- Tank replacement

- Advantages and disadvantages

- Switching from cast iron pipes to plastic products

- Dismantling cast iron pipes and cleaning the socket

- Installing the rubber cuff on the bell

- How to install a vertical outlet or floor outlet toilet

- Which installation to choose for the toilet

- Block or frame installation

- Block installation

- Frame installation

- Choosing an installation depending on the installation location

- Standard installation

- Low installation

- Corner installation

- Double sided installation

- Linear

- What are the flush control methods?

- Dual mode button

- Flush-stop

- Proximity sensor

- What is the weight of the installation?

- What you need to know about the installation tank

- Choosing a new toilet

- Pros and cons

- How to connect the toilet to the sewer pipes

- How to connect a toilet with a vertical outlet (to the floor)

- How to connect a toilet with a horizontal (into the wall) outlet to the sewer

- Process Features

Tank replacement

toilet cistern installation

Do-it-yourself toilet cistern replacement is the last step in the process of replacing a toilet bowl. If we are talking about a barrel that is attached to the toilet shelf, then the pipe must be connected to the neck with a rubber cuff. This will be enough to ensure a strong and tight connection.At the same time, one third of the rubber cuff is put on the pipe, and the remaining two thirds are turned inside out. Then this part must be pulled over the previous one. Here it turns out that the end of the pipe is released. Then the pipe and neck are combined with each other. The inverted part of the rubber cuff is pulled over the neck. Thus, we can say that the tank is perfectly fixed. No additional action is required. A rubber cuff is enough to ensure a tight connection. At the same time, it is worth checking the density of the cuff nozzle so that unpleasant events do not occur with neighbors from below.

attaching the toilet cistern to the toilet

Sometimes a situation arises when the tank is mounted at a short distance from the toilet on the wall. In this case, one rubber cuff is not enough. It will take a little more effort and skill. In this case, a pipe is screwed to the barrel, and its opposite end is lubricated with red lead and wrapped with tow. The neck of the toilet bowl and the pipe itself are connected by means of a cuff. It is fixed on the pipe with a thin wire. Now you can power the flush tank and adjust the water level in it.

Thus, the work on replacing the toilet bowl can be considered completed. As you can see, all actions do not require any special preparation. The work may well be done by hand. Of course, if we are talking about a toilet that is installed on the floor. Otherwise, it is difficult to do without the help of a plumbing specialist. By the way, even before starting work on replacing the floor toilet, you should consult with a professional. It will help you understand all the intricacies of the work.For those who are well versed in the work associated with the installation of plumbing, this manual will definitely help. It is also suitable for those who have never tried to do such work on their own before. Here is a detailed instruction describing all the main stages of work, as well as a video showing clearly how the toilet is replaced with your own hands. Many will definitely benefit from this guide. In addition to the work related to the installation of the barrel and the toilet itself, it contains information on how to correctly dismantle the old unit so that there are no further problems in operation. The video will help even those who decide to save money and not call specialists, although they are dealing with this type of work for the first time. Everything is shown clearly and will be understandable to absolutely everyone.

Advantages and disadvantages

The advantages of toilet models with a horizontal (parallel floor) outlet include the following features and factors:

- fits even where there used to be a toilet with an oblique type outlet (that is, there is versatility);

- it is possible to connect not only to a horizontal sewer pipe, but also directly to a vertical riser using adapters;

- mounted close to the wall, without taking up extra space;

- low cost;

- wide model range.

There are also many disadvantages:

- attachment of the installation site to one of the walls of the room - the one where the sewer pipeline passes;

- the relative complexity of installation, especially in terms of connecting the outlet to the sewer;

- careful sealing of the junctions of the outlet with the sewer main, the need for control at the first time after installation for the absence of leaks;

- the possibility of clogging the outlet channel.

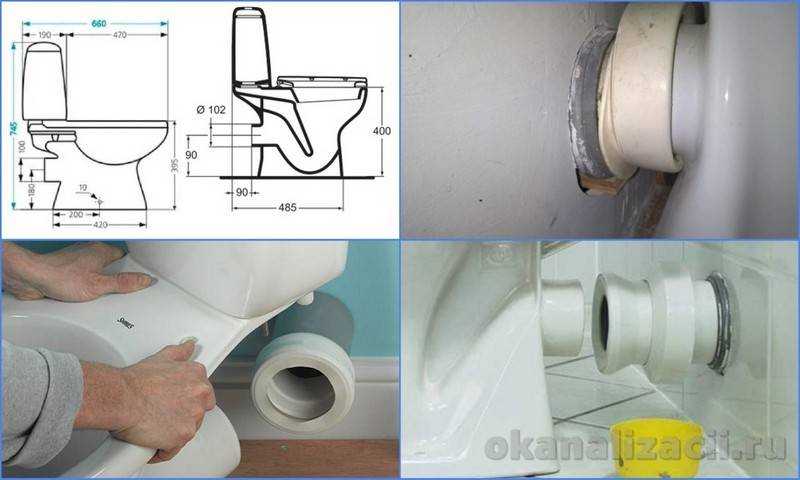

Switching from cast iron pipes to plastic products

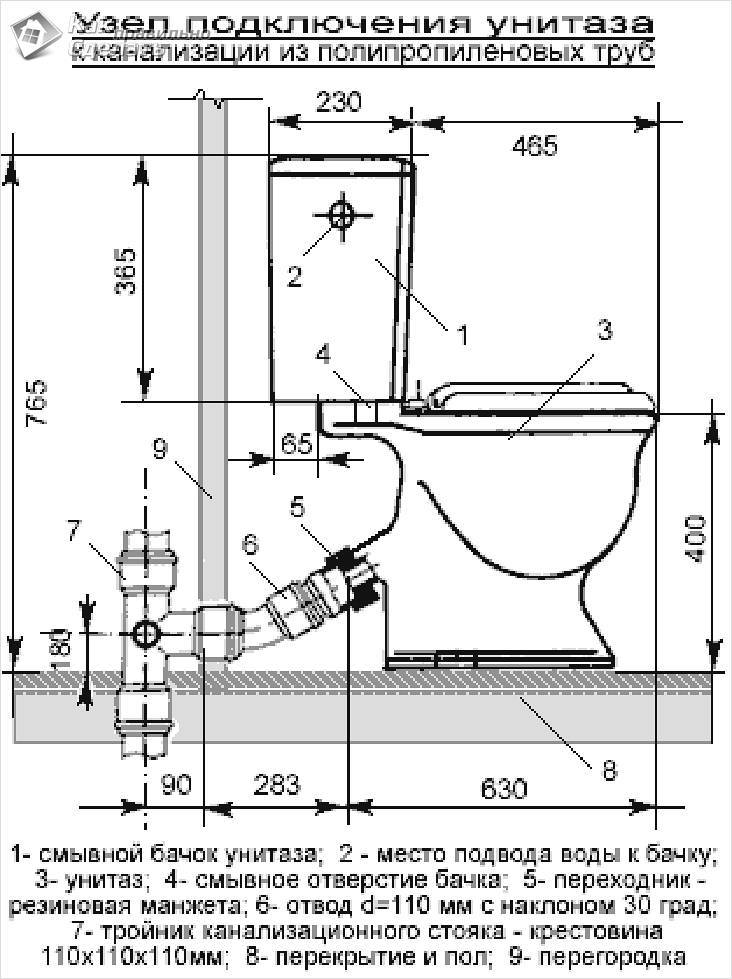

Cast iron sewer pipes from the toilet to the riser have a diameter of 123 mm, and from the bathroom and sink in the kitchen - 73 mm. Plastic products of gray or orange color differ from the elements of the cast-iron sewerage system in diameter: 110 mm and 50 mm, respectively.

When connecting a new toilet bowl or replacing an old pipe wiring, it becomes necessary to connect plastic pipes to a cast-iron riser with a larger diameter.

To solve this problem, a special rubber cuff is purchased, which is inserted into the cleaned sewer socket.

Dismantling cast iron pipes and cleaning the socket

To carry out dismantling work related to the removal of hardened cement mortar at the junction of the old pipe with the socket, it is necessary to stock up on a hammer, a flat screwdriver, and a pry bar.

By tapping gently with a hammer on the handle of the screwdriver, slowly but surely, the connection of the elements of the sewage system is released from the cement mortar. When the entire layer of cement has been removed, a wooden stick is inserted into the pipe.

Raising and lowering the stick, stir up the fixed position of the cast-iron pipe, and with a little effort pull it out of the socket

Raising and lowering the stick, stir up the fixed position of the cast-iron pipe, and with a little effort pull it out of the socket

Rust, plaque, deposits are removed with a metal brush mounted on an electric drill. Also, a flat screwdriver or a chisel is used to clean the cast-iron walls.

It is possible to treat the inner walls of the socket with a special substance that corrodes pollution in sewer pipes. This will greatly facilitate the process of cleaning the sewer outlet.To complete the cleaning of the socket, it is necessary to wipe its walls with a clean rag or rag.

The cleaner and smoother the walls of the socket are, the better and more reliably pipes made of different materials will connect.

The process of cleaning an old cast-iron sewer socket from the remnants of a linen cord impregnated with minium for the installation of a transition to a plastic sewer

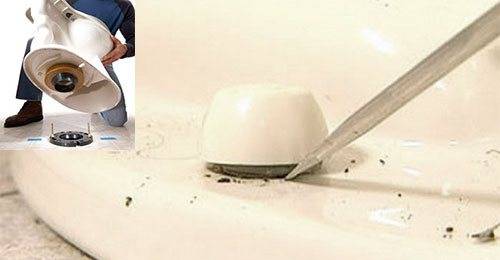

Installing the rubber cuff on the bell

Reliable fixation of the cuff in the sewer socket is provided with the help of a sealant, which is applied to its walls.

The sealant is applied in a thick layer on the outer surface of the cuff, after which it is inserted into the socket hole

The sealant is applied in a thick layer on the outer surface of the cuff, after which it is inserted into the socket hole

Gently tapping with a hammer on the edge of the cuff, they achieve tight adhesion of the adjoining walls of the two elements of the system. A small amount of technical petroleum jelly or a special plumbing lubricant is applied inside the cuff, which makes it easier to push the outlet of the plastic tee into the socket.

If the pipe does not want to climb into its place, take a piece of plywood, attach it to the pipe and tap it with a hammer. This will clog the pipe and not damage its walls.

Next, a corrugation or pipe is connected to the plastic tee, thereby connecting the toilet bowl to the sewerage system.

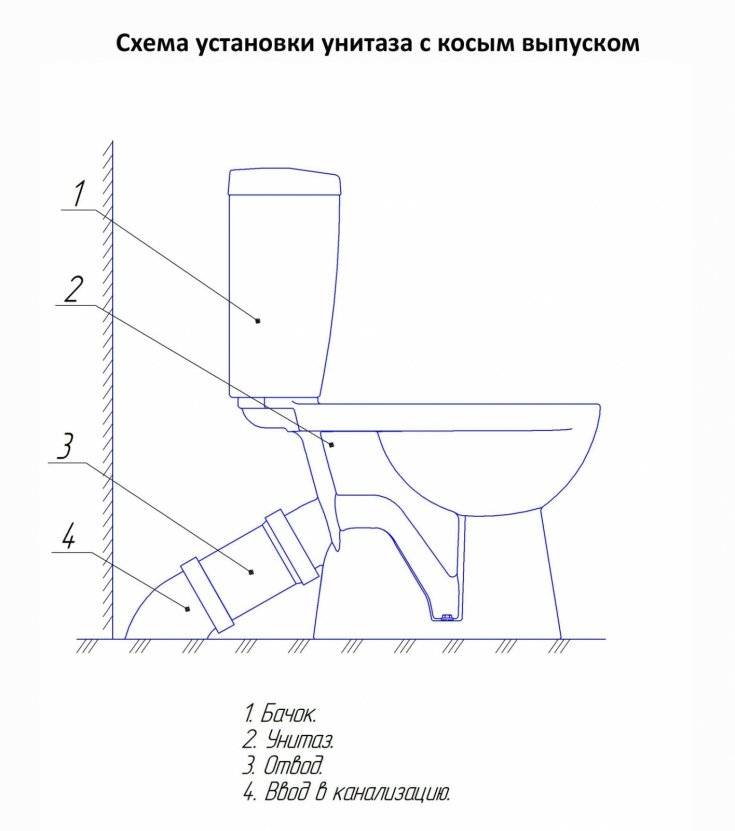

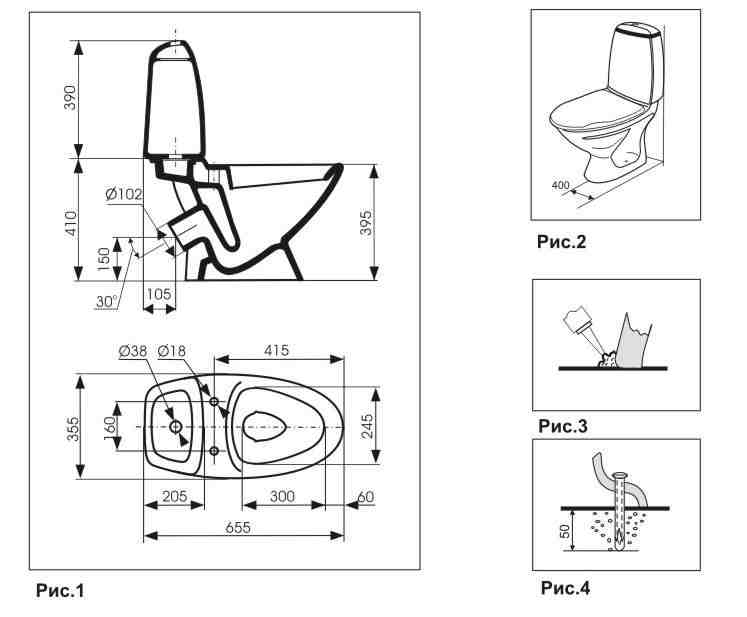

How to install a vertical outlet or floor outlet toilet

Floor standing toilets with floor outlet are in demand mainly in Europe. Structurally, they are arranged in such a way that the siphon in the bowl, together with the outlet pipe, is directed straight down. Toilet bowls with such a release are connected according to the following algorithm:

- At the point where the drain pipe exits the toilet, a screw-type flange with clamps is installed.

- A sewer pipe is located in the middle of the flange and is clamped as a result of turning.

- A toilet bowl is put on the flange, and the outlet pipe is securely and hermetically fixed.

The flange and vertical release of such models of toilet bowls are standard, so even beginners do not have insurmountable difficulties during installation and connection. The seal between the flange and the toilet drain hole guarantees a tight seal.

Which installation to choose for the toilet

When buying a wall-hung toilet, the type of supporting structure, installation method, location, price and reputation of the manufacturer must be taken into account. This section will cover the technical aspects of choosing the right installation for you.

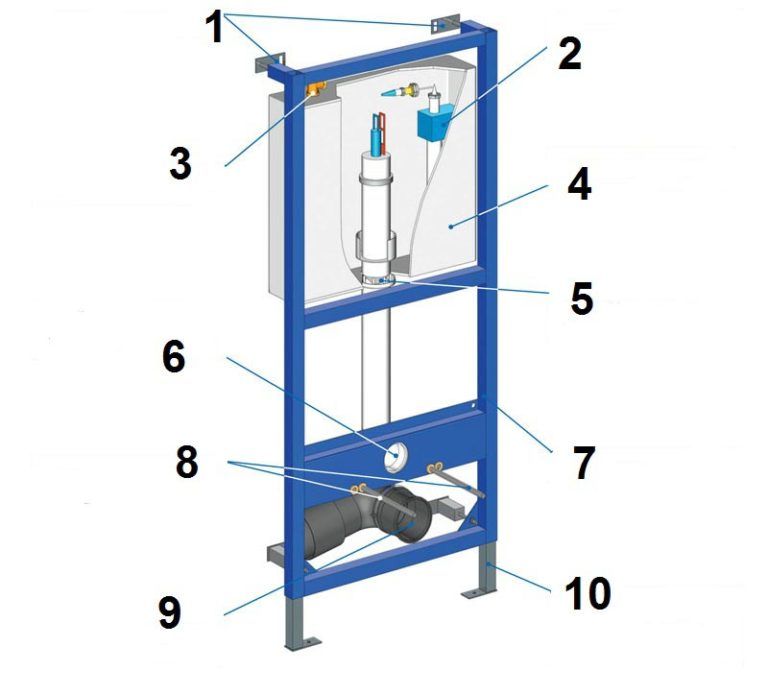

Block or frame installation

There are two main groups of installations for toilets, based on a different approach to the way they are installed.

Block installation

The block design consists of individual elements that are attached directly to the wall. Communications in this case have some freedom of placement. Such a kit consists of only the most necessary parts, so it is relatively cheap. It can only be installed on a load-bearing wall, which takes on an additional load. It will be quite difficult to add anything to such an installation during operation or replace the main components.

Frame installation

The frame structure has its own rigid frame, which can be easily hidden behind a decorative plasterboard wall. This type of installation rests on the floor and expands the options when choosing an installation location. The disadvantages of this option are the larger dimensions and the high cost of the kit.

Choosing an installation depending on the installation location

Manufacturers of wall-hung toilets have provided several options for installations, adapted to various features of the layout of bathrooms.

Standard installation

Such an installation has typical dimensions: 112 cm high, 50 cm wide and 12 cm deep. It is usually installed in medium or large toilets.

Low installation

This option has a height limit of 82 cm. It is used when there are structural elements in the room that prevent the installation of a higher support.

Corner installation

This type of installation is a great way to save space in a small bathroom by compactly installing the equipment in the very corner.

Double sided installation

This design consists of one frame and two toilet bowls, which are fixed on it from opposite sides, separated by a light wall. A good budget option that fits well into the space of a public toilet.

Linear

Linear installations allow you to place several of the same or different plumbing fixtures side by side, including a toilet, bidet, urinal or sink. This option is often found in shopping, office and entertainment centers.

What are the flush control methods?

When choosing the type of flush control unit, hygienic requirements, ease of use and economical water consumption are taken into account. There are only three most common options here.

Dual mode button

A good budget option, which includes a couple of buttons for an economical (up to 6 l) and a full drain (6-9 l). The volume of discharged water is usually amenable to pre-adjustment.

Flush-stop

Here, one button is activated, giving a command to open and close the valve.Such a system allows you to accurately control the supply of the required amount of water.

Proximity sensor

The device includes an infrared device that reacts to the hand raised to it. Such equipment is considered the most hygienic. It is installed in medical institutions and public toilets.

Parameters to pay attention to

Having decided on the type of installation you need, it's time to carefully consider the technical features of the model you like.

What is the weight of the installation?

Before buying, be sure to ask the seller and check in the product passport for information on the maximum loads for which the design is designed. The most reliable installations withstand more than 400 kg. The margin of safety is directly related to the service life of the device. Choose a model that saves you from unexpected emergency repairs.

What you need to know about the installation tank

Cheap installations are often equipped with a welded plastic tank. Solid-cast containers are considered more reliable. Responsible manufacturers cover them from the outside with a layer of insulating material, which prevents the deposition of condensate on the outer walls and greatly reduces the noise that occurs when water enters.

Installation cistern with soundproofing.

Pay attention to installation fittings

If you want to save yourself from leaks, buy equipment equipped with bronze or brass fittings. They do not change their structure and do not corrode for many decades. Steel products do not have similar qualities, but are cheaper.

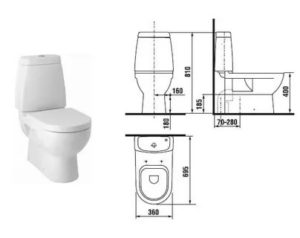

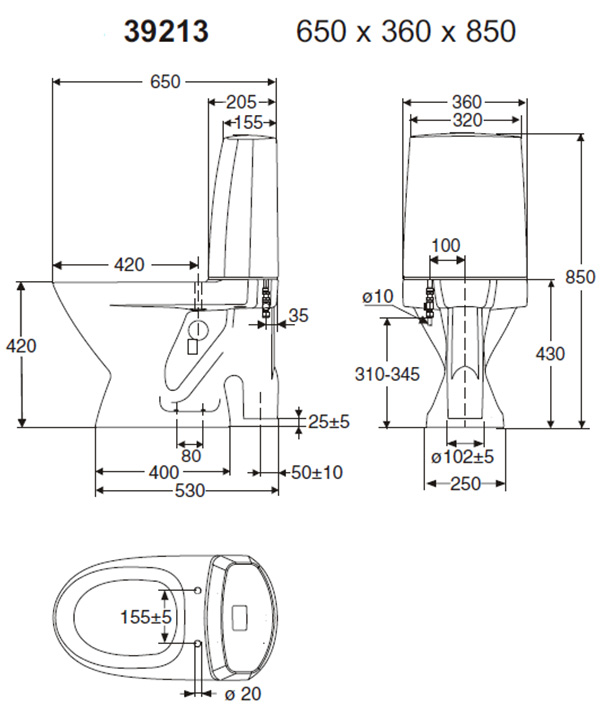

Choosing a new toilet

Before going to the store for a new toilet, you need to decide on the size of the device and how it is connected to the sewer pipe. This will depend on the outlet of the device. It can be of three types.

- Vertical.

- Horizontal.

- oblique.

Vertical sewer pipe

After that, you can choose a device from those models whose outlet drain design is suitable for connecting to your sewer system. No adapter will help connect a toilet with a vertical drain to a horizontal sewer pipe. So this choice parameter is the most important, everything else is a matter of taste and wishes.

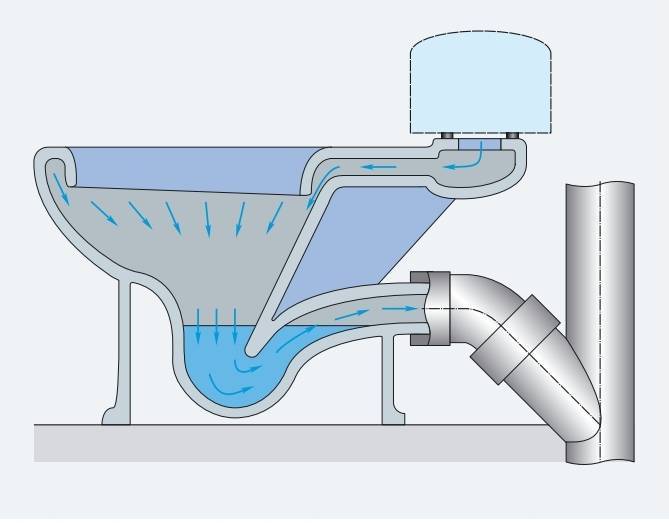

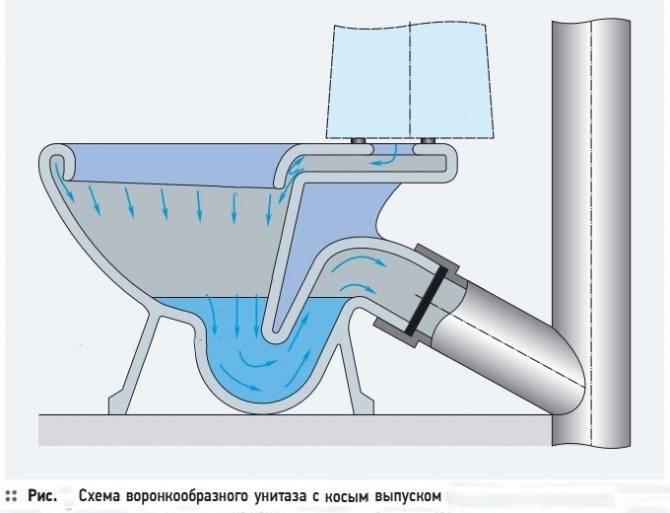

The shape of the toilet bowl can be:

- plate-shaped;

- funnel-shaped;

- visor.

Types of toilet bowls in the shape of a bowl

The visor design prevents the formation of splashes of water when flushing. Water flushing can occur in a circular manner or in a continuous stream.

The toilets themselves can be of different designs. It can be a monoblock, a corner toilet, a compact toilet or a separate one, when the bowl and the toilet are located separately.

Toilet bowls by mounting method

According to the method of fastening, toilet bowls differ in attached and standing separately. The attached toilet looks like a hanging toilet. Available for sale with or without tank. Attached in different ways. Most often, this is an option with two or four mounting ears for an anchor or screw, but there are models that are attached to special corners fixed to the floor.

Pros and cons

Before you install suspended plumbing, you need to make an objective decision. To do this, you need to know all the features of this equipment, let's start with the advantages:

- The cleaning process in the bathroom is greatly simplified, in particular, there are no problems with accessing the toilet, the same applies to the bidet and washbasin.

- The space of the room is used more rationally, since part of the equipment is built into the wall.

- Visually increases the space of the bathroom.

- The room takes on a more aesthetic appearance.

Of course, this solution has its negative sides, namely:

- Access to communications is blocked. Even if there are false panels, it will not be possible to quickly shut off the taps in the event of a leak, this will take some time or, alternatively, shut off the input.

- If the drain valve of the tank breaks, there will be problems with its replacement. In most cases, it will not be possible to solve the problem on your own, you will need the help of a specialist, which leads to additional costs. Choosing quality equipment from well-known brands such as Grohe, Jacob, Vitra or Belbagno significantly reduces the risk of such a problem.

- Problems arise when replacing plumbing equipment, primarily due to the search for a toilet bowl or sink from the same manufacturer or with a suitable fastening and connection of the water inlet and outlet. Replacing the same installation is tantamount to a major overhaul in the room.

- In order for the frame to withstand the required load, it must be installed on a solid foundation, partition walls are not suitable for this purpose, and this reduces the choice of installation sites.

How to connect the toilet to the sewer pipes

Pipes with rubber cuffs

It is the connection with the help of nozzles that is recommended by experienced plumbers.Despite some inconvenience that may arise when connecting a toilet bowl in difficult cases (when transferring a toilet bowl to a new place, etc.), using pipes, the connection will be the most durable, tight and durable. In the distant past, the toilet was installed on a wide board - a pedestal, but now much more often the installation is carried out directly on the tile. In this case, if the toilet will stand at a distance from the sewer riser, it is necessary to ensure the slope of the pipe of the order of 2 degrees for the unhindered passage of drains.

Toilet pipes

Since the outlet of the toilet bowl can have different exit options, the nozzles must be selected in strict accordance with the dimensions and angle of inclination. Consider connection methods depending on the type of toilet outlet.

How to connect a toilet with a vertical outlet (to the floor)

Toilet, outlet - vertical

Toilets with a floor outlet are designed for installation in houses where the sewer wiring runs under the floor. Such a system is especially relevant in private homes, since toilets with a vertical outlet can be placed not only close to the wall, but also in any convenient place.

Toilet-compact with vertical outlet

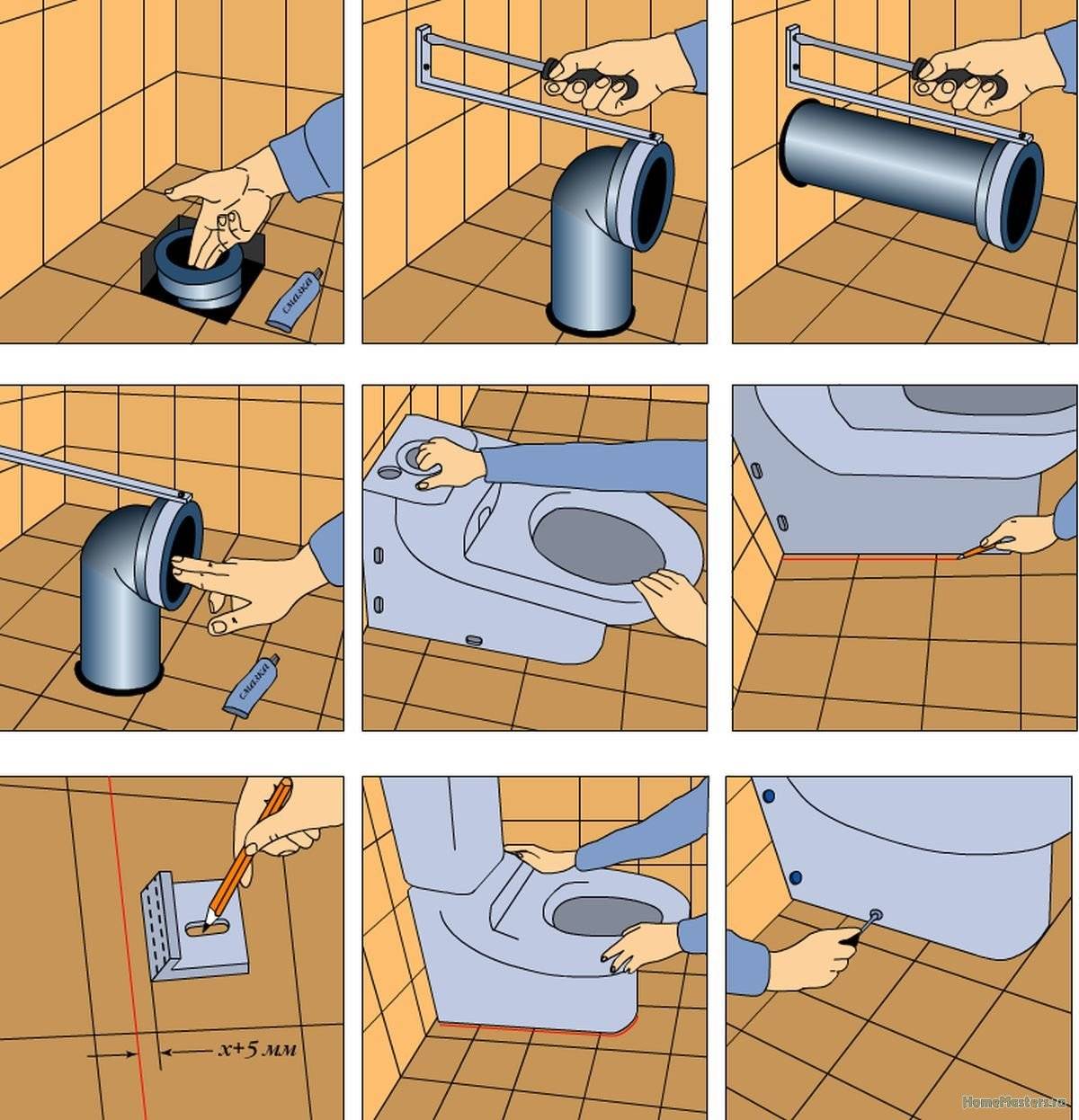

- The first stage is the purchase of a toilet bowl and the preparation of sewer wiring. Before installation, the toilet must be “tried on” to the installation site. It may turn out that the drain hole in the floor simply does not match the dimensions of the toilet bowl and you will have to disassemble the floor covering in order to move the sewer socket.

- The second step is to prepare for the installation of the toilet.To do this, marking is made for fixing the toilet bowl, and then processing the edge of the sewer pipe (the edge must be strictly flush with the floor covering and in no case protrude above the floor level), into which the sealing cuff is inserted.

- The toilet bowl is temporarily removed to the side, and holes are drilled under the fasteners according to the marking. Dowels are inserted into the holes.

- The toilet is put in place, the tightness of the occurrence of the flange (cuff) in the outlet pipe of the toilet is checked. Next, the fixing screws are tightened (a gasket washer must be used so as not to damage porcelain or faience) and the tank is connected to the water supply.

Toilet bowl outlet to the floor

There is another type of toilet mount with floor outlet. In this case, the cuff is supplemented with a special washer, into the grooves of which screws are inserted. A cuff-seal is inserted into the center of this washer and then the toilet bowl is installed using the technology described above.

Installing a toilet with a vertical outlet

Toilet connection

Toilet installation

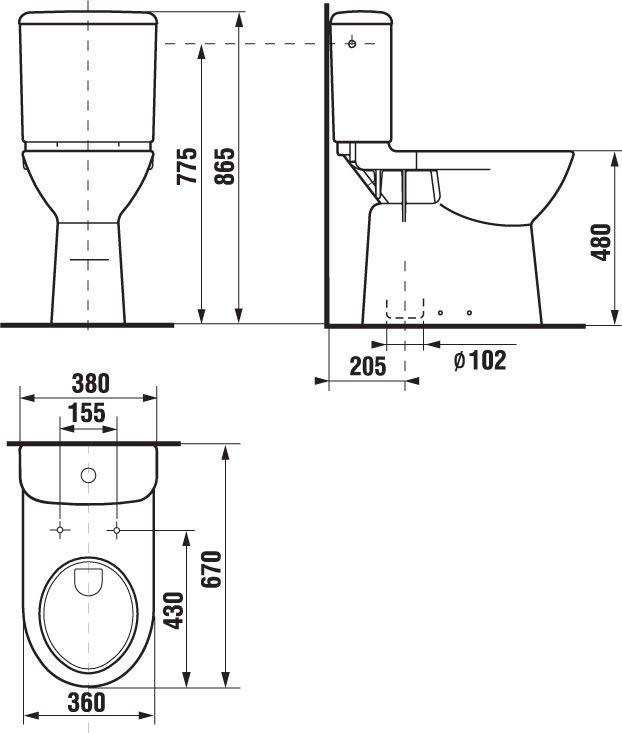

How to connect a toilet with a horizontal (into the wall) outlet to the sewer

Typically, this connection method is not compact, and all communications are hidden behind a decorative false wall. At the same time, in modern construction, a sewer distribution system is most often equipped, suitable specifically for connecting toilet bowls with outlet to the wall.

The outlet of the toilet bowl should be as close as possible to the sewer hole. In this case, the connection is made by sealing cuffs and a connecting pipe. If the release of the toilet somewhat offset from the sewer hole, the connection is made using an eccentric seal or several adapters.

Before installing the toilet, it is necessary to prepare and level the flooring and, of course, dismantle the old toilet.

First of all, let's deal with the sewer pipe and markings. We insert a rubber seal lubricated with sealant into the hole in the sewer pipe. And already inside the seal we insert an eccentric, or a connecting pipe. We install the toilet, combining the outlet with the pipe / eccentric. The part may not fit and an additional tap will be required. Then we make markings on the floor for fasteners and remove the toilet bowl to the side.

According to the marking, we drill holes, hammer in the dowels. Now we put the toilet in place, combining it with the eccentric and dowels. We fasten the toilet to the floor. We check for leaks, assemble and connect the tank. This completes the sewer connection.

Process Features

In fact, the correct installation of the toilet, of course, is a complicated matter. However, if you understand its technology, you can install a toilet bowl with high quality and save on plumbing services. At the same time, it will turn out to grow in their own eyes. Recently, the number of models of toilet bowls has increased significantly, if you wish, you can find one that will not seem difficult to install.

Together with them, in addition to the traditional mounting method, other mounting methods appeared. For example, now the method when the tank is hidden in the wall has become especially popular. Wall-mounted toilet bowls have also become widespread, which are mounted directly on the wall, completely freeing the floor.Such models look very interesting, they are no more difficult to mount than models with floor mounts.

Also, the installation of a toilet bowl is affected by the type of attachment, flush, supply of a sewer pipe, its dimensions.

Particular attention is paid to the evenness of the surface on which it is planned to install plumbing. That is why it is better to think over in advance the model of the toilet bowl and the type of room in which you will have to mount it yourself.

This is especially true for toilets and bathrooms in new buildings. It is worth considering the size of the room so that the installation is easy and correct.

When installing toilets in apartments or houses where there is already a toilet, you should also consider dismantling the old product, as well as repairing it. Another point that you should think about in advance is the availability of all the necessary tools, including a puncher, screwdrivers, dowels. When purchasing a new toilet, you should carefully inspect the bowl and tank before packing it. The product must be free of chips and cracks. They can cause leakage of a new product.

Particular attention should be paid to the internal cavities, as well as the release of the toilet bowl. It will not be superfluous to clarify what the complete set consists of.

For example, when buying in a store, you should ask the seller if there is a seat in it, fasteners to the floor or wall. If something is missing, it is better to immediately purchase all the missing items. This will allow installation without any problems.