- Operating principle

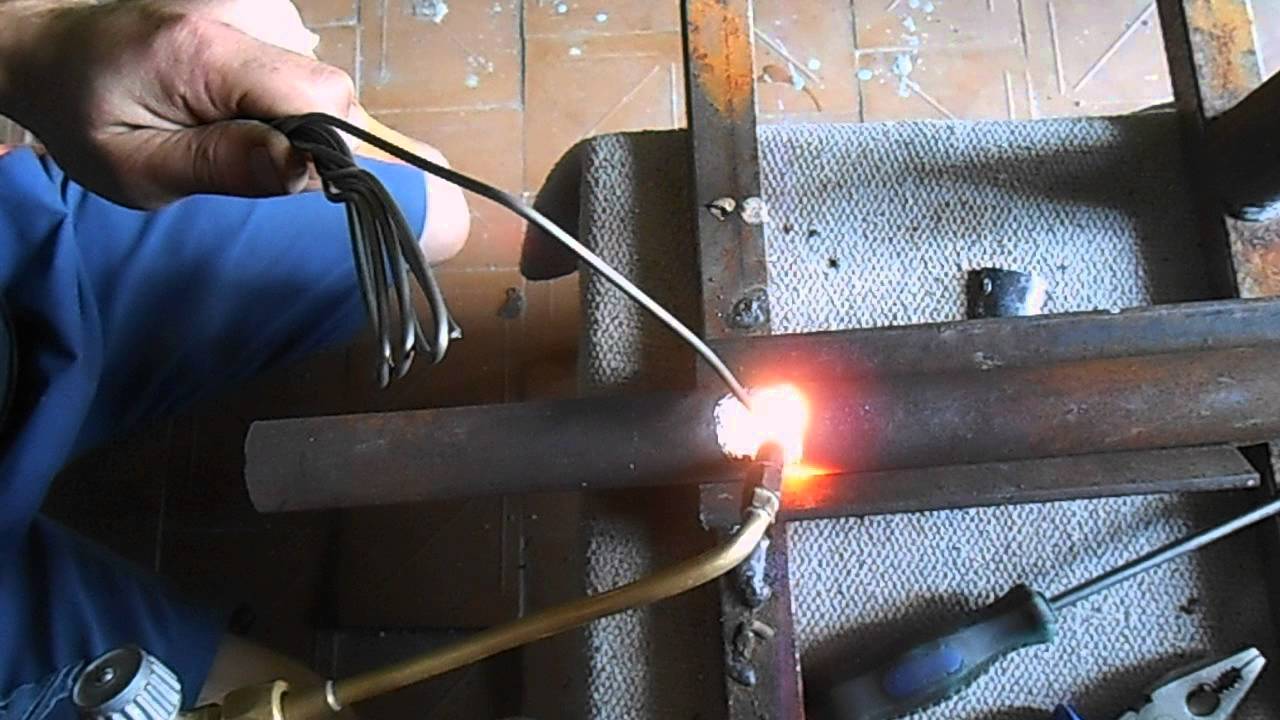

- How to weld a seam

- Welding vertical seams

- How to weld a horizontal seam

- Ceiling seam

- Information about the acetylene welding method

- The complexity of gas welding

- Technology Description

- Advantages of this method

- Disadvantages of using acetylene

- What metals are suitable for

- What does a beginner welder need to work

- Tools and means of protection

- Preparation for work

- protective equipment

- Tools and equipment

- Metal preparation

- Important Features

- Preparation of material for welding

- Pipe preparation for welding

- Part preparation

- Features of gas welding

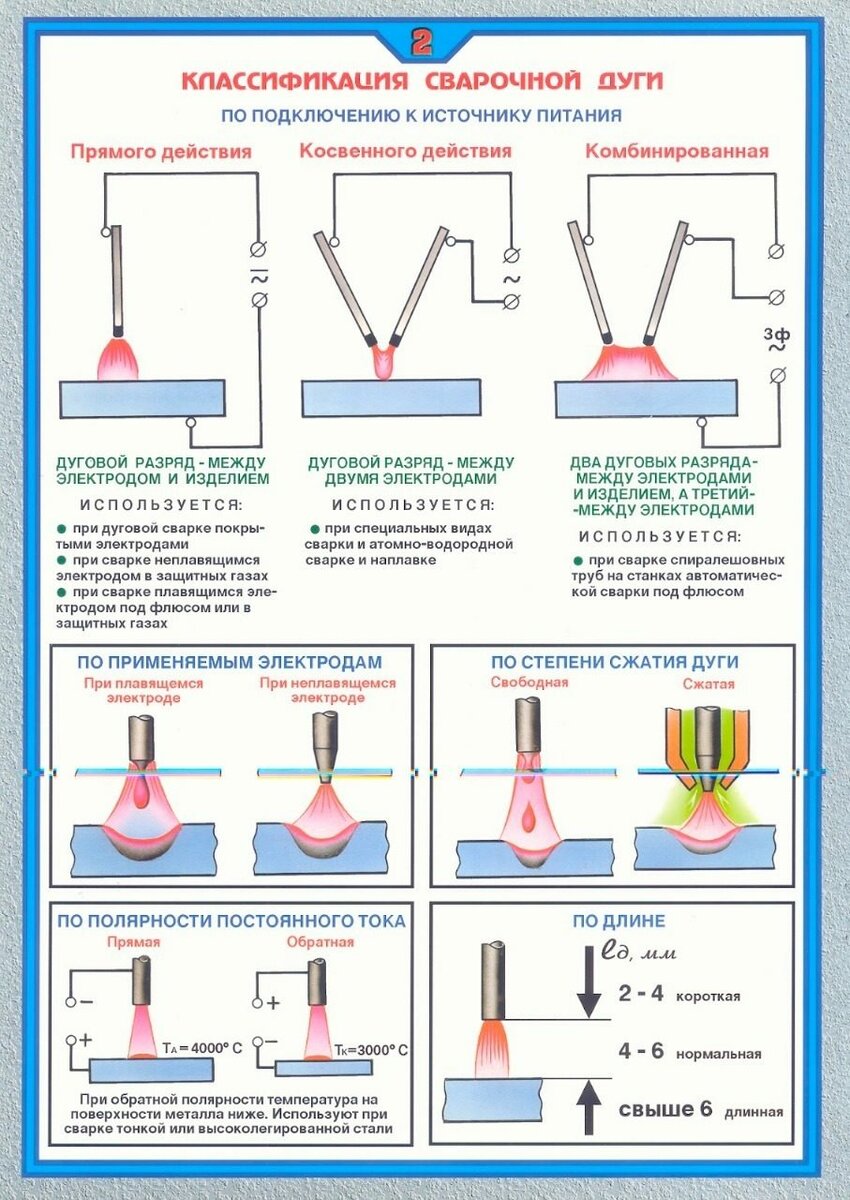

Operating principle

The main effect of gas welding is based, as already mentioned, on the combustion of combustible gas with the formation of a high-temperature flame. The acetylene molecule, along with a pair of hydrogen bonds, has an unstable but energetically powerful bond between carbon atoms.

If the balance is shifted in favor of the oxidizing agent, the flame will sharpen, and instead of dazzling white, it will acquire a bluish color.

Oxidizing flame is used only for working with brass parts. In this variant, films are formed on the surface that block the subsequent evaporation of zinc. If, on the contrary, the concentration of acetylene is increased, the flame turns red and begins to smoke. This mode is optimal for working with high-carbon steels.It is also used to process aluminum alloys, cast iron, and to weld strong metals.

In factory cylinders, this gas is mixed with acetone and is under pressure from 1.5 to 1.6 MPa. Additionally, charcoal is placed in the container, forming a kind of capillaries. Bottled oxygen is under pressure from 600 to 1500 kPa, and pipeline oxygen is up to 15 MPa.

From a consumer point of view, an important role is played by gas consumption, which directly affects the efficiency of welding. It depends primarily on the type of tip and the thickness of the metal to be welded. The benchmarks are:

- when connecting parts no thicker than 1 mm, 75 liters of gas will be spent in 60 minutes;

- if the thickness is from 2 to 4 mm, you will have to spend 300 liters of acetylene;

- metal from 9 to 14 mm can be welded if you spend 1200 liters of oxidizer.

During operation, it is required to continuously monitor the content of acetylene in the air. This means that special automatic signaling devices cannot be dispensed with. Saturation over 0.46% is not allowed. Cylinders with fuel should not be placed near stoves, boilers, sources of open flame. The containers themselves must stand strictly vertically and in a fixed state.

In the area where acetylene and oxygen are stored and used, only non-sparking tools should be used. All electrical appliances, including lighting, must have an explosion-proof solution. In the event of leaks, the cylinder is quickly locked with a special key. Fire extinguishers and other fire-fighting equipment should be available at the work site.

How to weld a seam

When welding in the lower position, no difficulties arise even for a novice welder. But all other provisions require knowledge of technology.Each position has its own recommendations. The technique for making welds of each type is discussed below.

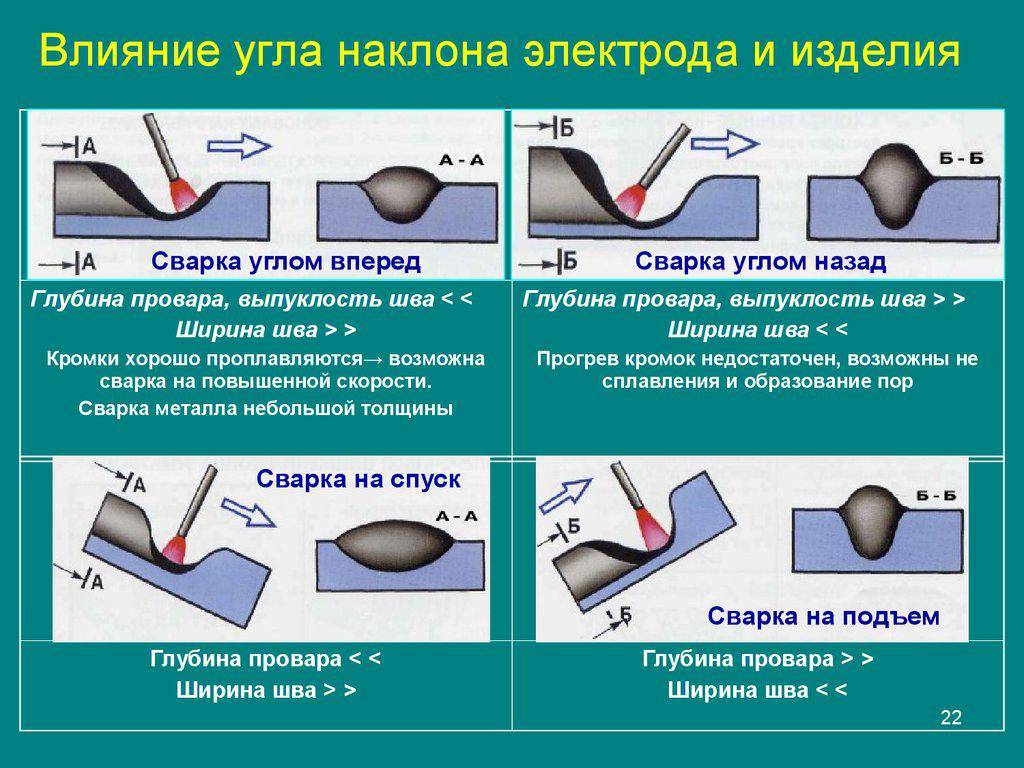

Welding vertical seams

During welding of parts in a vertical position, the molten metal slides down under the action of gravity. To prevent droplets from coming off, a shorter arc is used (the tip of the electrode is closer to the weld pool). Some craftsmen, if the electrodes allow (do not stick), generally lean them on the part.

Metal preparation (grooving) is carried out in accordance with the type of joint and the thickness of the parts to be welded. Then they are fixed in a predetermined position, connected with a step of several centimeters with short transverse seams - “tacks”. These seams do not allow the parts to move.

A vertical seam can be welded from top to bottom or from bottom to top. It is more convenient to work from the bottom up: this is how the arc pushes the weld pool up, preventing it from lowering down. This makes it easier to make a quality seam.

How to weld a vertical seam from the bottom up: the position of the electrode and possible movements

This video shows how to properly weld a vertical seam by electric welding with the movement of the electrode from bottom to top without separation. The short roll technique is also demonstrated. In this case, the electrode movements occur only up and down, without horizontal displacement, the seam is almost flat.

It is possible to connect parts in a vertical position with an arc separation. For novice welders, this may be more convenient: during the tear-off time, the metal has time to cool. With this method, you can even rest the electrode on the shelf of the welded crater. It's easier. The pattern of movements is almost the same as without a break: from side to side, with loops or a “short roller” - up and down.

How to cook a vertical seam with a gap, see the next video. The same video tutorial shows the effect of current strength on the shape of the seam. In general, the current should be 5-10 A less than recommended for a given type of electrode and metal thickness. But, as shown in the video, this is not always true and is determined experimentally.

Sometimes a vertical seam is welded from top to bottom. In this case, when starting the arc, hold the electrode perpendicular to the surfaces to be welded. After ignition in this position, heat the metal, then lower the electrode and cook in this position. Welding a vertical seam from top to bottom is not very convenient, it requires good control of the weld pool, but in this way you can achieve good results.

How to weld a vertical seam with electric welding top-down: position of the electrode and movement of its tip

How to weld a horizontal seam

A horizontal seam on a vertical plane can be carried out both from right to left and from left to right. There is no difference, to whom it is more convenient, he cooks like that. As when welding a vertical seam, the bath will tend to go down. Therefore, the angle of inclination of the electrode is quite large. It is selected depending on the speed of movement and current parameters. The main thing is that the bath stays in place.

Welding horizontal seams: electrode position and movements

If the metal flows down, increase the speed of movement, warming up the metal less. Another way is to make arc breaks. During these short intervals, the metal cools down a little and does not drain. You can also reduce the current a little. Only all these measures are applied in stages, and not all at once.

The video below shows how to properly weld metal in a horizontal position. The second part of the video about vertical seams.

Ceiling seam

This type of welded joint is the most difficult. Requires high skill and good control of the weld pool. To perform this seam, the electrode is held at right angles to the ceiling. The arc is short, the speed of movement is constant. Perform mainly circular movements that expand the seam.

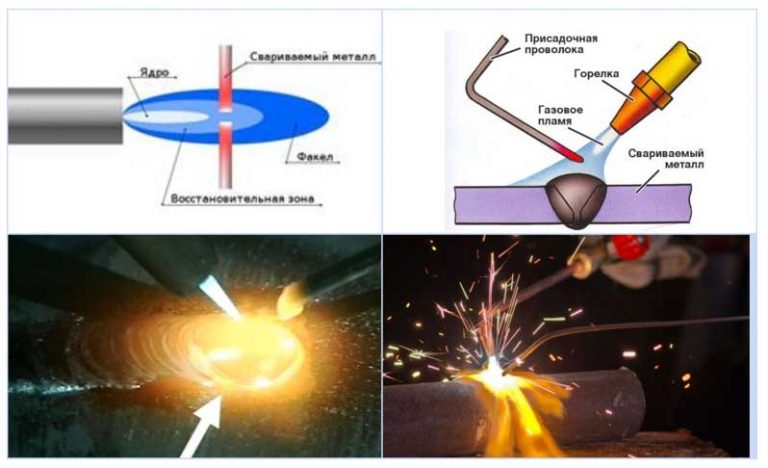

Information about the acetylene welding method

The main component in this type of welding is acetylene. It is obtained artificially by mixing water and calcium carbide. In the burner, its mixture with oxygen is formed, the combustion of which allows you to create a high temperature.

As a result of the combustion of acetylene in an oxygen environment, a high temperature is created, which makes it possible to melt the edges of the parts and firmly connect them to each other.

The complexity of gas welding

The main difficulty in welding with acetylene and oxygen is to get C2H2. Previously, this was done in a special apparatus, then the gas was supplied through hoses to the burner.

Oxygen from a cylinder was supplied to it, they mixed, and a flame formed. Calcium carbide and water were poured into the generator manually. This time-consuming process was carried out before each welding. After completing the work, the water was drained and the remaining carbide was reused.

Now it is much easier to carry out acetylene welding. It is no longer necessary to manually mix water with carbide: there are special cylinders and acetylene, they only need to be connected to the burner.

Technology Description

For welding, the acetylene supply is first opened on the burner. The fact that it comes out is indicated by an unpleasant odor. Then the gas is ignited and oxygen is slowly supplied from the cylinder.

The flame should turn blue. On tanks with oxygen and acetylene there are reducers. For the first gas, the pressure is set to 2 atm., And for the second - 2-4 atm. Larger values complicate the welding process.

In the process of gas welding, under the influence of high temperature, the edges of the workpieces to be joined pass into a liquid state, and after they solidify, a strong connection is obtained. Cylinders with oxygen are painted blue, and with acetylene - white.

Cylinders with oxygen and acetylene.

Advantages of this method

When such a gas burns in an oxygen environment, a temperature exceeding the degree of melting of steel and other metals is reached. A qualified welder with the help of such equipment performs work efficiently and with high efficiency.

In addition, acetylene welding has such advantages as:

- high mobility (no electricity connection required);

- the ability to adjust the temperature of the flame (this allows you to prevent deformation of parts and joints, control the speed of work);

- convenient execution of a rotary seam when the distance to the wall is small (in other types of welding, you have to make an operational joint);

- the ability to connect workpieces made of metals with different melting points;

- the ability to weld thin-sheet products from structural steel, copper, cast iron, brass (in such cases, other welding methods are ineffective);

- the use of different filler wires, which helps to improve the quality of the seam.

Disadvantages of using acetylene

Among the disadvantages of this method of welding, the following should be noted:

- The explosiveness of acetylene is high, but much depends on the person.

- During operation, a large area of the connected products is heated, which leads to a change in the properties of the material. In mechanical engineering, this method is not used.

- If you need to connect parts with a thickness of more than 5 mm, then it is better to use electric welding.

- Acetylene is not suitable for working with high carbon steel.

- If you overlap, then large stresses are formed in the products, and they are deformed.

- For materials and equipment, costs increase, in contrast to arc welding.

- Only an experienced welder can perform work.

Only an experienced specialist can handle acetylene welding.

What metals are suitable for

This type of welding is suitable for most ferrous and non-ferrous metals. It is practically indispensable when connecting thin-walled pipes and similar parts, when working with copper, cast iron, structural steel blanks.

What does a beginner welder need to work

First of all, you need to prepare equipment and overalls.

Tools and means of protection

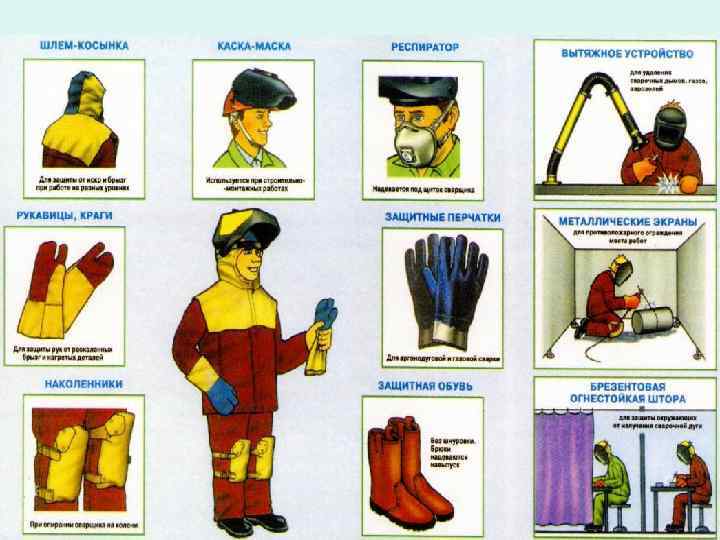

You will definitely need a welding machine, a set of electrodes, a hammer and a chisel for churning slag, a metal brush for cleaning the seams. The electric holder is used to clamp, hold the electrode and supply current to it. You also need a set of templates to check the dimensions of the seam. The electrode diameter is selected depending on the thickness of the metal sheet. Don't forget about protection. We are preparing a welding mask with a special light filter that does not transmit infrared rays and protects the eyes. Screens and shields perform the same function.A canvas suit consisting of a long-sleeved jacket and smooth trousers without lapels, leather or felted shoes to protect against metal splashes and gloves or mittens, canvas or suede with an overlap on the sleeves. Such tight, closed clothing prevents the welder from getting molten metal on the body.

There are special protective equipment that are used to work at heights and inside metal objects, when working in a prone position. In such cases, you will need dielectric boots, a helmet, gloves, a rug, knee pads, armrests, and for high-altitude welding you need a safety belt with straps.

Preparation for work

Before starting work, it is necessary to clean the gas welding station from all foreign objects, and also reliably protect flammable surfaces.

protective equipment

To protect against the negative effects of high temperatures, the gas welder must use:

- special glasses;

- leggings;

- fire resistant clothing and footwear.

Protective equipment.

Tools and equipment

To perform the work you will need the following tools:

- pliers;

- open-end wrenches;

- measuring instruments;

- metal brush;

- filler wire;

- lighter for burner;

- fire extinguisher.

In addition, you need to prepare such equipment:

- a hose for supplying acetylene and a cylinder with this gas;

- acetylene and oxygen reducers;

- a sleeve for supplying oxygen and a cylinder with it;

- gas burner with mouthpiece.

Metal preparation

At this stage, dirt, rust, and existing traces of preservation are removed from the products at the points of their connection.To do this, use a brush for metal.

Metal cleaning before welding.

Important Features

The quality and reliability of the seams obtained as a result of the use of oxygen-acetylene welding largely depend on compliance with the technology of work.

There are three main factors that affect the performance of a connection:

- flame power;

- filler material diameter;

- welding angle.

The main features of oxy-acetylene welding:

- flame power is selected depending on the characteristics of the material from which the welded products are made;

- the thicker the products to be welded, the greater the flame power should be (with thin parts they do the opposite), but with an increase in power, the gas consumption also increases;

- the thickness of the connected products affects the angle of the burner (the thicker they are, the greater the angle), for most parts it is 10-80 °;

- to warm up parts, regardless of their thickness, the burner is directed at an angle of 90 °;

- the diameter of the filler wire depends on the thickness of the connected elements (to calculate it, the thickness of the part in millimeters is divided in half and 1 mm is added);

- the burner is moved away from or towards itself.

Choose the right filler wire for acetylene welding.

Preparation of material for welding

Parts cleaned of dirt and rust must be properly prepared for welding. This will help to facilitate and speed up the process of their connection, as well as to get a better seam.

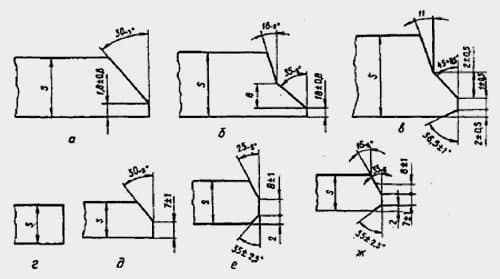

Product preparation includes the following steps:

- Editing - correction of deformations that could occur during the transportation and delivery of products.

- Markup. It is carried out with the help of manual measuring instruments or with the use of marking and marking machines.

- Flexibility if needed.

- Cutting and cleaning edges. The parts to be joined must be aligned. You can cut them cold (using machine tools or manual interventions), thermal (using burners).

- Construction assembly. All elements are laid out so that they take their spatial position and the necessary gap is formed between them. For this, stands, conductors, clamping devices, etc. are used.

Pipe preparation for welding

The welding process begins with preparation. First of all, you need to choose the electrodes with which the pipes will be welded. There are two selection criteria here: the material from which the metal rod is made, and the coating - the material that covers the rod.

For welding metal pipes, consumable and non-consumable electrodes are used. In the first, the rod melts, in the second, it doesn't. In the second case, an additional material is used - an additive, which fills the welding seam. Practice shows that welding of pipes with consumable electrodes is used more often in domestic conditions today. Simply because this way is easier.

Now, as for the coating of the electrodes. Here are several positions where various materials for the formation of a protective surfaces.

- Rutile.

- Acid.

- Rutile acid.

- Cellulosic.

- Rutile-cellulose.

- Basic.

Each position has its pros and cons, therefore, when choosing, it is necessary to take into account the conditions for welding pipelines. But among them there is a universal option - these are electrodes with a basic coating. This category includes such brands of electrodes as UONI, OZS, VI, EA, NIAT, OZSh and others less known. Beginning welders are recommended to weld pipes with UONI electrodes.

Before you weld two pipes, you need to understand that there are several types of welded joints.

- End-to-end, when two pipes are located opposite each other.

- Overlapping, this is how two pipes of different diameters, or the same diameter, are usually connected, only one of the pipes is expanded, that is, its diameter is mechanically increased.

- Tee connection, when two pipelines are joined in perpendicular planes.

- Corner joint, when the joint is made at an angle of less than 90 °.

By the way, option number one seems very simple. But therein lies the complexity of the process itself. Firstly, it is better to weld such a seam in the lower position, this is when the electrode is fed into the butt joint from above. Secondly, it is necessary to boil the metal in the entire thickness of the wall.

And some more helpful tips.

- For butt welding of pipelines and tees, it is best to use electrodes with a diameter of 2-3 mm.

- The welding mode, that is, the value of the set current should be in the range of 80-100 amperes. When welding with an overlap, the current strength must be increased to 120 A.

- The filling of the weld should be such that the metal rises 2-3 mm above the pipe plane.

- Welding of shaped pipes (square) is done pointwise. That is, first a small section is welded on one side, then on the opposite side, then on the adjacent one and then on the opposite adjacent one. After that, a complete welding of the joints is carried out. The goal is to prevent the pipe from warping as it heats up.

Before welding pipes by electric welding, they must be prepared. This is mainly for the edges. Here is the sequence on how to do it.

- The geometric dimensions are checked for compliance with the installation of pipelines. Pipes with different wall thicknesses can be joined, which can lead to a thick pipe not being pierced or a thin pipe being burned through.

- The cross section of the pipeline should be round, not oval or otherwise. This will simply ensure the quality of the welded joint and simplify the process itself.

- The walls of the pipes must be free of defects: cracks, creases, expansions, and so on.

- The edge cut must be straight (90°).

- The edges are protected to a metallic sheen (using a brush, sandpaper). The length of the cleaned area is not less than 1 cm from the edge.

- Remove oil and grease stains, paint, be sure to degrease the ends with any solvent.

And although the UONI electrodes are not capricious, that is, even rusty parts can be welded with their help, any metal defects affect the quality of the seam. Therefore, it is worth taking a little time to prepare the edges of the pipeline.

Part preparation

Before starting work on welding pipes, it is necessary to prepare the edges for making the connection. I always do it in this order:

- I check the pipes for compliance with the parameters specified in the design of the engineering system (water supply). The instruction requires compliance with the following parameters:

- geometric dimensions;

- certificate of conformity (especially for pipes through which drinking water is supposed to be transported);

- absence of defects in the circumference (pipes must be perfectly round, and not oval in the cut);

- absence of defects in thickness (the walls of metal pipes must be the same along the entire length of the part);

- compliance of the chemical composition of the metal with the requirements that are enshrined in GOST of Russia (this is clarified during a laboratory study or from accompanying documents).

Cleaning the end of the pipe with a grinder before welding.

- Preparing pipes for connection. To do this, I personally recommend doing the following:

- check that the cut of the pipe edge is made strictly at an angle of 90 degrees;

- clean the edge to a metallic sheen (the width of the cleaned area should be up to 10 mm from the cut);

- degrease the butt, remove all traces of oil, paint, rust, and so on.

For a correct connection, it is necessary that the opening angle of the pipe cut edges is about 65 degrees, and the blunting value is 2 mm. If this is not the case, it is necessary to perform additional machining of the end face.

For this, special bevelers, grinders and trimmers are used. Specialists designing large diameter pipelines use milling machines or special preparation methods (plasma or gas cutters).

Tools for processing the ends of pipes will help any novice craftsman in his work.

Features of gas welding

Acetylene-oxygen welding has three main parameters on which the quality of the final result depends. This is the power of the fire (flame), this is the angle at which the burner is located to the welding surface, the diameter of the filler rod used.

The power of the burner flame is selected depending on the thermophysical properties of the metal and on the thickness of the workpieces to be welded. The dependence is as follows: the thicker the parts, the higher the thermal conductivity and melting temperature of their metal, the greater the power of the burner flame should be.The latter is determined by the flow rate of the gas mixture. The higher the flow, the higher the power. For each type of metal, its own power indicator is selected. There are formulas by which it is determined. The main dependence is the thickness of the workpieces to be welded.

- For ferrous metals (steel and cast iron), the power is in the range (100-150) n, where n is the thickness of the part.

- For non-ferrous metals, for example, for copper, the range is (150-200) n.

The power of the flame, as well as the consumption of gases, has a unit of measurement - l / h.

As for the angle of inclination of the burner, it also changes depending on the thickness of the products to be joined. For example, if the thickness varies in the range from 1 to 15 mm, then the angle of inclination will vary from 10 to 80 °. And the thicker the metal, the greater the angle of inclination. But at the very beginning of welding, it is necessary to maintain the maximum angle of inclination, even up to 90 °, because at this value the parts to be joined will heat up faster, plus the weld pool will form faster.

The diameter of the filler rod is also selected depending on the thickness of the workpieces. The definition formula is simple: half the thickness plus one millimeter. For example, if parts with a thickness of 4 mm are welded together, then an additive with a diameter of 3 mm is required to connect them.