- Varieties of Zota boilers

- Electrical

- Solid fuel

- Automatic coal

- semi-automatic

- Pellet

- Description

- Types of solid fuel boilers

- Kindling types

- Operating tips

- Distinctive features of the Zota solid fuel boiler

- Installation rules

- Main Models

- Pellet boilers Zota Pellet

- Pellet boilers Zota Pellet Pro

- Universal boilers Zota Optima

- Features of the brand Zota

- Kindling preparation

- Installation and operation

- Popular Models

- Zota Smoke

- Zota Lux

- Other

- Solid fuel heaters

- The main disadvantages and advantages of the ZOTA Mix boiler

- More on this topic on our website:

Varieties of Zota boilers

Electric boilers Zota

The range of Zota boilers can be divided into several types. Each of them has its own features and characteristics.

Electrical

The Zota electric boiler is used for industrial and domestic purposes. At the moment, the company produces 5 models, the power of which is in the range from 3 to 400 kW.

- Zota Econom is an economical model, it can be used for heating a house or a cottage, power is from 3 to 48 kW.

- Zota Lux - connected to an autonomous heating system and can supply heat to a house or industrial premises, is able to heat water. Power - from 3 to 100 kW.

- Zota Zoom - organizes the heating system, automatically selects power to maintain a certain mode, power - from 6 to 48 kW.

- Zota MK - are mini boiler rooms for heating and water supply systems of any room, power - from 3 to 36 kW.

- Zota Prom - models are able to heat a room up to 4000 square meters, power - from 60 to 400 kW.

Solid fuel

Coal boiler - Stakhanov model

The company has launched the production of all types of solid fuel boilers, ranging from low-power models for heating country houses to automated boilers for providing heat and hot water to large country houses.

Model lines:

- Zota Сarbon - made of high quality steel, able to heat a small room.

- Zota Master - the case of these models is sheathed with basalt wool.

- Zota Topol-M - boilers with a gas-tight insulated body, it works both on coal and on wood, in the upper part there is a thermometer that measures the temperature of the liquid.

- Zota Mix - is able to provide the optimal working area of the heat exchange process, the efficiency is increased.

- Zota Dymok-M - models have the same characteristics as the previous one.

Automatic coal

Models of this type of boilers have one line of Stakhanov. The power of these devices is in the range from 15 to 100 kW. All models are equipped with large water chambers, controlled by the Windows system. Designed for heating purposes.

Each of the models can work on reserve fuel, firewood. However, the main fuel of the boilers is fractionated coal.

semi-automatic

Combined boiler for wood and coal

This group is also represented by only one series - Magna. They are distinguished by a built-in long-burning combustion chamber.It is made of fire-resistant material and high-quality steel. The case is hermetic and differs in the increased durability.

These models work on coal and wood. The control system and control of the heating process are fully automated. Power - from 15 to 100 kW.

Pellet

This group is represented by a model range called Pellet. The devices operate on pellets made from peat, wood, agricultural waste. The advantage of these boilers lies in the functioning without human intervention. This electric boiler is usually used for home heating.

Description

Pellet boilers ZOTA "Pellet S" work on wood fuel: firewood, fuel briquettes, pellets. The high autonomy of the equipment allows it to work continuously on one load for up to 5 days. The coolant pressure in the system must be 3 bar.

Key Benefits of Zota

- due to the supply of heated air to the burner, the boiler is automatically ignited;

- the thermal energy of flue gases is used, which, passing through the boiler, effectively give it away in a tubular heat exchanger;

- high fire safety due to the design features of the screws;

- the presence of a chronothermostat that allows you to automatically select the most economical mode of operation when the owner is not around for any reason;

- blocking the supply of fuel from the bunker for pellets, if necessary, by the "Stop-fuel" system;

- automatic regulation of the operating mode depending on the ambient temperature and the required room heating temperature, using an outdoor sensor and an internal remote control;

- the possibility of using electric heating elements in the boiler as an alternative source of heating (option of additional accessories);

- the ability to connect a GSM module for remote control of operating modes using a smartphone;

- a wide range of settings on the control panel: room temperature, heating power, coolant temperature, fuel supply rate, regulation depending on the outside temperature, fan operation mode, pumping equipment control, fuel consumption level, chronothermostat.

Types of solid fuel boilers

All equipment of this class can be divided into 2 groups:

- Automatic fuel supply

- Manual loading

The first are pellet boilers. In them, pellets play the role of fuel, they are loaded into special bunkers and from there they enter the furnace. Such devices have high efficiency and can work in automatic mode for weeks, without human participation in the process.

The latter, depending on the design features, are divided into 3 types:

- Classic

- Pyrolysis

- long burning

They can use firewood and wood waste as fuel.

A traditional or wood-fired solid fuel boiler has been produced for a very long time, and has practically not changed structurally. In it, the combustion chamber is located below and is considered its hottest part. Most often it is made of cast iron or steel. However, such heating of a wooden house with a solid fuel boiler is rarely used, as it requires frequent maintenance.

Pyrolysis devices are a new step in the environment of solid fuel equipment. Their work is based on the principle of decomposing wood into solid residues and gases and burning the latter. The advantages of this device include high efficiency, minimal ash and soot formation.Among the disadvantages is the need to burn dry firewood with a moisture content of not more than 20%.

Long burning - their principle of operation was developed in Russia and has no analogues in the world yet. It is a new generation boiler not only in terms of design, but also in terms of the principle of operation. Its main advantage is the simplicity of design and the ability to service once a day when operating on natural moisture fuel. A solid fuel wood-burning boiler has the most precise power control and can produce a given amount of heat.

Kindling types

Most devices of this type operate on various types of fuel:

- Firewood

- Peat briquettes

- granules

- Anthracite

- Kokse

- brown coal

Moreover, their calorie content is different, and the effective operation of the device depends on it. Therefore, those who purchase such a boiler should take into account that when burning less high-calorie fuel, the power drop can be up to 30% (at acceptable humidity) and even more at natural humidity.

There is one more nuance. Usually, the manufacturer indicates the best way to heat a solid fuel boiler and what fuel should be taken as the main one. It is advisable to comply with these requirements in order to achieve maximum return and make heating a country house with a solid fuel boiler as convenient as possible.

For example, when it is recommended to heat brown coal, it should be used as the main one, and fine-grained fractions should be added only to the hot layer and in small portions.

Briquettes - can be peat, straw or wood. It is ideal to use only those that are produced by pressing.Briquettes disintegrating into sawdust can only be used together with firewood or brown coal, so as not to render the boiler unusable.

Pellets can also be made from straw or wood waste. They are pressed, like briquettes, and are most often used in special solid fuel boilers.

The consumption of firewood in a solid fuel boiler will be minimal if they are dry, only then can you achieve maximum power from the boiler and extend its service life. Otherwise, the useful energy content of wood will be significantly lower.

Operating tips

The technical parameters and performance features that are declared by the manufacturer of the products themselves do not always coincide with what even a short experience in using the purchased unit demonstrates. It is from the reviews of other users that you can quickly find out how Zota units really work, and what operational features they have.

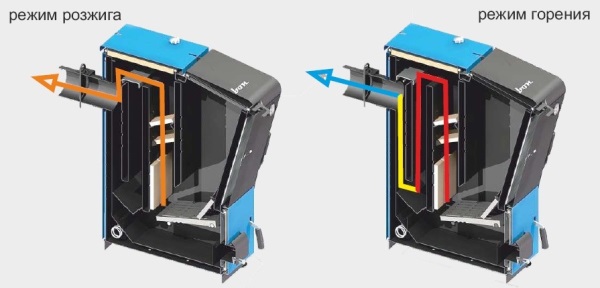

Ignition of boilers must be carried out in a special mode. As soon as the fuel has flared up perfectly, the firebox door is closed and the control lever switches to the firebox mode.

Solid fuel-type Zota devices should be fired with dry logs or quality coal. This is the main condition for excellent heating of the building. The coolant quickly picks up the desired temperature, and when it leaves the boiler, the heat that heats the room is proportional to the quality of the fuel that you used. But also the device will heat the water if necessary.

It is very easy to clean the product from soot. During rotation, a special grate helps to clean the firebox from carbon deposits, without even stopping the combustion process in the unit. Large doors give access to the smoke extraction system.

Zota devices are one of the best and unpretentious types of heating equipment, which has a long service life and low cost: in comparison with imported products, the price of domestic products is 2 times lower. Consumer reviews indicate that there are still certain shortcomings in these devices, but they fully compensate for the special versatility of the device during its operation.

You can learn how to properly connect a heating boiler in the video below.

Distinctive features of the Zota solid fuel boiler

Solid fuel boiler Zota is a modern heating device manufactured by a Russian company. This device can operate on various types of fuel, ranging from ordinary firewood to fuel pellets (pellets). There is a large range of models on the market, where boilers differ in their purpose. The technical characteristics of solid fuel boilers for long burning Zota are not inferior to European counterparts.

You can learn more about the features of wood heating here.

As a disadvantage, low productivity can be distinguished. Their efficiency does not exceed 60-70%. The Zota company tried to raise the efficiency of its products. Due to this, boilers generate a large amount of thermal energy on a similar amount of firewood.

In addition, the manufacturer paid special attention to the reliability of its devices, the duration of burning and automation of the fuel combustion process.

Characteristic features of Zota boilers:

- a large selection of models - both for domestic conditions and for industrial ones;

- the fuel burns for a sufficiently long period of time - this is achieved due to the special design of the devices and the individual developments of the manufacturer;

- heat exchangers of very good quality, which are characterized by high reliability;

- automation of work - for this, the product range includes automatic and semi-automatic solid fuel boilers.

Installation rules

Like all types of electric boilers, the Zota brand is available in two variations: floor and wall, single-phase and three-phase. The rules for installing single-phase models are simple:

- It is necessary to carry out the installation of the unit itself.

- Connect it to your home's heating system.

- Plug it in.

The only thing that needs to be done is to run a separate power cable from the switchboard and install a separate machine. With three-phase analogues it is more difficult. If you are not an electrician, then it is best to entrust the installation to professionals. It is both reliable and safe.

Operation of the boiler is quite simple. The instructions have provisions with which you can easily adjust the device to the desired air temperature parameter. The device will do the rest.

A fairly wide range of Zota electric boilers allows you to choose the right model exactly for the requirements of the consumer. Additional options will help increase ease of use. Of course, they increase the cost of the product, but the quality of work only improves from this.

Therefore, it is worth paying attention to the options and choosing the ones suitable for the operating conditions.

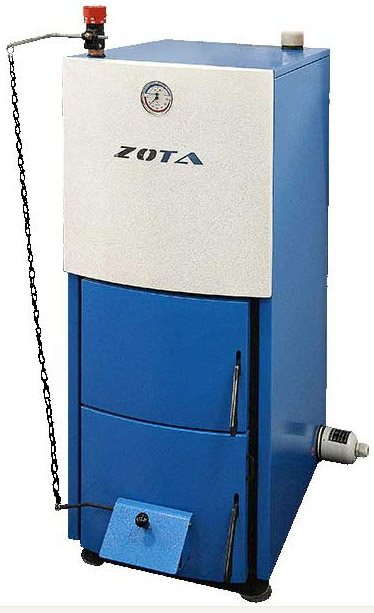

The domestic company ZOTA is known not only in Russia, but also abroad. It specializes in the production of heating equipment and additional accessories. By installing a ZOTA electric boiler in their home or country house, people make their choice in favor of a high-quality and reliable product from a Russian brand. In this review, we will cover:

- About the main lines of electric boilers;

- About popular models;

- About connection and operation of ZOTA boilers.

In conclusion, you will get acquainted with user reviews.

Main Models

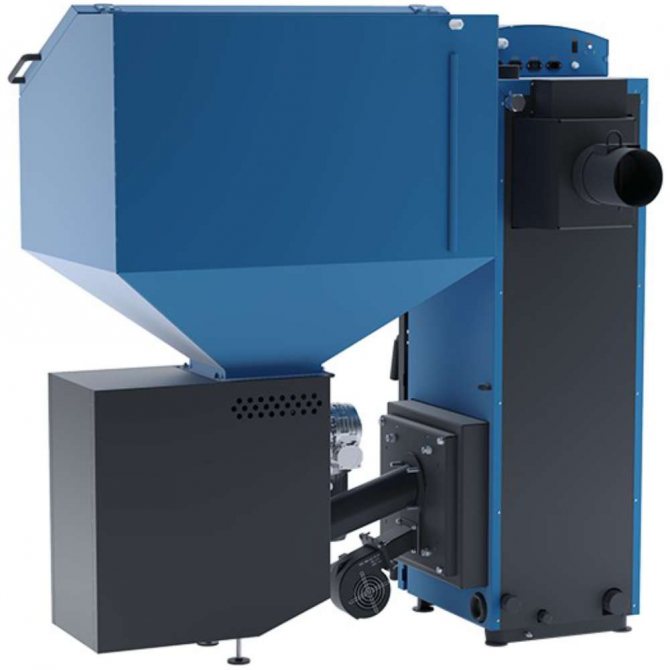

Zota pellet boilers are represented on the market by two model ranges - these are Zota Pellet and Zota Pellet Pro. Also on sale is the universal model Zota Optima, which can work on ten types of solid fuels. All equipment presented for sale is manufactured by OOO TPK Krasnoyarskenergokomplekt. All products are certified and meet strict quality standards.

Solid fuel pellet boilers Zota are used for heating buildings for various purposes - these are residential cottages, outbuildings, industrial hangars, warehouses and much more. They are equipped with capacious bunkers for laying pellets and are completed with convenient control panels. Let's consider this equipment in more detail.

Pellet boilers Zota Pellet

This series is represented by seven models with power from 15 kW to 100 kW. The equipment is equipped with auger fuel supply systems and pressurized fans. It works in automatic mode, focusing on the specified temperature indicators and regulating the supply of fuel to the combustion chamber. Ignition is carried out automatically using a small heating element.

Structurally pellet boiler Zota Pellet consists of two parts. In the first part there is a combustion chamber and a heat exchanger with an ash pan, and the second part consists of a burner and a capacious bunker.The system uses an electronic control system with the ability to control via a GSM module - this provides remote control of various indicators.

Other features of pellet boilers Zota Pellet:

- The left or right arrangement of the bunker with a torch at the request of the consumer;

- Ability to work on fuel wood and briquettes - in case of a power outage;

- Possibility to install a block of heating elements - provides support for the temperature of the coolant when the supply of pellets in the bunker is depleted;

- Built-in weather-dependent control;

- Safe design to prevent fires and ignition of fuel supplies;

- Water cooling jacket.

As a fuel in pellet boilers Zota Pellet, pellets from deciduous and coniferous wood are used. The equipment is intended for operation in heating with forced circulation of the coolant.

If necessary, the capacity of the bunker can be increased by retrofitting it with additional modules for fuel. The nominal volume is 293 liters.

Pellet boilers Zota Pellet Pro

This series includes high power models - from 130 to 250 kW. Here, productive vertical heat exchangers and air systems for automatic ignition are used. The nominal capacity of the bunkers is 560 liters, which is enough for a long time. Fuel supply to the burner is carried out using two augers.

Management in pellet boilers Zota Pellet Pro is electronic, with the ability to connect GSM modules. Also on board there is weather-dependent automation that monitors the weather on the street and corrects the parameters of the units. The electric network is used as a backup source of heat - blocks of heating elements are purchased and installed separately.

Universal boilers Zota Optima

These units are universal. They can work on brown coal, fuel briquettes, firewood, as well as on wood and sunflower pellets. Depending on the selected fuel, manual, semi-automatic and automatic operating modes are supported. The choice of buyers is presented with a model with a capacity of 15 and 25 kW, which is enough to heat buildings up to 250 square meters. m.

Boilers Zota Optima, able to work on pellet fuel, are endowed with built-in thermostats and weather-dependent automation. It is possible to install a block of heating elements with a power of 3 to 12 kW. The units are easy to clean and have a large ash pan for storing ash.

Features of the brand Zota

The described products have been manufactured in Krasnoyarsk since 2007. The manufacturer is Krastoyarskenergokomplekt. Regardless of the date of registration (2007), the company began its activities much earlier - back in 1999, by introducing heating appliances into domestic homes that can provide users with hot water. It was this niche that was chosen by the company's management for further development.

Today, the company is more specialized in the manufacture of Zota boilers operating on solid fuels. Such devices are capable of heating premises (both residential and industrial) with a total area of 30-4000 square meters. All models are divided into several model ranges, which we will talk about a little later. In addition to heating units, the company produces additional devices and accessories. These include, for example, tubular heating elements, automatic systems - all this is actively used in various fields.

Note! The production lines of the plant are constantly updated, so that each new generation of heating equipment becomes more durable and perfect. The process uses sheet benders, laser cutters and other mechanisms.

Each new development before going on sale is run in and tested on special sites. This means that the probability of marriage is practically reduced to zero, as well as "weak" places.

As a small conclusion

So we found out what Zota heating boilers are. As it turned out, there are a great many of them - many electrical appliances and appliances that operate on solid fuels, there are also models that consume pellets (of any origin) as fuel. Do not forget about automatic and semi-automatic units. All of them are in great demand among consumers, as over the years of their existence they have earned trust and a certain status.

Kindling preparation

In order for coal heating equipment to be safe and efficient, you need to pay attention to the following points:

- If the boiler or stove is rarely used (for example, seasonally), then before use, you need to make sure that there are no masonry cracks. Even small cracks in the structure of the stove are a wide path for carbon monoxide to escape into the room, where it can seriously harm the people present there. To get rid of this problem, all cracks must be covered with a mixture of sand and clay before melting the solid fuel boiler.

- Before you melt the boiler with coal, you need to inspect it visually. There should be no combustible objects near the heating equipment.The internal surfaces of the structure must be cleaned. It is advisable to wipe the firebox with a dry cloth so that the burning dust does not emit an unpleasant odor that enters the room.

- Coal stoves need to be heated several times a day, and the duration of each kindling should not be more than two hours (for more details: “How to heat a stove with coal and which coal is better”). For heating, dry coal of medium fraction is best suited.

- Various combustible wastes and liquids such as kerosene cannot be used to ignite coal equipment. In addition, the stove must be supervised during the burning process, especially if there are animals or children in the house.

The points described are not particularly difficult and allow you to make the operation of boiler equipment safe.

Installation and operation

In the process of connecting Zota boilers, it is necessary to strictly comply with the requirements for the installation of any solid fuel heating appliances. It is necessary to install a security system: sensors that will be responsible for monitoring the temperature of the coolant and pressure relief valves.

You will find a specific installation scheme in the instructions, it describes in detail the ignition process and the operation of the device.

Very often there are situations when the technical and operational characteristics declared by the manufacturer do not coincide with what even a short experience of using the boiler can show. Feedback from owners of Zota boilers shows a real picture of how these units function and what their characteristics are:

- the ignition of the boiler takes place in a special mode. After the fuel flares up well, the furnace door closes and the control lever switches to the furnace mode;

- it is best to fire the boiler with dry wood and coal. Compliance with this condition is the key to high-quality heating. The temperature of the coolant at the outlet of the boiler will directly depend on the quality of the fuel used;

- cleaning the boiler from soot is not difficult. Due to the fact that the grate rotates, you can clean the firebox from soot without interrupting the combustion process. And large doors provide unhindered access to the entire smoke exhaust system.

How to clean a solid fuel boiler from soot, you can read in this article

Popular Models

Model Dymok has a hob

The following models are the most common. They have gained popularity due to technical characteristics and properties.

Zota Smoke

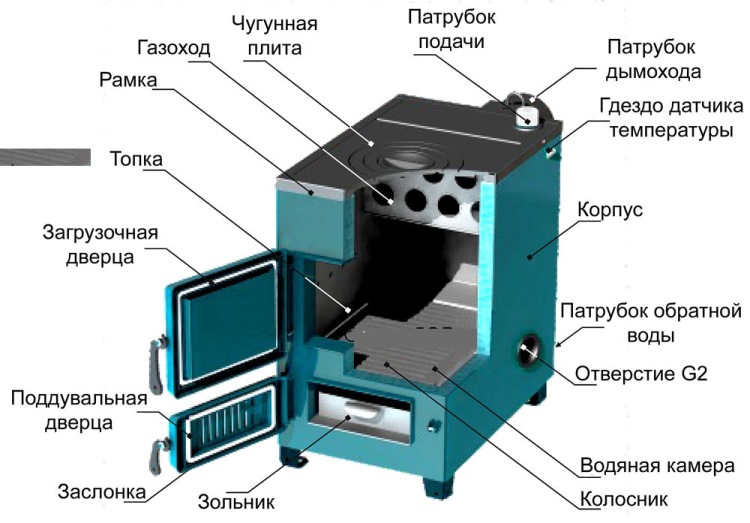

Zota electric boilers of the Dymok series are solid fuel direct combustion appliances. The air supply can be adjusted manually using a damper. Boilers are non-volatile.

The combustion chamber is made of steel and is equipped with a cast iron hob.

The company offers two modifications - KOTV and AOTV. The difference is that the AOTV series has a hob. The power of KOTV boilers is offered in two versions - 14 and 20 kW. The power of the AOTV series is divided into 3 levels - 12, 18, 25 kW.

The boiler system makes it possible to adjust many parameters, which will ensure autonomous and safe heating operation.

Zota Lux

Boiler Zota Lux for an apartment or a private house, wall-mounted

Electric boilers The Lux series are designed for autonomous heating of industrial premises and residential buildings. The area of the heated building is from 30 to 1000 m2.

The user can adjust the temperature from +30 to +90 degrees, which allows the use of devices in the "warm floor" system without auxiliary control equipment. The boiler will automatically maintain the set temperature.

The tunic has small dimensions and weight. The manufacturer has made it possible to easily connect to external circuits, such as sensors or pumps.

Other

List of other popular models:

- Zota MK - devices of medium power;

- Zota Smart - high-tech models with a wide range of functions;

- Zota Topol-M - products with a gas-tight insulated housing;

- Zota Master - models whose body is sheathed with basalt wool;

- Zota Econom - economical devices, characterized by optimal performance.

Solid fuel heaters

The Krasnoyarsk manufacturer supplies the market with solid fuel heating units of the following series:

- Carbon. Presented 7 models with power from 15 to 60 kW;

- Master. In a series of 6 models with powers from 12 to 32 kW;

- Topol M. There are 4 models with capacities from 14 to 42 kW;

- Mix. There are 4 variants in the series with power from 20 to 50 kW;

- Dymok-M. Five variations with power spread from 12 to 25 kW;

- Boxing. This series has one model with a power of 8 kW.

Advantages of carbon heating boilers:

- The small circuit is made of high quality boiler steel;

- Fuel is loaded from above;

- Ease of cleaning the heat exchanger.

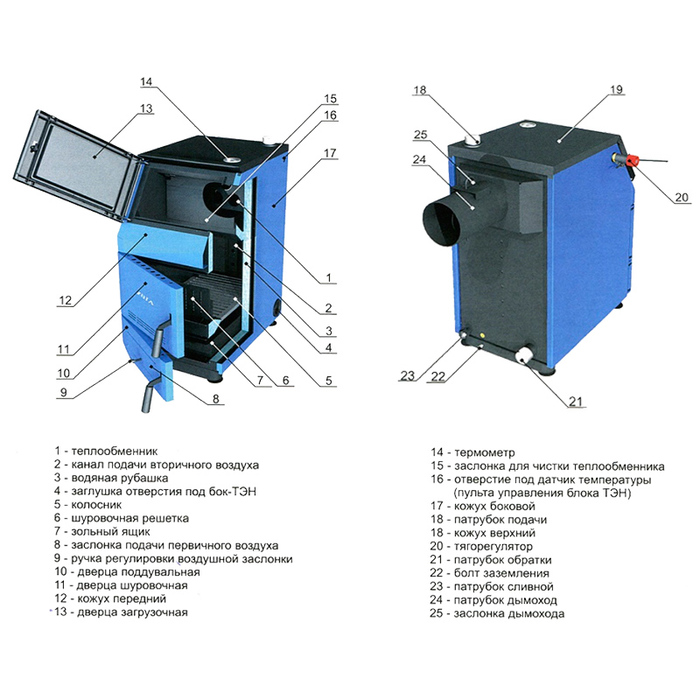

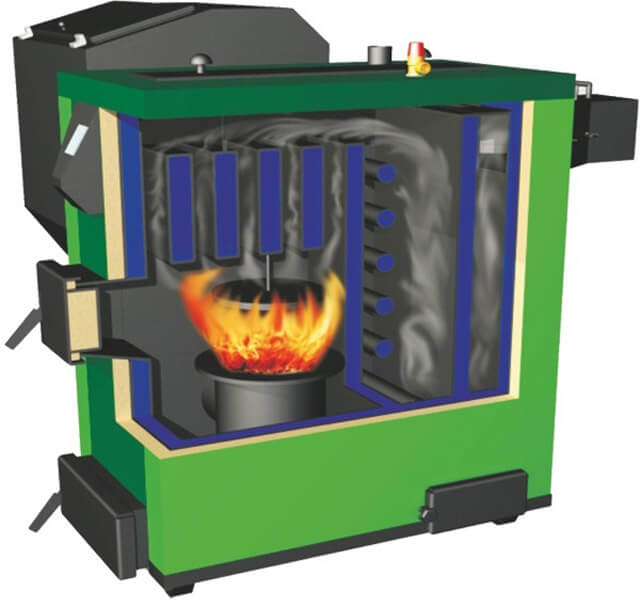

Diagram Zota Carbon

- Large diameter loading opening;

- Use of a draft regulator with tertiary air flow adjustment;

- moving grate;

- The design of the heat exchanger ensures the afterburning of fuel particles contained in the exhaust gases;

- Designed for a pressure of 3 atm;

- Adjustable chimney pipe included;

- The ash pan is mounted on a water-cooled surface, which contributes to an increase in efficiency;

- Possibility of using an additional heating element.

Additional heating element increases the operating time. When solid fuel runs out, the boiler does not stop working. If necessary and desired, it is allowed to re-equip the boiler for gas (liquefied or natural).

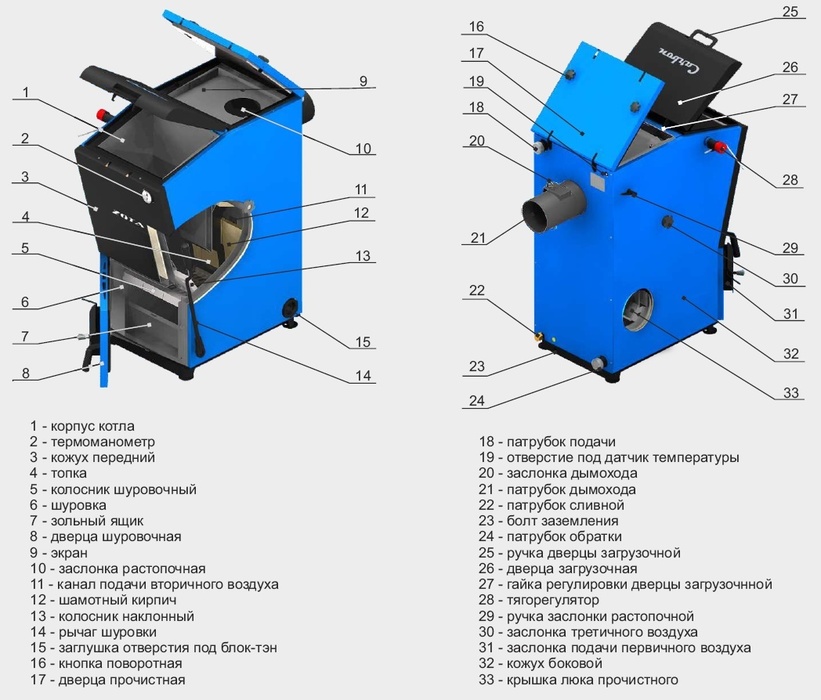

Additional benefits of the Master series include the following:

- Combined heat exchanger;

- Insulation with basalt cardboard;

- The air damper ash pan on the door adjusts the flow of incoming primary air;

- Possibility to install a mechanical draft regulator (option);

- The combustion chamber allows the use of coal and logs up to 70 cm long as fuel.

It is allowed to install an additional gas burner on Master-20.

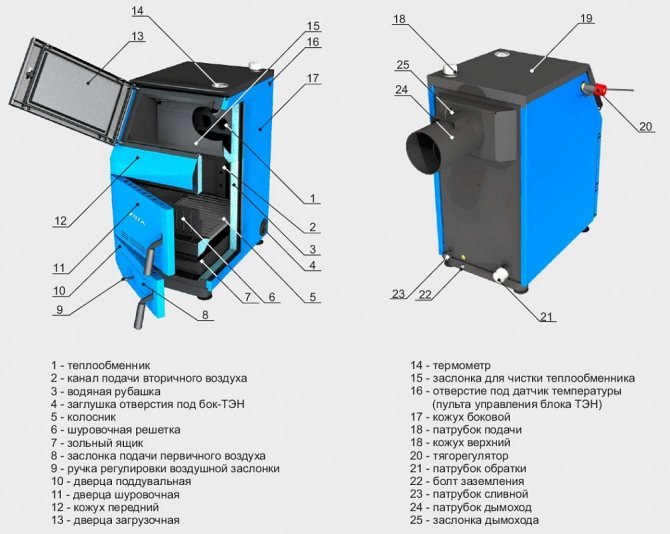

The boilers of the Mix series are equipped with an X-shaped heat exchanger, which makes it possible to obtain the largest area of contact with the flame. Wear-resistant powder paint is applied to the outer casing of the heater.

Dymok-M heaters are distinguished by a water jacket, the structural strength of which is increased due to the use of channels. This design allows them to be used in heating systems with pressures up to 3 and even with a short-term increase to 4 atm.

Device Zota Dymok-M

It is sold as a standard kit with a removable chimney pipe and an adjustable damper. A significant plus is tightly closing doors that do not allow gases to pass through and increase the duration of combustion and efficiency.

The main disadvantages and advantages of the ZOTA Mix boiler

The main advantage of this boiler is its availability, in every more or less large city there is a dealer who represents the ZOTA brand. The same applies to spare parts for boilers of this brand.

And yes, the price of the boiler is also very pleasant. The cost of a 31.5 kW boiler at dealers is now 33-35 thousand rubles, for a 50 kW boiler - 46-48 thousand rubles.

The main disadvantage is the ill-conceived design of the boiler and mediocre workmanship, many small inaccuracies and blots. Most complaints about boilers of this brand are due to annoying imperfections in the design of the boiler.

More on this topic on our website:

- The best TT boiler - from Zota to Buderus Do you think the owner, when building a house, thinks about the best solid fuel boiler, which one is better to choose for heating his ...

- Pellet boiler Kiturami KRP 20 - review and feedback from the owners Well, the Kiturami company could not stay away from the general trend. When all companies specializing in boiler equipment produce ...

- Electric boiler EVAN EPO ECONOMY - review and feedback from the owners These electric boilers of the ECONOMY series, which are now no longer independent and bought by a large NIBE holding, are quite ...

- Pellet boiler ZOTA Pellet / Zota Pellet reviews and characteristics When a gas pipe passes in front of the house along the border of the site and it is possible to connect at state tariffs, you can build any house ...