- How to punch punch

- Step-by-step instructions for drilling a well at the site

- Manual well drilling

- rotary method

- screw method

- What sources underground

- Verkhovodka

- Primer

- Sources between layers

- Artesian

- Drilling work: stages

- Needle hole drilling

- DIY drilling methods

- Rope drilling technology

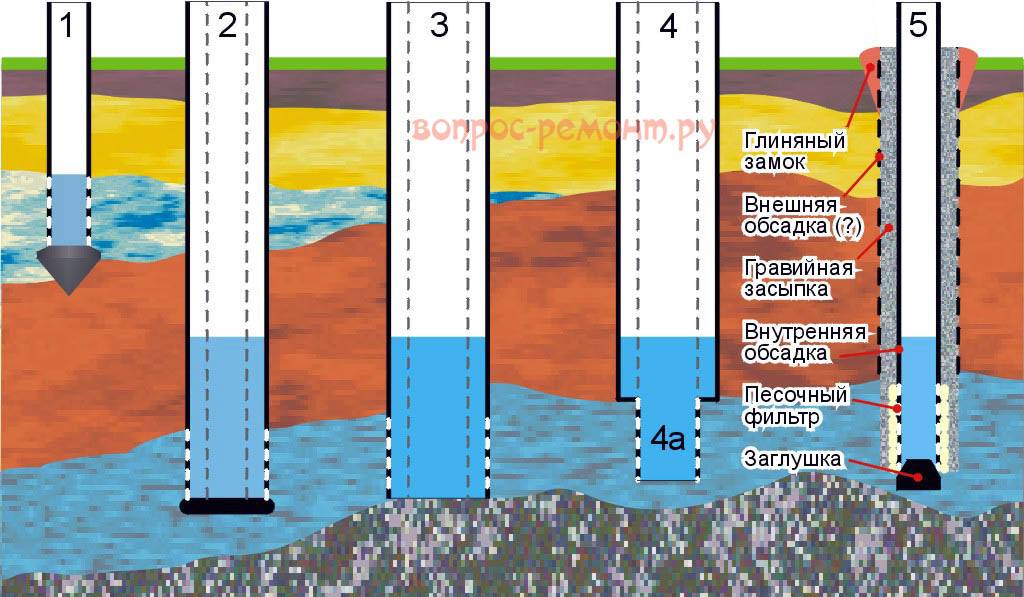

- 8 Casing and water filtration - the right choice

How to punch punch

This is the most inexpensive technology, but rather laborious. For work you will need the following devices:

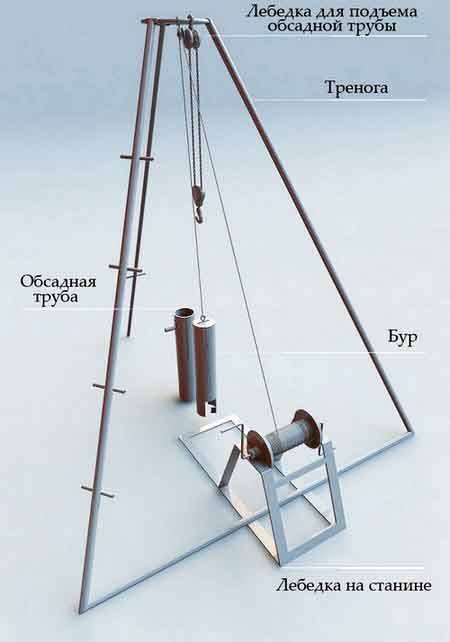

- a tripod made of rolled metal with a hook and a block on top;

- winch with a cable, equipped with a handle;

- driving tool - a glass and a bailer;

- welding machine;

- manual drill.

Ground punching cup

Before drilling the soil to the required depth, prepare casing pipes. Their diameter should be such that the working tool passes freely inside, but with a minimum clearance, and the length should correspond to the height of the tripod. One condition: impact technology is not applicable on rocks or in soils with stone inclusions. To penetrate such horizons, you will need a carbide-tipped drill.

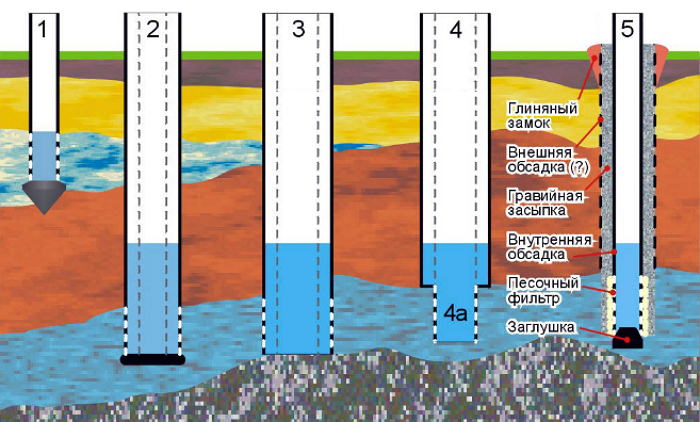

Independent drilling of a well for water is carried out in the following order:

From the first section of the casing, make a filter by drilling Ø8-10 mm holes in a checkerboard pattern with a step of 7-8 cm on a pipe section 1 meter long.From above, close the holes with a stainless steel mesh fixed with rivets.

Make a leader hole with a hand drill to a depth of 0.5-1 m

Here it is important to correctly set the tool at an angle of 90 ° to the surface so that the channel turns out to be strictly vertical.

Insert the first section of casing into the hole, correct the vertical and insert the impact tool inside.

Leaving a helper to maintain the casing, raise and lower the glass using the spool. When filling, take it out and clean out the rock

As the soil is removed, the pipe will take its place and gradually sink into the ground. To speed up the process, attach a couple of heavy weights to it.

When the edge of the first section drops to the ground, weld the second section to it, strictly controlling the vertical level. Continue in the same way until you reach the water layer.

Welding the next section in level

When the end of the pipe drops 40-50 cm below the groundwater level, stop punching the channel and proceed to "rocking" the source. To do this, lower the pipe connected to the surface pump to the bottom of the HDPE and fill the shaft with 2-3 buckets of water. Then turn on the unit and let it run for 2 hours, controlling the cleanliness and water pressure. The last step is to equip the well and connect it to the water supply at home, as described in another instruction. For more details on the drilling process, see the video:

Step-by-step instructions for drilling a well at the site

Before starting work on the summer cottage, it is recommended to ask the neighbors what the level of water occurrence in your district is, after that you can drill well on site. If there are wells nearby, look into them.If the water level is above 5 meters, this is a good sign, since in this case drilling tools all you need is a garden drill and a rough layout of the water source.

A small-sized drilling rig or a mechanical drilling device - a handbrake - can be rented. Thus, you will have the opportunity to use convenient equipment without overpaying an extra amount to get water on the site.

Let's describe the general instructions of the site of relative technology, how to make a water well with your own hands in the country:

- In the ground, it is necessary to make a square recess with dimensions of 1.5 × 1.5 m and a depth of 1 to 2 meters, this will be the so-called pit. It is needed in order to prevent shedding of the loose soil surface into the well. From the inside, the pit must be sheathed with boards or plywood, and a boardwalk is laid on top of it for ease of installation.

- After the installation is assembled, two coaxial holes are cut out in the upper and lower floors of the pit, after which drilling begins.

- The drill rod rotates manually or with the help of a geared motor. At the same time, a bodice is put on the bar, on which one of the workers will strike with a hammer. Another option: the drill is lifted with a winch and dropped in the same way as it is done with shock-rope drilling. If necessary, water or drilling fluid is supplied to the rod.

- In parallel with drilling, a casing pipe is installed in the well with a special shoe installed from below. It is also gradually built up, like the drill rod.

- After quicksand (soil with high humidity), drilling accelerates (due to the beginning of the aquifer), and then slows down again.This is a sign that the drill has reached the water-resistant layer and drilling can be completed.

- It is necessary to lower the filter column into the well, after which it can be washed with strong water pressure.

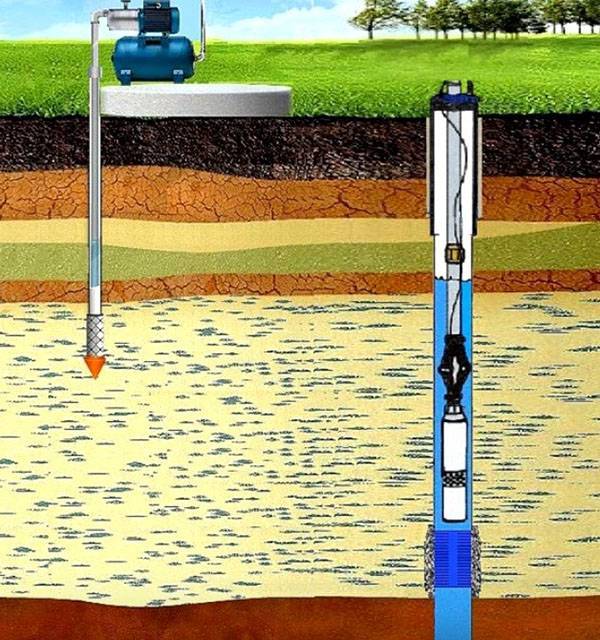

- A submersible pump must be lowered into the well to pump out water until it becomes crystal clear.

At the last stage of arranging the well in the country house with their own hands, a caisson is installed, all cavities must be filled with a sand-gravel mixture, and a pipeline is laid to the house in a trench. In this case, it is highly recommended not to lower the water pipe to the very bottom. It should not reach the extreme point of about 50 cm, so the best water flow to the top will be ensured.

The pipe that leads to the well must be provided with ventilation holes, otherwise, without air, the water will quickly dry out and it will become impractical to extract it for most needs. For permanent access to the well, a hinged cover can be equipped on the pipe.

Advice! After the well, made by hand, was put into operation, be sure to give the water obtained from it for examination. Water can be considered drinking water if it has the following characteristics: transparency of at least 30 cm, nitrate content - no more than 10 mg / l, 1 liter contains no more than 10 Escherichia coli, maximum odor and taste score - 3 points.

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well. You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes.The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydrodrilling of shallow wells on water can be carried out without a tower, and the drill string can be pulled out manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod to during the ascent facilitate removal of the rod. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes. To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew. At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult.Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears. If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used. The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm.In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump:

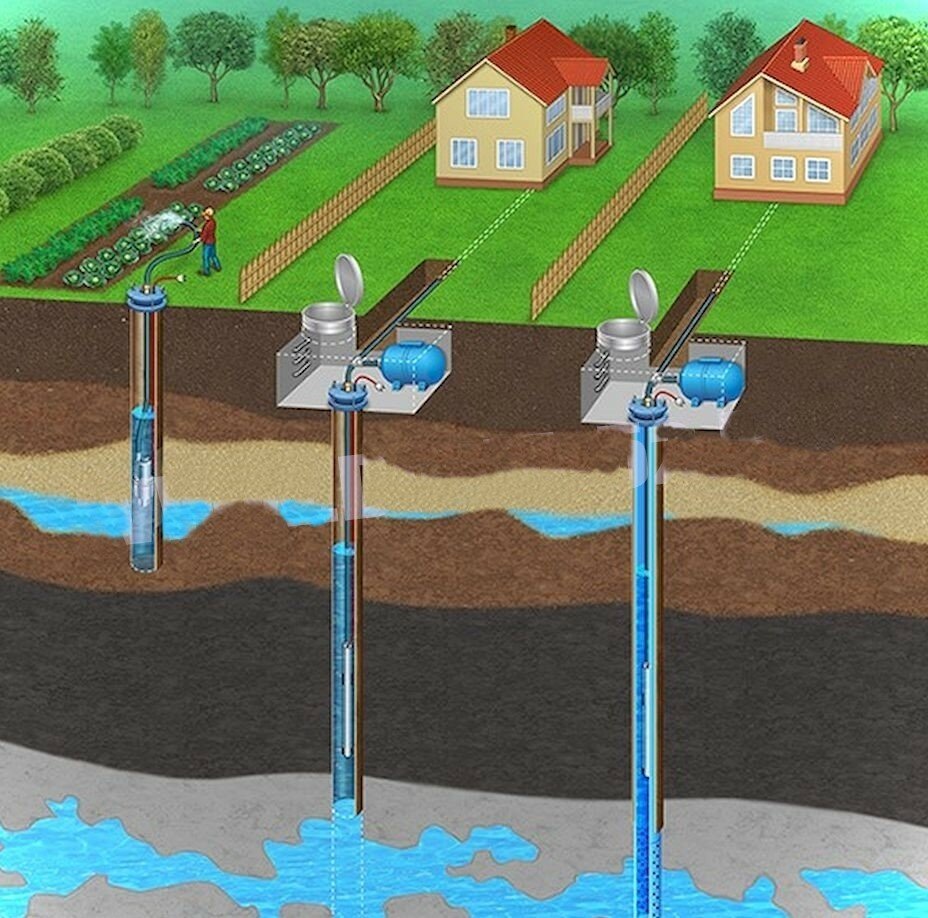

What sources underground

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch. Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth. On average 3-9 m depending on the region. For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution. Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to take water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks. Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

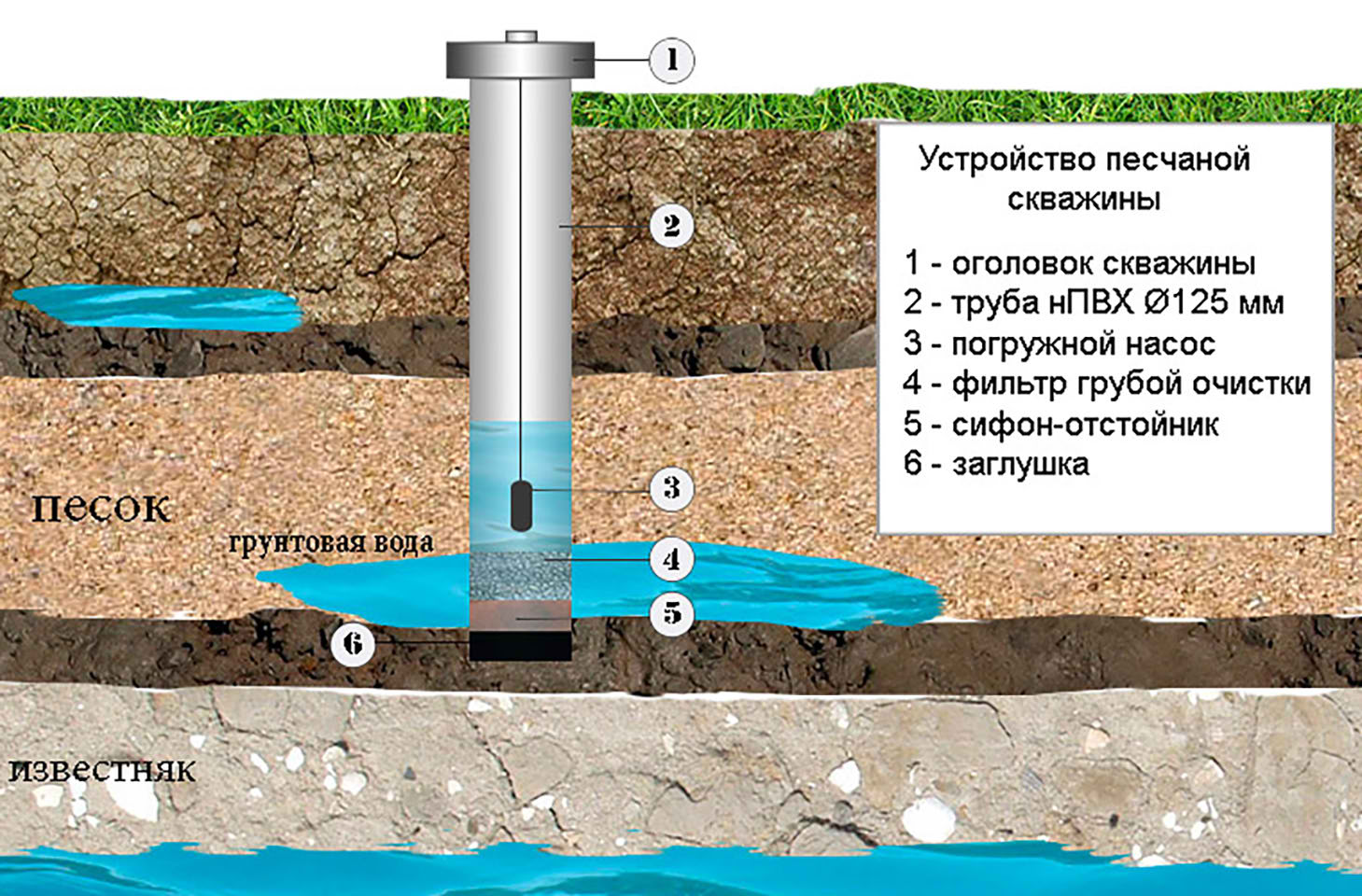

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. Depth of propagation - from 25 to 80 m. From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface. This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

Drilling work: stages

1. First you need to dig a hole or a pit, the dimensions of which are 150 by 150 cm. In order for the recess not to crumble, its walls are lined with plywood, boards, pieces of chipboard. Another option is to dig a trunk with a diameter of 15-20 cm and a depth of 1 m with an ordinary drill. This is done so that the pipe is more stable in a vertical position.

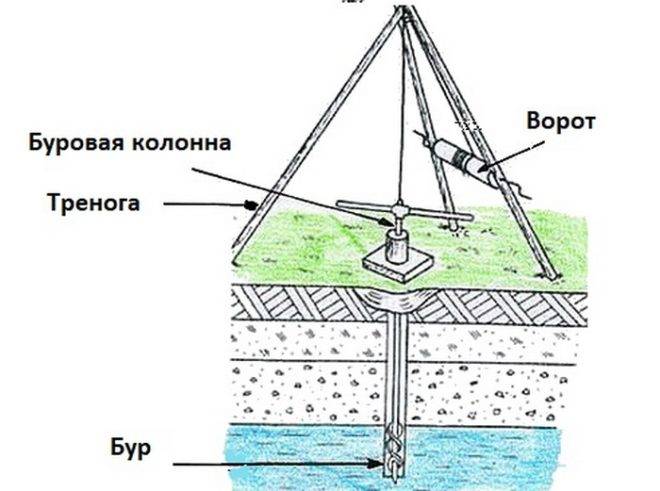

2. A strong metal or wooden tripod is placed directly above the recess (it is called a drilling rig), fixing a winch at the junction of its supports. Log towers are more common. A drill column with one and a half meter (with self-drilling) rods hangs on a tripod. The rods are threaded into one pipe, fixed with a clamp. This design is used for lifting and lowering equipment.

The pump is selected in advance in order to determine the diameter of the future well and core barrel. The pump must pass freely into the pipe. That is why the difference between the diameter of the pump and the inner diameter of the pipe must be at least 5 mm.

Descent-ascent of drilling equipment - and there is drilling a well. The bar is rotated while hitting it from above with a chisel. It is much more convenient to do this together: the first turns with a gas wrench, and the second hits the bar from above, breaking through the rock. Using a winch simplifies the process: it is much easier to lift and lower equipment into the well with it. The rod is marked during drilling. Marks are required for orientation.The markings help you determine when it's time to pull out the rod and clean the drill. It is usually recommended to do this approximately every half a meter.

3. To make it easier to overcome different layers of soil, special drills are used.

- spiral drill (otherwise, coil) - for clay soils;

- drill bit for loosening hard soils;

- drill spoons for sandy soil;

- bailer helps to raise the soil to the surface.

4. The sandy layer is easier to pass with a drill spoon, adding while drilling water. If the ground is hard, use a chisel. Drill bits are cross and flat. In any case, their purpose is to help loosen hard rocks. Quicksands are overcome by impact.

With clay soil, you will need a coil, bailer and drill spoon. Serpentine or spiral drills pass clay soils well, because they have a design similar to a spiral, and the spiral pitch is equal to the diameter of the drill. The size of the lower base of the drill is from 45 to 85 mm, the blade is from 258-290 mm. Pebble beds containing gravel are punched, alternating bailer and chisel, with casing pipes. Sometimes you can not do without pouring water into the hole. This can significantly simplify the task of drilling a well. The option of drilling a well with a pump also deserves consideration.

Soil drilling process

5

If the rock brought to the surface has become important, then the aquifer is already close. It takes a little more depth to cross the aquifer

Drilling will become noticeably easier, but you can not stop. You need to find a waterproof layer with a drill.

Needle hole drilling

For the rotational method, you will need a drill with metal blades at the bottom, arranged in a spiral. At the drilling site, a recess is made with a shovel.

To soften the soil, it is watered with water, but keep in mind that at the same time, the drill is pulled out more often, every half a meter, and cleaned of adhering earth. The penetration of dense clay, however, will require the use of a percussion-rotary method.

You will also need a metal pipe with a diameter that allows you to place a drill with blades in it. We get a pipe and a drill inside it. When the drill is rotated inside the pipe, the earth collects in the pipe and can be easily removed.

The tool used for drilling is called an auger. As you deepen into the ground, it becomes more difficult to manage, so assistance may be needed. A well or well is lined with factory concrete rings above the ground, strengthening the sediment.

DIY drilling methods

There are several ways in which you can get to the aquifer:

- auger drill - as it deepens into the earth, it is built up with new sections of a metal pipe;

- bailer - a device with sharp teeth at the end and a valve that prevents the earth from spilling back into the mine;

- using soil erosion - hydraulic method;

- "needle";

- percussion method.

Using auger drilling technology, it is possible to dig a well up to 100 meters deep. It is difficult to do this manually, therefore, stationary electrical installations are used, and the drill is built up with new sections as it deepens. Periodically it is raised to pour out the soil. To prevent the walls from crumbling, a casing pipe is laid after the drill.

If the drill cannot be built up, a bailer with sharp edges is attached to its base and the drill screws it in a few meters deeper. Next, the pipe is lifted and the accumulated soil is poured out.

The work with the auger can be done on soft ground. Rocky terrain, clay deposits and club mosses are not suitable for this method.

The bailer is a metal pipe with solid steel teeth soldered at the end. A little higher in the pipe there is a valve that blocks the exit to the ground when the device is lifted from a depth. The principle of operation is simple - the bailer is installed in the right place and manually turned, gradually deepening into the soil. The method takes more time than using electrical equipment, but it is economical.

The device needs to be periodically lifted and poured out of the earth from the pipe. The deeper the pipe goes, the harder it is to lift it. In addition, scrolling requires the use of brute force. Most often there are several people working. To make the soil easier to drill, it is washed out with water, pouring it from above into the pipe using a hose and a pump.

Percussion drilling is the oldest method still in use today. The principle is to lower the metal cup into the casing and gradually deepen the well. For drilling, you need a frame with a fixed cable. The method requires time and frequent lifting of the working pipe to pour the soil. To facilitate the work, use a hose with water to erode the soil.

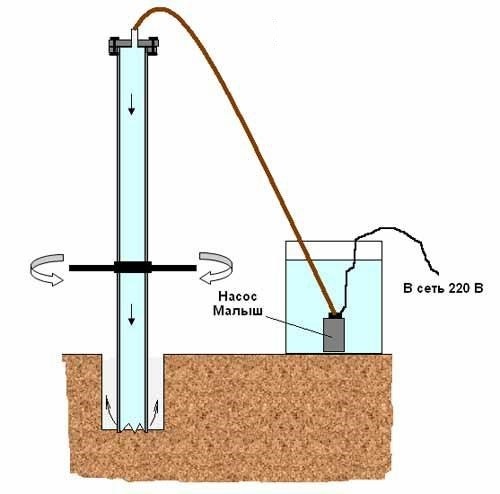

Needle method for Abyssinian well: when the pipe is lowered, the soil is compacted, so it is not thrown to the surface. To penetrate the soil, a sharp tip made of ferroalloy materials is needed. You can make such a device at home if the aquifer is shallow.

The method is cheap and time consuming.The disadvantage is that such a well will not be enough to provide a private house with water.

Rope drilling technology

Shock-rope method drilling consists of the following stages.

Stage 1. Preliminary "briefing". Before starting work, we must understand that the optimal depth of the well is 7-10 meters. You can drill no more than 20 meters on your own, if the groundwater is at a greater depth, then specialists must definitely do the drilling.

Stage 2. Align the pit (rectangular "box") in the place where the well will be located. The dimensions of the pit should be 2x1.5x1.5 m, and it is needed so that unstable upper layers of soil do not crumble. We take the boards and make the lining of the walls of the pit.

Pit

Stage 3. We mount the tripod at the drilling site. We securely fasten it, then we place the drill column in the hole and turn the rod. The drilling process has begun. Every 60-70 centimeters we clean the column from adhering earth.

Stage 4. When we reach the aquifer, the drill column should be pulled out, and the filter should be lowered instead. We will definitely use the filter, otherwise the water pump will quickly become unusable. The voids formed between the walls of the well and the filter are covered with sand. Then we install pipes through which water will rise, and dismantle the walls of the pit. We fill up the well.

Stage 5. We install a water pump, which will be the "core" of the entire well. Outwardly, it will not look very attractive, so it is advisable to decorate it with some decorative element, for example, a canopy.

Water pump

In this way, we can drill a well up to 20 meters.Water located at such a depth has repeatedly passed through natural filtration, it will be clean and soft.

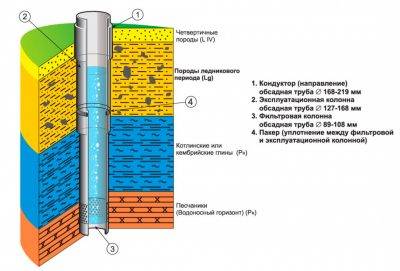

8 Casing and water filtration - the right choice

While drilling, we simultaneously install the casing pipe. It can be metal, but it is better to use plastic ones designed for casing. They are light, can be upset by the efforts of one person, withstand significant soil loads. In addition, corrosion is excluded, water does not deteriorate, the service life is 50 years. Installing the filter in a plastic casing is easier than in a metal casing - it does not slow down when lowered.

Water quality is ensured by a filter. This is the most critical node and, at the same time, the most subject to wear. His choice should be taken responsibly. For artesian wells filtering is not needed. For limestone wells, different simple perforated filters are used. They also serve as the basis for downhole filter with a sandy aquifer. From the bottom of the casing we make holes from 15 to 30 mm, depending on the soil, arranging them in a checkerboard pattern. The distance from the center of one hole to the center of another is 2.5 times greater than their diameter.

For an aquifer in sandy rock, we fill the bottom with gravel, the perforated layer begins above its level. Since gravel does not retain sand particles well, a sand filter must be installed. They are external and internal. External ones are resistant to silting of the well, but can be damaged when pipes are lowered, too expensive. Internal significantly reduce the flow of water, the well is silted with sand, which penetrates between the perforation and the filter walls.

Modern industry offers high-quality filters: