- Well deepening technology

- Preparatory work

- Use of rings of smaller diameter

- The use of pipes for the filter recess

- How to deepen a well with a quicksand bailer

- Latest company news

- Manufacture and installation of the casing of the well

- Stage two. We prepare everything you need

- drainage well

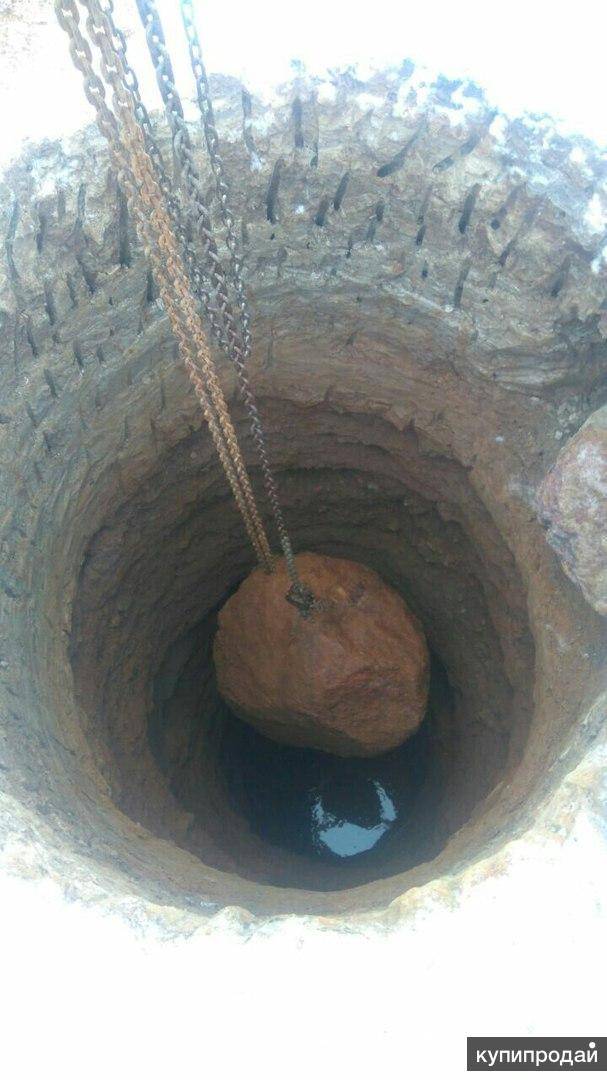

- Deepening a well by digging

- Carrying out preparatory work

- Deepening works

- Final work in the well

- Reasons for the decrease in water production

- We deepen the well with our own hands

- What plants to plant near the well

- Making a well ring with your own hands

- stone finish

- When should wells be deepened?

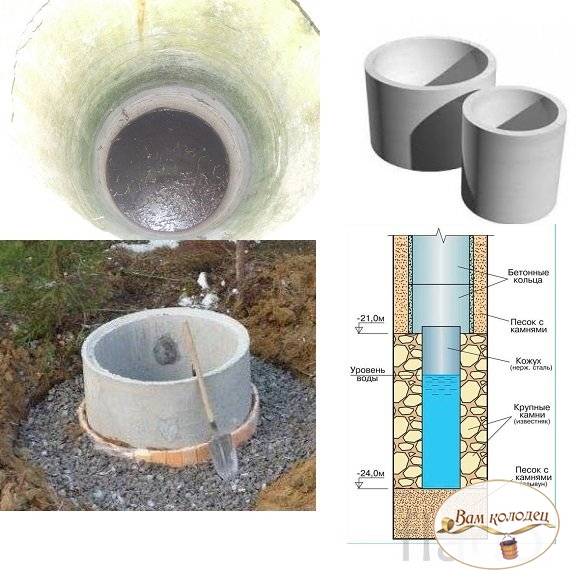

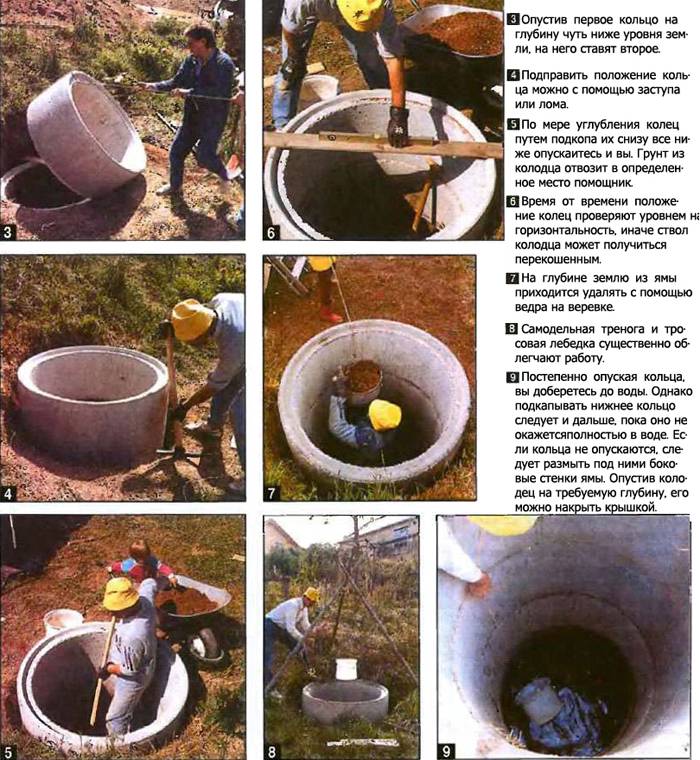

- Technology and stages of construction of a well from concrete rings

- Construction of a well with alternate installation of rings

- Installation of rings in the finished shaft

- Internal waterproofing

- External waterproofing of the well

- How to carry out preparatory work

- Tools and main activities

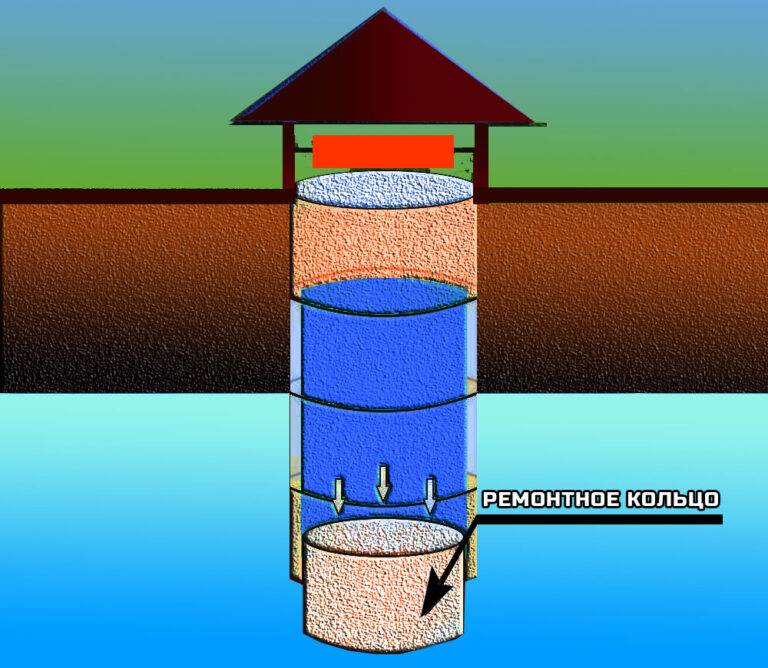

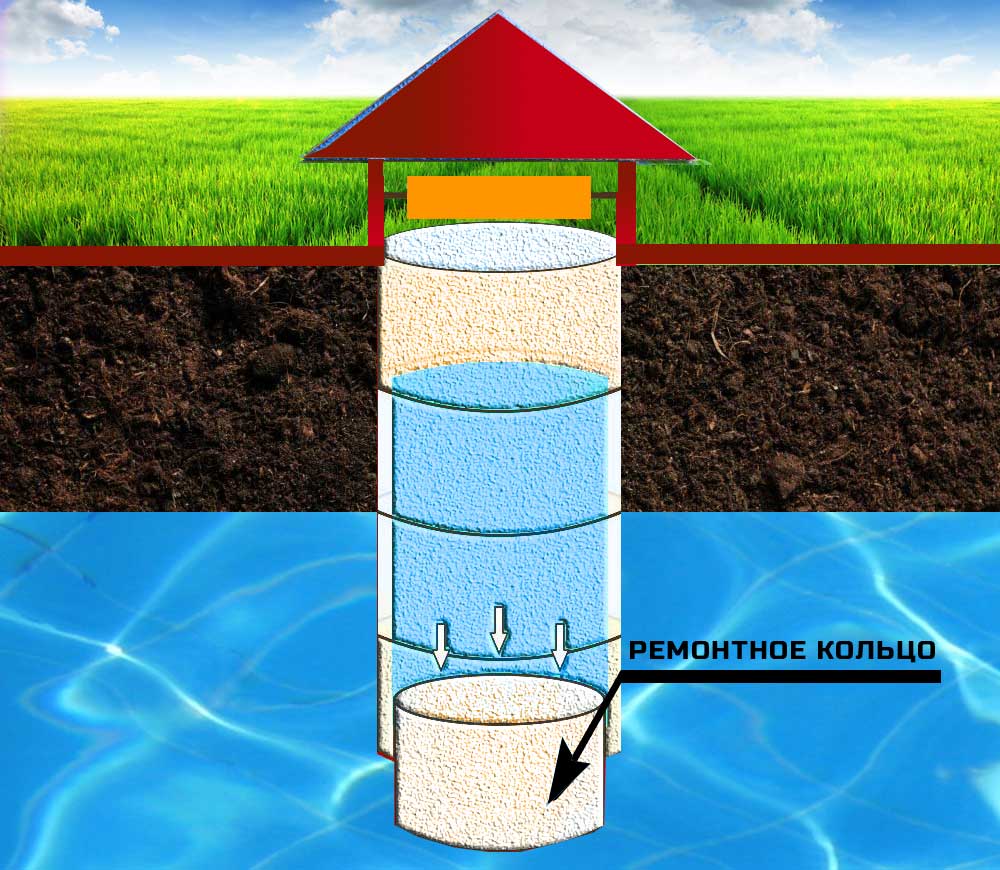

- Deepening the structure with repair rings

- Carrying out preparatory work

- Direct deepening process

- Finishing work in the well

- Completing of the work

- Need equipment

- Well preparation

- Deepening a well with a filter

- Deepening a well with digging

- Deepening a well in floating soil

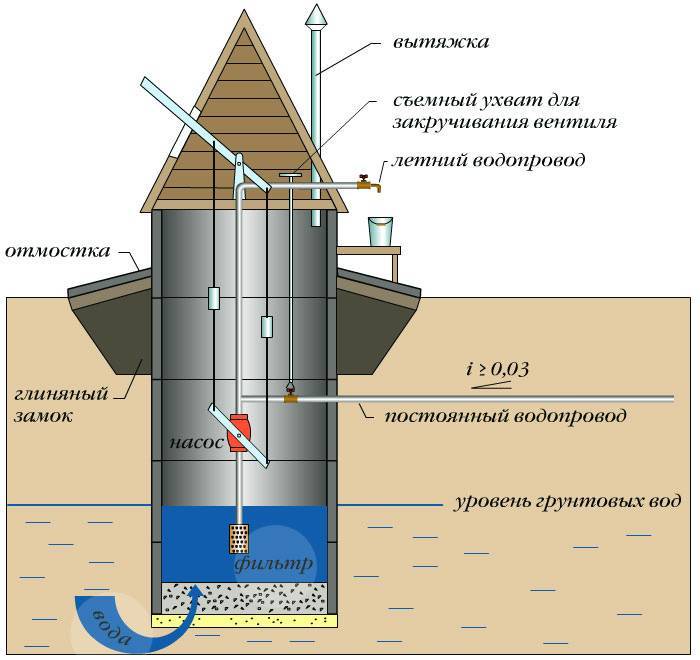

- The device and design of the well

Well deepening technology

Preparatory work

It is recommended to modify the existing source in such cases:

- There is no free space for a new spring.

- Pipes and electric cables are connected to the well, and their transfer will require significant financial costs.

- The produced water is of high quality.

- The trunk is deep enough - at least 10 rings.

- The daily intake of fluid is less than one ring or none at all.

Refuse revision in such cases:

- When a large quicksand is found.

- Seasonal fluctuations in water levels are very large.

- The depth of the mine is less than 8 m.

- The well is very old, you will have to not only dig, but also restore the entire structure.

- If the underground part consists of a log cabin, in which the decks are shifted relative to each other by 5 cm or more.

- The wooden parts of the mine have rotted away.

To work, you will need the following tools and fixtures:

- A shovel with a handy handle for use in confined spaces.

- Dirty water pump.

- Axe, crowbar or chipper for passing hard rocks.

- The winch with a capacity of 500-600 kg for lifting buckets with soil.

- A compact ladder that does not take up much space, such as a rope ladder.

- Light source.

Use of rings of smaller diameter

Work on deepening with additional rings is carried out in the following sequence:

- Make sure the bottom can withstand the additional load from the repair rings.

- Pump out all the water from their well.

- Dismantle the superstructure above the shaft.

- Lower the ring with a sharp edge into the spring, and on it - the repair ring. Seal the connection points.

- Fix the elements to each other with metal brackets.

- Using a plumb line, check the verticality of the walls of the new shaft.

- Remove the earth inside the products, first in the middle, then under the shoe, until the shaft settles.

- Repeat the operation until a powerful flow of water appears.

- Check the verticality of the building walls.

- Form a bottom filter.

- Fill the gap between the pipe and the wall with fine stone and sand.

- Perform the installation of dismantled buildings and removed equipment.

The use of pipes for the filter recess

The deepening of the well with pipes is carried out in the following sequence:

- Wrap the inside of the pipe with a fine-mesh stainless mesh and secure it in this position.

- Install the product vertically in the center of the well and temporarily fix it.

- Mount a tripod with a block over the shaft.

- Pass a rope through the block and fasten a bailer to it - a special device for removing soil. It looks like a pointed piece of pipe with a valve.

- Check that the bailer is located exactly in the center of the well.

- Raise the fixture with a rope and check that there is 1.5-2 m of free space under it.

- Release the rope - the device will fall into the well and enter the ground, part of which will fall through the hole into the device.

- Raise the bailer and remove soil from its cavity.

- Repeat the operation, periodically lowering the pipe to the vacant place.

- After obtaining the desired result, fill the space between the new and old shaft with gravel, stone and sand and concrete it.

- Place several layers of gravel on the bottom to create a bottom filter.

- Perform the installation of buildings and equipment removed at the beginning of work.

How to deepen a well with a quicksand bailer

- The water level in the spring is within 1 m, and it is not possible to increase it by any traditional means.

- The liquid in the well is cloudy brownish in color.

- In winter, intense heaving occurs, often leading to deformation of the structure.

Latest company news

- RusHydro commissioned a hydropower plant in North Ossetia February 4, 2020

- Gazprom sacrifices price to maintain its share of the European market February 3, 2020

- Russian oil companies may further cut production February 3, 2020

- UC Rusal to stop bauxite mining in Guyana due to unrest February 3, 2020

- Glencore and En+ exchange shares in UC Rusal February 3, 2020

- WSJ: Saudi Arabia Calls for Strong Oil Production Cut February 3, 2020

- General Director Uralvagon February 2, 2020

- Gardeners asked the state to make subsidies clearer and more transparent February 2, 2020

- Copper falls to three-year lows due to coronavirus February 1, 2020

- Lukoil quotes fell by mistake January 31, 2020

- Steelmakers are looking for a replacement January 30, 2020

- OPEC+ may call emergency meeting due to coronavirus January 30, 2020

- The largest mushroom project in Russia has been postponed indefinitely January 29, 2020

- Norilsk Nickel is trying to prevent a sharp rise in palladium prices January 29, 2020

- Gazprom expects to maintain its positions in Europe January 28, 2020

- A database of customers of the Krasnoye i Beloe alcohol market network has been published on the Internet January 27, 2020

- The project of Gazprom and Rusgazdobycha in the Baltic may rise in price January 27, 2020

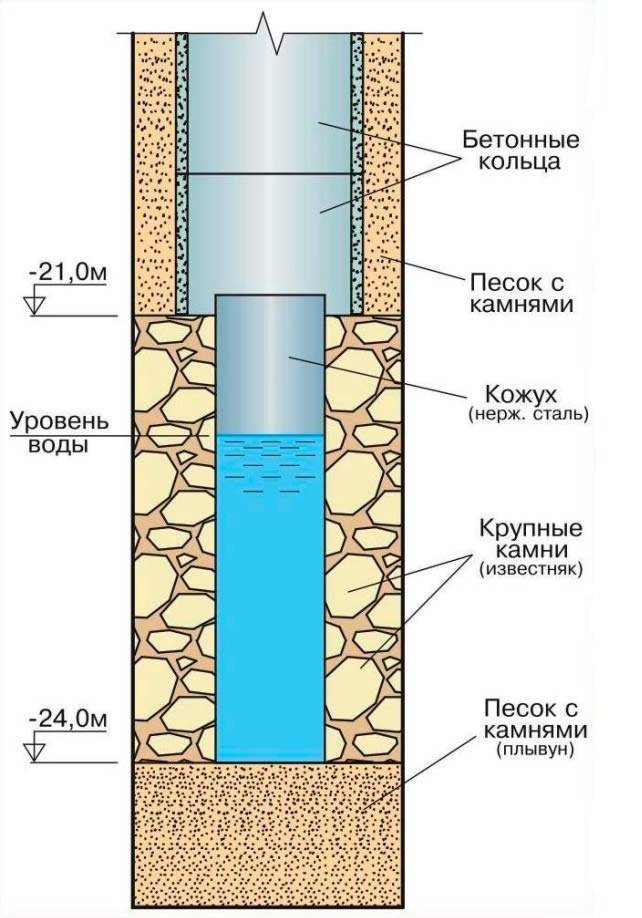

Manufacture and installation of the casing of the well

We purchased five sheets of stainless steel, from which we needed to make a cylindrical casing 3.0 m high and 0.7 m in diameter. First, we made a casing 2.0 m high from three sheets, and then attached another meter section assembled from the remaining sheets.To connect sheets and sections, Mb bolts with washers and nuts, also made of stainless steel, were used. Stainless steel bolts and sheets are quite expensive, but for the sake of durability they did not save.

The manufacturing process of the casing is quite simple, the only difficulties encountered when drilling holes in stainless steel. A lot of drills were dull and broken before we could put together a new casing. Special tightness in its manufacture should not be achieved - groundwater should seep into the casing.

So, the casing is ready, it remains only to lower it into the well shaft. Once again, the water was pumped out, if possible, the washed-up sand was removed from the bottom, and they began to carefully lower the casing. One worker had to go down the well to adjust the casing as he went down. We calculated the diameter of the casing correctly, and he calmly entered the shaft, cut through in limestone stones.

Having lowered the casing, they again pumped out the water to clean the bottom and lay on it a fine food filter mesh folded in half, which should clean the water entering the well from sand. The grid was tightly pressed against the casing and the bottom of the well with granite stones 50-70 mm in size laid on it.

Finally, all the installation work was completed, but the water in the well was still very cloudy from the sand that came from the quicksand. But its level is quite decent - a little more than 1.5 m.

Stage two. We prepare everything you need

Water supply from a wooden well

The procedure for the construction of wells is not standardized by any state regulations and standards. The classical device was formed for more than one century, until it acquired a modern look.

To do do-it-yourself wellyou need to prepare:

- a tripod made of metal corners or wooden poles;

- winch;

- rope ladder;

- shovel;

- scrap;

- material for strengthening the mine.

Well made of concrete rings

As for the last point, the most promising material is concrete rings. They are strong (reinforced with steel bars ø1 cm or more), durable (service life is 50 years), frost-resistant and waterproof.

| product name | Height x Wall thickness, cm | Internal diameter, cm | Weight, kg |

|---|---|---|---|

| KS-7−1 | 10x8 | 70 | 46 |

| KS-7−1.5 | 15x8 | 70 | 68 |

| KS-7-3 | 35x8 | 70 | 140 |

| KS-7-5 | 50x8 | 70 | 230 |

| KS-7-9 | 90x8 | 70 | 410 |

| KS-7-10 | 100x8 | 70 | 457 |

| KS-10-5 | 50x8 | 100 | 320 |

| KS-10-6 | 60x8 | 100 | 340 |

| KS-10-9 | 90x8 | 100 | 640 |

| KS-12-10 | 100x8 | 120 | 1050 |

| KS-15-6 | 60x9 | 150 | 900 |

| KS-15-9 | 90x9 | 150 | 1350 |

| KS-20-6 | 60x10 | 200 | 1550 |

| KS-20-9 | 90x10 | 200 | 2300 |

| KO-6 | 7x12 | 58 | 60 |

| KS-7-6 | 60x10 | 70 | 250 |

Concrete rings can be:

- wall (abbreviation - KS), which are used to equip the neck and are suitable for all types of wells;

- additional - used in cases where the standard options are not suitable, because these have non-standard sizes;

- Reinforced concrete rings - used for drainage and sewer wells, communication systems, gas and water pipes.

well ring

There are other types - with an overlapping slab, with a bottom, prefabricated, etc. In order to avoid displacement of the rings after installation, they are equipped with special grooves that prevent the moment of displacement.

After choosing a place and preparing everything necessary, we can begin construction.

drainage well

A drainage well is a special container into which water flows from a septic tank or drainage pipes.

It is an integral part of the sewer or storm system, can perform many different functions.

Before proceeding to study them, you need to consider what drainage wells are.

There are 4 main types in total:

drainage well

-

rotary - such wells are installed at the places where the drainage pipes turn. They are used to clean pumps that get dirty from time to time. Rotary wells are installed not at each turn of the pipe, but after one;

-

inspection drainage well - such devices are needed for inspecting and maintaining sewers, therefore they must be large enough, for example, 1 meter in diameter;

-

absorption or filtration - structures are needed in order to receive water, the discharge of which into the central sewer is impossible due to the lack of the latter. Here the water undergoes additional purification and enters the soil;

-

water intake or collector - such wells accumulate water to be further pumped out. They have a sealed bottom.

The main ones in this case are:

-

concrete rings of different sizes - wells made from them are highly durable and durable, and are quite cheap. But, the work on arranging structures is quite laborious;

-

plastic - plastic drainage wells are cheaper than concrete counterparts, they are distinguished by tightness and service life, and are resistant to corrosion. They have all the necessary outputs, are mounted easily due to their low weight. The corrugated surface of the well allows it to be securely fixed in the ground.

Deepening a well by digging

This method differs from the one described above in that the well is built up with repair rings from above. Moreover, their diameter does not differ from those that have already been installed.

The main danger in using this method is the possibility of the old column getting stuck in the ground, especially if the well is located on clay soils.

Carrying out preparatory work

We start by fixing the rings. At each joint we fix at least 4 staples. We drill holes for them, put metal plates 0.4x4x30 cm and fix them with 12 mm anchor bolts.

Thus, the casing string will be able to withstand possible ground movements. We pump out water from the well and completely remove the bottom filter, if it was present in the structure.

Deepening works

A worker descends on the belay and begins to dig. First, he selects the soil from the middle of the bottom of the structure, then from the periphery. After that, he begins to dig under two opposite points from the edges of the lower ring with a depth of 20-25 cm.

It is no longer necessary, otherwise there is a danger of an uncontrolled descent of the element. Then the tunnel is gradually expanded to the annular area.

During operation, the column must settle under its own weight. New rings are placed on the space vacated on top. Undermining is carried out until the water begins to arrive very quickly.

It should be noted that column subsidence does not always occur, especially if the well is “older” than 1-2 years. In difficult cases, the side digging method can be used as a way to lower a stuck ring.

It looks like a spatula, which is used for lateral digging of rings. The handle, longer than 40 cm, should be bent for comfort and precision

Consider it on the example with the lower ring. We carry out the digging as already described.Then we take three hemp or strong supports from a bar and place them under the ring so that there is a distance of about 5 cm between them and the bottom edge.

These supports will subsequently take on the entire weight of the settled structure. Then, in two opposite sections, we remove the sealing solution from the annular gap.

We insert nail pullers into the resulting gaps, and two people, simultaneously acting as a lever, can try to lower the ring. If all else fails, we take a special spatula for undermining the side walls. For its handle, fittings 10 cm long and 14 mm in diameter are used. The cutting part measuring 60x100 mm is made of 2 mm sheet iron. We insert the spatula 2-3 cm from the outer wall of the ring and proceed to hollowing out the clay.

To do this, hit the handle with a sledgehammer from the bottom up. Thus, we pass the entire ring except for the sections under which there are supports. We managed to remove the clay to a height of 10-15 cm from the lower edge of the ring. Now you can try again the lowering attempt with the nail pullers or any other levers. If not, take the next blade. The length of its handle should be 10 cm longer. We perform similar steps.

At the end of the repair work, you should once again inspect all the seams and carefully seal them, then cover them with sealant

A small note: when the length of the shovel handle reaches 40 cm or more, it will need to be bent a little. So it will be more convenient to work.

With proper lateral digging, the outer wall of the ring is gradually released, and it settles down. Similarly, work is carried out on other rings.

Final work in the well

Upon completion of the deepening works, all contaminated water is removed from the structure. All seams between the rings are securely sealed and sealed. If damage to old seams is noticed, they are also eliminated.

At the bottom of the structure we lay a new bottom filter of the desired design. Then we disinfect the walls of the mine with a solution of chlorine or manganese. The well is ready for use.

Reasons for the decrease in water production

The aquifer is unstable and can dry up over time.

Reasons for water loss include:

- climate features in a particular region;

- enhanced operation of the well shaft;

- lowering the level of groundwater;

- wear, damage to the materials of the well shaft.

We deepen the well with our own hands

Every land owner dreams of a well with enough good quality drinking water. Sometimes the quality of water changes at one moment and the reason for this may be drying out or a violation in the flow of water. When the decision is made to deepen the well, you should weigh your strength and decide:

- look for a team of specialists;

- carry out the procedure yourself.

If you are inclined towards the second option, you need to know and take into account many nuances. One of the most important requirements is that the work should be carried out during the period of calm groundwater. This period begins from the last month of autumn and lasts until the middle of winter.

There are two main deepening methods:

- filtration;

- use of repair rings;

- digging (digging).

This is interesting: Do-it-yourself water well - an independent device + useful tips

What plants to plant near the well

Directly near the source of water supply, you can plant decorative leafy and flowering horticultural crops.An interesting solution would be to use a gabion or a budget alternative to factory mesh to form a mesh frame around the above-ground part of the well structure.

Further design depends on the surrounding landscape design. If a significant part of the garden area is represented by alpine slides and a recreation area, then the space between the base of the well and the mesh frame can be filled with decorative stones. If it is necessary to make the decoration the most flourishing and picturesque, then the mesh holding the stones is used as a support for the arrangement of climbing vegetation.

Making a well ring with your own hands

If a cap or canopy is made, the gray concrete ring remains visible. The view is not the most attractive, and I want to decorate it.

stone finish

The most popular way to decorate a well is to finish it with stone - pebbles or medium-sized rubble. If everything is more or less clear with the finishing material - to buy or assemble, then the question of what to cling to it remains. There are several recipes:

- A bag of glue for tiles and natural stone 25 kg + a bag of dry mix 300 - 50 kg. We mix everything, in a dry form, we dilute to a pasty state with water. Stones are soaked in water. We apply a thin layer on the ring - a vertical strip from top to bottom, select and place the stones, sinking them into the solution. When a piece is made, before the solution has dried up, the stones are cleaned, the seams are overwritten.

Well lined with stone

We offer the third recipe for how to line a well with stone in video format. The composition of the mixture here is very similar, but before applying the solution, a mesh is fixed on the ring.With this technology, nothing will definitely fall off.

An interesting variant of the hinged cover on the well is proposed in the following video: it leans back almost completely, but whether such a device is needed is up to you.

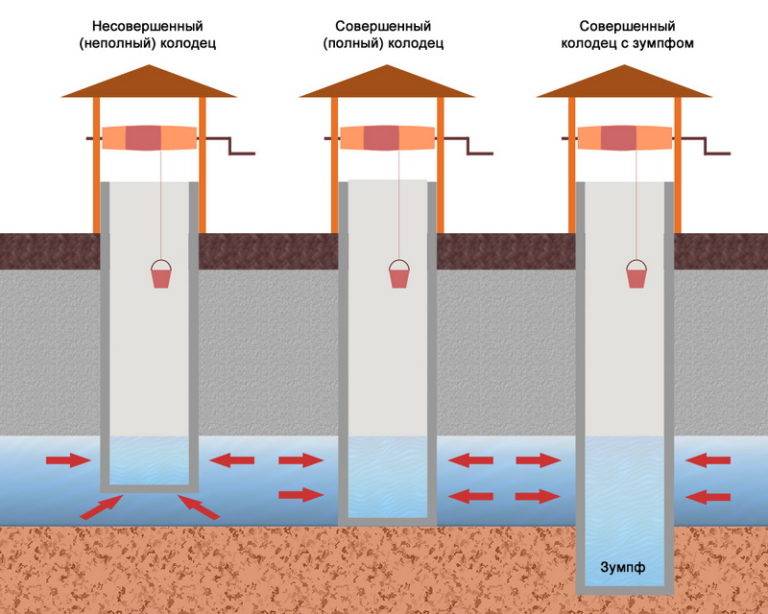

When should wells be deepened?

If you are faced with a similar problem - the water in the well has disappeared, then you need to ask your neighbors how things are with their water. If the same pattern is observed in neighboring areas, then, most likely, the reason for this was drought or frost. It is possible that water will reappear soon.

If water does not appear for a long time, then deepening is indispensable. In addition, this operation may be required if the source is installed on a quicksand, as a result of which it constantly becomes sandy. In this case, it should be deepened to the next aquifer (see also the article “Plastic manhole for a well - practical, convenient, beautiful”).

Well with a "fallen" water level

It should be said right away that it is technically and economically feasible deepen the well cottage in the following cases:

- The source is completely dry or the water rises no higher than one ring per day.

- The depth of the column is more than 10 rings.

- The structure is in good condition and the produced water is of good quality.

- There is no possibility to equip a new source of water supply on the site.

- The structure did not move the rings by more than 4 cm and the column was not bent.

Therefore, first of all, it is necessary to inspect the structure, determine its condition and then decide whether it is possible to deepen the well. Even better is to invite an experienced craftsman who will give his assessment.The fact is that in some cases it is cheaper and easier to rebuild the water source than to restore the old one.

But, let's assume that the structure turned out to be in good condition, with an even column and there are no complaints about water either. So you can start deepening, which will return the water to its previous level. However, get ready for the fact that this process will take a lot of time.

Types of deepening the well

Technology and stages of construction of a well from concrete rings

It is unlikely that anyone is going to pour concrete rings on their own, because this is not only a complex and time-consuming process, but also meaningless. It is much easier to buy ready-made products in the right amount, which is easy to calculate, knowing the depth of groundwater.

Construction of a well with alternate installation of rings

The mine is always dug with a short-handled shovel by hand, with such a tool it will be much easier to manage in a limited space. When the hole of the corresponding diameter is about half a meter deep, check the evenness of the bottom and install the first ring

It is important that it becomes exactly in the middle of the shaft and does not rest against one of the walls. After that, they continue to dig the ground, but already inside the reinforced concrete product

As the soil is excavated, the ring will gradually deepen under its own weight, and when it reaches the upper edge of the ground level, the next ring is placed on top of it and fixed with brackets.

Installation of rings in the finished shaft

There is another construction method, when the rings are lowered in turn into a mine completely dug to the aquifer. But this method is less popular and is not possible on all types of soil.It is also dangerous that at any moment, even before laying, the earth may collapse. Concrete rings are lowered into the pit with a crane, placed on top of each other and fixed with steel brackets around the circumference of the connection.

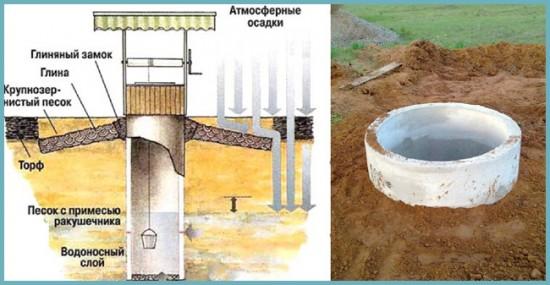

Internal waterproofing

All seams between the rings are sealed with a solution or a special ready-made composition. When lubricating them, do not forget about cracks and pits, which, under the influence of moisture, will quickly collapse and cause depressurization of the mine. It is strongly not recommended to use solutions that contain bitumen, as they can significantly spoil the taste of water.

External waterproofing of the well

The waterproofing of the well from the outside will prevent the top water from entering the mine. To do this, they make the so-called clay castle. A trench about 0.5 m wide and 1.5-2 m deep is dug around the last rings. Clay is poured into it and compacted tightly. As a result, it should lie slightly above the soil level closer to the well, and ensure that the sediments leave the slope from the mine.

The site is being concreted. Over the next 2-3 weeks, the water must be pumped out several times. It can be used for domestic needs, but for drinking purposes it is better only after a conclusion from the laboratory.

How to carry out preparatory work

Before deepening a well from concrete rings, it is necessary to perform high-quality preparation. At the first stage, the real state of the well structures is assessed. In addition, it is necessary to make sure that the soil is able to hold the newly installed rings, as well as to determine the changed level of groundwater.

The process of deepening wells can be carried out to a depth of 3 meters.In addition, the work is advisable in the case when the original design had no more than 15 rings, and each of the elements must be installed relative to the other without displacement. In the case when a slight displacement was detected, it is necessary to carry out work to align the column, for which brackets are installed on each of the seams of the water intake in order to fix the structure rigidly and prevent its rupture.

Naturally, any water-lifting structure is removed for the duration of the work, and the decorative upper house is also removed, if it was provided for by the design. In addition, all available water is pumped out of the well by a drainage pump.

So, the question of whether it is possible to deepen a well from concrete rings is decided positively, but it will also be necessary to prepare certain materials and tools:

It is necessary to prepare in advance everything that is needed to carry out work on deepening the well

- a shovel with a short handle, so that it is convenient to carry out earthworks in a limited space;

- a pump to pump out water entering the work site;

- a chipper, if in the process of deepening it is necessary to pass hard rocks;

- winch and buckets so that you can freely lift the soil from great depths and lower the rings (this winch should be able to withstand loads up to 600-700 kg;)

- ladder, preferably rope, so as not to take up much space;

- lighting.

The presence of all this "arsenal" will deepen the well with maximum speed and quality. You will also need insurance for the worker who will go down, and protective overalls - overalls, rubber boots, a helmet.

Tools and main activities

It is possible to carry out a deepening once, so you need to carefully think through and foresee everything. It is necessary to take into account the condition of the structure, you should not take on this matter if it is in poor condition and may collapse or not withstand the load. Then it's best to dig a new well

It is also important to take into account the depth of groundwater flow. It is important to know everything about the condition of the soil and its composition. After everything is prepared and calculated, you can prepare the equipment and necessary tools

After everything is prepared and calculated, you can prepare the equipment and necessary tools.

Required tools:

- 2 or more high-quality and powerful pumps;

- Shovels with different cuttings along the length;

- Several metal buckets;

- Strong winch with a endurance of more than 0.5 tons;

- Block for lifting;

- Ladder in the form of a rope;

- Jackhammer;

- Carrying out lighting;

- Overalls, helmet on the head.

Deepening the well raises the water level

Next, you need to know how to properly carry out all the necessary deepening measures:

- Removing the top of the well for easier access to it.

- Pumping out absolutely all the water. It can be moved to a pre-prepared tank.

- Reinforcement of all seams to strengthen the structure.

- Preparation and cleaning of the bottom.

You also need to staple the edges of the column, this will help prevent the seams from breaking.

You should not start work without certain knowledge and skills, as this occupation is quite dangerous. But if, nevertheless, a decision has already been made, then all work must be carried out carefully, observing safety precautions.

Deepening the structure with repair rings

This is the most commonly used method of deepening wells.Masters warn against the mine method of conducting work, when the assembled repair column is lowered by digging the soil from below. In this case, it can easily get stuck and it will be very difficult to bring it down.

It is optimal to perform a phased lowering of the elements and make all connections right inside the well.

In the course of preparatory work, be sure to connect the rings with metal staples, 4 pieces per seam. This will protect the column from rupture in case of possible ground movements.

For work, we need: a shovel with a short handle and an ordinary bayonet, a ladder, lighting equipment, a device for lifting the excavated soil to the surface, a winch, a jackhammer, a manual or electric drill, a level and a pump for pumping water.

From the materials it is necessary to purchase repair rings of a smaller diameter than those in the well, a sealant for processing seams, staples and fittings for temporary fixing of parts. Let's analyze the process step by step.

Carrying out preparatory work

We start by inspecting the new rings and walls of the well. We check if there are any serious irregularities that may prevent the descent of the structure.

We lower the drainage pump into the structure and completely pump out the water. We remove silt and sediments from the exposed bottom, raise them to the surface. If there was a bottom filter in the well, remove all the backfill. Remove all water-saturated soil.

Once again, we examine the walls of the well. If they are heavily soiled, we clean them. We scrape off moss and deposits from the walls of concrete rings. If, as a result of the inspection, cracks and chips are revealed, we repair the walls of the well and the seams between the rings.

Now you can start strengthening them. To do this, we connect the joints of the rings with special brackets, at least 4 on each seam, which guarantees the immobility of the elements. Thus, we minimize the risk of deformation of the old column.

It is impossible to lower the repair rings into the well alone. Requires special equipment and assistance from other workers

Direct deepening process

We start digging. We move from the center of the mine to its edges. We continue to work until the walls of the pit begin to crumble under the pressure of water coming from outside.

After that, we lower the repair rings to the bottom, building a new column. If the soil is prone to shedding, work should be done differently. In this case, we dig a shaft to a shallow depth, lower the first repair ring and temporarily fix it with reinforcement.

After that, we continue to work, taking out the soil from the inside of the structure and digging it. Gradually, the ring will settle, and it will be possible to put the next one on it.

We fasten the rings together with brackets or corners. After the aquifer is reached, we seal the seams with concrete mortar and seal them. We fasten the old and new columns together with brackets. We close the gap between the new and old ring with crushed stone.

Finishing work in the well

After the repair rings are installed in place, the final stage of work begins. It consists in inspecting the entire shaft and identifying possible defects in the seams.

We close them carefully and seal them. Let's start laying the bottom filter. It can be new or even old backfill, but in the latter case, it must be thoroughly rinsed. After that, we disinfect the walls of the well shaft.

This is how a structure ready for operation will look, deepened with repair rings of a smaller diameter

Completing of the work

First you need to think about how much it costs to deepen the well. Sometimes this work will be much more expensive than making a new one.

Therefore, before starting work, it is worthwhile to carefully calculate everything. If you can’t dig another one, then we’ll go directly to the question of how to deepen the old well.

Need equipment

It is possible to deepen a well in a country house only with the use of certain equipment and it should be prepared in advance:

- You will need a pump to pump out the water. Only here you will need a rather powerful one, if there is none, then you can use two;

- You will also need a shovel, only it should have a short handle, otherwise you will not be able to work inside;

- Prepare buckets, and not one, but several;

- You will also need a rope ladder;

- You should also prepare a chipper and lighting supply.

- To repair the well, you will need special clothing that does not get wet, rubber boots with a high top, a helmet that will protect your head from impacts. After all, a well with water and this is worth remembering

Well preparation

Let's start in the following order:

- First you need to dismantle the well house, since you will need convenient access to the well in the future.

- Then the water should be pumped out. You can simplify this task if you have a submersible pump. Otherwise, you will have to pump out the water manually using buckets.

We pump out water

Deepening a well with a filter

During the deepening of the well with the help of filtration, a special pipe is used:

- It can be plastic or metal, its diameter should be approximately 50 cm, length about one meter.

- It is necessary to make holes in the pipe, whose diameter should not exceed 1.5-2 cm, then they should be tightened with a stainless metal mesh. As a result, you will get a do-it-yourself filter, we lower it to the bottom.

- It is necessary to remove the sand from the pipe using a bailer, this will make it possible to deepen the well to the proper level.

Deepening a well with digging

You can deepen the well with rings of smaller diameter. Thus, you can get to the next aquifer.

As mentioned earlier, before you start digging for the installation of a trunk for repair, you need to dock concrete rings using special plates.

Well deepening scheme

So:

- We dig until the walls of the mine begin to collapse.

- Then you should make a descent and start scraping the rings for repair.

- Then you can resume digging with a further increase in the shaft from the outside.

- At the end of the work, the repair and old columns should be connected using angle brackets for this. Then the old shaft will not slide onto the new well shaft.

- At the final stage, it is necessary to update the bottom filter. This can be done by filling the bottom of the well with gravel and gravel.

Deepening a well in floating soil

If it is placed on a quicksand, then everything should be very careful.

So:

So:

- Experience confirms that it is possible to overcome the most difficult soil zones if you use accelerated penetration with four repair rings, which will increase the load. The main and additional repair shafts must be scraped off.But, for this you will need special equipment, which makes it possible to unload a lot of sand from the well mine in one pass. This will greatly increase the rate of sedimentation of the new fragment.

- The efficiency of fast penetration is influenced by the entry of a new part of the well into the zone of a floating rock with hard ground rocks. In the event that this happens, you will have to stop the tunneling. It is necessary to put a prepared larch raft on the bottom, then pour in the filter material. Water inflow will increase compared to the previous state, before the repair.

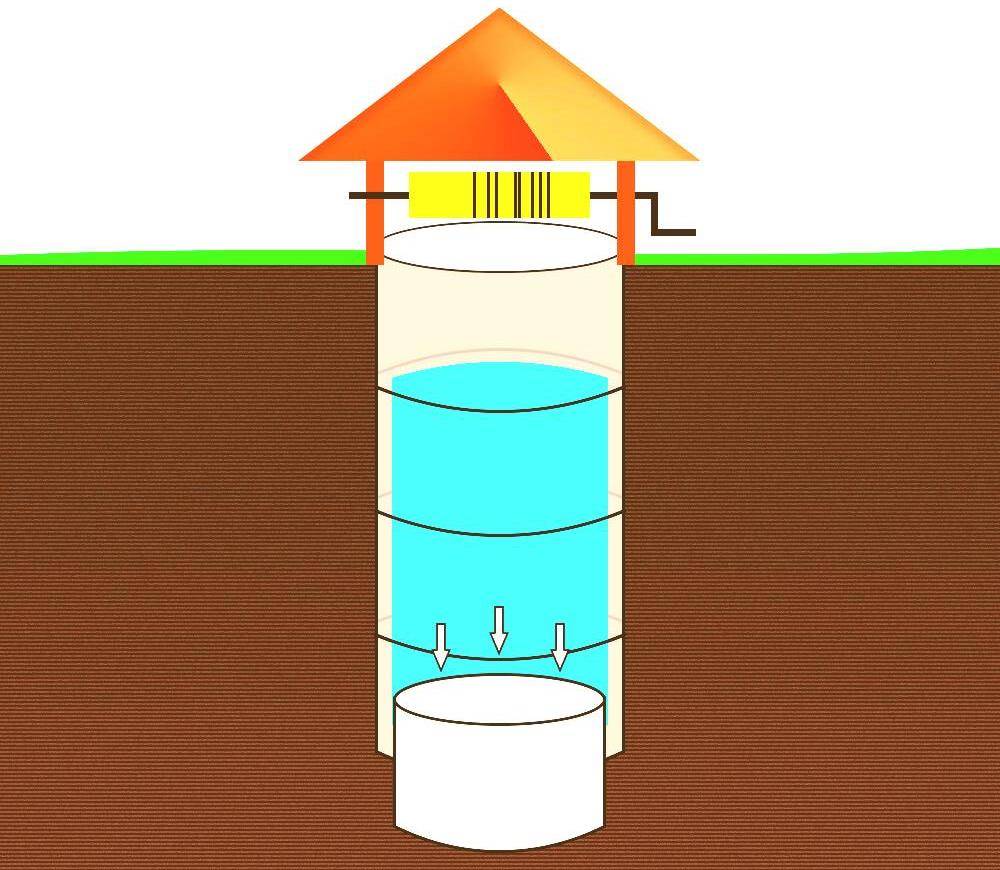

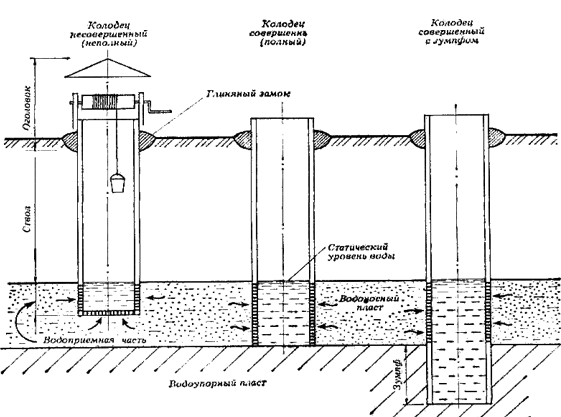

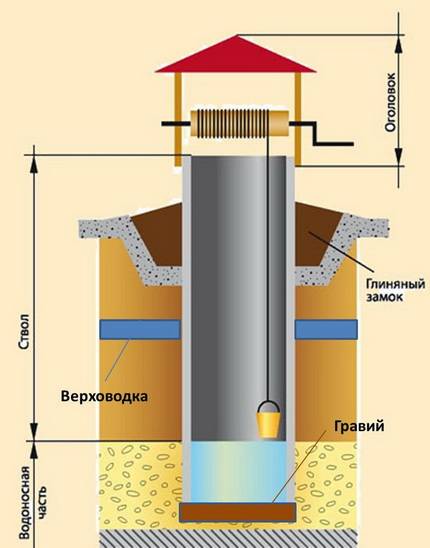

The device and design of the well

The design of the well has not changed for hundreds of years. The structure is a mine, the bottom of which is located in the aquifer.

The walls of the trunk are strengthened from shedding. For these purposes, stone, wood or a modern version - reinforced concrete rings can be used. At the bottom, a filter is usually arranged, which is a backfill of gravel 10-15 cm high. There are more complex multi-layer filters consisting of crushed stone, gravel and sand.

The mine is closed by the so-called over-well house, in which there is a mechanism for raising water. The structure can be equipped with a pump, which greatly facilitates the supply of water.

The figure shows a diagram of the device of a mine well. Any structure of this type is arranged in a similar way.

The well is considered the main "competitor" of the well. Each source has its strengths and weaknesses. In order to choose the best option for you personally, we suggest that you familiarize yourself with a comparative review.

However, despite the advantages of a well, many prefer a traditional source of water.With proper operation, the well will last longer than it does, while maintaining cleanliness in the mine is much easier than in a tubular borehole.

A structure with a manual water lifting mechanism does not need electricity and can be operated in any conditions, while a borehole pump is always volatile. Besides, a well can be dug and equip manually, without the involvement of special equipment and mechanisms. However, trouble-free operation of wells is rare.