- Installation

- Mounting

- Gas connection

- Health check

- Installation of a gas convector

- Convector Alpine air

- Convector Akog

- Secrets of the popularity of the gas convector

- Option #3. Upgrading with a duct fan

- How to install a gas convector

- Mounting

- Gas connection

- Health check

- Gas connection

- Gas supply: main stages

- Precautionary measures

- When and why is it effective to use gas convectors?

- Classification of gas convectors

- 1. According to the place of installation:

- 2. According to the source of gas supply:

- 3. According to the method of organizing combustion:

- 4. According to the material of manufacture of the heat exchanger:

- 5. According to the degree of energy dependence:

- 6. For additional features

- Convector selection

- Machine power

- Heat exchanger material

- Combustion chamber type

- Presence of a fan

- Room type

- Type of fuel

- The amount of fuel consumed

- LPG convector

- Gas connection

- What is a gas convector

- What is a convector made of?

- Gas convector - principle of operation

- Advantages and disadvantages

- Types of convectors

Installation

When the type of heater is determined, preparations for installation can begin.

It is necessary to stock up on the necessary tools, materials:

- drill with a set of drills of different diameters;

- pipe cutting tool;

- wrenches, adjustable wrenches;

- perforator;

- a set of screwdrivers with different sections;

- self-tapping screws, dowels;

- high temperature sanitary silicone;

- gas cock.

Mounting

it is necessary to determine the place for the hole where the pipe enters;

The installation stage is the most difficult, it can take a long period of time.

- it is necessary to drill holes for mounting the heater by hammering in the dowels;

- after, the exhaust pipe is connected. The joint between the heating device and the pipe must be carefully treated with silicone that can withstand high temperatures;

- mounting heating equipment on the wall. You need to invite a companion, the convector is heavy, it is difficult to install it yourself.

Gas connection

The stage is the most unsafe. If there is no experience in connecting heat carriers to gas, it is better to hire a specialist. Sequencing:

if there is a thread on the gas pipe, the outlet from the convector must be screwed on. If there is no thread on the tap, it must be done by welding on the pipe;

then, the pipeline from the gas source is connected to the apparatus with a fitting

It is necessary to act extremely carefully, carefully;

the pipe that is connected is fixed with clips. The step between the fasteners should be 1 meter. The pipe is fixed on the outside of the building;

joints, fittings are treated with heat-resistant silicone;

The pipe is fixed on the outside of the building;

joints, fittings are treated with heat-resistant silicone;

Health check

When the installation procedures are completed, do not rush to heat the room. It is necessary to make a start, check the correct operation. It is better to start the equipment for the first time with a specialist who will evaluate the operation of the device with knowledge of the case. The verification process is as follows:

- you need to open the gas valve, check for leaks. Can be made with a fixture, a soapy solution applied to the joints;

- press the start button for about one minute. It is necessary that the gas enters the combustion chamber;

- when the burner is lit, it is necessary to check the operation of the adjustment of the device.

If everything works well at all steps of the first start, you can try to heat the room.

Installation of a gas convector

It is very easy to install a gas type convector on your own

But before moving on to the installation process, it is important to choose the right model of the device. On sale there are both domestic inexpensive options, and foreign ones, the cost of which is higher. The most important thing is that the product is of high quality and reliable.

The most important thing is that the product is of high quality and reliable.

Convector Alpine air

Of the imported devices, one can name the Alpine air gas convector from a Turkish manufacturer. This is a high-quality series of devices with a cast-iron heat exchanger. The appearance of the unit is quite attractive. The heating power ranges from 2.5-9 kW. There are products equipped with a fan.

Convector Akog

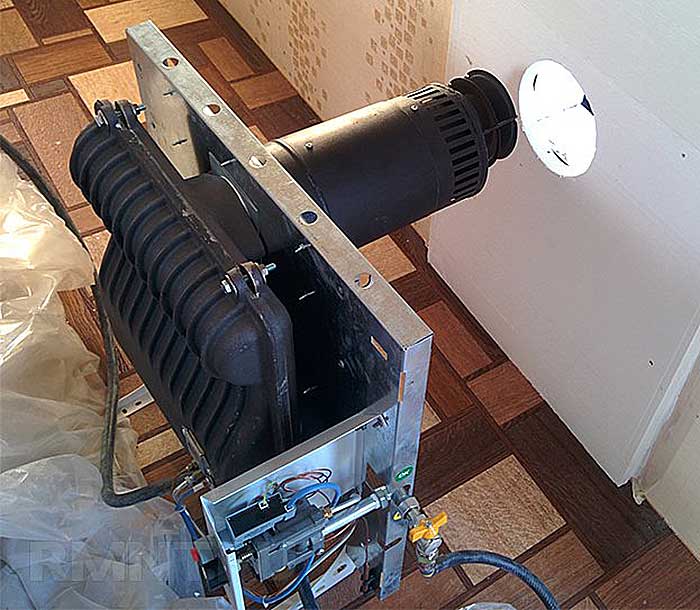

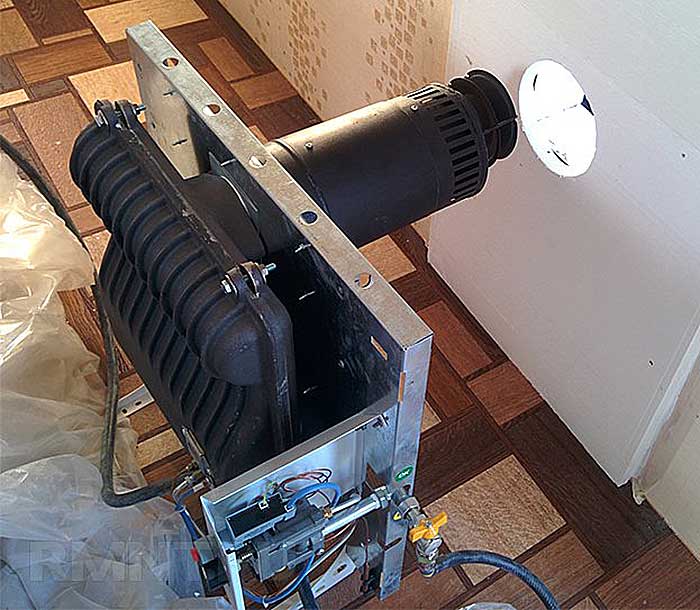

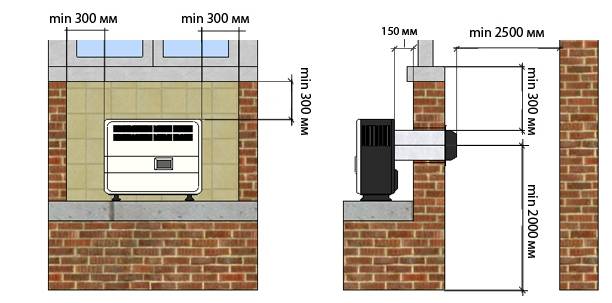

When gas equipment is purchased, it is necessary to determine the location of its location. It must fit the size of the device. It is allowed to place convectors only under the window. For installation, it is necessary to prepare the following tools: an electric drill, a pipe cutter, mounting foam, silicone, a wrench, a metal-plastic pipe, a set of screwdrivers, a gas valve, plastic dowels and self-tapping screws.

When the place is chosen, mark the output of the coaxial pipe. Using a perforator, a hole with a round crown is cut. It is necessary that there is a slight slope towards the street. This will avoid problems in rainy weather.

When the place is chosen, mark the output of the coaxial pipe. Using a perforator, a hole with a round crown is cut. It is necessary that there is a slight slope towards the street. This will avoid problems in rainy weather.

The dimensions of the pipe offset are made taking into account the characteristics of the model.The device is attached to the wall with four dowels. Studs may also work. It all depends on the weight. A gap is formed between the pipe and the wall. It must be filled with special mounting foam. Gas is supplied either by a flexible gas hose or a rigid pipeline

It is important to check the tightness of the connection. The fan and automation are powered by the mains, which must be connected individually. But you can also connect

But you can connect and.

Despite the fact that gas reviews of all users converge on heating convectors on such an advantage of these units as ease of installation, it is advisable to trust the installation to specialists with a license to carry out such work. This is especially true for connection to the gas pipeline. After all, the safety and durability of the operation of the equipment largely depends on the quality of the installation.

Our engineering and installation company Seti Service solves the problems of Muscovites, as well as residents of the region, who are associated with heating, water supply and sewerage. We are ready to offer you many options for solving your engineering problems with communications. For example, installation of convectors will help to quickly heat your home and maintain the required temperature level.

One of the advantages of this equipment is the absence of noise during operation. Such characteristics can also boast, which is in demand among our customers. But it is also worth mentioning that installation of heating convectorswill be convenient anyway. After all, it is absolutely easy to control the operation of these units - they have a simple and understandable control.

Convectors of the latest generation are produced according to the most modern designs.Therefore, this equipment can be characterized as energy-saving. Russian manufacturers offer units that are best suited for our conditions. By the way, the convector can be used as the main heating device, and auxiliary. Only high-quality ones compete with convectors.

Secrets of the popularity of the gas convector

Convectors, which use gas, equip residential, industrial and commercial facilities. They are especially in demand in private houses, small workshops, cafes that are not connected to centralized heating systems.

Often it is gas convectors that are used in heating large vehicles: campers, trucks, buses. They are more convenient to operate than solid fuel stoves and diesel fuel heaters, more economical than electrical appliances.

of Convectors, in which the air is heated by a gas burner, are installed in city apartments that are not connected to a centralized gas supply or located on the first floors of insufficiently insulated high-rise buildings. Almost all models of gas convectors can operate both on main fuel supplied by gas supply organizations and on bottled fuel The connection of the gas convector, into the chamber of which the gas for the combustion process should be supplied, is made with a hose to the cylinder or to the pipe of the public gas supply network. country houses. For organization of gas heating no need to lay pipelines, install a boiler, install shut-off and control valves With the help of gas convectors can quickly and inexpensively improve conditions in the entrances of multi-storey residential buildings, shopping malls, sports complexes, public buildings, commercial establishments. Gas-powered convectors are the best solution for arranging facilities remote from areas with developed infrastructure. They will perfectly heat car service points, tire shops and other workshops located on the highway. Gas convectors are actively used in the heating of various vehicles, as well as tents and campers. Gas convector in the interior of the apartment. Connecting the device to a centralized gas supply. in a country houseImprovement of conditions at the entranceHeating of car repair shops and gas stationsChimney convector in a motor vehicle

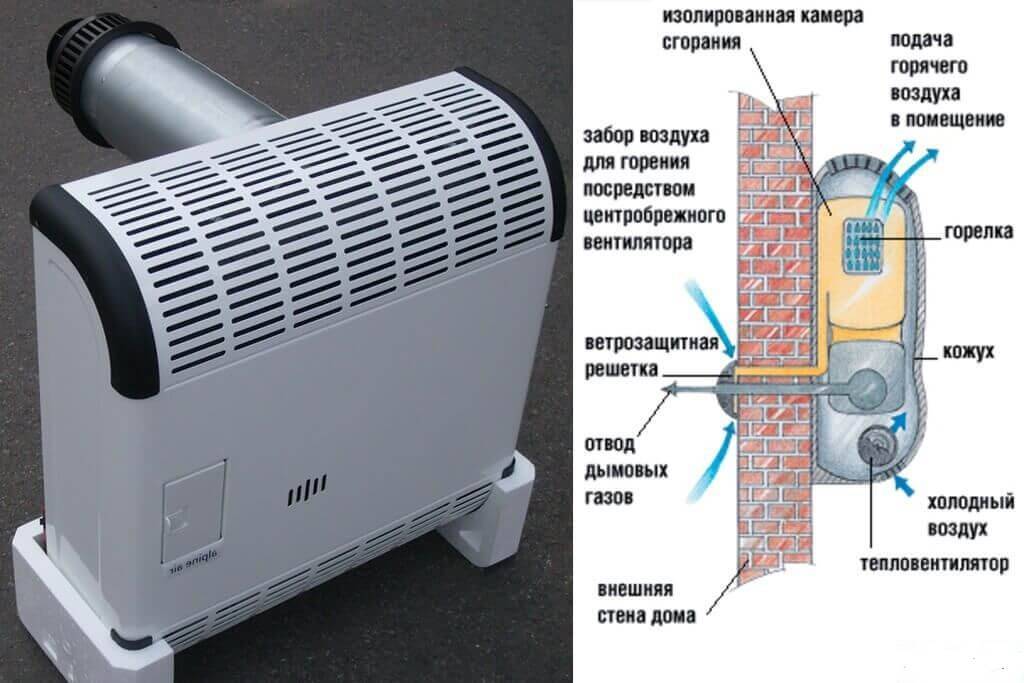

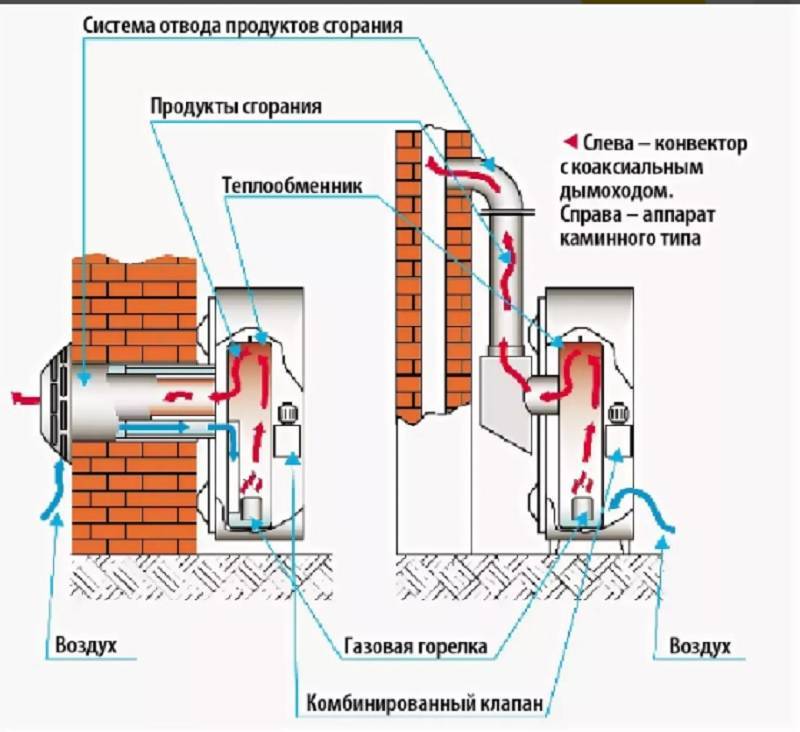

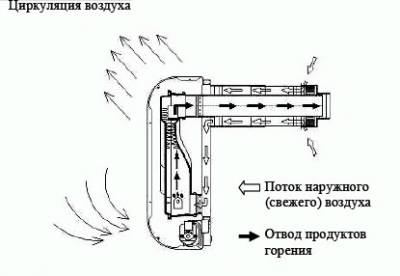

The operation of convective type devices is based on the natural movement of heated air passing through a combustion chamber located inside with a heat exchanger. The heat exchanger heats the gas burner, into which gas is supplied through a nozzle through a hose or pipe.

A 30 m² garage is heated by a convector without casing in about five minutes. Gas consumes no more than 500 rubles in the winter month. In autumn and spring, it works less often, which means that the costs are even reduced.

Option #3. Upgrading with a duct fan

The essence of the alteration is to install an air duct with an exhaust fan on the front grille.The heat generated by the convector is directed to the working area of the owner. There are no special tricks, but there is a significant reduction in heating costs.

Features of the device and operation of the modernized gas convector are presented in the video:

The products of combustion are removed outside the object as usual - through a coaxial pipe, through which fresh air is supplied to the burner to maintain the flame. This homemade product is much safer than the previous model, but it will still be necessary to periodically ventilate the treated room. Indeed, without a doubt, she will “drive” clouds of dust.

How to install a gas convector

After you have chosen and bought a heater, you can proceed to the preparation of the installation. Make sure you have the following tools and materials:

Tools needed to install a gas convector.

- drill and a set of drills;

- pipe cutter;

- a set of wrenches and an adjustable wrench;

- scapula;

- perforator;

- screwdrivers;

- sanitary and high temperature silicone;

- dowels and screws;

- gas cock.

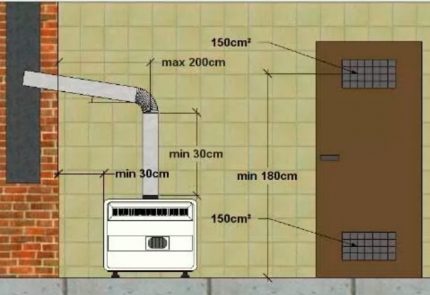

When everything is ready, you need to choose the location of the convector. For the correct selection, use GOST. The latter requires the mandatory installation of a heater under the window. Do not be too lazy in the process to try on the device to the selected place, and also make markings after that. The next step is to prepare the premises. The room should be covered, as a large amount of dust will appear during operation.

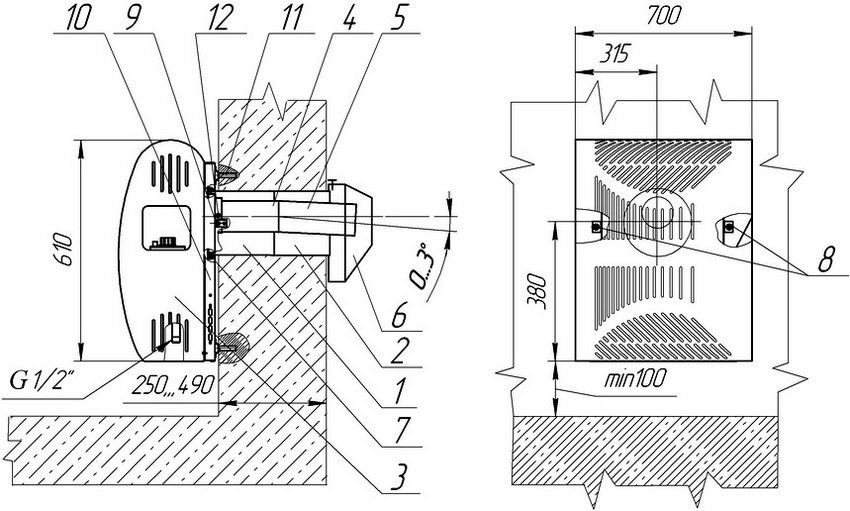

Mounting

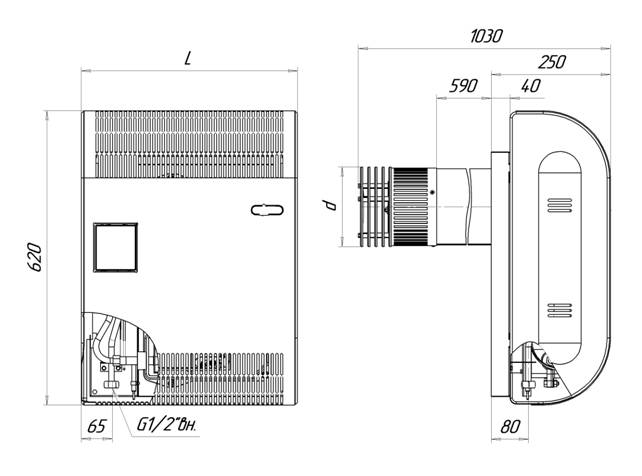

Technical requirements for the installation of a gas convector.

Installation is carried out according to the following plan:

- Determine the opening for the gas pipe inlet. Do not forget to leave a distance for summing up this very pipe and fitting.

- According to the diameter of the exhaust pipe, you need to drill a through hole in the wall using a puncher. This is the most difficult stage, since the hole is large, so the work will take time (depending on the wall and puncher), and a lot of dust will also appear.

- The next step is to drill holes for mounting the heater itself and hammer dowels into them.

- Now we connect an exhaust pipe to the convector and make a joint with silicone (capable of withstanding high temperatures).

- The heater itself is fixed with screws on the wall. This is where outside help comes in handy, since the weight of the device is considerable.

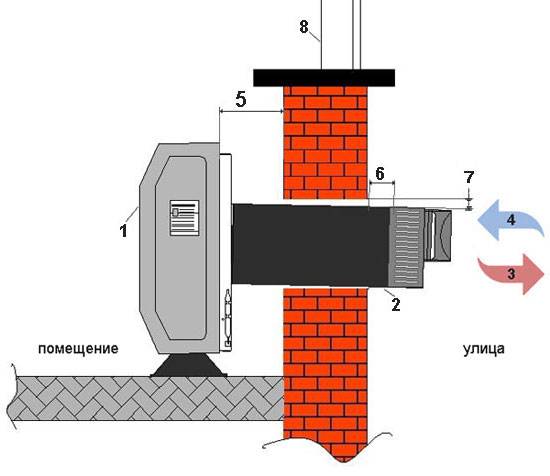

Gas connection

Take this step very seriously. If you doubt your skills, then it is better to entrust the connection to specialists.

Mount according to the following scheme:

In accordance with GOST, the pipe must be carried out from the street.

- If there is a special branch with a thread on the gas pipe, then this will make life easier. You just need to screw the gas valve onto the pipe. But if there is no withdrawal, then it must be done.

- Next, bring the pipe to the convector. It is better to use metal-plastic. The connection of the fittings must be perfect.

- During the laying of the pipe through each meter, it must be fixed to special clips. You also need to drill holes for this.

- To check the connections, you must call a gas service employee.

Health check

Before turning on the appliance, be sure to call the gas service to check the connections for gas leaks.

After completing the installation work, it is necessary to make a test run:

- First of all, open the gas valve, listen to all joints for possible leaks (you can use soapy water or a special device).If leaks are found, close the faucet and fix them.

- After checking all joints, start the convector. During start-up, hold down the button for a minute so that the gas enters the combustion chamber.

- After the burner ignites, adjust the operation of the appliance.

Gas connection

Friends, at this stage it is important to be extremely careful! Let's say that you do not have the skills to work with gas appliances - then it is better to contact specialists to perform the following work

Installation of a gas heater to a gas supply source is carried out according to the following algorithm.

- Let's imagine that there is a special branch with a thread on a gas pipe. Then you just need to screw a gas valve onto this pipe. If there is no special withdrawal, then it will need to be done!

- The next step is to bring the gas pipe to the convector and connect them with a fitting. This process is not rushed.

- Fix the connected pipe with special clips. The distance between them is 1 meter. To do this, it will be necessary to drill holes on the outer wall of the building.

- Treat fittings and pipe joints with silicone to ensure tightness.

- Be sure to call a gas service representative so that he can verify that the installation and connections are correct.

Gas supply: main stages

The installation of the gas convector has been completed, now you need to deal with the gas supply. This stage is quite complex and responsible at the same time. To supply gas, do the following:

- According to regulatory documents, the pipe suitable for the convector must run along the street. There are two options here: the first - the pipe has a pre-extracted threaded connection, the second - there is no such connection.If there is a thread, then you can screw on the gas valve yourself, which will shut off the gas supply to the convector. In the absence of a withdrawal, it must be done. To do this, call professional gas welders from the local Gorgaz or a similar office.

- After installing the gas cock, it is necessary to lead a metal-plastic pipe to the convector itself. Using a tape measure, calculate the length of the pipe, simultaneously determining the presence of fittings.

- You need to buy a pipe and fittings. The principle of the purchase is that the seller needs to clarify the presence of a certificate of conformity of these pipes and fittings for this type of work.

- Lay the pipe, fix it with clips every m. To install the clips, you need to drill holes in the wall.

- When installing the necessary fittings, carefully lubricate the pipe and the fitting itself with silicone, which will give an additional seal. The silicone will also act as a lubricant and make pipe installation easier.

As a result of the work, you should get a convector mounted on the wall with a gas pipe connected to it.

Now the last stage of the installation remains. A test run is required.

Before starting, open the gas cock and go over all the joints of the fittings and threaded connections with a brush moistened with an aqueous solution of soap or shampoo. So you can notice the inflated bubbles (if any), which indicate gas leaks. If this happens, close the gas supply valve immediately. After checking the joints, start the convector. To do this, hold down the gas supply button for one minute. So the gas will have time to pass through the pipes and get into the combustion chamber. Press the piezo igniter, the spark should ignite the gas. A blue flame will ignite in the furnace.

Adjust the operation of the convector by setting a comfortable temperature. During the first few hours of operation, you may experience an unpleasant smell of burning oil. This is normal, since the convector is new and the combustion chamber is burning. If the smell lingers for a long time, then it is worth turning off the gas and re-checking all joints and threaded connections.

It is advisable that all work on the installation of gas convectors be performed by a professional who has sufficient experience in performing such work. This is also due to the fact that self-installation of the convector can void your warranty for the device. The gas convector must be taken over by Gorgaz.

You must have documentary permission for the tie-in in your hands. In addition, all installation decisions, as well as the conclusions of the commissioning commission of the device, must be documented and signed in an appropriate way.

Gas convectors are not as popular as their electric counterparts. Gas devices require a connected centralized gas supply or cylinder, and are also not as safe. But gas models are cheaper to use, so they will be an excellent solution in a country house or cottage where constant maintenance of heat in the room is not required.

Precautionary measures

The use of household appliances requires compliance with safety regulations. Be careful and listen to the advice of manufacturers:

- do not use a convector with a damaged viewing window,

- if the device spontaneously extinguished, do not rekindle it earlier than after 3 minutes,

- to prevent burns, the convector is protected with a protective grille.

It is strictly prohibited:

- dry things on a working device,

- turn the device on and off for children and people with limited legal capacity,

- operate the device with the outer casing removed,

- repair the device on your own,

- place flammable objects at a distance of less than 1 m from it,

- leave it on if there are signs of a gas leak.

If there is an unpleasant smell in the house, urgently take precautionary measures:

- turn off the gas supply,

- Extinguish all open flames

- do not touch the switches and mobile phones,

- ventilate the room

- urgently call the emergency gas service,

- contact the gas convector service center.

When and why is it effective to use gas convectors?

Gas convectors are characterized by low resource consumption, but they are not able to develop the proper power for heating large rooms. Therefore, small private houses for one or two living rooms, summer cottages, garages and temporary buildings became the scope of their application. In such conditions, the heating gas convector provides the following advantages:

- compactness, relative cheapness and ease of installation of equipment;

- no need to develop and approve project documentation;

- autonomy in case of supplying the convector from gas cylinders;

- high efficiency (up to 90% in industrial production devices and up to 80% in home-made convectors);

- resistance to low temperatures, no “freezing effect”;

- the use of atmospheric oxygen, and not located indoors;

- fuel versatility, that is, the possibility of switching from methane to propane by replacing nozzles.

Among the shortcomings of the system, the most significant are serious losses in efficiency when heating large rooms and an increase in their warm-up time.

The second problem is partly eliminated by installing convectors with forced circulation, that is, equipped with a blower fan, however, in houses with three or more rooms, the rationality of such a solution is very doubtful.

Another problem that may arise when trying to convert an apartment for convector heating is the prohibition of the municipal gas service, caused by the potential danger of the device for neighbors. Therefore, residents of apartment buildings need to coordinate such work in advance.

Classification of gas convectors

1. According to the place of installation:

- wall. The wall-mounted gas convector is compact, does not take up floor space, and does not create restrictions on the placement of interior elements. Installing the equipment above the window allows you to get the effect of a thermal curtain, when the air entering through the window will warm up as it enters the room. Wall convectors are distinguished by low power (up to 10 kW.), however, they are more popular;

- floor. The floor gas convector is more powerful and is designed for heating large rooms. The power of a floor convector can reach 100 kW, which affects the weight and dimensions of the unit.

- built-in convectors. But they belong to the "water convector" group.

2. According to the source of gas supply:

main (natural gas). All convectors are initially focused on connection to the gas pipeline;

liquefied gas (propane-butane from a cylinder). The transition to this type of gas supply is possible due to the installation of an adapter kit.But, it should be noted that the heating costs will be the same as with heating in the traditional way, and the requirements for a heating device from a cylinder are much more stringent.

The method of gas supply determines the mobility of the convector and the cost of heating.

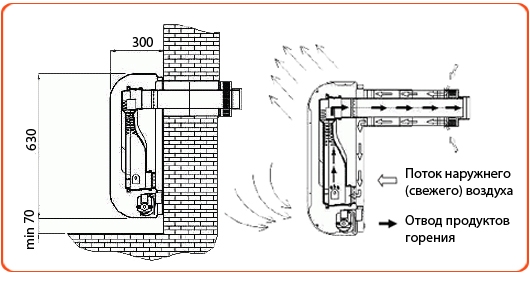

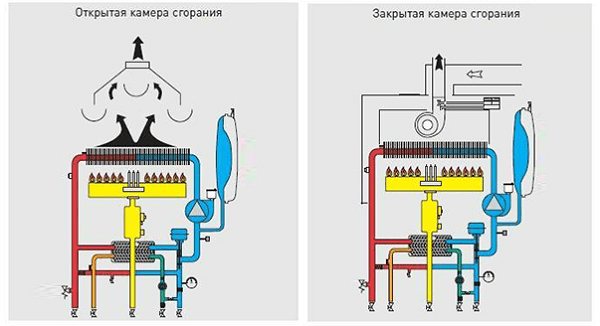

3. According to the method of organizing combustion:

closed chamber (for example, Alpine Air NGS 50 gas convector). Here, air supply and exhaust are organized through a horizontal telescopic pipe, which allows you to avoid the arrangement of a traditional chimney, replacing it with a coaxial chimney (pipe in a pipe). This principle allows exhaust gases to be removed through the inner pipe, and air is supplied through the outer one.

open chamber (for example, gas convector Hosseven HP-8 or Alpine Air M-145). In this case, the organization of the chimney is required. The heater, according to the principle of operation, is similar to a fireplace, and users can watch the play of live fire.

4. According to the material of manufacture of the heat exchanger:

cast iron. Withstands higher temperatures;

steel. Used in units in the lower price range.

Note that the material from which the heat exchanger is made determines the duration of the operation of the convector.

5. According to the degree of energy dependence:

independent. They do not require an electrical connection to operate. Demanded in regions with power outages;

dependent. Electricity is used to ignite the main burner. This technique has a positive effect on gas consumption, reducing it by a quarter, compared with independent models.

6. For additional features

As such are:

fan. Allows you to increase the speed of air passing through the heat exchanger.On the one hand, this reduces the time for warming up the room, on the other hand, it cools the heat exchanger itself, preventing its failure;

timer. Allows you to automate turning on and off the unit.

Convector selection

How to choose a gas convector? First of all, attention is drawn to the technical characteristics of the unit. The best option can be considered a device with a closed combustion chamber and a cast iron heat exchanger. The presence of a programmable control unit is considered important.

Consider other factors that you should pay attention to when choosing a domestic gas convector

The presence of a programmable control unit is considered important.

Consider other factors that you should pay attention to when choosing a domestic gas convector

Machine power

Since heating occurs due to air circulation, the units work effectively only in one room. Therefore, each room will require the installation of a separate unit. Power is determined from the calculation: 100 watts are required per 1 m 2 of area.

Heat exchanger material

Since gas heating convectors operate on gas that burns in a special chamber, the heat exchanger is subjected to strong temperature effects. If it burns out after a while, the device fails. Therefore, the material of this part must be resistant to high temperatures. The leader among the materials for the heat exchanger is cast iron. This metal is resistant to thermal stress, in addition, it cools very slowly and evenly distributes heat. Gas convectors with a cast-iron heat exchanger can last up to 50 years. The main disadvantages of such devices are the high price and the large mass of the unit.A heater with a steel heat exchanger is cheaper and lighter

But when choosing a unit, you should pay attention to the quality of the steel. Steel heat exchangers can last at least 20 years

Combustion chamber type

Heaters may differ structurally according to the type of combustion chambers:

- open the combustion chamber. Installation of a unit with such a chamber requires the installation of a chimney with access to the roof. In addition, during the operation of the unit, to maintain the combustion process, air will be taken from the room. Therefore, good ventilation of the room is required.

- Closed the combustion chamber. Such models are more popular, since the pipe does not need to be led through the roof (a coaxial pipe is installed opposite the device). And another plus can be called the fact that oxygen in the room is not burned out, since air is taken from outside the building.

Presence of a fan

A gas convector with a fan quickly and evenly heats the entire room. Due to the forced air supply to the heat exchanger, the latter is better cooled. And since overheating is not allowed, the service life of the heat exchanger is significantly increased.

Room type

If you want to install a convector in the apartment

, then the best choice would be a device with a closed combustion chamber and a chimney with a coaxial pipe. This type of apparatus does not burn oxygen in the room. ATprivate buildings you can install any . But when using a device with an open combustion chamber, the room must have forced ventilation.

Type of fuel

The use of liquefied gas is prohibited in apartment buildings. Therefore, the device is connected only to the highway

. In private houses, use a gas convectoron bottled gas it is possible, provided that the cylinder is installed outdoors in a special metal cabinet.

The amount of fuel consumed

Fuel consumption in gas heating equipment is considered economical. To calculate the gas flow rate, the following basic parameters are accepted:

- 1 kW of power will require 0.11 m 3 of gas from the main;

- 0.09 m 3 of liquefied gas will be required per 1 kW of power.

Based on these indicators, you can make a calculation. For example, a 4 kW heater (designed for 40 m 2 of area) will consume 0.44 m 3 of gas per hour of operation, and 10.56 m 3 per day. But, since the device does not work constantly, this figure will be much less.

LPG convector

The air heater can be converted to work on bottled (liquefied) gas. For this, special nozzles and a gearbox are purchased. If there are several such convectors in the house, then they will equip a special room on the outside of the house for storing propane cylinders.

A comfortable temperature in the house is obtained using the built-in thermostat. It prevents overheating of the air in the room, while the gas is consumed more efficiently.

Important! Gas combustion products will not enter the air space of the room if they are vented into the chimney. Before you buy an air heater, calculate the required power to heat the volume of the room in which you plan to install it.

Be sure to consider the height of the ceilings, otherwise the device may not meet your expectations. The best location for convectors is under the windows.In this case, cold air does not have time to penetrate into the room.

Before you buy an air heater, calculate the required power to heat the volume of the room in which you plan to install it. Be sure to consider the height of the ceilings, otherwise the device may not meet your expectations. The best location for convectors is under the windows. In this case, cold air does not have time to penetrate into the room.

Sometimes these devices are used as an additional source of heat in severe frosts. Approximately 0.095 kg of liquefied gas per 1 kW of heat transfer power burns per day. Keep in mind that a cast-iron heat exchanger in a gas convector lasts much longer than a steel one. Its service life can last up to 50 years, but such a device costs much more. Manufacturers give a factory warranty of up to 5 years. Make sure that all documents, including the warranty card, are filled out in the store when purchasing the device.

Gas connection

Friends, at this stage it is important to be extremely careful! Let's say that you do not have the skills to work with gas appliances - then it is better to contact specialists to perform the following work

Installation of a gas heater to a gas supply source is carried out according to the following algorithm.

- Let's imagine that there is a special branch with a thread on a gas pipe. Then you just need to screw a gas valve onto this pipe. If there is no special withdrawal, then it will need to be done!

- The next step is to bring the gas pipe to the convector and connect them with a fitting. This process is not rushed.

- Fix the connected pipe with special clips. The distance between them is 1 meter.To do this, it will be necessary to drill holes on the outer wall of the building.

- Treat fittings and pipe joints with silicone to ensure tightness.

- Be sure to call a gas service representative so that he can verify that the installation and connections are correct.

What is a gas convector

It should be noted right away that the convector is not a type of boiler, it works not only according to a different principle (it does not heat the coolant, but the air in a certain room), but also has a slightly different scope. Most often, gas heaters are used in small houses where there is no need for constant heating. They are able to heat only the room where they are installed.

What is a convector made of?

The design of the device is not too complicated, it includes:

Scheme of a standard gas convector with a fan for forced convection.

- a heat exchanger that heats the air;

- programmer - a device for controlling and maintaining the temperature in the room;

- control panel with various indicators;

- gas valve to control the gas supply;

- a fan supplying air to the valve and heat exchanger;

- a fan that provides forced supply of warm air into the room.

Gas convector - principle of operation

As you can see from the diagram, everything is quite simple. The convector plays the role of a gas burner, cold air enters from below under the action of convection, heats up and exits through an opening at the top.

The device works quite simply: the principle of operation is based on the phenomenon of convection - when heated, warm air rises and cold air descends. Gas models can work both by natural convection and by forced convection.In the latter case, a special fan is used to supply air.

Advantages and disadvantages

The quality of the device itself, as well as its work, depends on the price. By choosing a cheap model, you will not save money, since the device can last you less than a year. Repair in this situation will be unprofitable. Therefore, we will consider the advantages and disadvantages based only on high-quality devices. So the pros:

- efficiency and rapid heating of the room;

- simple installation of a gas convector with your own hands;

- there is no need to make a heating system (water);

- low price;

- unlike electrical counterparts, gas models do not burn oxygen;

- fully autonomous mode of operation;

- not tied to electricity (except convectors with forced circulation);

- It is possible to connect the heater to a gas cylinder.

But gas convectors are not without drawbacks:

- if gas is used from a centralized system, then it is imperative to obtain permission to connect the device;

- it is necessary to punch holes in the wall outward where the heater will be attached;

- considerable dimensions;

- if you decide to install several convectors, then the gas will have to be supplied to each of them, moreover, only outside the building.

Choose models with a built-in fan. They are more efficient than their fanless counterparts.

Types of convectors

Devices can be classified by their power, as well as by execution. If everything is clear with power: choose the one that is able to heat the room, then with the types of performance, things are a little more complicated.

There are two types of heaters:

Wall models can very well fit into the interior.

- Floor - devices are installed on the floor, do not require special skills and abilities in installation. Such a convector can heat a rather large room (even an industrial one), but it is heavy and requires a special foundation.

- Wall-mounted - more compact models that fit well into the interior of the house. Often, devices are mounted under a window to create a thermal curtain from cold air passing through the glass. Convectors of this type have low power, so they are only suitable for heating rooms in houses up to 100 square meters.

There is another subtype of heaters - built-in. They can be installed on the floor or wall, not only do not spoil the interior, but also decorate it. In terms of parameters, such models do not differ from wall-mounted ones. But it is more difficult to install them, since it is necessary to prepare a niche for the device in advance.

When choosing a convector, you should also pay attention to the material of the heat exchanger. The latter can be made of steel, cast iron or copper.

Models with a steel heat exchanger are now more common, however, cast iron ones have a higher efficiency due to the properties of the alloy, and are also able to last longer. Their only drawback is their heavy weight. Copper counterparts are effective and durable, but expensive.

All considered convectors are closed. Open ones also exist, but they take the air necessary for the combustion of gas from the room, and the waste enters the general ventilation. Due to these properties, it is highly not recommended to install open-type heaters in residential premises.