- Choosing a working option

- Which pipes are suitable for underfloor heating

- Coefficient of linear thermal (thermal) expansion for some common materials such as: aluminum, copper, glass, iron and more. Print option.

- Advantages of polypropylene pipes

- Influence of pipe diameter on efficiency for a heating system in a private house

- Pipe section selection: table

- Details

- Connection of profile pipes without welding

- Heating system calculation example

- Thermal power calculation

- Diameter definition

- Features of heating systems with natural circulation

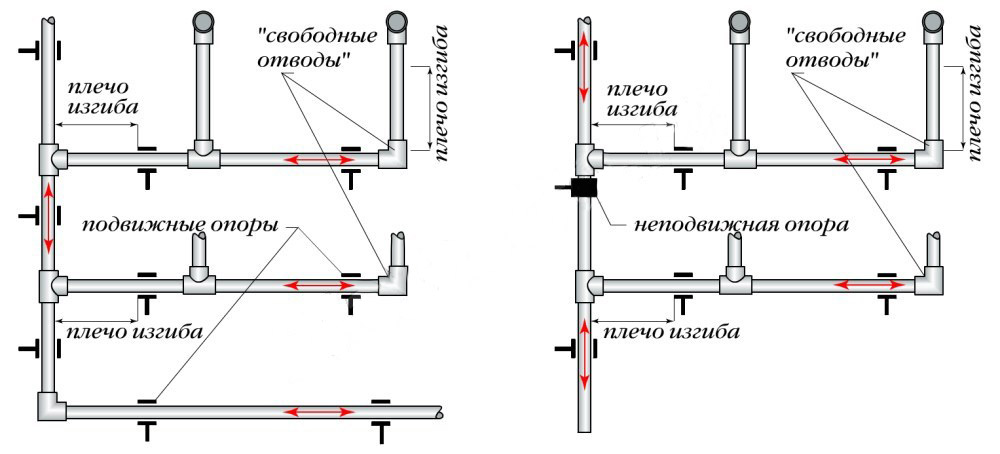

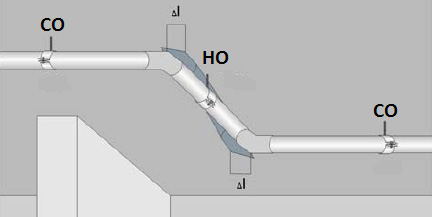

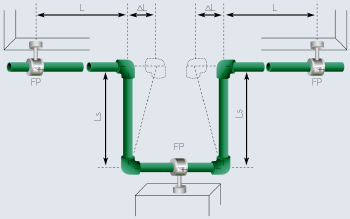

- Installation taking into account the linear expansion index

- Pipe expansion joints

- Kozlov compensator

- Conclusion

Choosing a working option

Currently, there are the following three ways of arranging the external lining:

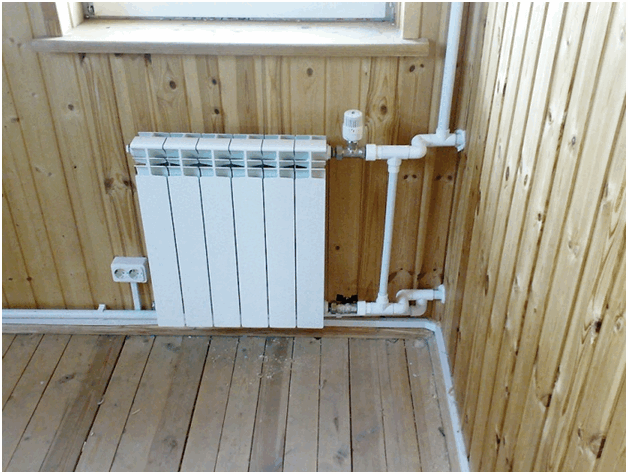

- Top + bottom. The discharge pipe is mounted at the highest possible height. The lower pipeline is laid almost on the surface of the floor in the area of \u200b\u200bthe baseboard. Excellent for natural circulation of working fluid.

- bottom wiring. Both pipes are installed at the bottom of the rooms. The option is used only with forced circulation of the heat carrier. The pipeline is almost invisible to the eye, since it is located in the area of \u200b\u200bthe plinth and is often decorated under it.

- Radiator installation.The injection pipeline, which has a large cross section, is pulled between the heaters directly under the window sills. This is done from one stub to another. The downpipe is laid in the floor area. As a result, fewer pipes are needed. The system is getting cheaper. It is possible to connect heating devices either in parallel or in series.

External laying of communications, although simpler, is less attractive from the point of view of aesthetics.

Which pipes are suitable for underfloor heating

Polymer pipes for laying under the screed

Naturally, modern underfloor heating is mounted from plastic, but it can be different and has different characteristics. Laying heating pipes in a private house under a screed replaces traditional radiator systems. To select a material, you need to determine the selection criteria:

The laying of heating pipes in a private house under a screed is carried out only in whole segments, without connections. Based on this, it turns out that the material must bend and the direction of the coolant flow must change without the use of fittings. Products made of single-layer polypropylene and polyvinyl chloride do not fall under this characteristic;

heat resistance.

All polymer pipes for heating outdoor and hidden laying can withstand heating up to 95 degrees, moreover, the temperature of the coolant rarely exceeds 80 degrees. In a warm floor, water heats up to a maximum of 40 degrees;

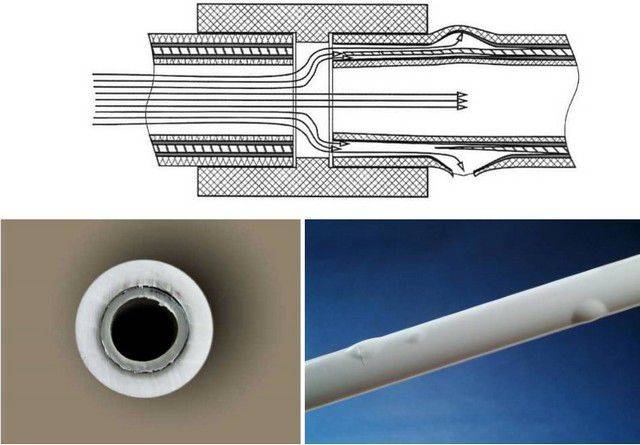

For laying heating pipes in the floor screed, only reinforced products are used, they are also called metal-plastic. Although the reinforcement layer is not only metal. Each material has a certain thermal elongation. This coefficient indicates how much the contour lengthens when it is heated by one degree.The value is determined for a section of one meter. Reinforcement is needed in order to reduce this value;

After laying the heating pipes in the floor screed, there will be no access to them. In the event of a leak, the floor will have to be dismantled - this is a sawing and time-consuming process. Manufacturers of polymer pipes give a guarantee on their products for 50 years.

Reinforced polymer pipes consist of five layers:

- two layers of plastic (internal and external);

- reinforcement layer (located between polymers);

- two layers of glue.

Thermal linear expansion is the property of a material to increase in length when heated. The coefficient is indicated in mm/m. It shows how much the contour will increase when it is heated by one degree. The value of the coefficient shows the amount of elongation per meter.

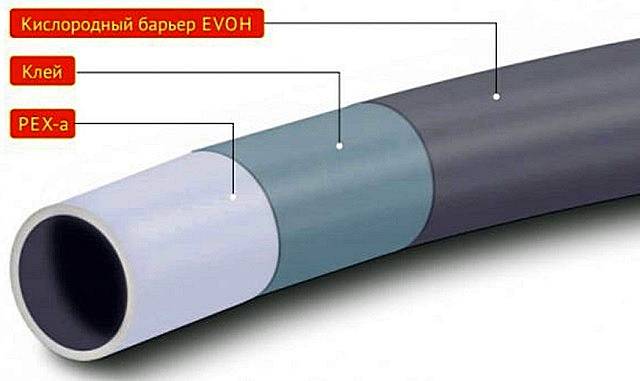

PEX pipe reinforced with aluminum

Immediately it should be mentioned about the types of reinforcement. It could be:

- aluminum foil (AL), 0.2–0.25 mm thick. The layer can be solid or perforated. Perforation is the presence of holes, as in a colander;

- fiberglass fibers are thin fibers of plastic, steel, glass or basalt. In the marking are designated FG, GF, FB;

- ethylene vinyl alcohol is a chemical element that changes the composition of plastic. Marked with Evon.

Before laying heating pipes in a private house, care should be taken that they have a reinforcement layer with aluminum foil or ethylene vinyl alcohol. Since one of the requirements when choosing a material is the elasticity of the contour. Products reinforced with fiberglass cannot be bent; fittings and couplings are used to change the direction of the coolant flow, which is unacceptable in our case.

Let's look at the types of materials used for the production of metal-plastic pipes:

polypropylene. Such products are marked PRR / AL / PRR. Thermal linear expansion is 0.03 mm/m;

cross-linked polyethylene. It differs from conventional low and high density polyethylene in that it undergoes an additional manufacturing step called crosslinking. On it, the number of bonds between molecules increases, thereby the product is given the necessary characteristics. It is marked PEX/AL/PEX and has a coefficient of thermal linear elongation of 0.024 mm/m, which is less than that of propylene.

We will separately consider products made of cross-linked polyethylene reinforced with ethylene vinyl alcohol, since it is best to lay such heating pipes in the floor. They are labeled PEX / Evon / PEX. This method of reinforcement allows you to kill two birds with one stone. Firstly, it reduces the linear expansion of the material to 0.021 mm / m, and secondly, it creates a protective layer that reduces the air permeability of the pipe walls. This figure is 900 mg per 1 m 2 per day.

The fact is that the presence of air in the system not only leads to cavitation processes (the appearance of noise, water hammer), but also provokes the development of aerobic bacteria. These are microorganisms that cannot exist without air. Their waste products settle on the inner walls, and the so-called silting occurs, while the inner diameter of the pipe decreases. For polypropylene pipes with aluminum foil reinforcement, the air permeability of the walls is zero.

Coefficient of linear thermal (thermal) expansion for some common materials such as: aluminum, copper, glass, iron and more. Print option.

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| ABS (acrylonitrile butadiene styrene) thermoplastic | 73.8 | 41 |

| ABS - fiber reinforced glass | 30.4 | 17 |

| Acrylic material, pressed | 234 | 130 |

| Diamond | 1.1 | 0.6 |

| Technical diamond | 1.2 | 0.67 |

| Aluminum | 22.2 | 12.3 |

| Acetal | 106.5 | 59.2 |

| Acetal, fiberglass reinforced | 39.4 | 22 |

| Cellulose acetate (CA) | 130 | 72.2 |

| Cellulose acetate butyrate (CAB) | 25.2 | 14 |

| Barium | 20.6 | 11.4 |

| Beryllium | 11.5 | 6.4 |

| Beryllium copper alloy (Cu 75, Be 25) | 16.7 | 9.3 |

| Concrete | 14.5 | 8.0 |

| concrete structures | 9.8 | 5.5 |

| Bronze | 18.0 | 10.0 |

| Vanadium | 8 | 4.5 |

| Bismuth | 13 | 7.3 |

| Tungsten | 4.3 | 2.4 |

| Gadolinium | 9 | 5 |

| Hafnium | 5.9 | 3.3 |

| Germanium | 6.1 | 3.4 |

| Holmium | 11.2 | 6.2 |

| Granite | 7.9 | 4.4 |

| Graphite, pure | 7.9 | 4.4 |

| Dysprosium | 9.9 | 5.5 |

| Wood, fir, spruce | 3.7 | 2.1 |

| Oak wood, parallel to the grain | 4.9 | 2.7 |

| Oak wood, perpendicular to the grain | 5.4 | 3.0 |

| Wood, pine | 5 | 2.8 |

| Europium | 35 | 19.4 |

| Iron, pure | 12.0 | 6.7 |

| Iron, cast | 10.4 | 5.9 |

| Iron, wrought | 11.3 | 6.3 |

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| Gold | 14.2 | 8.2 |

| Limestone | 8 | 4.4 |

| Invar (an alloy of iron and nickel) | 1.5 | 0.8 |

| Inconel (alloy) | 12.6 | 7.0 |

| Iridium | 6.4 | 3.6 |

| Ytterbium | 26.3 | 14.6 |

| Yttrium | 10.6 | 5.9 |

| Cadmium | 30 | 16.8 |

| Potassium | 83 | 46.1 — 46.4 |

| Calcium | 22.3 | 12.4 |

| Masonry | 4.7 — 9.0 | 2.6 — 5.0 |

| Rubber, hard | 77 | 42.8 |

| Quartz | 0.77 — 1.4 | 0.43 — 0.79 |

| Ceramic tiles (tiles) | 5.9 | 3.3 |

| Brick | 5.5 | 3.1 |

| Cobalt | 12 | 6.7 |

| Constantan (alloy) | 18.8 | 10.4 |

| Corundum, sintered | 6.5 | 3.6 |

| Silicon | 5.1 | 2.8 |

| Lanthanum | 12.1 | 6.7 |

| Brass | 18.7 | 10.4 |

| Ice | 51 | 28.3 |

| Lithium | 46 | 25.6 |

| Cast steel grating | 10.8 | 6.0 |

| Lutetium | 9.9 | 5.5 |

| Cast acrylic sheet | 81 | 45 |

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| Magnesium | 25 | 14 |

| Manganese | 22 | 12.3 |

| Copper nickel alloy 30% | 16.2 | 9 |

| Copper | 16.6 | 9.3 |

| Molybdenum | 5 | 2.8 |

| Monel metal (nickel-copper alloy) | 13.5 | 7.5 |

| Marble | 5.5 — 14.1 | 3.1 — 7.9 |

| Soapstone (steatite) | 8.5 | 4.7 |

| Arsenic | 4.7 | 2.6 |

| Sodium | 70 | 39.1 |

| Nylon, universal | 72 | 40 |

| Nylon, Type 11 (Type 11) | 100 | 55.6 |

| Nylon, Type 12 (Type 12) | 80.5 | 44.7 |

| Cast nylon, Type 6 (Type 6) | 85 | 47.2 |

| Nylon, Type 6/6 (Type 6/6), molding compound | 80 | 44.4 |

| neodymium | 9.6 | 5.3 |

| Nickel | 13.0 | 7.2 |

| Niobium (Columbium) | 7 | 3.9 |

| Cellulose nitrate (CN) | 100 | 55.6 |

| Alumina | 5.4 | 3.0 |

| Tin | 23.4 | 13.0 |

| Osmium | 5 | 2.8 |

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| Palladium | 11.8 | 6.6 |

| Sandstone | 11.6 | 6.5 |

| Platinum | 9.0 | 5.0 |

| Plutonium | 54 | 30.2 |

| Polyallomer | 91.5 | 50.8 |

| Polyamide (PA) | 110 | 61.1 |

| Polyvinyl chloride (PVC) | 50.4 | 28 |

| Polyvinylidene fluoride (PVDF) | 127.8 | 71 |

| Polycarbonate (PC) | 70.2 | 39 |

| Polycarbonate - glass fiber reinforced | 21.5 | 12 |

| Polypropylene - glass fiber reinforced | 32 | 18 |

| Polystyrene (PS) | 70 | 38.9 |

| Polysulfone (PSO) | 55.8 | 31 |

| Polyurethane (PUR), rigid | 57.6 | 32 |

| Polyphenylene - glass fiber reinforced | 35.8 | 20 |

| Polyphenylene (PP), unsaturated | 90.5 | 50.3 |

| Polyester | 123.5 | 69 |

| Polyester reinforced with fiberglass | 25 | 14 |

| Polyethylene (PE) | 200 | 111 |

| Polyethylene - terephthalium (PET) | 59.4 | 33 |

| Praseodymium | 6.7 | 3.7 |

| Solder 50 - 50 | 24.0 | 13.4 |

| Promethium | 11 | 6.1 |

| Rhenium | 6.7 | 3.7 |

| Rhodium | 8 | 4.5 |

| Ruthenium | 9.1 | 5.1 |

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| Samarium | 12.7 | 7.1 |

| Lead | 28.0 | 15.1 |

| Lead-tin alloy | 11.6 | 6.5 |

| Selenium | 3.8 | 2.1 |

| Silver | 19.5 | 10.7 |

| Scandium | 10.2 | 5.7 |

| Mica | 3 | 1.7 |

| Hard alloy K20 | 6 | 3.3 |

| Hastelloy C | 11.3 | 6.3 |

| Steel | 13.0 | 7.3 |

| Austenitic stainless steel (304) | 17.3 | 9.6 |

| Austenitic stainless steel (310) | 14.4 | 8.0 |

| Austenitic stainless steel (316) | 16.0 | 8.9 |

| Ferritic stainless steel (410) | 9.9 | 5.5 |

| Display glass (mirror, sheet) | 9.0 | 5.0 |

| Pyrex glass, pyrex | 4.0 | 2.2 |

| Refractory glass | 5.9 | 3.3 |

| Construction (lime) mortar | 7.3 — 13.5 | 4.1-7.5 |

| Strontium | 22.5 | 12.5 |

| Antimony | 10.4 | 5.8 |

| Thallium | 29.9 | 16.6 |

| Tantalum | 6.5 | 3.6 |

| Tellurium | 36.9 | 20.5 |

| Terbium | 10.3 | 5.7 |

| Titanium | 8.6 | 4.8 |

| Thorium | 12 | 6.7 |

| Thulium | 13.3 | 7.4 |

| Material | Coefficient of linear thermal expansion | |

| (10-6 m/(mK)) / ( 10-6 m/(mC)) | (10-6 in./(in.oF)) | |

| Uranus | 13.9 | 7.7 |

| Porcelain | 3.6-4.5 | 2.0-2.5 |

| Phenolic-aldehyde polymer without additives | 80 | 44.4 |

| Fluoroethylene propylene (FEP) | 135 | 75 |

| Chlorinated Polyvinyl Chloride (CPVC) | 66.6 | 37 |

| Chromium | 6.2 | 3.4 |

| Cement | 10.0 | 6.0 |

| Cerium | 5.2 | 2.9 |

| Zinc | 29.7 | 16.5 |

| Zirconium | 5.7 | 3.2 |

| Slate | 10.4 | 5.8 |

| Plaster | 16.4 | 9.2 |

| Ebonite | 76.6 | 42.8 |

| Epoxy resin, molded rubber and unfilled products thereof | 55 | 31 |

| Erbium | 12.2 | 6.8 |

| Ethylene vinyl acetate (EVA) | 180 | 100 |

| Ethylene and ethyl acrylate (EEA) | 205 | 113.9 |

| Ether vinyl | 16 — 22 | 8.7 — 12 |

- T(oC) = 5/9

- 1 inch = 25.4mm

- 1 foot = 0.3048 m

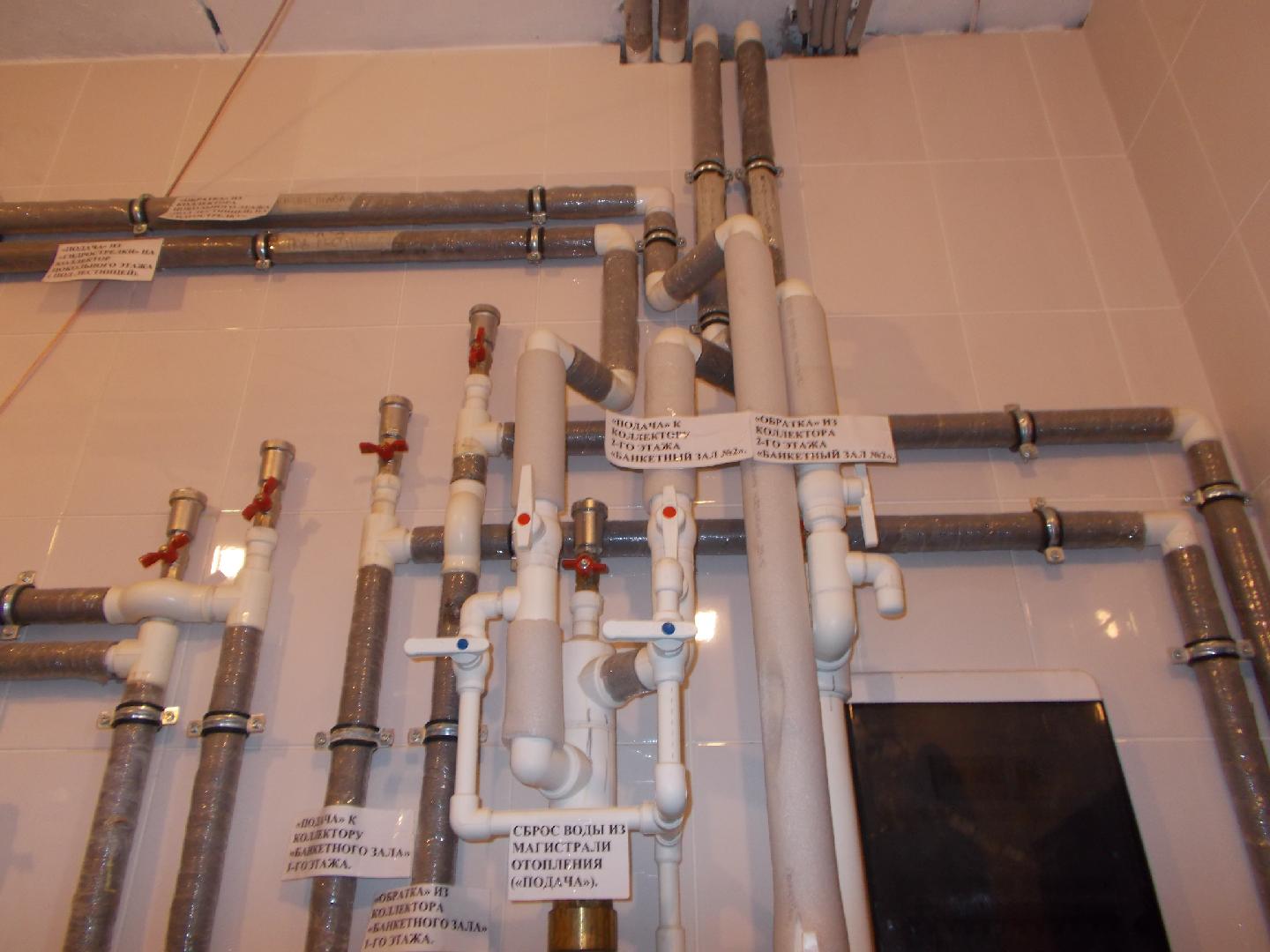

Advantages of polypropylene pipes

You can save on home heating by installing a heating system made of polypropylene pipes. After all, polymer products and their installation cost less compared to metal parts.

Construction concept

This allows you to lay low-cost durable engineering communications, since PP pipes under standard conditions will last 50 years. They also differ:

- Light weight, which simplifies the installation process and reduces the load on the supporting structures of the building.

- Good ductility to prevent rupture when water freezes inside tubular parts.

- Low clogging due to smooth walls.

- Resistant to high temperatures.

- Easy assembly with special soldering equipment.

- Excellent soundproof properties. Therefore, noise from moving water and water hammer is not heard.

- Neat design.

- Low thermal conductivity, which allows not to use insulating material.

Unlike XLPE pipes, polypropylene pipes cannot be bent due to increased elasticity. Bending of communication is carried out using fittings.

Polypropylene also has a high linear expansion. This property makes it difficult to lay in building structures. After all, the expansion of pipes can cause deformation of the main and finishing material of the walls. To reduce this property during open installation, compensators are used.

Influence of pipe diameter on efficiency for a heating system in a private house

It is a mistake to rely on the “more is better” principle when choosing a pipeline section. Too large a pipe cross section leads to a decrease in pressure in it, and hence the speed of the coolant and heat flow.

Moreover, if the diameter is too large, the pump simply may not have enough capacity to move such a large volume of coolant.

Important! A larger volume of coolant in the system implies a high total heat capacity, which means that more time and energy will be spent on heating it, which also affects the efficiency not for the better.

Pipe section selection: table

The optimal pipe section should be the smallest possible for a given configuration (see table) for the following reasons:

However, do not overdo it: in addition to the fact that a small diameter creates an increased load on the connecting and shut-off valves, it is also not able to transfer enough thermal energy.

To determine the optimal pipe section, the following table is used.

Photo 1. A table in which the values are given for a standard two-pipe heating system.

Details

Types of reinforcement with aluminum:

1. apply a layer with an aluminum sheet on top of the pipe.

2. aluminum sheet is applied inside the pipe.

3. carry out reinforcement with perforated aluminum.

All methods are the bonding of polypropylene pipes and aluminum foil. This method is ineffective, since the pipe can delaminate, changing the quality of products for the worse.

The fiberglass reinforcement process is more functional and durable. This method assumes that inside and outside the pipe polypropylene remains, and fiberglass is laid between them. The reinforcing pipe has three layers. Such pipes are not subject to thermal change.

Comparison of the expansion rate before and after the reinforcing procedure:

1. Simple pipes have a coefficient of 0.1500 mm / mK, in other words ten millimeters per linear meter, with a temperature change of seventy degrees.

2. Reinforced pipe products with aluminum change the value to 0.03 mm / mK, in another way it is equal to three millimeters per linear meter.

3. During fiberglass reinforcement, the indicator drops to 0.035mm/mK.

Polypropylene pipe products with a reinforced layer of fiberglass will be used in various fields.

Features of reinforcement of pipes made of polypropylene. The reinforcing material is solid or perforated foil, which has a thickness of 0.01 to 0.005 centimeters. The material is laid on the wall outside or inside the product. The layers are connected with glue.

The foil lays down as a continuous layer, which becomes a protection from oxygen. A large amount of oxygen forms corrosion on heating devices.

The fiberglass reinforcing layer is made up of three layers, the middle layer being fiberglass. It is welded with adjacent polypropylene layers.

This is how the most durable product is formed, endowed with a low linear expansion index.

Attention! Fiberglass, as a reinforcing material, has more advantages, it is monolithic and does not delaminate, unlike aluminum reinforcement.All products made of polypropylene: reinforced and non-reinforced, are flexible, as they have a high elasticity index

All products made of polypropylene: reinforced and unreinforced, are flexible, as they have a high elasticity index.

The property makes the assembly of pipelines a simple process, reduces the cost of installation time, because before laying it is not necessary to strip the reinforcing layer of aluminum.

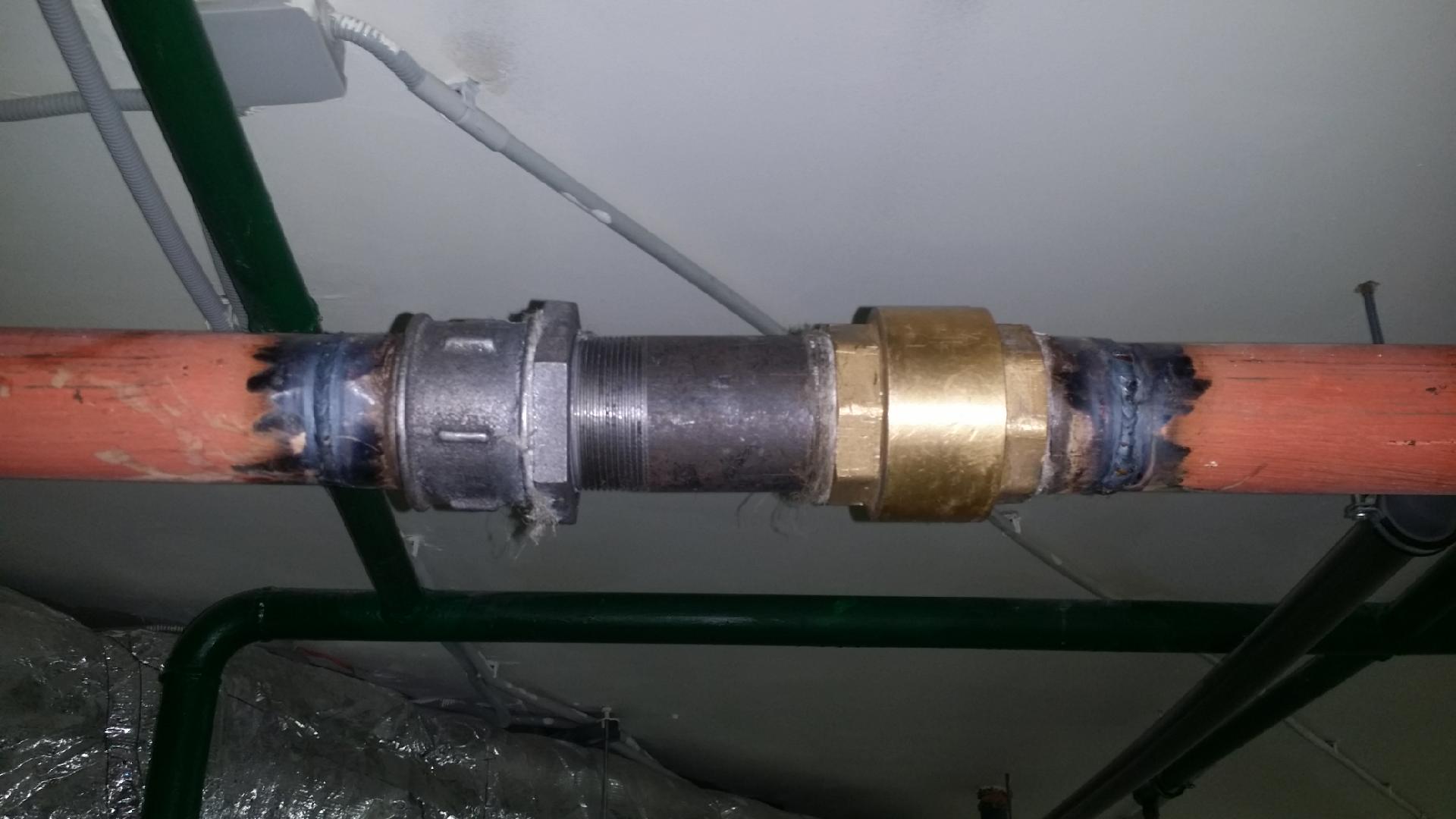

Connection of profile pipes without welding

Docking profile pipes can be performed without the use of welding equipment. How to connect profile pipes without welding:

- use of the crab system;

- fitting joint.

The crab system for pipes consists of docking brackets and fixing elements. The connection in this case is carried out with the help of nuts and bolts and in the final form form an “X”, “G” or “T”-shaped profile structure. With such a connection, from 1 to 4 pipes can be joined, but only at a right angle. In terms of strength, they are not inferior to welded seams.

Fitting docking is used when it is necessary to branch from the main pipe. There are several types of pipe connectors that allow you to mount blanks in various configurations. The main ones are:

- clutch;

- corner;

- tee;

- cross.

Crab systems are most often used in the installation of simple street structures, such as a greenhouse or a canopy.

Heating system calculation example

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

The diameter of the pipe for heating with forced circulation is determined in the following sequence:

the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also focus on tabular data;

The value of heat output depending on the temperature difference and pump power

given the speed of water movement, the optimal D is determined.

Thermal power calculation

A standard room with dimensions of 4.8x5.0x3.0m will serve as an example. Heating circuit with forced circulation, it is necessary to calculate the diameters of the heating pipes for wiring around the apartment. The basic calculation formula looks like this:

The following notation is used in the formula:

- V is the volume of the room. In the example, it is 3.8 ∙ 4.0 ∙ 3.0 = 45.6 m 3;

- Δt is the difference between the temperature outside and inside. In the example, 53ᵒС is accepted;

Minimum monthly temperatures for some cities

K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (efficient thermal insulation is used, the floor and roof are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). The example uses an intermediate option - the apartment has standard thermal insulation (K = 1.0 - 1.9), accepted K = 1.1.

The total thermal power should be 45.6 ∙ 53 ∙ 1.1 / 860 = 3.09 kW.

You can use tabular data.

Heat flow table

Diameter definition

The diameter of the heating pipes is determined by the formula

Where designations are used:

- Δt is the temperature difference of the coolant in the supply and discharge pipelines.Given that water is supplied at a temperature of about 90-95ᵒС, and it has time to cool down to 65-70ᵒС, the temperature difference can be taken equal to 20ᵒС;

- v is the speed of water movement. It is undesirable that it exceeds the value of 1.5 m/s, and the minimum allowable threshold is 0.25 m/s. It is recommended to stop at an intermediate speed value of 0.8 - 1.3 m / s.

Note! Incorrect choice of pipe diameter for heating can lead to a drop in speed below the minimum threshold, which in turn will cause the formation of air pockets. As a result, the efficiency of work will become zero.

The value of Din in the example will be √354∙(0.86∙3.09/20)/1.3 = 36.18 mm

If you pay attention to the standard dimensions, for example, of a PP pipeline, it is clear that there is simply no such Din. In this case, simply select the nearest diameter of the propylene pipes for heating

In this example, you can choose PN25 with an ID of 33.2 mm, this will lead to a slight increase in the speed of the coolant, but it will still remain within acceptable limits.

Features of heating systems with natural circulation

Their main difference is that they do not use a circulation pump to create pressure. The liquid moves by gravity, after heating it is forced upward, then passes through the radiators, cools down and returns to the boiler.

The diagram shows the principle of circulation pressure.

Compared to systems with forced circulation, the diameter of pipes for heating with natural circulation must be larger. The calculation basis in this case is that the circulation pressure exceeds friction losses and local resistances.

Example of natural circulation wiring

In order not to calculate the value of the circulation pressure each time, there are special tables compiled for different temperature differences. For example, if the length of the pipeline from the boiler to the radiator is 4.0 m, and the temperature difference is 20ᵒС (70ᵒС in the outlet and 90ᵒС in the supply), then the circulation pressure will be 488 Pa. Based on this, the coolant velocity is selected by changing D.

When performing calculations with your own hands, a verification calculation is also required. That is, the calculations are carried out in the reverse order, the purpose of the check is to establish whether the friction losses and local resistance circulation pressure.

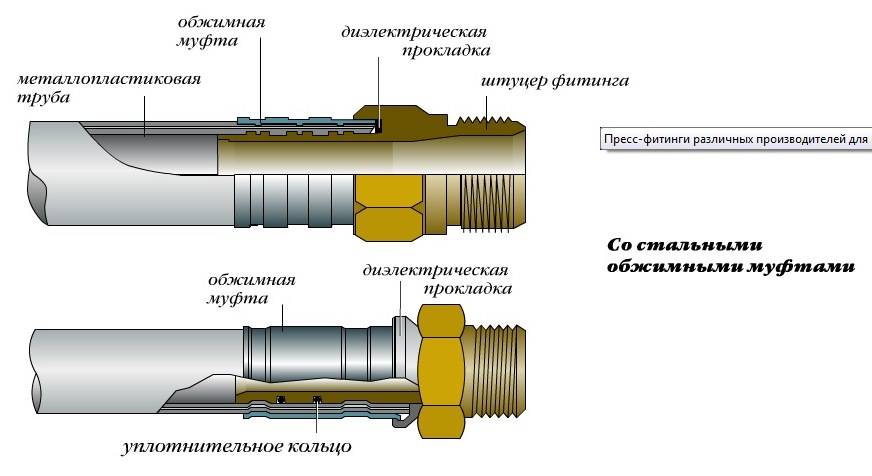

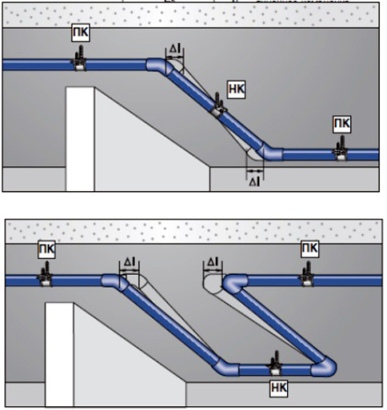

Installation taking into account the linear expansion index

When installing a pipeline for hot water supply and heating (including the "warm floor" system), it is necessary to take into account the elongation of the pipe as a result of exposure to high temperatures.

The optimal choice of products for the installation of the pipeline is reinforced pipes with a fiberglass or aluminum inner layer. Reinforcement - a layer of foil or fiberglass - absorbs part of the thermal energy from the coolant and reduces the coefficient of thermal expansion of the polymer. Due to this, the need to compensate for physical changes will also be reduced.

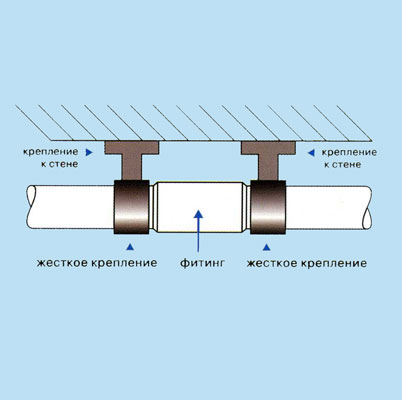

Rules for installing pipes, taking into account linear expansion:

a small gap must be left between the pipeline and the wall in the room, because

pipes can deviate from their axis when heated and go in waves;

it is especially important to leave small gaps in the corners of the premises where pipes are connected by swivel couplings or flanges;

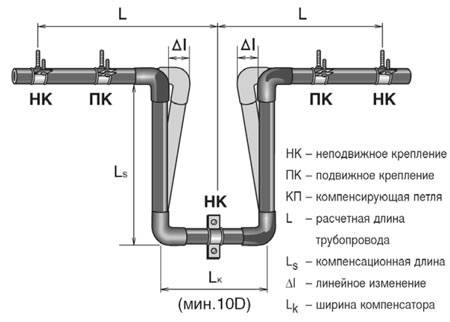

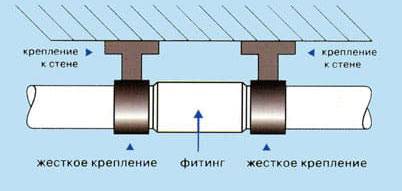

on long sections of the pipeline, special expansion joints are installed, which simultaneously fix the pipeline in its plane, but allow it to move in the direction of installation;

it is desirable to reduce the number of rigid joints in order to provide flexibility to the pipeline. In some hot water and heating systems based on reinforced and non-reinforced products, you can see various methods of so-called

self-compensation of thermal expansion due to elastic deformation of polypropylene

In some hot water and heating systems based on reinforced and non-reinforced products, you can see various methods of the so-called. self-compensation of thermal expansion due to elastic deformation of polypropylene.

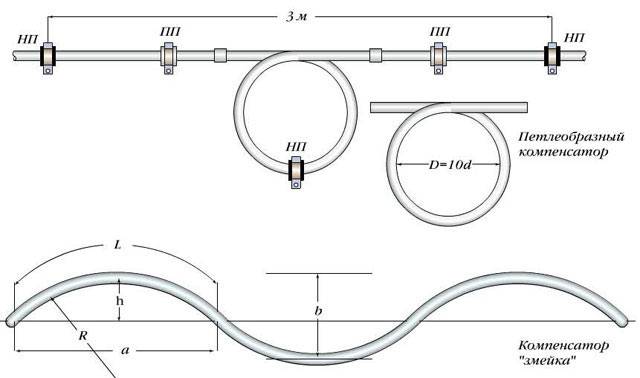

Most often, loop-shaped compensating sections are used - ring turns with movable fixation on the wall. The loop obtained as a result of such an installation shrinks and expands when the coolant is heated / cooled, without affecting the position and geometry of the pipeline in other sections.

Pipe expansion joints

In addition to self-compensation, it is possible to prevent pipe deformation as a result of thermal expansion with the help of additional devices - mechanical compensators. They are installed on the L- and U-shaped sections of pipelines and are sliding supports through which the pipe passes.

Special expansion compensators are divided into several types:

- Axial (bellows) - devices in the form of two flanges, between which there is a spring that compensates for the compression and expansion of the pipeline section. Attached to a support.

- Shear - used to compensate for the axial deviation of the pipeline section during thermal expansion.

- Swivel - are installed on the sections of the turn of the highway to reduce deformation.

- Universal - combine expansions in all directions, compensating for rotation, shear and compression of the pipe.

Kozlov compensator

There is also a new type of device, named after its developer - the Kozlov compensator. This is a more compact device that looks like a section of a polypropylene pipeline.

Inside the compensator there is a spring that absorbs the expansion energy of the pipes within the site, shrinking when the water is heated and expanding when it cools. The advantage of the Kozlov compensator over other types of devices is easier and simpler installation, as well as a reduction in reinforcement consumption.

Unlike the loop-shaped section, when installing the Kozlov compensator, it is enough to connect the pipe section in a flanged or welded way.

The linear expansion of polypropylene pipes occurs as a result of exposure to different temperatures, as a result of which a more or less obvious change in dimensions occurs. In practice, it can manifest itself both in an increase in size in the case of an increase in temperature, and in a decrease in the case of a decrease in temperature.

Since polymeric materials have an increased coefficient of linear elongation compared to metals, when designing heating systems, cold and hot water supply, they calculate elongations or shortenings of pipelines when temperature drops occur.

Conclusion

Working with polypropylene pipes is not particularly difficult.Previously, any installation of the heating system has a ready-made scheme and thermal calculations. With the help of the drawn up scheme, you will be able not only to calculate the required number of pipes for your heating circuit, but also to correctly place the heating devices in the house.

The use of polypropylene pipes at home allows you to reinstall the radiator at any time. The presence of appropriate shut-off valves will ensure that you turn the radiators on and off at any time. However, during the installation process, certain rules and instructions should be followed.

- avoid using a combination of individual pipe fragments made of different materials during installation.

- Excessively long piping without the proper number of fasteners can sag over time. This applies to small heated objects, where there is a powerful autonomous boiler, respectively, the water in the pipeline has a high temperature.

When installing, try not to overheat the pipe, fittings and couplings. Overheating leads to poor soldering quality. Molten polypropylene boils, obscuring the internal passage of the pipe.

The main condition for the durability and quality of the pipeline of the heating system is the strength of the connections and the correct piping. Feel free to install taps and valves in front of each radiator. By installing an automation system and adjusting the heating mode, with the help of taps you can mechanically turn on and off the heating in the room.

Oleg Borisenko (Site Expert).

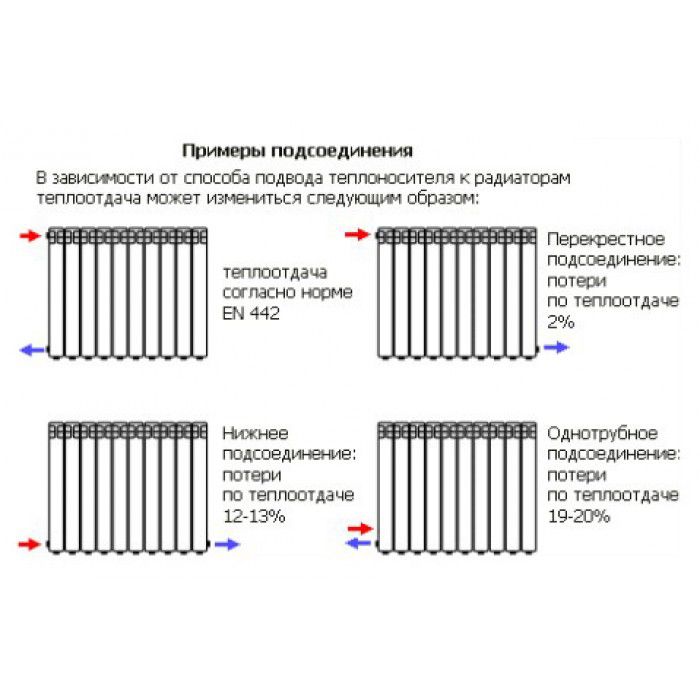

Indeed, the configuration of the room may require a combined connection of radiators.If the design of the radiator allows, then several radiators can be mounted in one circuit by connecting them in different ways - side, diagonal, bottom. Modern threaded fittings, as a rule, are high-quality products with consistent thread parameters. However, to ensure the tightness of threaded connections, various seals are used that differ in characteristics. The sealing material must be selected depending on the design features of the heating system and its location (concealed, open), since sealants can be designed to adjust (tighten) threaded joints, or they can be a one-time use that does not allow deformation after curing. Select a sealant for sealing threaded connections will help the material of this

- Do-it-yourself project and calculation of a brick fireplace

- How to lay and insulate heating pipes in the ground?

- Why do you need a plinth for heating pipes?

- Choosing ribbed registers, radiators and heating pipes

- How to hide a heating pipe?