- Installation schemes in various types of systems

- 8 Connection Features

- Technology for installing pumping equipment in the network

- Installation area selection and connection

- Connecting the pump to the power supply

- Where to put the circulation pump?

- The main functions of the pump in the system

- Choosing a pump

- Conclusion

Installation schemes in various types of systems

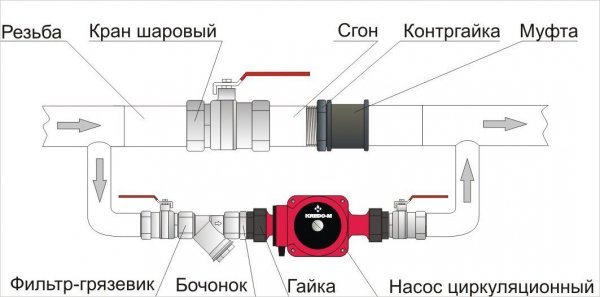

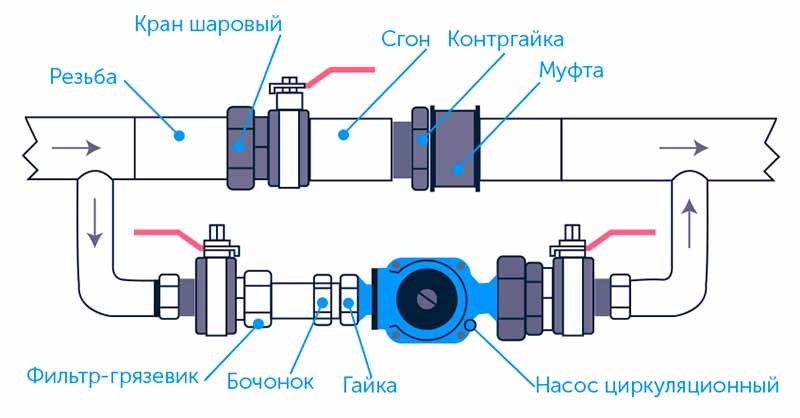

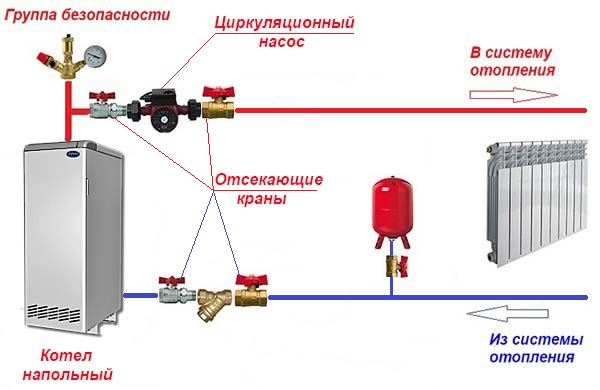

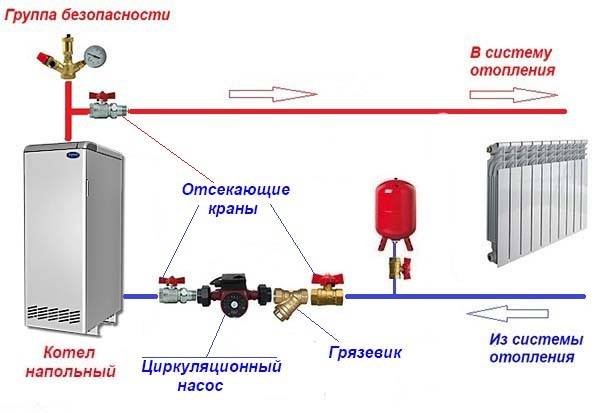

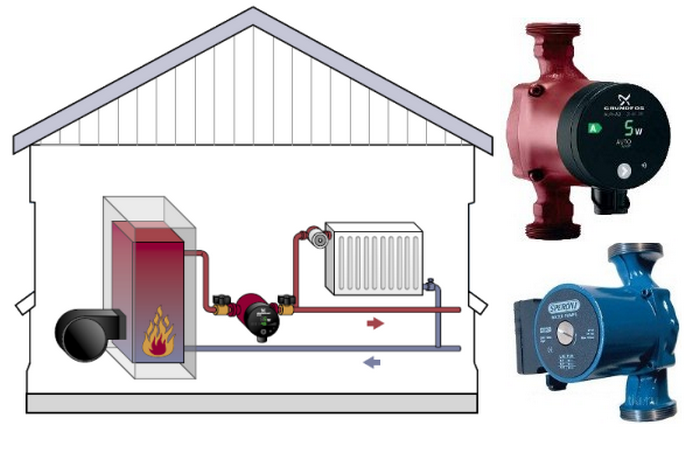

To begin with, let's specify the place where to put the flow pump, which ensures the circulation of water through the boiler and forcibly directs it to the radiators of the heating system. According to our expert Vladimir Sukhorukov. whose experience is trustworthy, the installation site must be chosen in such a way that the unit can be easily serviced. At the supply, it should be after the safety group and the fittings cutting off the boiler, as shown in the installation diagram:

In order for the equipment to be removed and serviced, shut-off valves must be installed

On the return line, the pump must be placed directly in front of the heat generator, and in tandem with a filter - a mud collector, so that you do not have to buy and install extra taps. The piping scheme of the pumping unit looks like this:

Use 1 less tap for return mounting

Recommendation. The circulation pump can be installed in this way both in a closed and in an open heating system, there is no big difference.The statement also applies to the collector system, where the coolant moves to the radiators through separate pipes connected to the distribution comb.

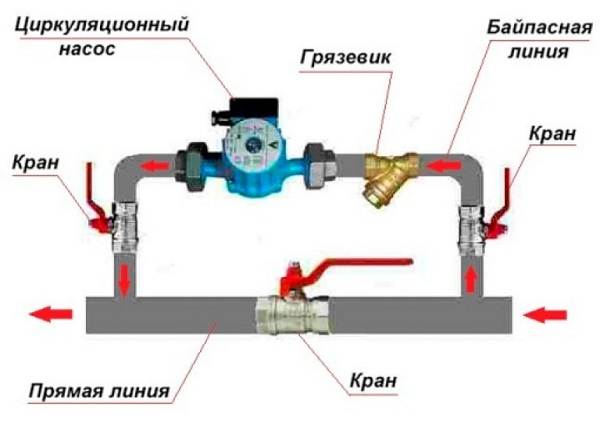

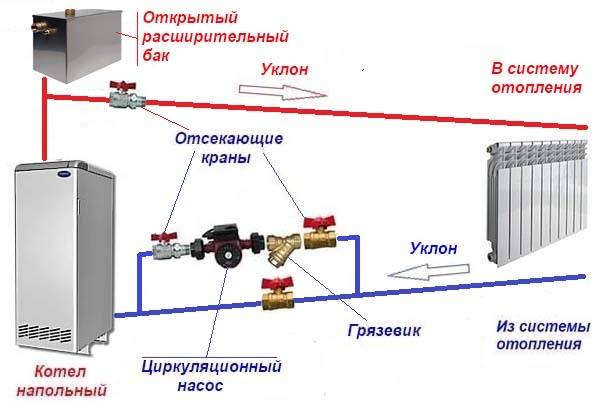

A separate issue is an open heating system with a circulation pump capable of operating in 2 modes - forced and gravity. The latter is useful for homes where power outages often occur, and incomes do not allow owners to buy an uninterruptible power supply unit or a generator. Then the apparatus with shut-off valves must be placed on the bypass, and a tap should be inserted into a straight line, as shown in the diagram:

This circuit can work in forced and gravity mode.

An important point. On sale there are ready-made bypass units with a pump, where instead of a tap on the duct there is a check valve. Such a decision cannot be called correct, since the spring-type check valve creates a resistance of the order of 0.08-0.1 bar, which is too much for a gravity-flow heating system. Instead, you can use a petal valve, but it must be placed only in a horizontal position.

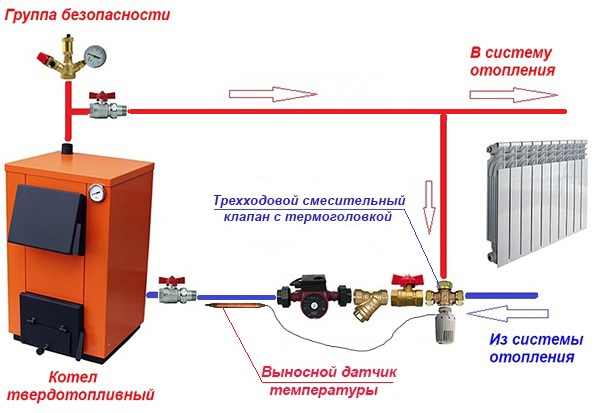

Finally, we will explain how to install and connect the circulation pump to a solid fuel boiler. As mentioned above, it is better to put the unit on the line going from the heating system to the heat generator, which is shown in the diagram:

As you can see, the piping uses a pump connected to the boiler circulation circuit with a bypass and a three-way mixing valve

The important role of these strapping elements is described in detail here.

8 Connection Features

When connecting the pump to the electrical network in heating systems with natural circulation, it is necessary to use an automatic fuse with a flag, which will be both a switch and a fuse. An automatic fuse must be installed at a distance of at least half a meter from boiler equipment and heating appliances.

To connect the pump to a network with forced circulation, it must be taken into account that one is already located and starts its work if a thermal sensor is triggered. For synchronous operation of two devices, the additional one must also be connected to a thermal sensor or to the main pump using a parallel connection.

In heating systems with an electric boiler, the pump can be connected to the boiler itself, then the circulation system will start working only during the heating of the coolant.

Installing a pump in a heating system is quite a feasible task for any home master. A careful study of all stages of installation will make it possible to make the heating system reliable and efficient. Taking into account all the features during the performance of this work, you can forget about the problem of uneven distribution of the coolant and the appearance of air locks in the system.

Technology for installing pumping equipment in the network

Stages of work: select a supercharger, determine the tie-in zone, install and connect.

Installation rules:

- Bypass and ball valves allow you to turn off equipment, quickly remove and replace or repair without interrupting the network. An air valve of a manual or automatic type must be cut into the upper part of the bypass.

- Superchargers with manual adjustment must be vented before starting. To do this, open the air release valve, start the device for 10 minutes, turn it off and open the valve again. The process is performed every time the network is put into operation.

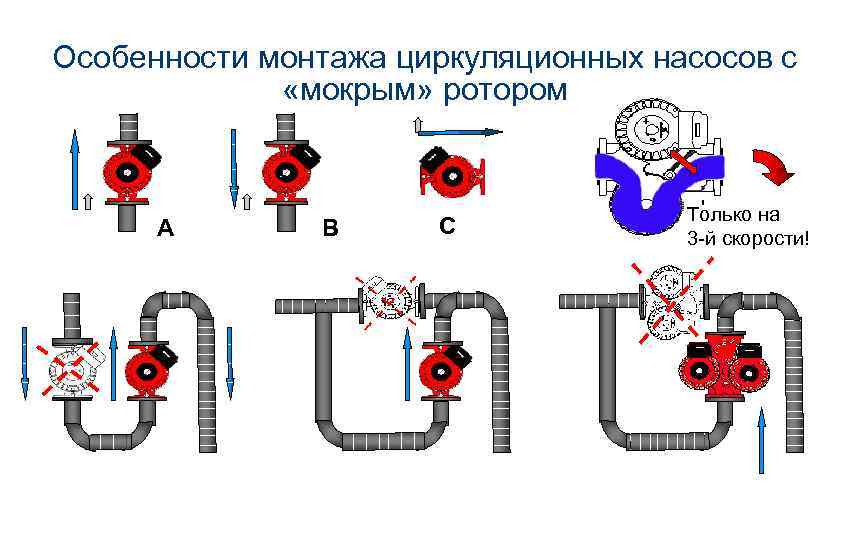

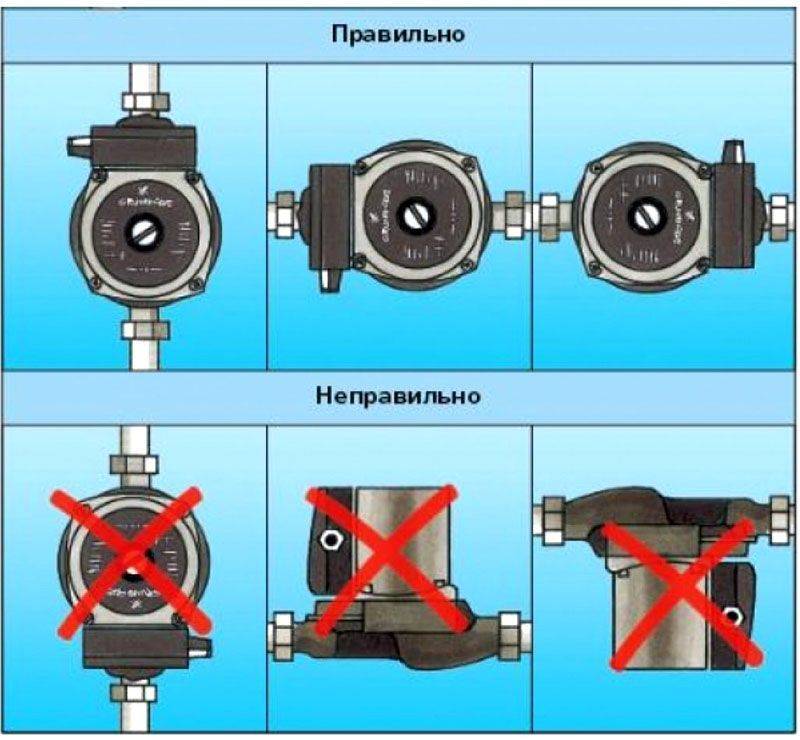

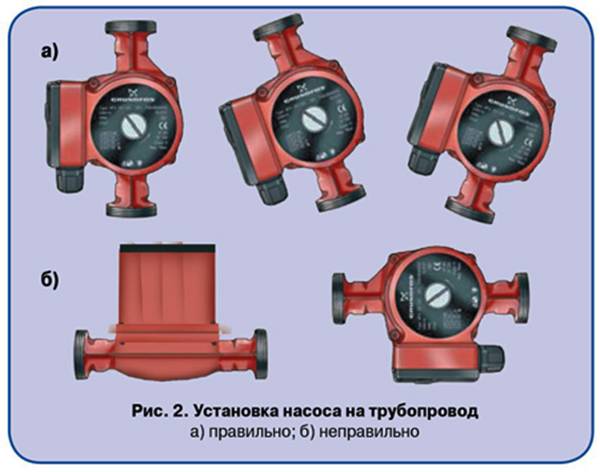

- The pump is placed only horizontally so that the blades are immersed in the coolant when the pipeline is partially filled. The terminals are at the top.

- The socket for connection is separate, sealed and grounded.

- With a pipeline length of up to 80 m, one pump is enough. If there are branches, more than 5 batteries or a network longer than 80 m, several superchargers are cut in. For every additional 20 meters, one pump. A separate device is mounted on a dead end branch, for example, when heat is supplied to a remote room.

Installation area selection and connection

Most often, the owners adhere to the installation scheme of the circulation pump in the heating system in the reverse circulation circuit.

The reasons are:

- temperature and density are lower, the equipment will last longer;

- increased static water pressure reduces the load.

It is allowed to insert the pump into the heating system to the supply circuit, but only if the coolant is heated up to + 110 C at peak loads. This means that in a network with solid fuel boilers, it is better to install the blower in the return pipe, and in all other cases, you can crash into the supply circuit.

Do-it-yourself heating pump connection and piping depend on the network diagram:

- In a system with gravity circulation, a bypass is first installed. This is a jumper to keep the line running during a power outage. Bypass is available in stores. The complete set includes existence of cranes, the valve, the drain valve.Mount according to the scheme in the passport. As soon as the electricity is turned off, a ball valve is opened on the bypass, the water will bypass the pump. A closed bypass valve and an open water supply valve to the pump start the operation of the network with forced circulation.

- For a network with forced circulation, the blower is cut into a break in the supply or return pipe. On both sides of the pump, ball valves are needed to disable the equipment from work in the event of a breakdown or disturbance. It is not necessary to drain the coolant from the entire network - only from the section of the network with the pump.

Recommendations:

- The rotor is rotated only horizontally. Such placement will not disable the equipment when the pipeline is partially filled with water.

- Before installation, it is necessary to inspect the device - there is an arrow on it showing the direction of flow. Install on it.

- If the pump can work in a horizontal and vertical position, the tie-in is vertical. But this will reduce the performance of the equipment by almost a third.

Connecting the pump to the power supply

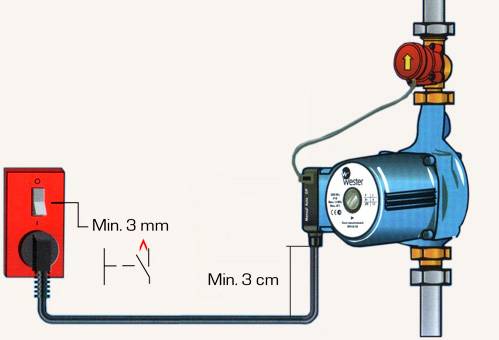

Standard household blowers operate on 220 volts. The basic rule is that the outlet must be separate, sealed and grounded. To form a connection, three wires are needed - phase, zero, ground.

How to connect the pump to the heating system:

- Equip the outlet with a circuit breaker. If the blower is equipped with a power cable, a terminal block must be connected directly to the cable and terminals.

- The terminals are located under the cover, the connectors are signed with letters: N is zero, L is phase, the “ground” connector is not marked.

- Three wires are joined to the connectors, fixed, and the cover is closed. After that, they check the grounding, test the network, put it into operation.

Backup power is organized by a stabilizer with storage devices. The larger the volume of drives, the longer the device will work without a centralized power supply. On average, the consumption of the pump is up to 300 W per day, and you can clarify the indicator in the data sheet of the device.

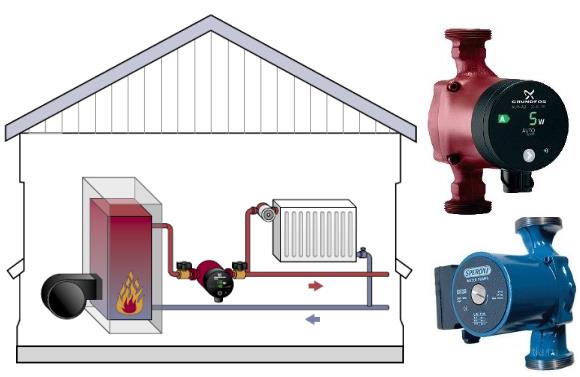

Where to put the circulation pump?

Most often, the circulation pump is installed on the return line, and not on the supply. It is believed that there is a lower risk of rapid wear and tear of the device, since the coolant has already cooled down. But for modern pumps this is not necessary, since bearings with so-called water lubrication are installed there. They are already designed specifically for such operating conditions.

This means that it is possible to install a circulation pump in the supply, especially since the hydrostatic pressure of the system is lower here. The installation location of the device conditionally divides the system into two parts: the discharge area and the suction area. The pump installed on the supply, immediately after the expansion tank, will pump water out of the storage tank and pump it into the system.

The circulation pump in the heating system divides the circuit into two parts: the injection area, into which the coolant enters, and the rarefaction area, from which it is pumped out

If the pump is installed on the return line in front of the expansion tank, then it will pump water into the tank, pumping it out of the system. Understanding this point will help to take into account the features of hydraulic pressure at various points in the system. When the pump is running, the dynamic pressure in the system with a constant amount of coolant remains constant.

It is important not only to choose the optimal place for the installation of pumping equipment, but also to install it correctly. We recommend that you familiarize yourself with the nuances of installing a circulation pump

The expansion tank creates a so-called static pressure. Relative to this indicator, an increased hydraulic pressure is created in the injection area of the heating system, and a reduced one in the rarefaction area.

The rarefaction can be so strong that it reaches the level of atmospheric pressure or even lower, and this creates the conditions for air to enter the system from the surrounding space.

In the area of pressure increase, air can, on the contrary, be pushed out of the system, sometimes boiling of the coolant is observed. All this can lead to incorrect operation of heating equipment. To avoid such problems, overpressure must be ensured in the suction area.

To do this, you can use one of the following solutions:

- raise the expansion tank to a height of at least 80 cm from the level of the heating pipes;

- place the drive at the highest point of the system;

- disconnect the accumulator branch pipe from the supply and transfer it to the return line after the pump;

- install the pump not on the return, but on the supply.

Raising the expansion tank to a sufficient height is not always possible. It is usually placed in the attic if there is the necessary space.

At the same time, it is important to follow the rules for installing the drive in order to ensure its trouble-free operation.

We provided detailed recommendations for installing and connecting an expansion tank in our other article.

If the attic is not heated, the drive will have to be insulated.It is quite difficult to rearrange the tank to the highest point of the system with forced circulation, if it was previously created as natural.

Part of the pipeline will have to be redone so that the slope of the pipes is directed towards the boiler. In natural systems, the slope is usually made towards the boiler.

An expansion tank installed indoors does not need additional protection, but if it is installed in an unheated attic, care should be taken to insulate this device

Changing the position of the tank nozzle from supply to return is usually not difficult to perform. And it is just as easy to implement the last option: to insert a circulation pump into the system on the supply line behind the expansion tank.

In such a situation, it is recommended to choose the most reliable pump model, which can endure contact with the hot coolant for a long time.

The main functions of the pump in the system

Place in the circulation system

Owning a private house or a cottage, the owners in the overwhelming majority of cases face a serious problem consisting in uneven heating of all rooms of the house supplied from the central system.

Quite often, this situation is accompanied by the occurrence of the process of heating water in the boiler to 100 degrees Celsius at a time when the temperature of the pipes in remote rooms remains at a minimum.

In order to bring the system into working condition of proper quality, it is recommended to use two options for the development of the process:

- use pipes of larger diameter and redevelop the entire system;

- use a circulation type pump that cuts into a certain part of the system and plays an important role in the process of distributing fluid in the system.

The second option is the most in demand, because it requires the least investment in re-equipment of the system in order to achieve the required supply of hot water to remote parts of the system. Among other things, the installation of the pump is many times faster compared to a full-fledged modernization associated with the use of the first technology.

In the case of a pump tie-in, the following indicators can be achieved:

- bringing the temperature of the entire system to a single indicator;

- elimination of possible traffic jams from the air, which, as a rule, are an insurmountable barrier in the way of water movement;

- to make a significant increase in the radius of the contour of the heating system of the building;

The purchase of the necessary parts of the equipment and the pump itself is carried out in specialized places of sale for the purpose of subsequent use in order to increase the throughput of the system.

In order to purchase the necessary version of the pump, it is necessary to understand that calculations in this matter play one of the main roles, because with their help it is possible to obtain the optimal value of the throughput that the pump should have.

In order to conduct a competent calculation, it is necessary to use the existing formula according to which it is recommended to perform computational actions and increase the result by 10 percent to purchase the necessary injection-type equipment.

Choosing a pump

To choose the right pump, you should evaluate the characteristics of the product and take into account some recommendations.

BC 1xBet has released an application, now you can officially download 1xBet for Android by clicking on the active link for free and without any registration.

- Before buying a unit, you need to calculate the flow rate of the liquid and coolant, as well as the length of the pipeline.

- The flow rate of the coolant that passes through all sections of the heating system is calculated in the same way as the flow rate of the liquid in the equipment.

When choosing a pump, take into account the diameter of the pipe, the pressure of the coolant, the performance of the boiler, the water temperature and the throughput of the boiler. The table shows the water consumption at a standard travel speed of 1.5 m/s.

| Water consumption | 5,7 | 15 | 30 | 53 | 83 | 170 | 320 |

| Pipe diameter (inches) | 0,5 | 0,75 | 1 | 1,25 | 1,5 | 2 | 2,5 |

Conclusion

What kind of pump do you have at home?

Wet RotorDry Rotor

Circulation pumps are necessary and important elements of the heating system of a private house. The best installation method is the return line, where the temperature of the coolant is much lower than at the outlet of the boiler.

When choosing a pump, you should pay attention to its parameters:

- Performance

- pressure

- Power

- Maximum temperature

First of all, you should consider the products of well-known and reliable companies. They are more expensive, but these costs are always justified. According to experts and ordinary users, a properly selected circulation pump is practically maintenance-free and provides a long service life without failure.

- Pumping station for a summer residence. How to choose? Model overview

- How to choose a generator for a summer residence. Main criteria and review of the best models

- Surface pumps for wells. Overview and selection criteria

- Pumps for watering the garden. How to choose, rating models