 8 m³ must be ensured.

- The width of the door leaf is from 80 cm or more.

- The air flow is natural, based on the area of the air holes of 8 cm2 for each kW of a gas appliance.

- Smoke exhaust system with pipe outlet to the outside. The configuration of the channel, the section of the elements are calculated individually for a particular private house, depending on the material of the walls, the wind rose and a number of other factors.

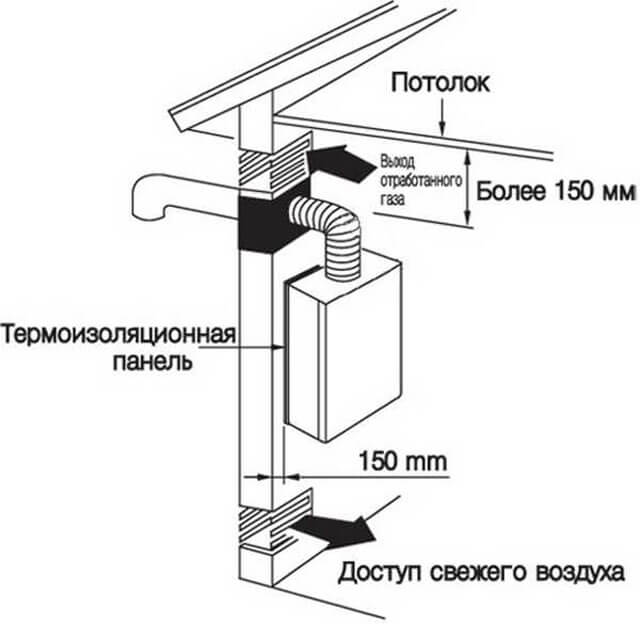

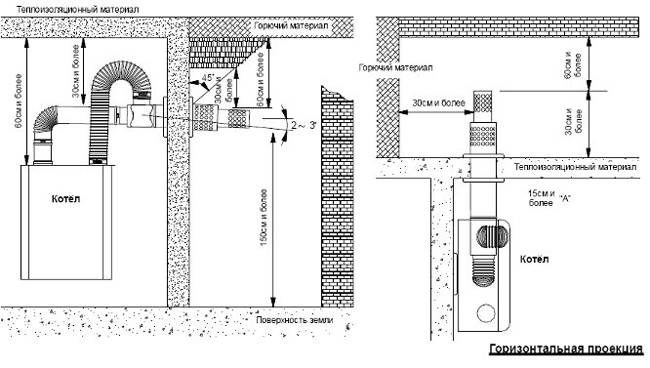

For a chimney system, it is advisable to give general rules for installing gas equipment:

- The minimum allowable elevation above the roof (ridge): flat - 1.2 m, pitched - 0.5 m.

- There should be no pipe joints within the ceiling slab.

- Along the entire length of the route, the chimney should not be located closer than 100 cm relative to materials of the “flammable” category.

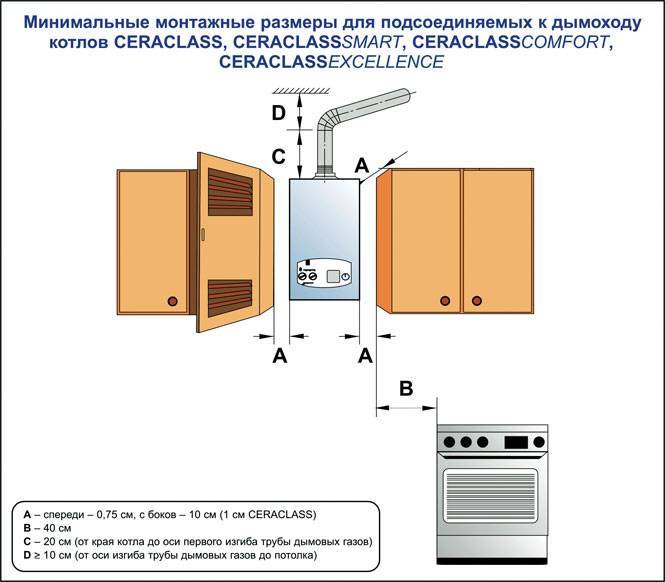

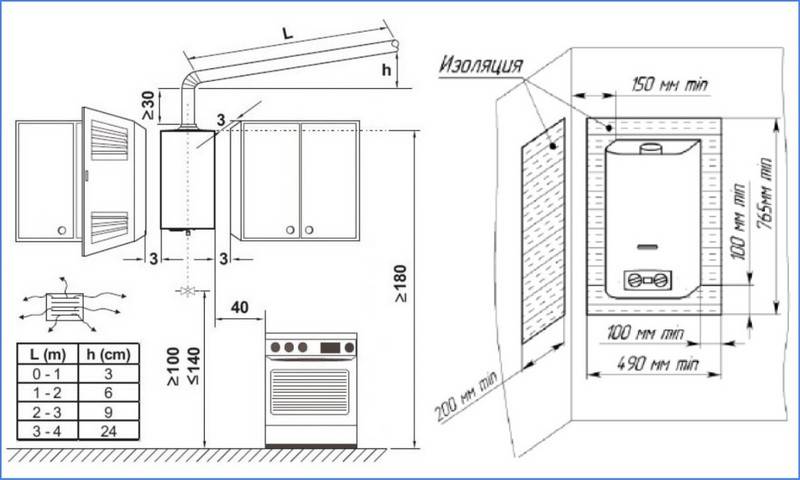

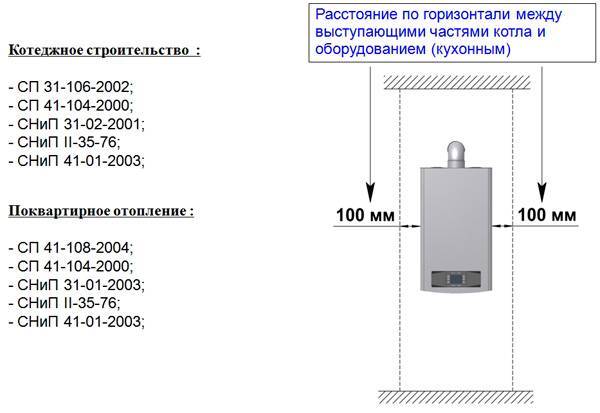

Wall boilers

Given the fact that this equipment has a power limit, the requirements for its installation are not so numerous.

- The minimum distance to other devices, combustible materials is 0.2 m.

- The distance from the floor covering is from 0.8 to 1.5 m (along the lower edge of the gas appliance).

- For private houses made of wood, a non-combustible layer is required between the wall and the boiler (for example, asbestos sheet). The minimum thickness of the “protection” is 3 mm.

Gas stoves

Installation of such equipment is much easier. The stove is placed in the kitchen, therefore, both the opening sash of the window and the hood are, by definition. Where to place the device, the owner decides, depending on the ease of use and the overall design of the room. But only a licensed specialist can connect to the highway. It is only necessary to take into account that the ceiling height (limit, minimum) is 2.20 m.

Forbidden

- Use combustible materials for finishing the furnace, arrange raised floors, and so on.

- To make welded joints during the installation of gas equipment - only on the thread.

- Lay the internal gas pipeline from pipes other than steel. In some cases, it is allowed to connect gas appliances with a special flexible hose.

- Gas equipment operating from the industrial/voltage network should be connected through stabilizers.

- In order to simplify the installation of the smoke exhaust system and increase the efficiency of the boiler, it is advisable to install coaxial chimneys.

Arrangement of a room for a boiler

It is best to install a wall-mounted gas appliance in a kitchen, the layout of which meets the standards for the placement of such equipment. Also in this room there is already a supply of both water and gas.

Here's what the norms for installing a gas boiler in an apartment look like:

- The area of the room where the installation of equipment is planned, when the ceilings in it are not lower than 2.5 meters, must exceed four square meters.

- It is mandatory to have a window that opens. Its area should be 0.3 square meters. m. per 10 cubic meters of volume. For example, the dimensions of the room are 3x3 meters with a ceiling height of 2.5 meters. The volume will be 3x3 x2.5 = 22.5 m3. This means that the area at the window cannot be less than 22.5: 10 x 0.3 \u003d 0.675 square meters. m. This parameter for a standard window is 1.2x0.8 \u003d 0.96 square meters. m. It will do, but the presence of a transom or window is required.

- The width of the front door cannot be less than 80 centimeters.

- There must be ventilation holes located under the ceiling.

Recommendations for the installation of gas equipment

In the documents attached to the product, each manufacturer describes the requirements for installing a gas boiler in an apartment. For the manufacturer's warranty to be valid, the unit must be installed in accordance with their recommendations.

The list of requirements is as follows:

- The wall-mounted boiler is separated from the walls with non-combustible material. When they are tiled or covered with a layer of plaster, this will be enough. Do not hang the appliance directly on a surface lined with wood.

- The floor unit is placed on a non-combustible base. If the floor has ceramic tiles or it is concrete, nothing needs to be done.A sheet of heat-insulating material should be placed on a wooden floor covering, and a metal sheet should be fixed on top of it, the size of which exceeds the dimensions of the boiler by 30 centimeters.

Is self-installation possible?

With your own hands, you can carry out the installation of a wall-mounted gas boiler of the simplest modifications. Such as, for example, single-circuit devices with an open combustion chamber.

To install them, you will need to connect the heating system, supply gas and organize a chimney. However, some boiler manufacturers in the technical documentation for their products indicate that the installation should only be carried out by specialists.

Installing and connecting a gas boiler is a responsible and rather complicated job. Many manufacturers of heating equipment require that it be carried out by professionals

In this case, self-assembly of even the simplest models is prohibited. Thus, if you plan to install the equipment yourself, you should make sure that the manufacturer allows this before buying it.

Checking the correctness of the installation and connecting the device to the gas line should only be carried out by a specialist with a special permit.

In addition, the representative of the gas service must also issue a permit for the operation of the installed equipment. Without this, the owner of a self-installed and launched device will face serious fines.

Thus, without the invitation of specialists, it is only possible to connect the device to the heating system and to the water supply. Moreover, it is advisable to do this only if you have a certain experience.

Wall-mounted gas boilers are installed in self-contained forced-type heating circuits with natural circulation of the coolant

How to hide a gas boiler indoors

In order to aesthetically hide the boiler in the kitchen, two main methods are used:

-

acquisition and subsequent installation of equipment that comes with a decorative element in the form of a panel. This solution will help save money and not engage in the selection of equipment to hide the boiler. At the same time, many manufacturers do not just equip this boiler with a conventional panel, but manufacture such elements according to individual orders with various patterns and from different types of wood;

-

when arranging the kitchen, it is also possible to install a gas boiler in a wooden box, which completely closes the boiler body from outside view. Such a box can be purchased immediately after the purchase of the boiler or can be ordered during the installation and design of the kitchen. The cost of the box is more expensive than the front panel, as usual, since it is made from materials for finishing the facades of the kitchen.

You may also be interested in information about what the combination of colors in the interior of the kitchen and the rules of behavior in the kitchen can be.

In general, the installation of gas boilers will require the owner to have special skills, tools and safety knowledge, so the best option when installing such equipment is to contact specialists.

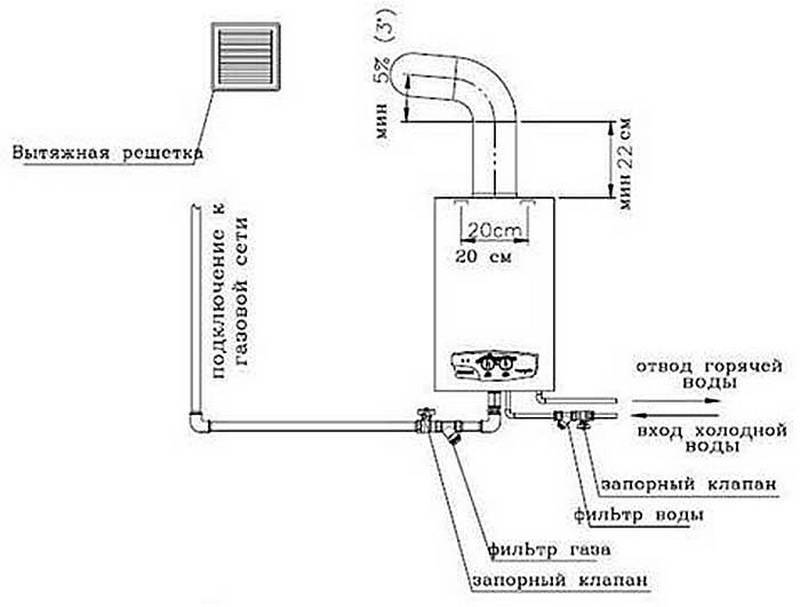

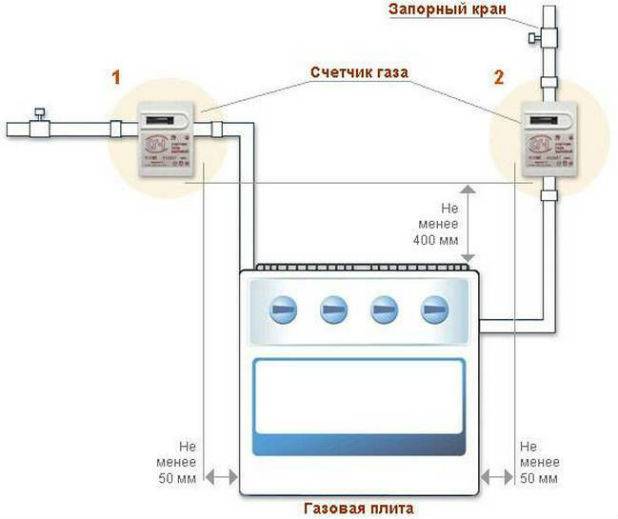

Rules for installing a wall-mounted gas boiler

Rules for installing a gas heating boiler - installation and connection instructions

Connecting a double-circuit gas boiler to the heating systemInstallation of heating boilers - how to install a solid fuel boiler with your own handsDuring the work, you will need to install the following elements:

- ball valve (gas), which is mounted at the inlet to the unit;

- gas meter and leak sensor - they are cut into the line in front of the device;

- thermal shut-off valve (according to fire safety regulations). When the temperature near the wall-mounted heating unit rises to a critical value, for example, in the event of a fire, this device will automatically shut off the gas supply.

Installation of gas heating - from the choice of equipment to the installation of the heating system

When installing a pipe section leading from the boiler to the chimney, the following rules are observed:

- the vertical part, located at the outlet of the device, must be at least two diameters long to the point of rotation;

- then the pipe should be inclined towards the unit;

- the section connected to the chimney should be as short as possible.

Safety regulations

Gas is a cheap type of fuel, burns without residue, has a high combustion temperature and, as a result, a high calorific value, however, when mixed with air, it is explosive. Unfortunately, gas leaks are not uncommon. In order to protect yourself as much as possible, you must strictly follow the safety rules.

First of all, it is necessary to study the operating instructions for gas equipment and follow them, monitor the normal operation of gas appliances, chimneys and ventilation.

The owners of residential premises are prohibited from disturbing the ventilation system of residential premises during the redevelopment and reorganization of the apartment.

Before lighting the gas stove, the room must be ventilated, the window should be left open for the entire time of working with the stove.The valve on the pipe in front of the stove is opened by moving the flag of the handle to the position along the pipe.

The flame should light up in all holes of the burner, have a bluish-violet color without smoky tongues. If the flame is smoky - the gas does not burn completely, it is necessary to contact the specialists of the gas supply company and adjust the air supply

Please note: if the flame detaches from the burner, this means that too much air is supplied, and in no case should you use such a burner!

If you catch the characteristic smell of gas in the room, you should not turn on or off any electrical appliances in order to avoid an electrical spark that can lead to a gas explosion. In this case, it is urgent to shut off the gas pipeline and ventilate the room. In case of departure to the country or on vacation, it is necessary to turn off the gas by turning the tap on the pipe. Ideally, turn off the gas valve after each use of the stove or oven.

It is necessary to immediately contact the emergency gas service in the following cases:

- there is a smell of gas in the entrance;

- if you find a malfunction of the gas pipeline, gas valves, gas appliances;

- when the gas supply suddenly stops.

Remember that inspection and repair of gas equipment can only be carried out by employees of gas facilities. Their authority is confirmed by service certificates, which they must present to the owner of the apartment.

Room for the installation of a gas boiler

The volume of the room for a gas boiler depends on the type of unit and its power.All requirements for the boiler room or other place where the device is located are prescribed in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 .

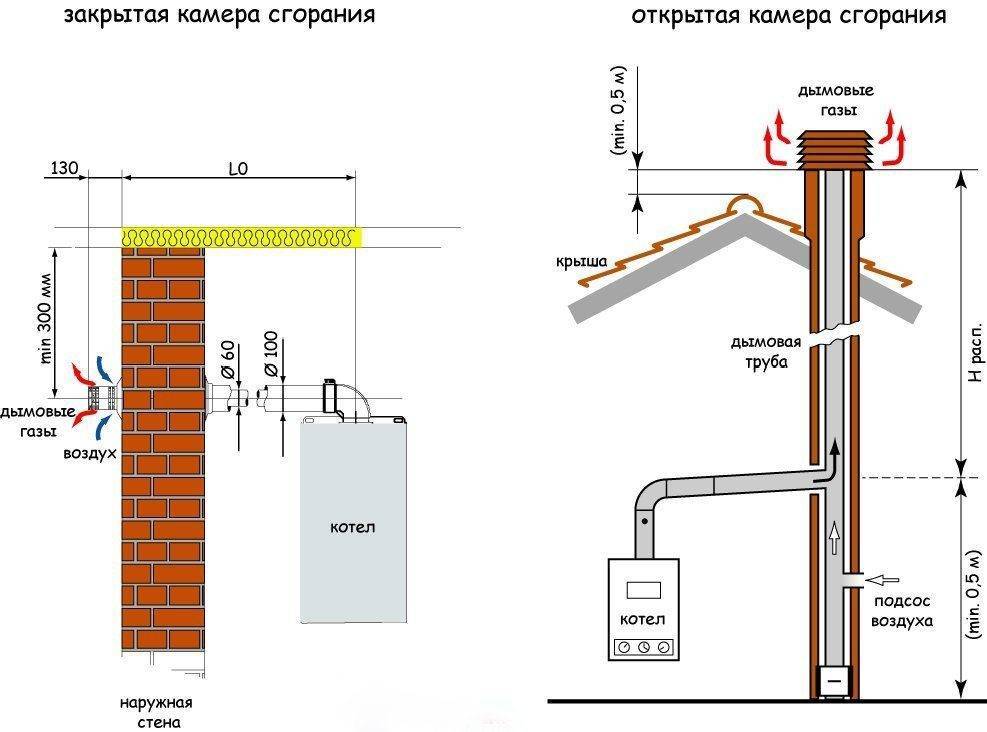

Gas boilers differ in the type of combustion chamber:

…

- units with an open combustion chamber (atmospheric);

- devices with a closed firebox (turbocharged).

To remove combustion products from atmospheric gas boilers, you will need to install a full-fledged chimney. Such models take air for the combustion process from the room in which they are located. Therefore, these features require a device for a gas boiler in a separate room - a boiler room.

Units equipped with a closed firebox can be placed not only in a private house, but also in an apartment in a multi-storey building. The removal of smoke and the influx of air masses is carried out by a coaxial pipe that exits through the wall. Turbocharged devices do not require a separate boiler room. They are usually installed in the kitchen, bathroom or hallway.

boiler room requirements

The minimum volume of the room for installing a gas boiler depends on its power.

| Gas boiler power, kW | Minimum volume of the boiler room, m³ |

| less than 30 | 7,5 |

| 30-60 | 13,5 |

| 60-200 | 15 |

Also, a boiler room for placing an atmospheric gas boiler must meet the following requirements:

- Ceiling height - 2-2.5 m.

- The width of the doors is not less than 0.8 m. They must open towards the street.

- The door to the boiler room must not be hermetically sealed. It is required to leave a gap between it and the floor 2.5 cm wide or make holes in the canvas.

- The room is provided with an opening window with an area of at least 0.3 × 0.3 m², equipped with a window. To ensure high-quality lighting, for every 1 m³ of the volume of the furnace, 0.03 m2 of the area of the window opening should be added.

- The presence of supply and exhaust ventilation.

- Finishing from non-combustible materials: plaster, brick, tile.

- Electric light switches installed outside the boiler room.

Note! Installing a fire alarm in the boiler room is not a mandatory, but recommended condition. It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

The boiler must be freely accessible from the front panel and from the side walls.

It is strictly forbidden to store flammable liquids and objects in the boiler room. The boiler must be freely accessible from the front panel and from the side walls.

…

Requirements for the room for the installation of a turbocharged unit

Gas boilers with a closed combustion chamber with a power of up to 60 kW do not require a separate furnace. It is enough that the room in which the turbocharged unit is installed meets the following requirements:

- Ceiling height over 2m.

- Volume - not less than 7.5 m³.

- Has natural ventilation.

- Closer than 30 cm next to the boiler there should not be other appliances and easily combustible elements: wooden furniture, curtains, etc.

- The walls are made of fire-resistant materials (brick, slabs).

Compact hinged gas boilers are even placed between cabinets in the kitchen, built into niches. It is more convenient to install double-circuit units near the water intake point so that the water does not have time to cool before it reaches the consumer.

In addition to generally accepted standards, each region also has its own requirements for a room for installing a gas unit

Therefore, it is important to find out not only how much space is needed to install a gas boiler, but also all the nuances of placement operating in a given city.

Requirements for a room for installing a gas boiler

Comprehensive information on the proper preparation of the premises is contained in one of the above documents. In particular, there are regulations on the dimensions of the boiler room, the arrangement of the front door, the height of the ceiling and other important parameters (see key requirements below).

It is immediately worth noting that if the maximum thermal power of a gas boiler is more than 30 kW, then a separate room must be allocated for its installation. Models with a lower capacity and with an appropriate location for the chimney outlet can be installed, for example, in a kitchen room. It is strictly forbidden to install a gas boiler in the bathroom.

You can not install it in the bathroom, as well as in rooms that are considered residential for their intended purpose. As an alternative, it is allowed to equip the boiler room in a separate building. At the same time, their own norms are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the basement level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

In accordance with the rules for installing a gas boiler in a private house, it must be equipped with the following criteria:

- The area is not less than 4 m2.

- One room is calculated for no more than two units of heating equipment.

- Free volume is taken from 15 m3.For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling should be 2.2 m (not less).

- The boiler is installed so that the distance from it to the front door is at least 1 m; it is recommended to equip the unit near the wall, which is located opposite the doorway.

- On the front side of the boiler, at least 1.3 m of free distance must be left for setting up, diagnosing and repairing the unit.

- The width of the front door is taken in the region of 0.8 m; it is desirable that it opens outwards.

- The room is provided with a window with a window opening outward for emergency ventilation of the room; its area must be at least 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or ignition.

- A separate power line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, with an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a top coat of absolutely non-combustible materials (ceramics, stone, concrete)

To make it easier to set the boiler, the floors are made strictly according to the level.

On a curved surface, the installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is forbidden to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not work correctly, with increased noise and vibrations.

To fill the water heating system and feed it during operation, it is necessary to enter a cold water pipeline into the boiler room.To drain the system for the period of maintenance or repair of equipment, a sewer point is equipped in the room.

To the chimney and ensure air exchange in boiler room of a private house there are special requirements, therefore this issue is considered in a separate subparagraph below.

If the room for the installation of a gas boiler is equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- the presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- it is allowed to install no more than two gas boilers in the same boiler room;

- the presence of a properly equipped chimney;

- it must be freely accessible for cleaning and other operations;

- for supplying piece lighting and heating equipment, a separate input with an automatic machine of the appropriate power is provided;

- the water supply must be organized so that the mains do not freeze during the cold season.

Mini-boiler room mounted near the house.

The floors, walls and ceilings of a separately equipped boiler room must also be made and finished with materials that correspond to the class of non-combustible and heat-resistant.