- Regulations and project documentation

- Installation of a gas boiler in combined kitchens

- Requirements for a room for installing a gas boiler

- Installation of boilers in houses of individual development

- Installation of floor boilers in a separate furnace

- Features of the preparation of boiler rooms with a gas boiler

- Choosing a gas boiler

- Required documents

- Where it is possible and where it is impossible to put a gas boiler

- Instructions and important tips for installing a wall-mounted boiler

- Installation of the wall unit is carried out in several steps

- Coordination of the installation of a gas boiler

Regulations and project documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of specifications. The presence of this document entitles the applicant to begin installation and connection of heating equipment to the central gas main. The application is made in the gas service, where it is considered by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible hitches, the application must indicate the estimated average daily volume of natural gasrequired for heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water circuit and used in central Russia, the fuel consumption is 7-12 m3 / day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flowing gas heater (gear) consumes 0.5 m³ / day.

For a number of reasons, after consideration by the gas service of an application for a connection permit, a refusal may be given. At the same time, the responsible authority is obliged to issue a document to the owner of a private house, which officially indicates all the reasons for the refusal. After their elimination, the application is submitted again.

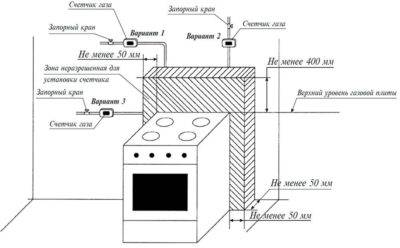

2. The next step after obtaining specifications is an even longer, but necessary process - the creation of a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in the preparation of the project. At it should be permission to do this work. It is not possible to develop a project on your own. In any case, the gas service will not take into consideration a document prepared by a non-specialist.

After drafting the project, it must be submitted for approval. This is done by the department of the gas service, which controls the gas supply in a particular settlement or area.As a rule, it takes up to 90 days to agree on a project, and only after receiving a positive response can work begin on the arrangement of the boiler room and the installation of the heating unit.

Together with the project and the application for its consideration, the following documents must be attached:

- technical passport (available with the equipment);

- official instruction manual (you can copy);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with the specialist who drafted the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, similarly to the receipt of technical specifications, may end in failure. At the same time, the owner is issued a prescription in which errors, shortcomings or inconsistencies that need to be eliminated are indicated. After corrections, the application is submitted and considered again.

Installation of a gas boiler in combined kitchens

In modern construction, the arrangement of studio apartments or layouts is actively practiced, in which the living room and kitchen are combined into one large space. Of course, such a solution has a lot of advantages - for example, a large part of the free space appears, which is perfect for implementing all kinds of design ideas.

The problem is that such layouts are regarded by gas services as residential, so the installation any gas equipment are prohibited in them.In studios, this problem cannot be solved, but when combining the living room with the kitchen, options are possible.

Requirements for a room for installing a gas boiler

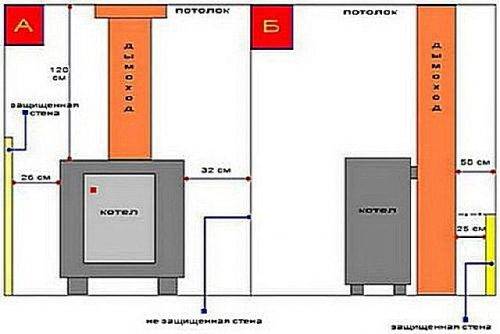

Comprehensive information on the proper preparation of the premises is contained in one of the above documents. In particular, there are regulations on the dimensions of the boiler room, the arrangement of the front door, the height of the ceiling and other important parameters (see key requirements below).

It should immediately be noted that if the maximum thermal gas boiler power more than 30 kW, then it is necessary to allocate a separate room for its installation. Models with a lower capacity and with an appropriate location for the chimney outlet can be installed, for example, in a kitchen room. It is strictly forbidden to install gas boiler in the bathroom.

You can not install it in the bathroom, as well as in rooms that are considered residential for their intended purpose. As an alternative, it is allowed to equip the boiler room in a separate building. At the same time, their own norms are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the basement level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

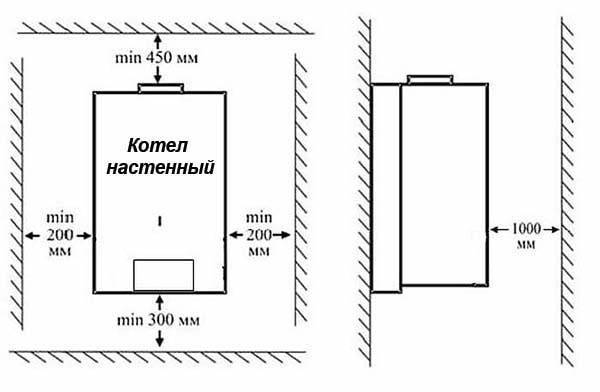

In accordance with the rules for installing a gas boiler in a private house, it must be equipped with the following criteria:

- The area is not less than 4 m2.

- One room is calculated for no more than two units of heating equipment.

- Free volume is taken from 15 m3. For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling should be 2.2 m (not less).

- The boiler is installed so that the distance from it to the front door is at least 1 m; it is recommended to equip the unit near the wall, which is located opposite the doorway.

- On the front side of the boiler, at least 1.3 m of free distance must be left for setting up, diagnosing and repairing the unit.

- The width of the front door is taken in the region of 0.8 m; it is desirable that it opens outwards.

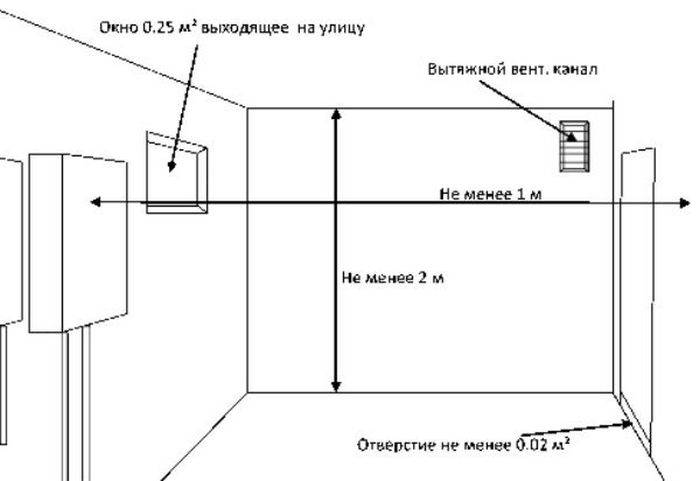

- The room is provided with a window with a window opening outward for emergency ventilation of the room; its area must be at least 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or ignition.

- A separate power line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, with an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a top coat of absolutely non-combustible materials (ceramics, stone, concrete)

To make it easier to set the boiler, the floors are made strictly according to the level.

On a curved surface, the installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is forbidden to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not work correctly, with increased noise and vibrations.

To fill the water heating system and feed it during operation, it is necessary to enter a cold water pipeline into the boiler room.To drain the system for the period of maintenance or repair of equipment, a sewer point is equipped in the room.

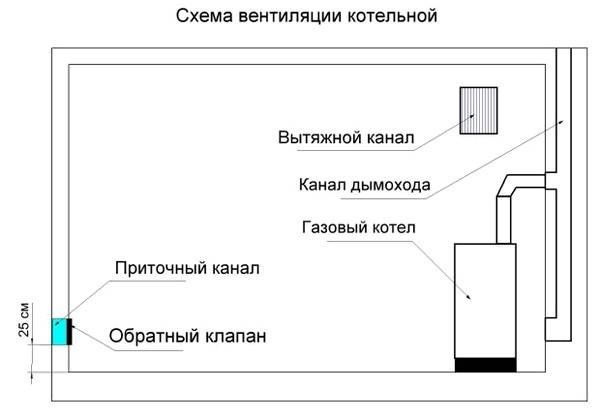

There are special requirements for the chimney and ensuring air exchange in the boiler room of a private house, therefore this issue is considered in a separate subparagraph below.

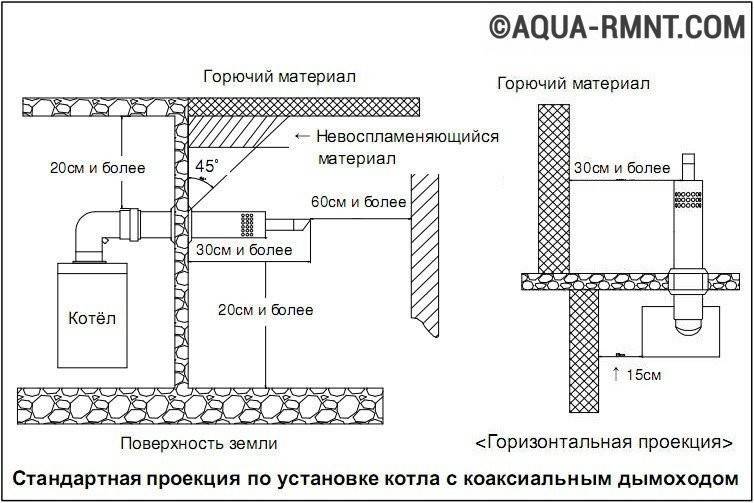

If the room for the installation of a gas boiler is equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- the presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- it is allowed to install no more than two gas boilers in the same boiler room;

- the presence of a properly equipped chimney;

- it must be freely accessible for cleaning and other operations;

- for supplying piece lighting and heating equipment, a separate input with an automatic machine of the appropriate power is provided;

- the water supply must be organized so that the mains do not freeze during the cold season.

Mini-boiler room mounted near the house.

Floors, walls and ceilings of a separately equipped boiler room are also must be fulfilled and finished with materials corresponding to the class of non-combustible and heat-resistant.

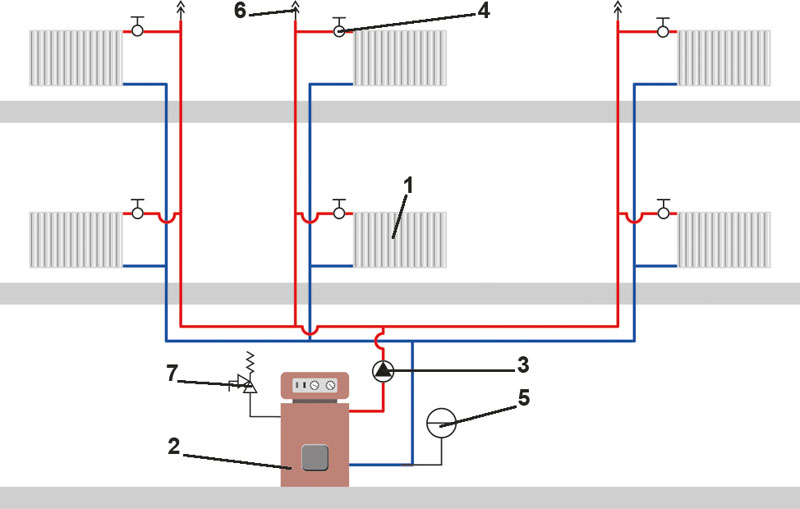

Installation of boilers in houses of individual development

The method of placing a heating boiler in a residential building depends on its design and can be floor or wall. It should be noted that floor models in most cases exceed the heat output of mounted heat sources.

In addition, a freer circuit of the coolant circulation in such devices allows their installation for operation in autonomous heating systems with natural circulation.

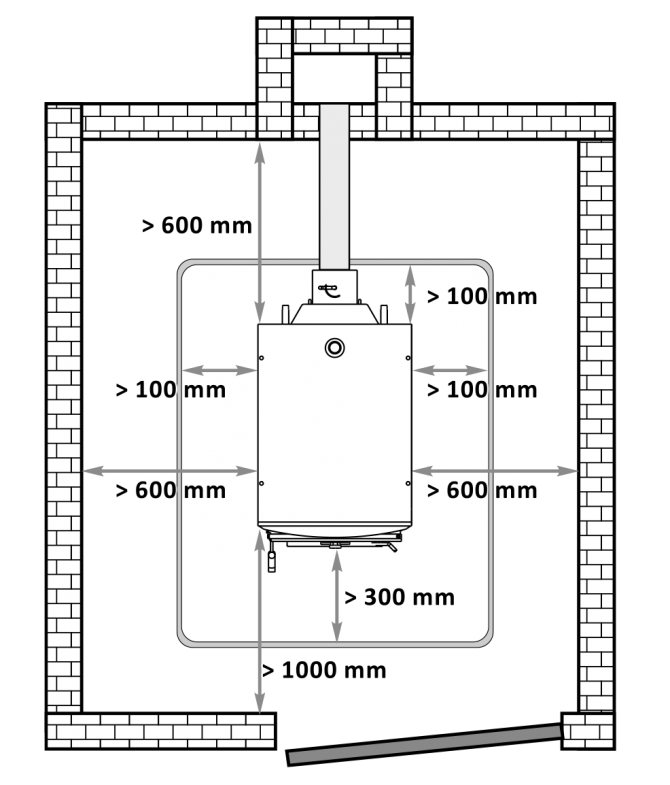

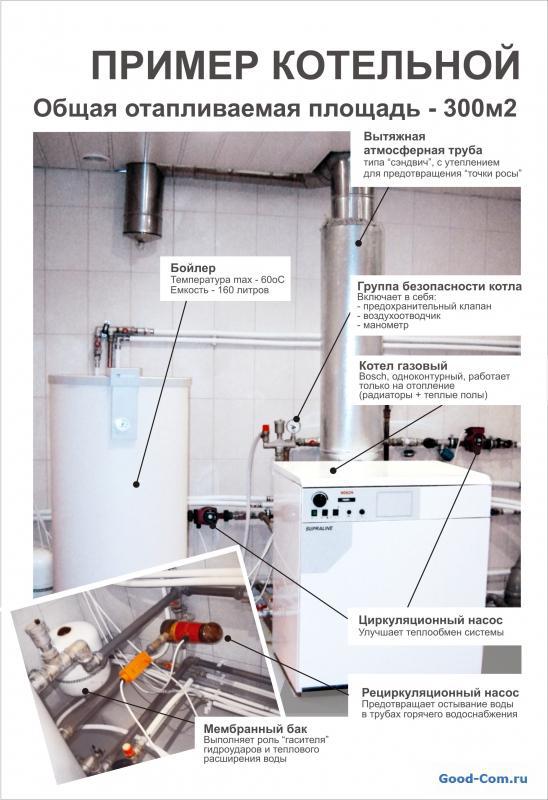

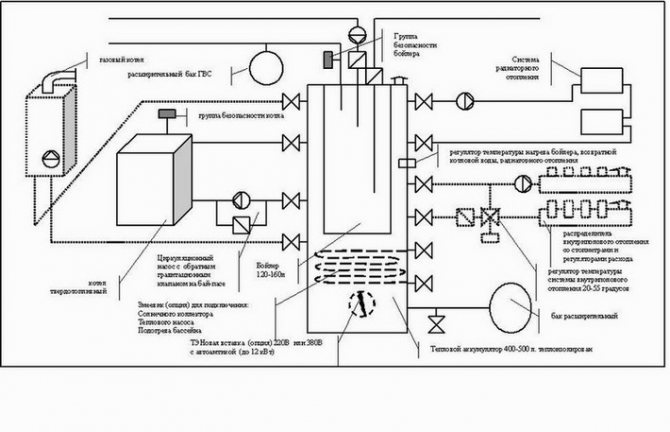

Installation of floor boilers in a separate furnace

If you need to set the source heat with a power of more than 32 kW, choose gas boilers with installation on the floor, since the thermal performance of serial mounted models does not exceed the named value. The developed typical schemes of furnaces, for private houses, provide for the presence of:

- expansion tank;

- domestic hot water heater;

- capacitive or high-speed separator;

- distribution comb;

- at least two circulation pumps.

In addition, it is required to install emergency relief lines and safety valves that operate when the pressure in the pipelines rises.

Boiler installation work begins with the preparation of brick or concrete bases not only for it, but also for all tanks, which, after filling with water, will become quite heavy. After that, it is necessary to assemble the distribution manifolds and pumping units with shut-off valves, and fix them on the wall according to the design scheme.

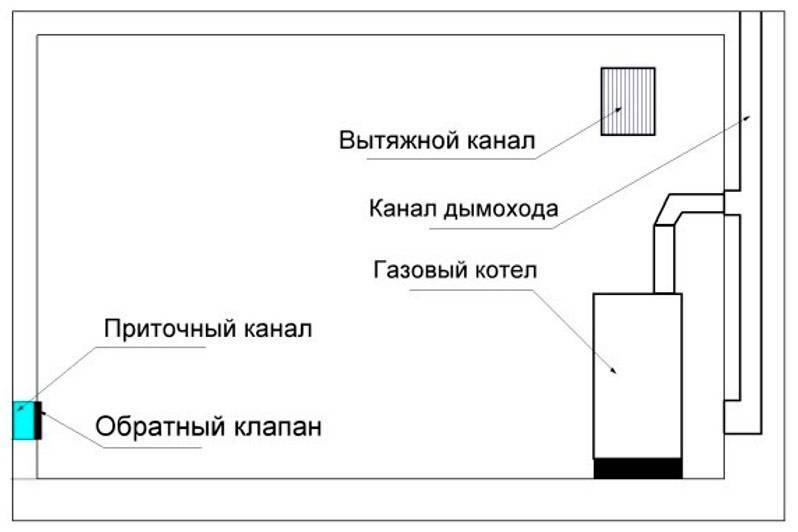

Features of the preparation of boiler rooms with a gas boiler

In addition to the general ones, additional requirements are imposed on each type of device, but in relation to gas units they are more serious. This is explained by the increased explosion hazard of gas-powered devices, therefore, rooms equipped in this way must be carefully prepared.

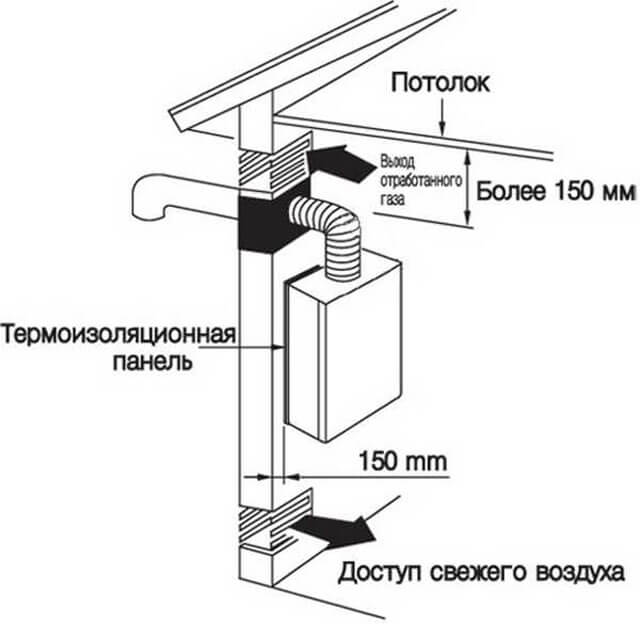

Installation of a heating device in an autonomous room is carried out in accordance with the standards regulated by the current SNiP and must comply with the following conditions:

- erection of a separate foundation and podium for the unit installed directly on the floor;

- availability of free space of 1 sq.m. in front of the device

- providing a passage to the heating equipment with a width of at least 0.7 m;

- arrangement of a chimney located above the roof;

- insulation of the chimney channel with heat-insulating material;

- the presence of a device that provides automatic shutdown of gas in case of an accident.

Communication networks are laid to a separately located furnace building: a pipeline with water that feeds the heating system, a sewage system for draining the coolant.

Maintenance of devices and communications is carried out at least once a year.

Choosing a gas boiler

Before you put the boiler in the apartment, you need to make the best choice. In a multi-storey building, wall and floor boilers can be installed. Wall models are considered more aesthetic and convenient in terms of placement. Their dimensions are comparable to the dimensions of kitchen wall cabinets and therefore they fit well into the interior of the room.

With the installation of floor units it will be more difficult, since they can not always be pushed close to the wall. This nuance depends on the location of the smoke outlet. If it is on top, then the device, if desired, is moved to the wall.

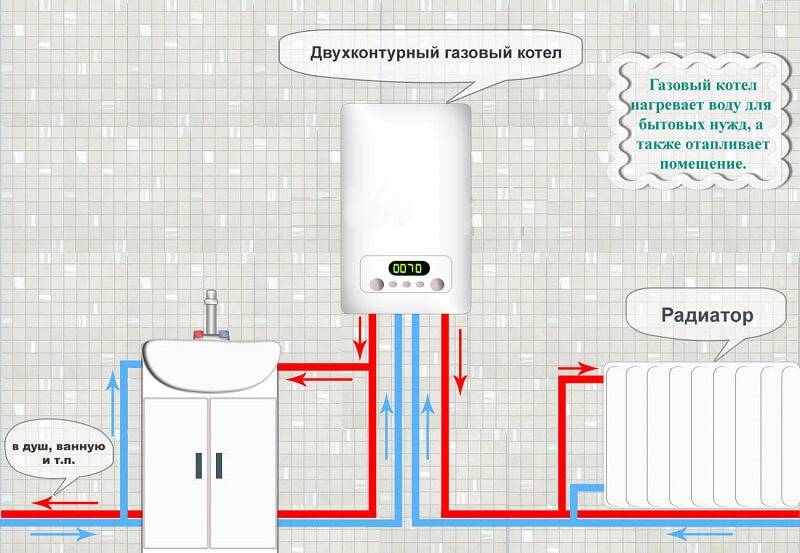

Boilers also come in single and double circuit. The first of them work only for heat supply, and the second - for heating and water heating. When other equipment is used for DHW, then a single-circuit model will suffice.

If the water is heated by a gas boiler, then you will have to choose one of two methods: an indirect heating boiler or a flow coil. At Both options have disadvantages. When a coil is used, which means flow heating is carried out, not all units are able to maintain the set temperature.

For this reason, it is necessary to set special operating modes in boilers; they are called differently in different devices. For example, in Navien models (read about Navien boiler malfunctions), Beretta is “hot water priority”, and in Ferrolli it is “comfort”.

The disadvantage of boiler heating is that gaseous fuel is consumed to maintain a stable water temperature in the tank. In addition, the reserve of heated water is limited. After its consumption, you have to wait until the new portion heats up.

The choice of the above methods is an individual matter, but you need to remember that with the flow option, you will have to focus on the water heating capacity per minute, and with the boiler - on the volume of the tank.

Gas units differ in the type of burner used, which are:

- single position;

- on-off;

- modulated.

The cheapest are single-position, but at the same time they are the most uneconomical, because they always work at full capacity. Slightly more economical - on-off, which are able to function both at 100% power and at 50%. The best burners are considered modulating, as they have many operating modes, which saves fuel. Their performance is controlled automatically.

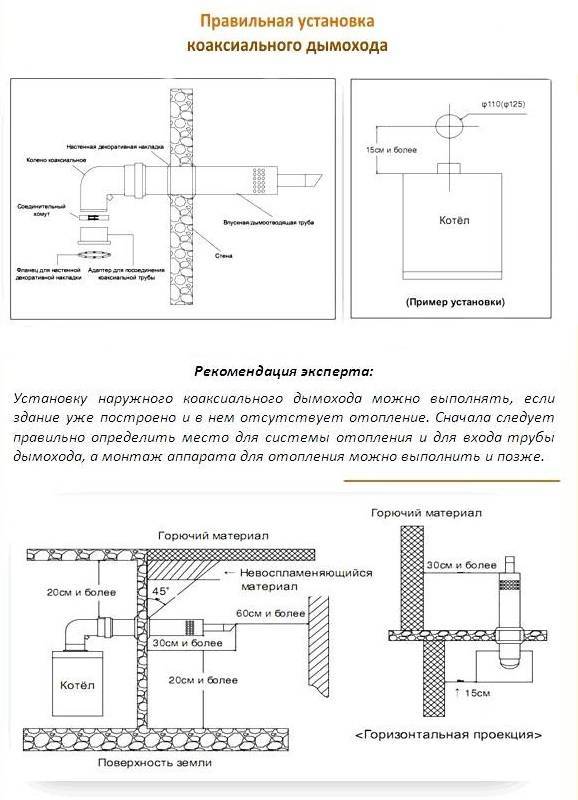

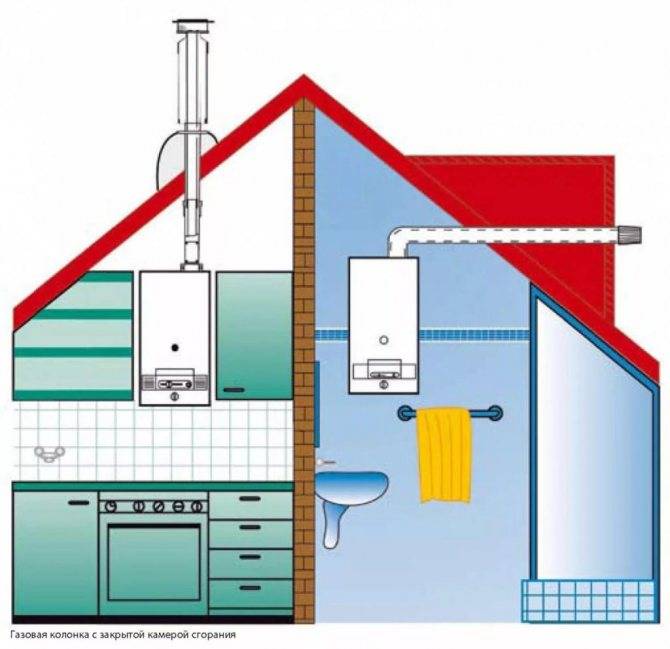

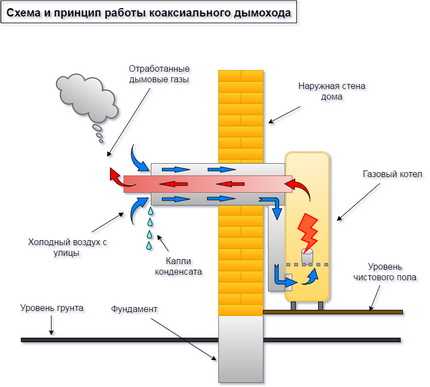

The burner is located in the combustion chamber, which can be open or closed. Oxygen for open chambers comes from the room, and combustion products are removed through an atmospheric chimney.

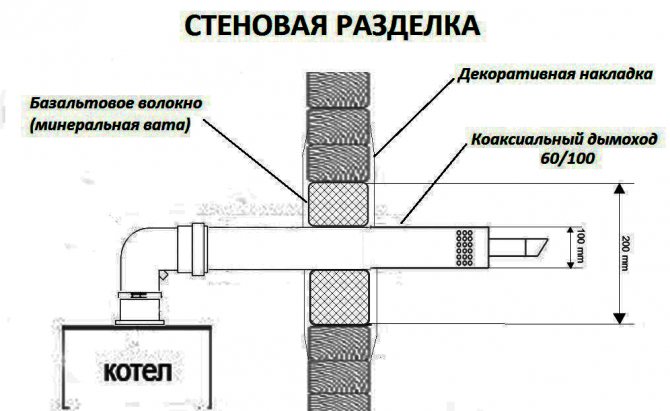

Closed chambers are equipped with a coaxial chimney structure, and oxygen for combustion enters them from the street. In this case, combustion products are discharged along the central contour of the chimney, and air enters through the outer one.

Required documents

All work on gas equipment is carried out by specialists with the appropriate approval group. Without fulfilling this requirement, it will not be possible to issue a contract in the future. for individual gas supply for heating and hot water.

Together with the project and the application for its receipt, attach:

- Technical passport of the boiler unit received by the owner upon purchase;

- manufacturer's official instructions;

quality certificates; - a document certifying that the boiler complies with state standards on the territory of the Russian Federation.

After completion of all installation and commissioning work on the equipment, a representative of the gas organization is invited in order to obtain a conclusion that the installed gas equipment complies with state standards and regulations and is functioning properly, after which they begin to operate the unit. When issuing a technical passport, they designate the functional affiliation of the room as a boiler room or furnace.

Where it is possible and where it is impossible to put a gas boiler

The rules for installing a gas boiler provide for the following requirements for installing a HEATING boiler, regardless of whether it also provides domestic hot water or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications of the admissibility of a ceiling of 2 m. This is not true. 8 cubes is the minimum free volume.

- The furnace must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with combustible materials, the presence of a false ceiling or raised floor in it is unacceptable.

- Air must be supplied to the furnace through a through, non-closable vent with a cross section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

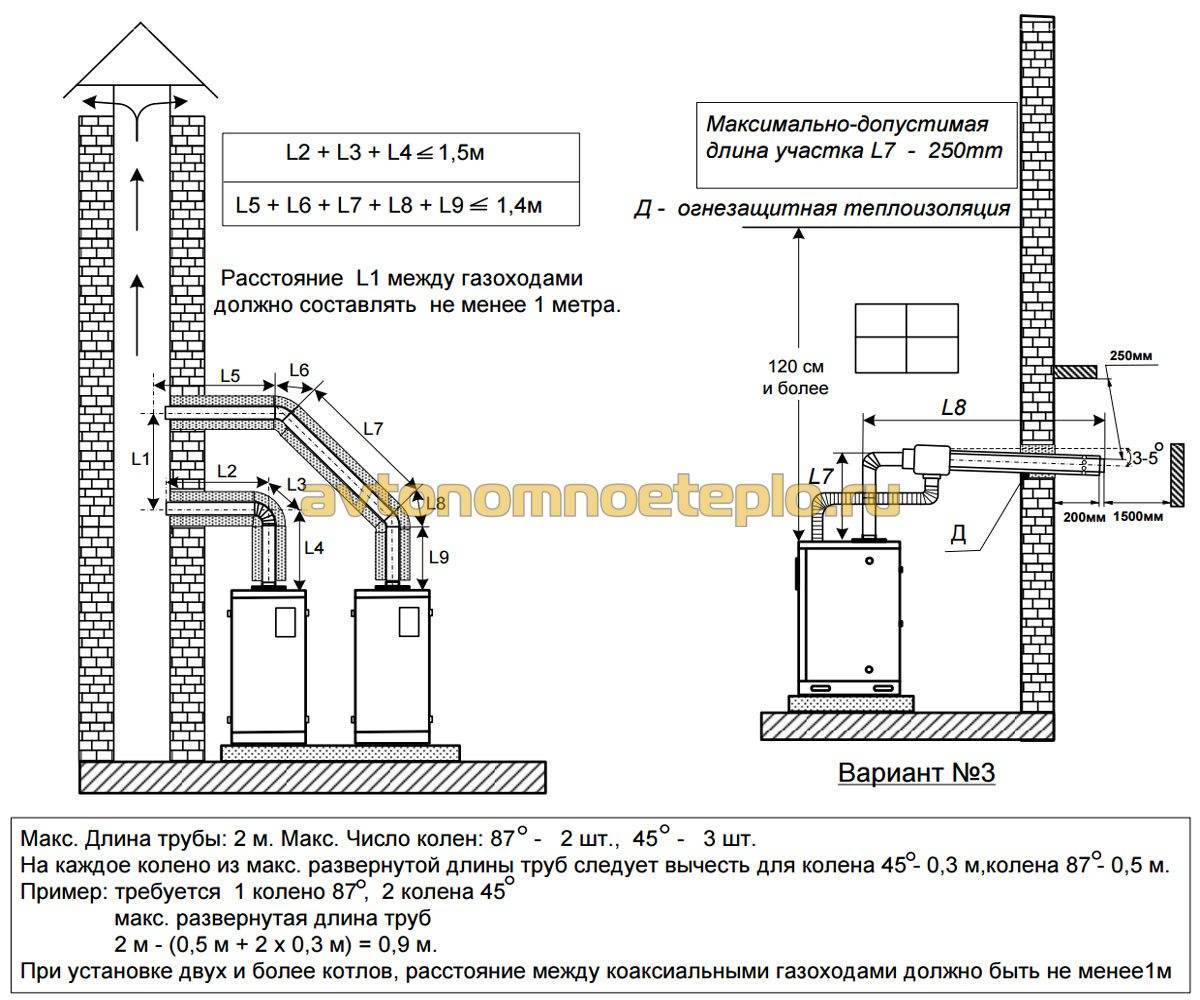

- The boiler exhaust must exit into a separate flue (often incorrectly referred to as a chimney); the use of ventilation ducts for this is unacceptable - life-threatening combustion products can get to neighbors or other rooms.

- The length of the horizontal part of the flue must not exceed 3 m within the furnace and have no more than 3 angles of rotation.

- The outlet of the flue must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since the products of combustion form chemically aggressive substances during cooling, the chimney must be made of heat- and chemical-resistant solid materials. The use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest branch pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A strong fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- The room should not have cavities in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition heating systems in the apartment / house:

- The slope of the horizontal pipe sections must be positive, but not more than 5 mm per linear meter in terms of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler in which everything is provided for: rules are rules.

- The condition of the heating system must allow it to be pressure tested at a pressure of 1.8 atm.

The requirements, as we see, are tough, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a hot water boiler, if:

- You live in a block Khrushchev or other apartment building without a main flue.

- If you have a false ceiling in your kitchen, which you do not want to clean, or a capital mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which, in principle, can be removed, and then there will be no mezzanine, gas workers look through their fingers.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment that only the owner can do.

In all other cases, you can put a hot water boiler in the apartment; heating wall is possible, and floor - very problematic.

In a private house, any boiler can be installed: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside under the furnace, then the authorities will only have fewer reasons for nit-picking.In it, you can put a floor gas boiler of high power for heating not only the mansion, but also office space.

For private housing of the middle class, the optimal solution is a wall-mounted boiler; under it is not required, as for the floor, to arrange a brick or concrete pallet with sides of half a meter. Installing a wall-mounted gas boiler in a private house also does without technical and organizational difficulties: a fireproof closet for a furnace can always be shielded, at least in the attic.

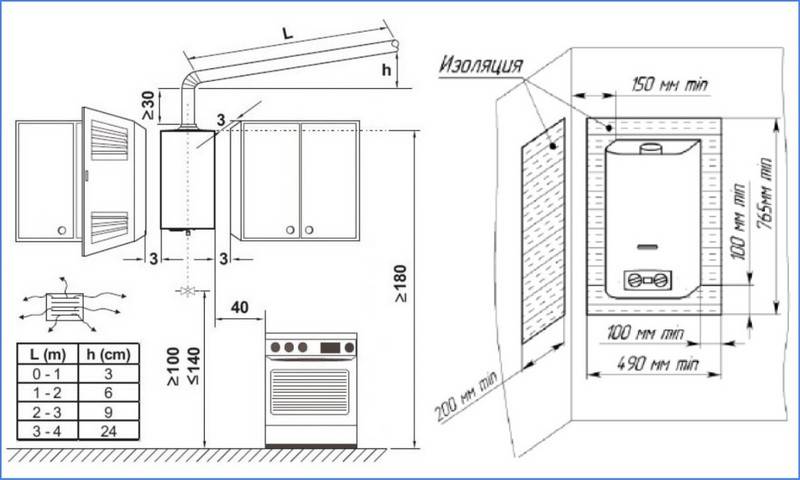

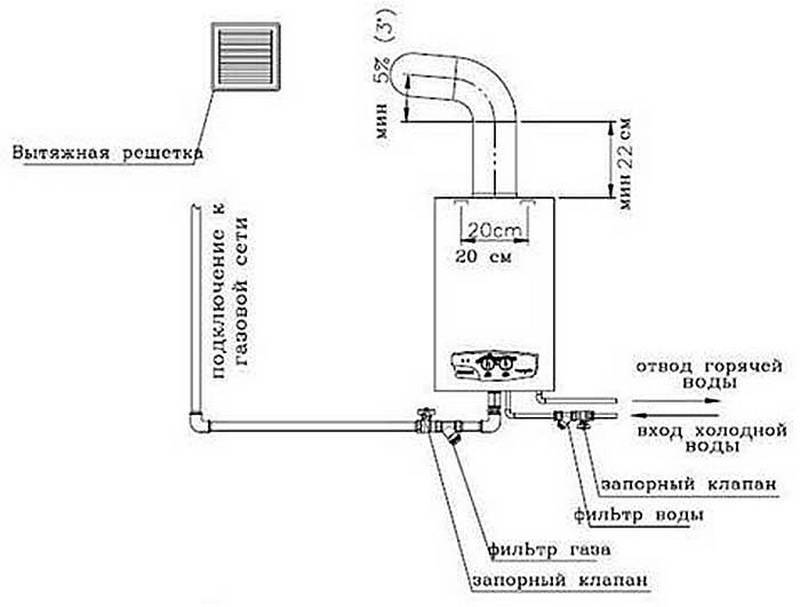

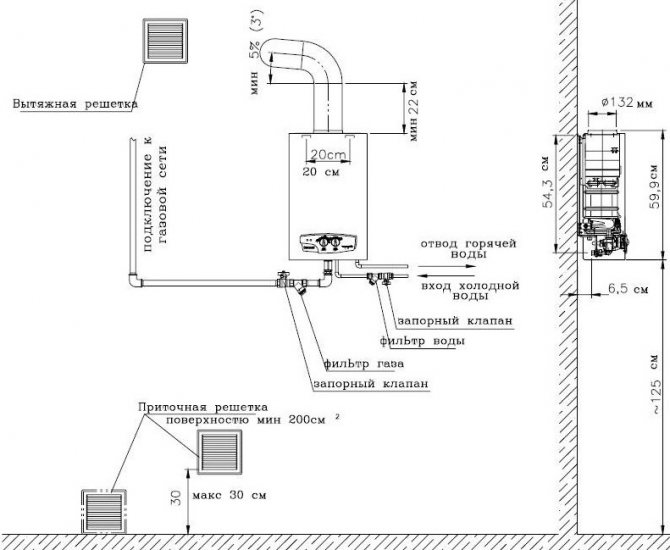

Instructions and important tips for installing a wall-mounted boiler

Instruction and important installation tips wall boiler

The design feature of wall-mounted gas boilers imposes certain requirements for the installation of such equipment.

- The distance between the edge of the lowermost boiler nozzle and the floor must be at least 800 mm. Also, the edge of this pipe should be located not lower than the level of the sink spout.

- It is forbidden to place anything in the space under the wall-mounted boiler.

- In the room allocated for the installation of a wall-mounted boiler (usually a kitchen), it is forbidden to leave open cavities in which waste from the operation of the equipment can accumulate.

- The floor under the boiler must be covered with a sheet of durable metal. Traditionally, a square with a side of 100 cm is laid.

- At the highest point of the system, a special expansion tank must be installed, as well as an air cock.

Before buying a boiler, be sure to check that it is complete and has the necessary fasteners. The set is detailed in the instructions. If the manufacturer did not complete the boiler with fasteners, buy them yourself.

Ask the seller for certificates for the proposed equipment.Without certificates, your boiler will simply be refused to be registered. Make sure that the number on the inside of the boiler is the same as the number on the accompanying documentation.

Certificate of conformity

If the boiler is to be mounted on a wall made of combustible material or a surface with a flammable finish, be sure to lay a fire-resistant coating on the base. Usually this is a sheet of metal or special substrates designed specifically for installing a wall-mounted boiler. The thickness of such a protective layer should be at least 2 mm.

There must be 40-50 mm of free space between the boiler body and the wall surface. Before connecting the unit, run water through its internal pipes. Such processing will remove dust and various kinds of debris from products.

Installation of the wall unit is carried out in several steps

Wall mounted gas boilers

First step. Attach the mounting brackets to the wall. The distance between such strips and the floor should be about one and a half meters. The minimum allowable distance is 100 cm. Make sure that the planks are fixed evenly using the building level. If necessary, align the slats and only then hang the gas boiler itself.

Second step. Attach the filter to the water supply pipe. Thanks to a special hard filter, clogging of the heat exchanger will be prevented.

Third step. Install the flue pipe and check the draft. For the operation of most modern boilers, strong traction is not needed, because. in such units, the removal of combustion products is carried out using a special fan. Make sure that there is no reverse thrust, its presence is unacceptable.

Regulatory requirements for a room for installing a gas boiler

Fourth step.Connect the gas boiler to the pipeline. To do this, use a threaded socket. From below, you need to connect the water return pipe, while the water supply pipe is connected from above. It is most convenient to use gas welding to connect elements. The maximum allowable slope is 0.5 cm per 1 m of pipe.

In the end, it remains only to connect the boiler to the mains if you have chosen a volatile model with automatic failure protection, and then invite gas service specialists to check the correct installation of the boiler, test run the equipment and put the unit into operation.

Coordination of the installation of a gas boiler

In order to install a gas boiler in a private house or apartment, it will not be enough to study the SNiP documents. To begin with, it is necessary to obtain technical conditions that will become the basis for organizing further work on connecting equipment to gas pipelines.

To do this, the landlord submits an application to the local gas supply service, which indicates the estimated gas consumption required for use in a particular building for heating and for other needs. This parameter is calculated approximately on the basis of SNiP 31-02, clause 9.1.3, which shows the average daily gas volume for a single-family house:

– gas stove (cooking) – 0.5 m³/day;

- hot water supply, that is, the use of a flowing gas water heater (column) - 0.5 m³ / day;

- heating using a domestic gas unit with a connected water circuit (for central Russia) - from 7 to 12 m³ / day.

In the local organization that controls the gas supply and installation of boiler equipment, the request is considered by specialists.For the applicant, a document is drawn up with technical conditions or with a reasoned refusal. The review process may take from one week to a month, depending on the efficiency of the work of this controlling service.

If the request is satisfied, then technical conditions are issued, which must be fully implemented during the installation of gas equipment. This document will simultaneously be a permission to carry out the relevant work.