- Ways and methods of deepening

- What is a well

- The device and design of the well

- Deepening a well by digging

- Carrying out preparatory work

- Deepening works

- Final work in the well

- Well digging options

- Open digging method

- Closed digging method

- Selection of pumping equipment

- Type and structure

- Type of well shaft

- How to identify an aquifer

- Bottom filter in the well

- Selection of concrete rings

- How and when to dig

- 4 Digging a well - when should a concrete ring be installed?

- Conclusions and useful video on the topic

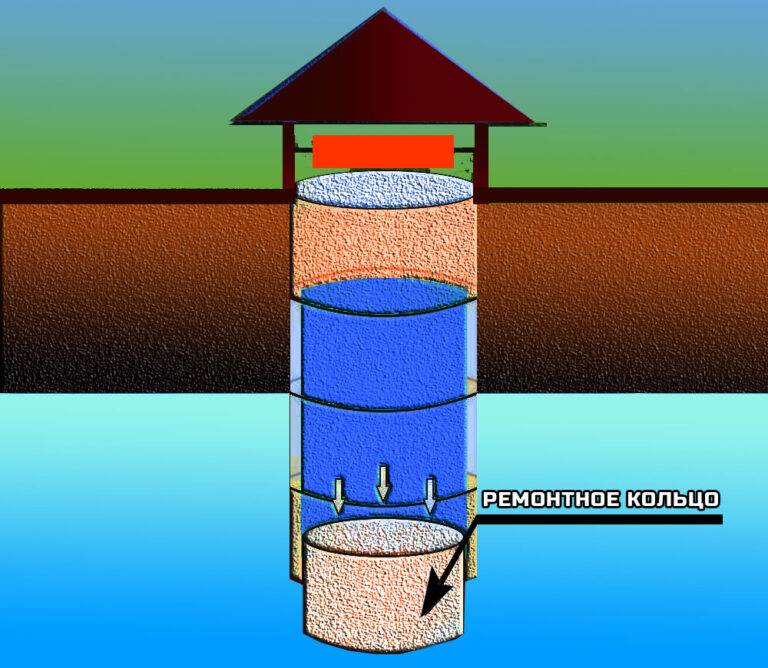

Ways and methods of deepening

There are several methods to increase the depth of the well. Each of them has its own technology, advantages and disadvantages.

Table. How to make a well deeper.

| Methodology | Description |

|---|---|

|

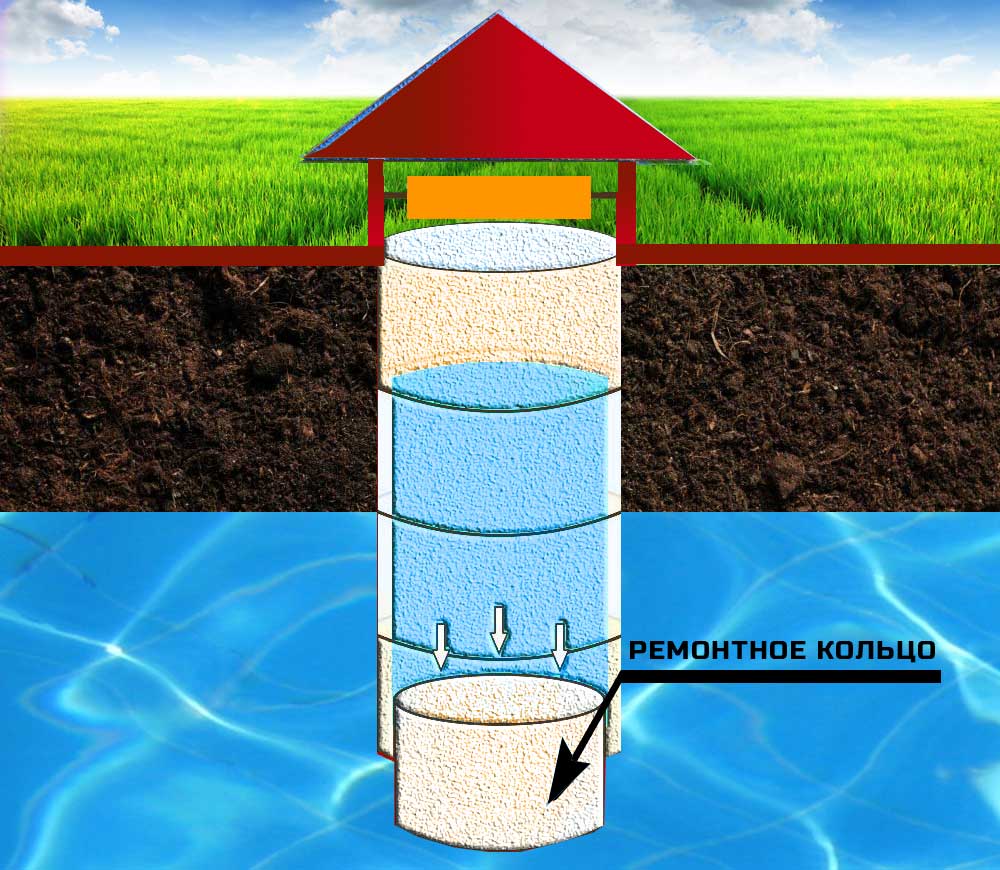

Installation of repair rings | The most popular method is to make the intake structure deeper. Here, soil is removed from the bottom of the well, and then rings of concrete are lowered down, having a smaller diameter than the rings used to build the mine itself. |

Well creation | To implement this method, a casing pipe is lowered to the bottom of the well, and a pump is installed. This method is able to turn an ordinary well into a well.However, such a structure will require regular cleaning, and the procedure is so difficult that you will have to call specialists. And during a power outage, it will not be possible to extract water from the well. |

Undermining | The technique involves a lot of time and is quite difficult to implement. Usually, experienced craftsmen are invited for this, especially if the structure has a depth of more than 10 m. First, a person descends into the well, then evenly and carefully digs the ground around the perimeter of the lower ring. Excess soil rises to the surface. So the well system itself, under its own weight, will begin to settle on the devastated space. Undermining is carried out until the moment when the water begins to arrive quickly. |

Settling with weights | The method is similar to the previous one, but is only suitable for structures that were created no later than 2 months ago. Otherwise, the shaft will not settle evenly, it may break, which, as a rule, cannot be repaired. In this case, the well is under enormous pressure, under which it falls down. |

Wall extension | With this technique, soil is also excavated in the lower part of the mine, but the walls are strengthened by concrete with reinforcement or brickwork. The method is recommended to be used if it is not possible to besiege the well. It is quite laborious and requires the purchase of only high-quality material to strengthen the walls. At the same time, the deepening at a time is made by no more than 30-40 cm, so it will take a lot of time to achieve the desired depth. When implementing this method, it is worth remembering that there is a risk of sudden subsidence of the mine, and under its weight, fresh and not frozen masonry can simply break. |

Demolition of old walls | Sometimes the well is deepened with the complete dismantling of the old mine. All old walls are removed, the pit is widened, deepened, after which the rings can be installed again. The method is dangerous, complicated and often impractical. There is a high probability of damage to the withdrawn concrete rings. And with a well depth of more than 4-5 m, it is life-threatening to be inside it, since unreinforced and unprotected walls can easily crumble, and it is not always possible to save the injured person in time. |

Filter Depth Enhancement | To do this, a plastic or metal pipe is purchased with a diameter of at least 0.5 m and a length of about 1 m. Small holes with a diameter of up to 1.5-2 cm are formed on its walls. bottom of the building. Next, the soil is removed and the filter is precipitated; its upper opening should not be closed by contaminated liquid. The emerging liquid is pumped out by a pump. The filter is mounted to a depth of 2-3 rings, after which the excess soil is removed, and smaller concrete elements are lowered to the bottom. This case belongs to the private ones from the category of deepening wells with the help of repair rings. |

Well cleaning

What is a well

This is a rather complex structure, therefore, before proceeding with its creation, it is necessary to familiarize yourself with the construction technology and types of structures.

Let's take a closer look:

- Digging to a certain depth.

- There are wells for sand and gravel, for limestone.

- The depth of this structure reaches 15 m.

- The sand well can be 6-8 m.

- At this depth, the water quality is not at a high level.

- At greater depths, the water is cleaner and of better quality.

- It's not enough just to dig.

- It must be equipped with high quality both outside and inside (see Well construction: construction options for the structure).

- For this, special modern materials are used that meet environmental standards.

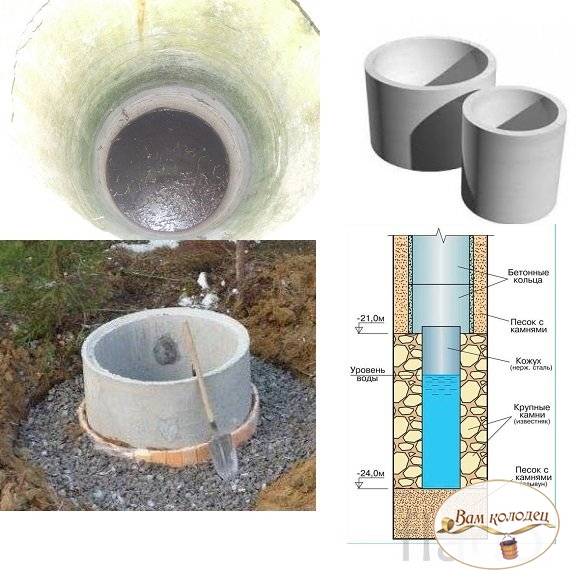

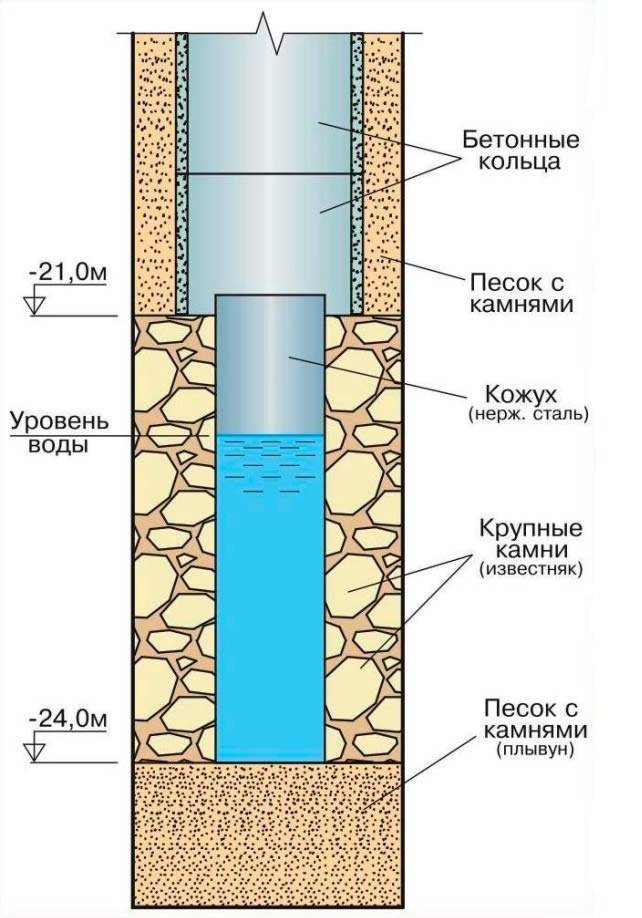

The device and design of the well

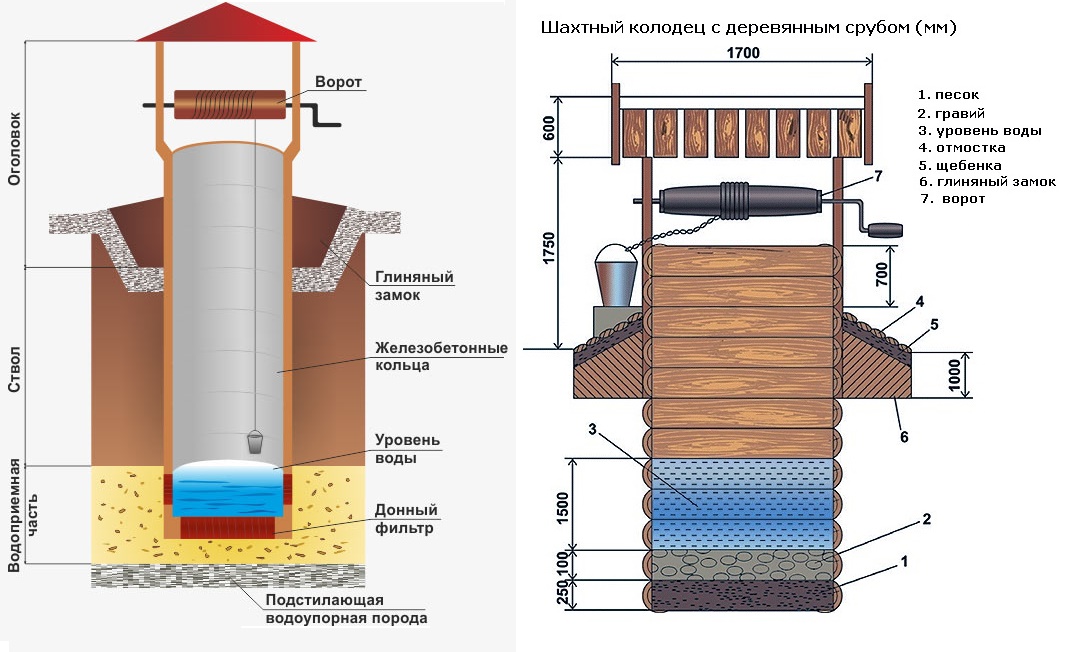

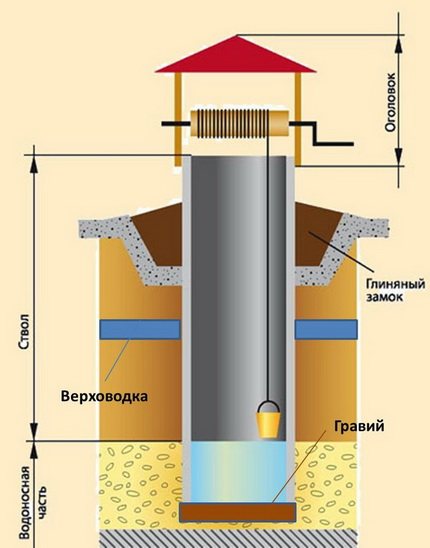

The design of the well has not changed for hundreds of years. The structure is a mine, the bottom of which is located in the aquifer.

The walls of the trunk are strengthened from shedding. For these purposes, stone, wood or a modern version - reinforced concrete rings can be used. At the bottom, a filter is usually arranged, which is a backfill of gravel 10-15 cm high. There are more complex multi-layer filters consisting of crushed stone, gravel and sand.

The mine is closed by the so-called over-well house, in which there is a mechanism for raising water. The structure can be equipped with a pump, which greatly facilitates the supply of water.

The figure shows a diagram of the device of a mine well. Any structure of this type is arranged in a similar way.

The well is considered the main "competitor" of the well. Each source has its strengths and weaknesses. In order to choose the best option for you personally, we suggest that you familiarize yourself with a comparative review.

However, despite the advantages of a well, many prefer a traditional source of water. With proper operation, the well will last longer than it does, while maintaining cleanliness in the mine is much easier than in a tubular borehole.

A structure with a manual water lifting mechanism does not need electricity and can be operated in any conditions, while a borehole pump is always volatile.In addition, the well can be dug and equipped manually, without the involvement of special equipment and mechanisms. However, trouble-free operation of wells is rare.

Deepening a well by digging

This method differs from the one described above in that the well is built up with repair rings from above. Moreover, their diameter does not differ from those that have already been installed.

In fact, this is a continuation of the work begun many years ago with the initial digging of the well. The main danger in using this method is the possibility of the old column getting stuck in the ground, especially if the well is located on clay rocks.

Carrying out preparatory work

We start by fixing the rings. At each joint we fix at least 4 staples. We drill holes for them, put metal plates 0.4x4x30 cm and fix them with 12 mm anchor bolts.

Thus, the casing string will be able to withstand possible ground movements. We pump out water from the well and completely remove the bottom filter, if it was present in the structure.

Deepening works

A worker descends on the belay and begins to dig. First, he selects the soil from the middle of the bottom of the structure, then from the periphery. After that, he begins to dig under two opposite points from the edges of the lower ring with a depth of 20-25 cm.

It is no longer necessary, otherwise there is a danger of an uncontrolled descent of the element. Then the tunnel is gradually expanded to the annular area.

During operation, the column must settle under its own weight. New rings are placed on the space vacated on top. Undermining is carried out until the water begins to arrive very quickly.

It should be noted that column subsidence does not always occur, especially if the well is “older” than 1-2 years. In difficult cases, the side digging method can be used as a way to lower a stuck ring.

It looks like a spatula, which is used for lateral digging of rings. The handle, longer than 40 cm, should be bent for comfort and precision

Consider it on the example with the lower ring. We carry out the digging as already described. Then we take three hemp or strong supports from a bar and place them under the ring so that there is a distance of about 5 cm between them and the bottom edge.

These supports will subsequently take on the entire weight of the settled structure. Then, in two opposite sections, we remove the sealing solution from the annular gap.

We insert nail pullers into the resulting gaps, and two people, simultaneously acting as a lever, can try to lower the ring. If all else fails, we take a special spatula for undermining the side walls.

For its handle, fittings 10 cm long and 14 mm in diameter are used. The cutting part measuring 60x100 mm is made of 2 mm sheet iron. We insert the spatula 2-3 cm from the outer wall of the ring and proceed to hollowing out the clay.

To do this, hit the handle with a sledgehammer from the bottom up. Thus, we pass the entire ring except for the sections under which there are supports. We managed to remove the clay to a height of 10-15 cm from the lower edge of the ring.

Now you can try again the lowering attempt with the nail pullers or any other levers. If not, take the next blade. The length of its handle should be 10 cm longer. We perform similar steps.

At the end of the repair work, you should once again inspect all the seams and carefully seal them, then cover them with sealant

A small note: when the length of the shovel handle reaches 40 cm or more, it will need to be bent a little. So it will be more convenient to work. With proper lateral digging, the outer wall of the ring is gradually released, and it settles down. Similarly, work is carried out on other rings.

Final work in the well

Upon completion of the deepening works, all contaminated water is removed from the structure. All seams between the rings are securely sealed and sealed. If damage to old seams is noticed, they are also eliminated.

At the bottom of the structure we lay a new bottom filter of the desired design. Then we disinfect the walls of the mine with a solution of chlorine or manganese. The well is ready for use.

Do not forget that the normal operation of the water intake mine working and the preservation of its water abundance is directly related to competent arrangement, the rules for the implementation of which will be introduced by the article we have proposed.

Well digging options

There are several ways to dig a well with your own hands in the country, each of them has its own advantages and disadvantages.

To date, common digging techniques are closed and open methods.

Let's consider each of them separately.

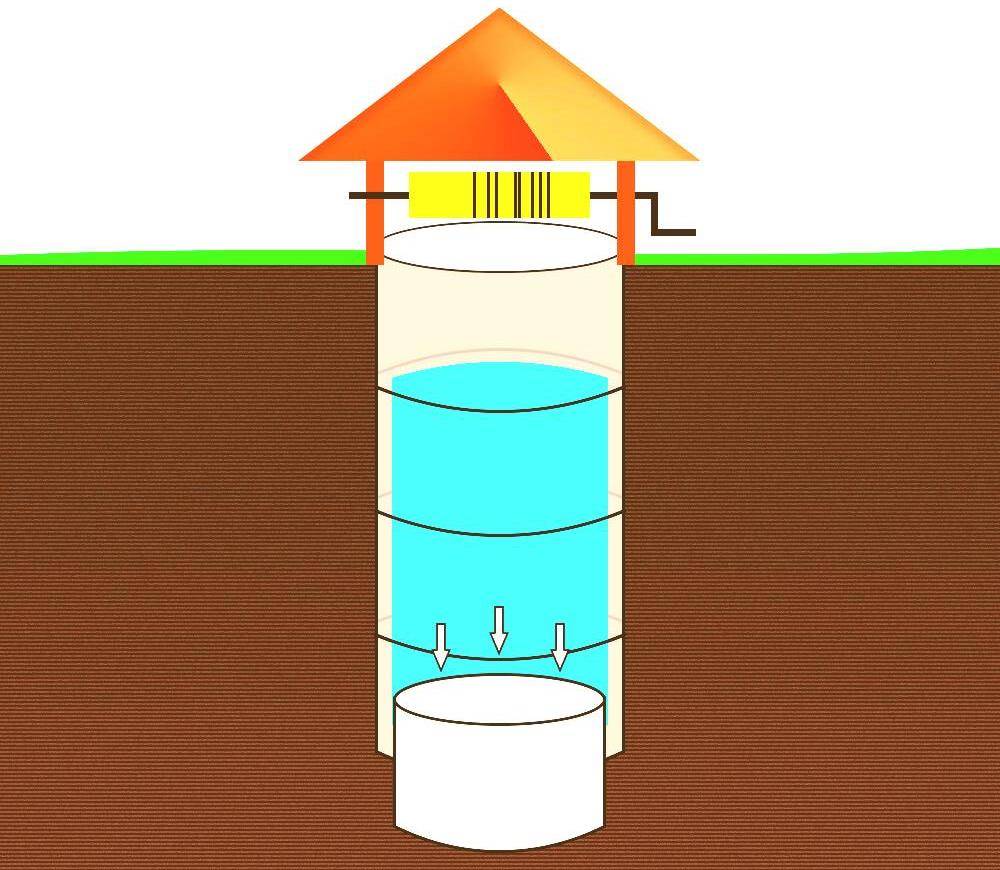

Open digging method

Open pit digging is suitable for areas with dense clay soil.

A shaft dug in such soil and temporarily not reinforced with concrete rings will not collapse, its walls will remain the same thanks to the clay layer.

The first stage involves digging a hole to the aquifer, its diameter should be 15 cm, the diameter of reinforced concrete rings.

Further, the reinforced concrete rings are lowered in turn into the well shaft with the help of a winch. Their use allows you to organize high-quality walls.

Joints of reinforced concrete products are sealed with special rubber seals. If such seals are not at hand, then cement mortar or liquid glass is used for this purpose.

Additionally, in order to prevent the displacement of correctly set rings, they are equipped with special metal brackets from the outside.

After the complete formation of the s / w column, the space between the walls of the excavated shaft and the outer walls of the rings is covered with coarse sand.

To learn more about how to properly dig a well, we recommend watching a thematic video.

Closed digging method

The following scheme and the proposed video material, which will facilitate the process of digging a well in a country house in sandy soil.

It is quite difficult to dig a well on your own in loose earth, since the walls of the mine will constantly crumble and move.

But for this, there is a closed technology with which it is much easier to do the job.

“In the ring” - this is how experts call such a step-by-step method of digging a source of water:

- In the intended place for the future well, they dig out the top layer of soil, observing the appropriate diameter of the reinforced concrete rings;

- Next, they dig a hole with a depth that depends on the strength of the walls of the mine. The recess can be made by 20 cm or more, approximately can be equal to two meters;

- With the help of a winch, the first ring is lowered into the recess, and further digging takes place under it. As a result, the weight of the reinforced concrete ring will gradually lower it lower and lower;

- Then such a reinforced concrete product is placed on its surface, the weight of the structure increases even more and it falls into the excavated recesses of the mine. Thus, by the method of alternate installation of rings, it is possible to properly get to the bottom of the aquifer.

Sealing the seams of the walls of a concrete column and sealing the structure from the outside is carried out according to the same principle as digging a well in an open way.

Thematic video material will allow to supplement the above.

Video:

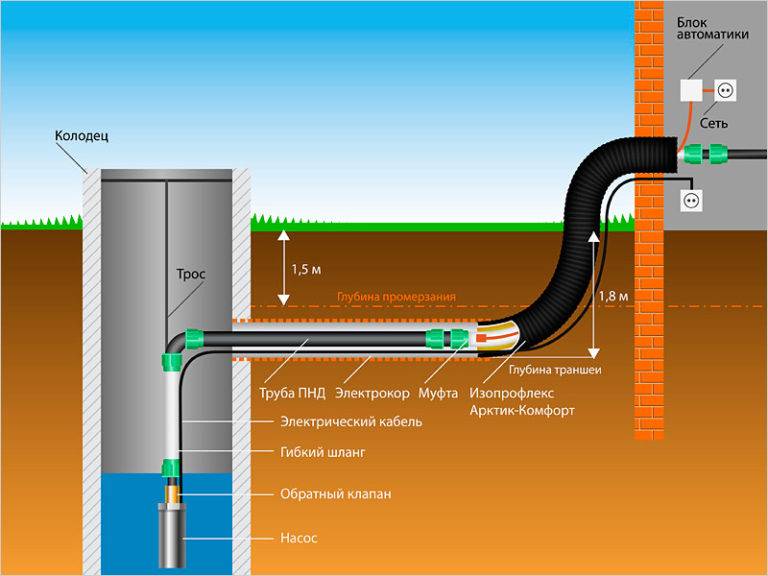

Selection of pumping equipment

Scheme of water supply to the house

As you know, all types of pumps are divided into two types:

1 Surface: they have only a suction pipe in the water; such units are able to lift it only from a depth of up to 10.3 m; it is to such a height that water can rise through the tube, pushed out by atmospheric pressure into the tube; in practice, due to friction losses and fluctuations in atmospheric pressure, this parameter decreases and equals 5-7 m; mechanisms with ejectors (water flow accelerators) can lift water from greater depths, but their efficiency is too low.

2 Submersible: the entire mechanism is completely lowered into the liquid, which allows you to deliver water from a great depth; since such units do not expend suction power, there is no loss of suction; their efficiency is much higher than superficial ones.

Thus, it is desirable to pump water for a summer residence from deep wells with pumping stations equipped with submersible pumps. It remains only to determine their power and performance. It is necessary to take into account not only the needs of the family, but also the flow of water in the well itself. Otherwise, it may turn out that a too powerful unit will run idle.

Please also note that the overall efficiency of the system will depend not only on the power of the unit, but also on the number of turns and narrowing of the water supply. With a small influx of water, it makes sense to purchase a low-power pump, while equipping a storage tank from which water will be supplied to the house to the taps.

Another important parameter for the pump is the pressure force, that is, the ability to transfer (move) the pumped water further through the pipes. This parameter is directly related to the working pressure. That is, for 10 m of a vertically located pipe there is a pressure of 1 atmosphere.

How to make beautiful and unusual DIY wall shelves: for flowers, books, TV, kitchen or garage (100+ Photo Ideas & Videos) + Reviews

Type and structure

If you have decided on a place, it remains to choose which one you will make your mine. You can only dig a shaft well, and the Abyssinian can be drilled. The technique here is completely different, so further we will talk about the mine well.

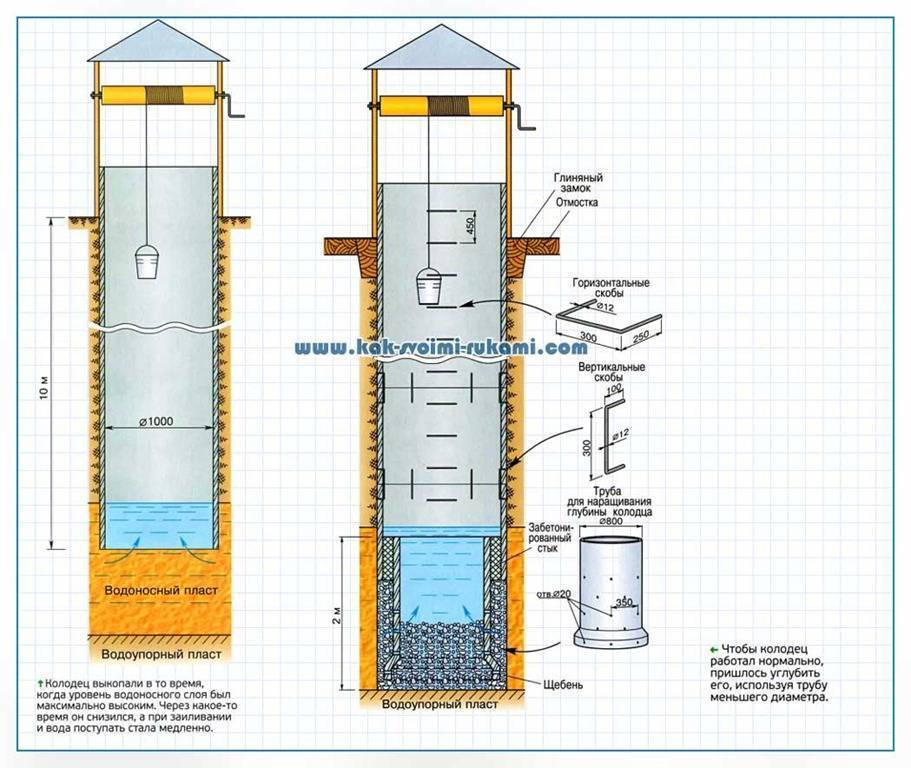

Type of well shaft

The most common today is a well made of concrete rings. Common - because it's the easiest way. But it has serious drawbacks: the joints are not airtight at all and through them rain, melt water enters the water, and with it what is dissolved in it, and what is drowned.

Lack of a well made of rings and logs

Of course, they try to seal the joints of the rings, but those methods that will be effective cannot be applied: the water must be at least suitable for irrigation. And just covering the joints with a solution is very short and inefficient.The cracks are constantly growing, and then not only rain or melt water enters through them, but also animals, insects, worms, etc.

There are lock rings. Between them, they say, you can lay rubber gaskets that will ensure tightness. There are rings with locks, but they are more expensive. But gaskets are practically not found, like wells with them.

The log shaft suffers from the same “disease”, only there are even more cracks. Yes, that's what our grandfathers did. But they, firstly, had no other way, and secondly, they did not use so much chemistry in the fields.

From this point of view, a monolithic concrete shaft is better. It is cast right on the spot, putting a removable formwork. They poured out the ring, buried it, put the formwork again, stuck the reinforcement, poured another one. We waited until the concrete "grabbed", again removed the formwork, digging.

Removable formwork for a monolithic concrete well

The process is very slow. This is the main drawback. Otherwise, only pluses. First, it turns out very cheap. The cost is only for two galvanized sheets, and then for cement, sand, water (proportions 1: 3: 0.6). It is much cheaper than rings. Second, it's sealed. No seams. Filling goes about once a day and because of the uneven upper edge, it turns out to be almost a monolith. Just before pouring the next ring, scrape off the risen and almost set cement laitance (gray dense film) from the surface.

How to identify an aquifer

According to the technology, the soil is taken out inside the ring and under it. As a result, under its weight, it settles. Here is the soil that you take out and will serve as a guide.

As a rule, water lies between two water-resistant layers. Most often it is clay or limestone. The aquifer is usually sand.It can be small, like a sea, or large interspersed with small pebbles. Often there are several such layers. As the sand has gone, it means that water will soon appear. As it appeared at the bottom, it is necessary to dig for some more time, taking out the already wet soil. If the water comes actively, you can stop there. The aquifer may not be too large, so there is a risk of passing through it. Then you have to dig until the next one. Deeper water will be cleaner, but how much deeper is unknown.

Next, the well is pumped - a submersible pump is thrown in and water is pumped out. This cleans it, deepening it a little, and also determines its debit. If the speed of the arrival of water suits you, you can stop there. If not enough, you need to quickly pass this layer. With the pump running, continue to excavate the soil until go through this layer. Then they dig to the next water carrier.

Bottom filter in the well

Bottom filter device for a well

If you are satisfied with the speed of the arriving water and its quality, you can make a bottom filter. These are three layers of cameos of different fractions, which are laid at the bottom. They are needed so that as little silt and sand as possible get into the water. In order for the bottom filter for the well to work, it is necessary to lay out the stones correctly:

- Large stones are placed at the very bottom. These should be fairly large boulders. But in order not to take much of the height of the water column, use a flatter shape. Spread at least in two rows, and do not try to keep them close, but with gaps.

- The middle fraction is poured in a layer of 10-20 cm. The dimensions are such that stones or pebbles do not fall into the gaps between the bottom layer.

- The top, smallest layer. Pebbles or small stones in a layer of 10-15 cm.Sand will settle in them.

With this arrangement of fractions, the water will be cleaner: first, the largest inclusions settle on large stones, then, as you move up, smaller ones.

Selection of concrete rings

Since the deepening of the well is not complete without casing - concrete rings play its role - it is important to choose the right diameter. It is naturally smaller than the concrete laid corridor, since the insertion will occur from above. In order not to be mistaken, the outer diameter of the new ring should be equal to the inner old one ± 2-3 cm, taking into account the thickness of the fastening reinforcement

In order not to be mistaken, the outer diameter of the new ring should be equal to the inner old one ± 2–3 cm, taking into account the thickness of the fastening reinforcement.

However, when choosing the optimal size, consider the following features:

- If the shaft of the old well has remained flat since the time of operation, without shifts, then an 80-ku is laid on a diameter of 90 cm.

- If the distortion is observed with the naked eye, then the diameter of the lower ring is even smaller - about 70 cm. This will entail an increase in the gap, which is subsequently poured with fine gravel, which serves as a water filter.

By contacting the manufacturer of such products, you can get comprehensive information on this issue if confidence in your own knowledge is low.

The deepening of the well is carried out with rings of a smaller diameter, which is selected depending on the curvature of the mine

How and when to dig

When is the best time to dig a well? This question is no less important, so you need to pay due attention to it:

in the spring, during the melting of snow, it is undesirable to dig a well, because you can make a mistake with the depth.This is due to the fact that at this time the groundwater level is high, for example, a well dug in April may turn out to be dry in winter - the level of water fluctuation is in the range of 1-2 m; the best time is the end of winter (no later than March) or the end of summer, because then the level of the water horizon is the lowest

Undoubtedly, it is difficult to dig a well in winter, but there are cases when it is impossible to dig it at other times of the year: we are talking about mines passing through floating waters; we dig a well with our own hands - the right decision, but you also need to pay attention to the availability of free time, because you need to dig continuously so that the column does not stick. It is advisable to take a vacation during this time, because the weekend is not the best option, you may have to take out the rings, which is a laborious task. The next aspect is how to properly dig a well

Basically, three people dig a well: one works with a crowbar / shovel at the bottom, filling a bucket with soil, the second lifts the bucket with the help of a gate, taking the worked out rock to the dump, and the third is resting. The work is intensive, workers often replace each other

The next aspect is how to properly dig a well. Basically, three people dig a well: one works with a crowbar / shovel at the bottom, filling a bucket with soil, the second lifts the bucket with the help of a gate, taking the worked out rock to the dump, and the third is resting. The work is intensive, workers often replace each other.

Visual process of digging a well

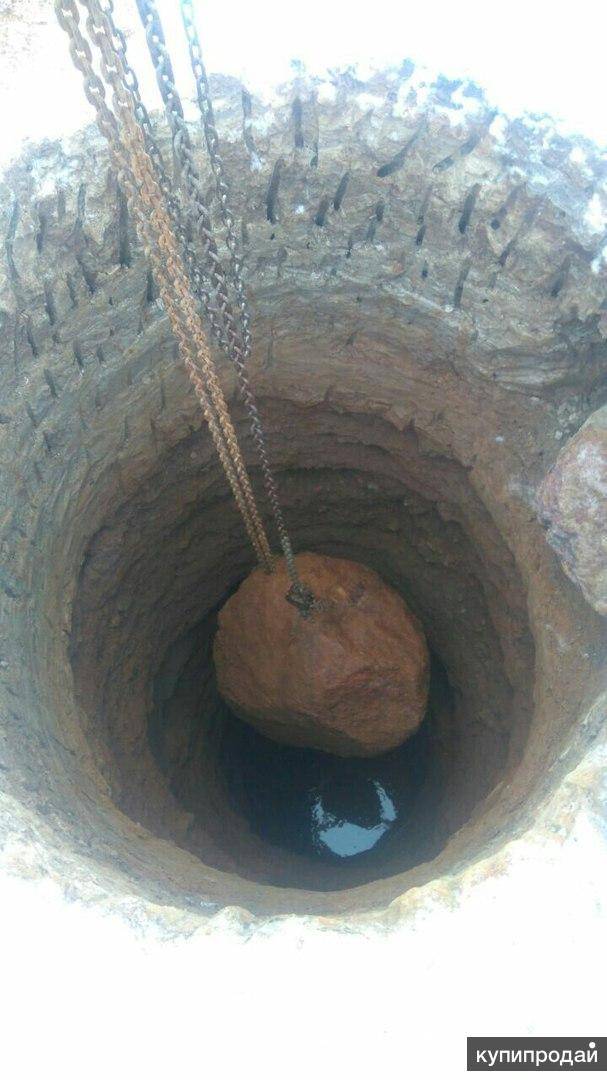

If stones are found, they are turned out with a short crowbar, then tied with ropes, and removed from the well using the same gate on wooden goats.

4 Digging a well - when should a concrete ring be installed?

Having prepared the equipment necessary for work, as well as concrete rings, you can proceed directly to digging the earth. It can be recommended to build a simple structure in the form of two intersecting rails. Such a cross is useful to us to control the size of the diameter of the well shaft. There are two main construction methods - open and closed, differences in which are already in the initial stages. With the open method, the diameter of the pit is 20-30 cm larger than the cross section of the ring, that is, the mine will be about one and a half meters. If you have chosen a closed digging method, then the section of the hole is not much different from the ring. He digs in such a way that this very ring, without distortions, is normally installed in the mine.

The entire removed layer of soil and soil must be immediately removed at a distance of several meters from the excavation site. If you come across a layer of clay, then it can be used for other purposes, for example, to perform waterproofing. So you should not mix clay with earth. After deepening into the ground to the height of one concrete ring, you can act in different ways. With the closed method, the ring is immediately installed in the pit, the further digging process is carried out already under it. In this case, the concrete will sink under its own weight. After some time, you can install the second ring, securing both rings with the existing locking connection.

The closed method has found application in drilling problematic soil types, where there are underground rivers, quicksand, quicksand and similar phenomena. A distinctive feature of this method is that the digger descends along with the ring, always being surrounded by it.Digging in this case is much easier, since the ring lowers itself, which does part of the work of the digger. In addition, you do not need powerful lifting equipment, since the rings are installed on the surface.

There are also disadvantages. First of all, the problems associated with boulders should be noted. After all, a large stone that has fallen under the rim of the ring will become an obstacle, since you will have to spend a lot of effort to extract it. Which is very difficult to do due to the huge weight of the ring or even several concrete products located on top of each other. Working in such a ring is not very convenient, especially for large men.

You can turn to the help of the second method, which is called open. Its essence is very simple: the shaft of the mine is dug to the depth of finding clean water. Rings are installed only after finding the bottom of the well. There are some negative points here, for example, it will take much more to dig, the same applies to the volume of soil extracted using buckets. It is also much more difficult to fasten and mount rings, since all work on their fastening will take place at a depth in a limited space. The main drawback is the likelihood of walls collapsing, especially in the presence of a large number of aquifers, as well as precipitation. Indeed, with the closed method, the walls of the trunk are strengthened immediately at the time of installation of the first ring.

It is best to strengthen the walls at the first sign of the appearance of perch

As practice shows, it is best to act in a mixed way. This procedure is very simple.At first, the soil is dug out using an open method, but at the first sign of the appearance of perched water or any other symptoms indicating the instability of the walls, a ring immediately descends into the mine. In the future, excavations of the well shaft are carried out using a closed technology.

The aquifer causes the greatest difficulties in the process of digging. In this case, it is necessary to constantly pump out water, continuing to dig at least to the height of one or two concrete rings. In order to avoid problems in the future, it is recommended to treat the joints of the first rings with various cement-containing mixtures. The shaft shaft is built up with the condition that the last ring protrudes about 50 cm above the surface level. This protrusion will later become the basis for the head, which can be beautifully designed as a log house. A special wrench device is mounted above the head, designed to lift water.

Conclusions and useful video on the topic

Maintenance work of a wooden well:

Repair of a concrete well with joint insulation:

Repair of a well using a plastic pipe:

Repairing a damaged well is quite simple. It is necessary to accurately determine the cause of the problem and choose the best way to solve it.

It is important to understand that the work will have to be carried out at a depth, which is quite risky.

Therefore, you should not neglect the safety rules. Competently performed repair work guarantees further trouble-free service of the water source.

If you have already had to deal with the repair of a well and you have successfully completed this task, please share your valuable experience with our readers. Tell us what problem you had and how you managed to solve it.