- SOLID FUEL BOILERS WHERE THE MAIN / REQUIRED FUEL IS WOOD

- Description of the dor series

- Brief description and operation

- Brief description and operation

- What to heat, from sawdust to anthracite

- Solid fuel equipment with a water circuit

- Criterias of choice

- Boiler on coal and wood Dakon DOR pros and cons

- More on this topic on our website:

- Characteristics of gas heaters

- Main advantages

- Gas boilers Dakon

- price issue

- Some more theory from dealer booklets

- Dacon company - history of development

- Solid fuel boilers DAKON DOR characteristics and features

- What consumers say

- Gas

- Mounted single-double-circuit boilers

- Advantages of solid fuel boilers from the Czech Republic

- Atmospheric boilers floor type

- floor standing

- Boilers gas floor single-circuit steel Dakon

SOLID FUEL BOILERS WHERE THE MAIN / REQUIRED FUEL IS WOOD

- Dakon DOR D (Czech Republic) - floor steel solid fuel boilers.

The prescribed fuel is wood (moisture up to 35%). Reserve fuel - brown

coal, briquettes, coke.

The power of the boilers of this model (range of options for power):

Dakon DOR 32 D (power - 9-28 kW); Dakon DOR 45 D (power - 18-45 kW).

- Buderus Logano G211 D (Germany) - floor cast iron solid fuel

boilers designed specifically for burning wood (max. moisture content of firewood - 20%,

log length - up to 68 cm).

The power of the boilers of this model (range of options for power):

16 kW, 20, 25, 30, 34 kW.

- Buderus Logano S111 D (Germany) - floor steel solid fuel

boilers designed to burn wood.

The power of the boilers of this model (range of options for power):

Logano S111-32D (heating capacity (minimum) - 9/28 kW); Logano S111-45D

(heating capacity (minimum) - 18/45 kW).

- VIADRUS U22 D (Czech Republic) - floor cast iron solid fuel

boilers. Intended fuel: wood (up to 22 cm in diameter). Possible incineration

coke, coal.

The power of the boilers of this model (range of options for power):

power - 23.3 kW; 29.1; 34.9; 40.7; 46.5; 49; 58.1 kW.

It should be borne in mind that a tree with 12 - 20% water content

has a calorific value of 4 kWh per 1 kg of wood, wood with 50%

water has a calorific value of 2 kWh / 1 kg of wood. Raw wood heats little,

does not burn well, smokes strongly and significantly reduces the life of the boiler and chimney

pipes. The boiler power is reduced by up to 50%, and the fuel consumption will double.

Description of the dor series

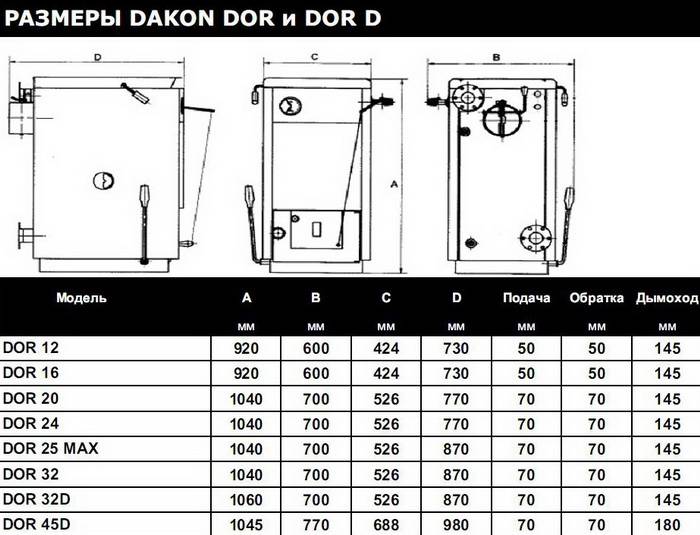

The Dakon solid fuel boiler of the dor series has seven models with a minimum power of 12 kW and a maximum power of 45 kW.

Tab. 1 Main technical parameters of boilers Dakon dor

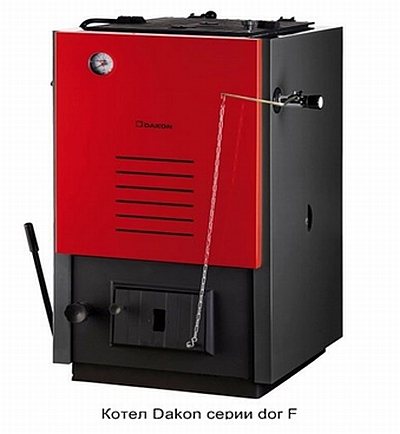

The company has developed a more modern solid fuel device of the dor F series. The main and main difference is that the design of the upper part for fuel loading has been changed. Due to this, filling the fuel became more convenient, and the appearance became worse at the same time, the upper door lost its lining. The design has also changed slightly, and the minimum power has become 13.5 kW. The operation of the dor f boiler is non-volatile.

The solid fuel model dor FDWT has appeared in the Dakon boiler line. This model has a cooling coil. You can use firewood, brown coal, walnut, briquettes and coal, compressed fuel, coke.

Rice. 2

Solid fuels are used for Dakon boilers, mainly wood and coal in its various forms. Solid fuel is considered the cheapest in comparison with other types of fuel, moreover, it is environmentally friendly and affordable. Fuel can have moisture content up to 35%, which is high for combustion.

The burning time is the same for both types, the burning time is 8-12 hours, at a temperature outside the window of -30 degrees, the time will be halved. Brown coal is considered the most economical, since it is on this fuel that the dor boiler runs the longest. The choice of boiler power directly depends on the heated area and the level of heat loss. So, with an area of 100 - 120 square meters, a solid fuel boiler dakon dor 16 will be optimal.

Tab. 2 Main parameters of boilers Dakon dor F

There is a series of cast-iron solid fuel boiler dakon FB. The main fuel for them is wood, reserve coal. This model can work with liquid fuel and gas fuel. For this, a separate kit is purchased. The power of such boilers is from 17 to 42 kW.

Brief description and operation

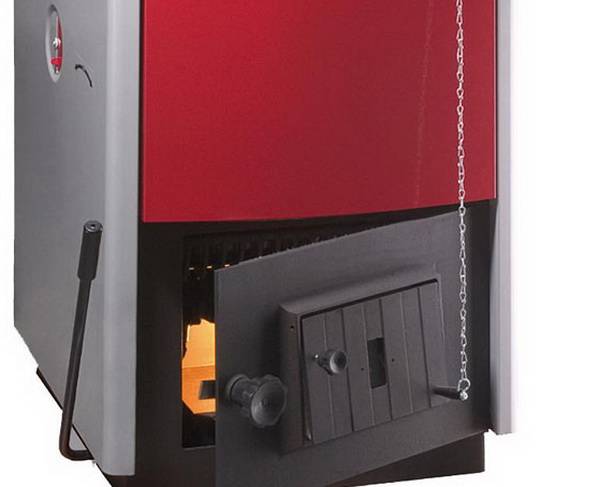

Structurally, the dakon solid fuel boiler consists of a body in which there are water sections, a fuel combustion chamber and grates. The combustion chamber, together with a new grate system, primary and secondary air supply and its regulation, ensures good fuel combustion. The combustion chamber is lined with fireclay for reliability.

The grate bars of Dor heaters are rotary, they are controlled by a shaking lever.It is located in a convenient place on the side of the boiler, and when it is necessary to separate the ash and slag from the fuel, you just need to shake it.

In the upper part there is a cover with a funnel expanding towards the bottom for loading fuel. On the front left side there is a device that combines the capabilities of a pressure gauge and a thermometer, which is convenient to monitor the temperature and pressure in the system.

On the right side, a power control device is installed, which is connected to the throttle through a chain. The heat exchanger of the Dakon solid fuel boiler is three-way. It is made of heat-resistant steel, which can withstand significant thermal shocks.

About the advantages of Dakon solid fuel boilers:

Cons of Dakon solid fuel boilers:

- A small bookmark with fuel, which in cold winter conditions has to be refueled up to 4-5 times a day;

- The temperature of the coolant must not be lowered below 65°C, otherwise condensation will form, which contributes to the destruction of the device.

So which Dakon machine should you choose? Series Dor, or maybe another. Among the variety of solid fuel appliances, it is easy to get lost

We focus on the question of what area to heat. From this we select the power of the device

Each series of devices is distinguished by its nuances, first of all, it concerns the DakonFB series.

Rice. 3

Rice. 3

An important role is played by the size of the combustion chamber, it is no secret that in Western countries they mainly use briquettes, it is very difficult for us to purchase even wood to fit the size of the furnace. If in the future it is planned to connect the central gas pipeline, then the issue of purchasing a Dakon solid fuel apparatus with the possibility of connecting a gas burner should be considered. Moreover, this feature is optional.

One conclusion can be drawn.Any solid fuel product manufactured by Dakon is the best choice.

Brief description and operation

Structurally, the dakon solid fuel boiler consists of a body in which there are water sections, a fuel combustion chamber and grates. The combustion chamber, together with a new grate system, primary and secondary air supply and its regulation, ensures good fuel combustion. The combustion chamber is lined with fireclay for reliability.

Asbestos-free technology is used for thermal insulation of Dor devices.

The grate bars of Dor heaters are rotary, they are controlled by a shaking lever. It is located in a convenient place on the side of the boiler, and when it is necessary to separate the ash and slag from the fuel, you just need to shake it.

In the upper part there is a cover with a funnel expanding towards the bottom for loading fuel. On the front left side there is a device that combines the capabilities of a pressure gauge and a thermometer, which is convenient to monitor the temperature and pressure in the system.

On the right side, a power control device is installed, which is connected to the throttle through a chain. The heat exchanger of the Dakon solid fuel boiler is three-way. It is made of heat-resistant steel, which can withstand significant thermal shocks.

About the advantages of Dakon solid fuel boilers:

Cons of Dakon solid fuel boilers:

- A small bookmark with fuel, which in cold winter conditions has to be refueled up to 4-5 times a day;

- The temperature of the coolant must not be lowered below 65°C, otherwise condensation will form, which contributes to the destruction of the device.

So which Dakon machine should you choose? Series Dor, or maybe another. Among the variety of solid fuel appliances, it is easy to get lost

We focus on the question of what area to heat. From this we select the power of the device

Each series of devices is distinguished by its nuances, first of all, it concerns the DakonFB series.

Rice. 3

An important role is played by the size of the combustion chamber, it is no secret that in Western countries they mainly use briquettes, it is very difficult for us to purchase even wood to fit the size of the furnace. If in the future it is planned to connect the central gas pipeline, then the issue of purchasing a Dakon solid fuel apparatus with the possibility of connecting a gas burner should be considered. Moreover, this feature is optional.

One conclusion can be drawn. Any solid fuel product manufactured by Dakon is the best choice.

Dakon manufactures the following gas boilers:

- Wall gas;

- Floor gas;

- Pig-iron gas floor.

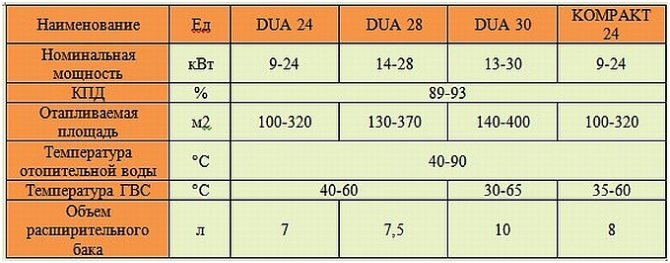

Dakon boilers of the DUA series are available in three types with a capacity of 24, 28 and 30 kW, while they are able to heat an area from 100 to 400 square meters. The temperature of the water in the system is between 40 and 90°C.

There are a lot of performance options. The Dakon company is constantly expanding models of gas boilers, and today there are 16 modifications, both for heating and for hot water supply, with and without chimneys, with boilers and running water.

When choosing a solid fuel boiler Dakon, we are guided, of course, by the technical characteristics of gas appliances. A good choice would be to purchase gas equipment with a boiler. But in the general case, it is better to purchase Dacon gas equipment with two circuits. This will ensure the availability of water for both heating and water supply.Gas heating is more common than other types of heating.

Tab. 3 Technical characteristics of gas, wall-mounted boilers DAKON

Tab. 4 Manufacturing options gas wall-mounted boilers DAKON

There are 21 models of gas appliances in the range of Dakon floor boilers. Models are named Dakon P lux for steel execution, and Dakon GL EKO cast iron boilers. Minimum power 18 kW, maximum 48 kW. Non-volatile, have a two-stage power adjustment. The devices use HONEYWELL CVI electronics without a gas wick. Such devices are used in closed and open systems.

Dakon P lux have advantages over other systems:

- Operation at reduced power, fuel economy is achieved at the beginning and end of heating seasons;

- High safety, presence of the thermostat against freezing.

Advantages of gas boilers GL EKO:

- Reliability due to the use of a cast-iron body;

- Possibility of additional connection of gas equipment, draft damper, pump, thermostats and other elements;

- Power adjustment in different periods of the heating season;

- Reliable shut-off valves;

- Complete combustion of fuel due to the low emission level of the gas burner.

What to heat, from sawdust to anthracite

Firewood

Firewood is a classic solid fuel, its use dates back as many years as a person is familiar with fire. For boilers, firewood from various types of wood is used; the efficiency of the heating system and its uninterrupted operation largely depend on the type of wood and humidity.As for humidity, it is clear that the lower it is, the higher the heat transfer, since energy is not spent on the evaporation of moisture, and the properties of various types of wood when used as fuel deserve more careful consideration.

Deciduous trees are considered the most suitable option, among them the champions in heat transfer are: oak, beech, hornbeam and ash, birch is not far behind, but with insufficient air supply to the place of combustion, birch begins to emit tar, which is deposited on the walls of the smoke exhaust system.

They have proven themselves well - hazel, ash, yew, pear and apple tree, they easily split and burn hot, but elm and cherry emit a lot of smoke when burned. Poplar and linden, familiar to urban residents, are not the most suitable option for a firebox, they burn well, but quickly burn out and spark strongly during combustion, aspen and alder are a completely different matter, which not only do not emit soot, but contribute to its burning out on the walls of the chimney .

Coniferous trees are characterized by the presence of resins in the composition of wood, which is eventually deposited on the inner surface of the pipe, the process of deposition of resin and soot is especially relevant for boilers in which the combustion process occurs at a not very high temperature. The heat transfer of conifers is noticeably lower than that of hardwoods.

Briquettes

Briquettes are produced in the form of a cylinder or a parallelepiped, cylindrical products of some manufacturers have an internal hole along the entire length. Briquettes are not susceptible to fungus damage, have a high calorific value and are very convenient to use, as they have a low ash content of no more than 3%.

Pellets

Pellets are a granular type of fuel that greatly facilitates the task of automating solid fuel heating devices. The material for production is woodworking and agricultural waste - sawdust, bark, wood chips, shavings, flax waste, sunflower husks, etc. The material is processed into flour and pressed into cylinders under high pressure, the pellet diameter is 5–8 mm, and the length is not exceeds 40 mm. As in the case of briquettes, the binding material is a natural component - ligin.

The advantages of pellets include: low ash content, environmental friendliness, ease of transportation in bags or packages, the possibility of automating the supply to the combustion chamber. The disadvantage is the additional costs for special equipment for burning pellets.

Coal

The quality of coal depends on age, mining conditions and chemical composition. By age, all coal is divided into three main groups: brown (the youngest), stone and anthracite. The older the fossil, the lower the moisture content and volatile components, the lowest rates for anthracite

It is important for the consumer to know the labeling, which indicates the grade and size class, brown coal is denoted by the letter B, anthracite - A, and hard coal has seven grades from long-flame - D, to lean - T. The size of individual pieces determines the name of the class:

- private (P) - no size limit;

- shtyb (W) - less than 6 mm;

- seed (C) from 6 to 13 mm;

- small (M) 13–25 mm;

- walnut (O) 26–50 mm;

- large (K) 50–100 mm.

Read in detail about all types of fuel, their calorific value, advantages and disadvantages here.

Solid fuel equipment with a water circuit

This design works as follows: water enters the cavity between the walls of the furnace and the outer casing of the boiler, heating up, it goes through the upper pipe into the heating system, giving off heat, the water returns through the lower pipe into the cavity of the water jacket. Circulation is possible in a natural way or with the help of a special pump.

Criterias of choice

There are general requirements that boiler equipment must meet. Their significance for themselves is determined by each specific buyer.

Main criteria:

- Price: the consumer chooses from several models with similar characteristics the one that costs less. It makes no sense to overpay for the same set of properties.

- Type of fuel: the buyer determines in advance the fuel resource that will be more profitable to use.

- Convenience: there is a set of features that facilitate the process of working with heating equipment. The criterion is individual for each person. One will find a large firebox convenient, the other - energy independence.

- Quality. The criterion implies the assembly of the unit from high-quality materials and components. It is better to choose products of well-known manufacturers who value their reputation.

- Power. The characteristic is determined on the basis of an average of 1 kW per 10 square meters. m of heated space. A small operating margin is added to the result.

Boiler on coal and wood Dakon DOR pros and cons

The main advantages of the Dakon DOR solid fuel boiler include the following factors:

- Sufficient reliability of the boiler, many users note this. Most users of Dakon DOR boilers are satisfied with their choice.

- Sophisticated design of thrust adjustment and fuel combustion process.

- Sufficiently affordable prices for Dakon DOR boilers.The cost of the "junior" boiler in the line is only 30,000 rubles from an authorized dealer who is ready to provide installation and service.

The main disadvantage of the Dakon DOR boiler is the insufficient volume of one fuel load. Initially, these boilers were intended for European countries, where winters are quite warm.

In the case of Russia, when in the Siberian expanses -40С all the time and when -50С is also a normal phenomenon, such boilers often have to be heated. The frequency of the owner's approaches to the boiler is the biggest disadvantage of the Dakon DOR boiler.

More on this topic on our website:

- Boiler for wood and coal Viadrus Hercules U22 reviews and table Boilers, which are produced under the Viadrus brand in the Czech and Slovenian factories, in the Hercules modification with a capacity of 11 to 58 kW.

Pyrolysis boiler Dakon KP Pyro - review and reviews Today we have "for a snack" pyrolysis boilers under the Dakon brand. And, since this is a well-known brand in the "solid fuel environment", then.

Solid fuel boilers Dakon Dor 16 - reviews and installation examples About Dakon Dor solid fuel boilers manufactured in the Czech Republic, we wrote a review on the pages of this site. Also published.

Solid fuel boiler KChM 5 - specifications and reviews KChM 5 boilers are produced by the Kirov Plant, founded back in the 18th century. Over the years of operation, the boiler has proven itself to be very reliable and reliable.

Characteristics of gas heaters

The main fuel of the units is a natural mixture of gases based on methane obtained from main pipelines.When it is required to organize autonomous gas heating, it is possible to switch to a propane-butane liquefied mixture supplied from a gas tank or a ramp with cylinders.

According to the installation method, the units are wall-mounted and floor-standing, and the latter usually do not need electricity. Mounted heat generators are mini-boiler rooms equipped with an expansion tank, a circulation pump and an electronic control unit.

According to the method of fuel combustion and efficiency, gas heaters are divided into 3 categories:

- Atmospheric, open combustion chamber, efficiency - up to 90%. Air is supplied to the burner in a natural way from the boiler room, the gases that give off heat are emitted into a traditional chimney.

- Turbocharged (supercharged), the combustion chamber is completely closed, efficiency - 93%. The air is blown by a fan, the smoke goes outside through a double-walled coaxial pipe.

- Condensing units use the latent heat of combustion of hydrocarbons, so the efficiency reaches 96-97%. The design is similar to a turbocharged boiler, but the closed chamber and burner are cylindrical in shape.

Turbocharged model of a suspended boiler equipped with a plate heat exchanger for heating water

All of these heaters can be supplied with a DHW water circuit. For this purpose, 2 types of heat exchangers are used - a separate stainless steel plate heat exchanger and a copper shell-and-tube heat exchanger (mounted inside the main heater).

The price of boilers increases in the order listed - atmospheric devices are considered inexpensive, followed by heaters with a turbine. The cost of condensing equipment is about twice as high as conventional heat generators (one manufacturer).

Low temperature condensing units are well suited for underfloor heating

Advantages of gas boilers:

devices are quite economical and reliable in operation;

a high degree of automation - the homeowner does not need to pay attention to the device;

ease of operation, maintenance - 1 time per year;

the boiler room is clean, the noise level is low;

for a pressurized model, you do not have to build a classic chimney - the pipe is led horizontally through the wall.

On the shortcomings: the gas heat generators themselves are impeccable, the problem is different - connecting the main to a private house and obtaining the necessary permits. The first service costs a lot of money, the second takes a lot of time. An intermediate option is a device for autonomous supply of liquefied gas from cylinders or an underground tank.

Main advantages

Electric heating boilers Dakon perform well in work. They are equipped with high-precision automation, which allows you to make the most convenient settings for the user and maintain the operating mode at the set mark without additional control from the owner. All actions performed, the current temperature regime and other useful information will be displayed on the display.

To protect the device from sudden power surges, it is worth installing a special stabilizer in the house. Automation has its own fuses that will burn out so that expensive equipment does not get damaged. But constantly replacing them will also be expensive, and the stabilizer will come in handy in any case, since there are no power grids in any Russian city where the voltage supplied would never go off scale above the established norm.

Gas boilers Dakon

All gas boilers Dakon with an open combustion chamber.

The Dakon gas boiler is only available for floor installation.The power of the units varies from 18 to 48 kW, and the efficiency is within 92%. Absolutely all models are equipped with an open combustion chamber - this is when oxygen comes from the room. The design of the heater makes it possible to connect additional devices. The boiler is equipped with automation, a draft interrupter, an ionization sensor. The steel body is insulated with non-combustible thermal insulation, respectively, it does not heat up. They also read: “The gas boiler from Beretta is simple, reliable and functional.”

Dakon gas boilers are available with two types of automation:

- with the ability to adjust the power - marked HL;

- operating in automatic mode.

The line of gas boilers for an open heating system is marked with the letter Z.

All these boilers are volatile and work only when connected to the network. The Dakon company has developed a line of heaters in which there is not a single energy-dependent element; such boilers are used in gravity heating systems with natural circulation of the coolant.

It is necessary to select a chimney pipe for each model of a gas boiler individually, since the diameter of the pipe may vary. Gas connections for all units are standard ¾ inches. The connection must be carried out by special services.

According to the standard, coating bituminous waterproofing should be applied from the side exposed to moisture. It doesn't work on break.

What are the types of liquid waterproofing written on this page.

price issue

The heating equipment of the Czech manufacturer belongs to the middle price category. Their cost ranges from 45,000 rubles for classic models to 124,000 rubles for pyrolysis machines.If we compare these data with the prices for domestic solid fuel products, they are much higher. But at the same time, comparison with Western European products has the opposite effect.

Consumer reviews, watch the video:

However, Dakon solid fuel boilers, the price of which differs depending on the series and model, fully justify it. After all, this equipment can easily compete with the products of the most famous companies in terms of quality, economy and ease of operation.

Some more theory from dealer booklets

As noted above, the Dakon boiler is very easy to operate - power indicators are adjusted due to the special design of the combustion chamber with the possibility of supplying secondary and primary air, as well as suction - for this, a blower fan with adjustable speed is used.

For this heat generator, it is possible to connect external control devices - a programmer or a thermostat controlled by room temperature.

There is another big plus - a well-thought-out system for retaining flue gases when opening the furnace door. When you need to add firewood, the movement of flue gases in the firebox is such that there is no emission of smoke into the boiler room. Naturally, the chimney for the TT boiler must comply with the manufacturer's requirements.

Dacon company - history of development

In 1949, a small production facility for the production of heating equipment appeared in the Czech Republic. But less than 20 years later, Dakon became one of the first manufacturers in its country to produce universal models of heating equipment.In those years, the company's production capacity consisted of 5 factories, but the constant improvement of products has led to the emergence of new models.

In 2004, the company was bought out by the well-known German manufacturer Buderus and became part of the Bosch Corporation. This merger resulted in a large industrial group specializing in the production of heating equipment. Today, the company's products are known all over the world, they are of high quality, unsurpassed reliability, and its Dakon solid fuel boiler is also distinguished by a price that is lower than that of similar devices from other manufacturers.

Solid fuel boilers DAKON DOR characteristics and features

The boiler block is made of high quality stamped steel;

A long burning process is ensured by large volumes of the loading chamber and ash pan;

A new grate system that allows combustion of lower quality fuels in a continuous cycle, with dust-free ash screening, with joint regulation of primary and secondary air;

Wide range of applications due to the diverse choice of fuels: firewood, lignite, hard coal, pressed fuel;

Suitable for use in pumping or gravity systems;

Ease of maintenance and cleaning of the loading chamber and ash pan;

Ecological cleanliness: firewood as a fuel, being a product of photosynthesis, does not disturb the balance of CO2 in the atmosphere when burned;

Built-in heat exchanger (additional option);

Installation speed.

What consumers say

Scrolling through the many pages on the net that have reviews of Dakon products, you will see that they are positive.Among them, it is simply impossible to find a negative one. Everyone who has Dakon solid fuel boilers installed write reviews with words of gratitude to this manufacturer and note that these devices have a number of advantages, including:

- Convenient loading

- The presence of a new grate system, which makes it possible to burn even lower quality fuel

- Non-asbestos insulation

- Modern design

- Automatic power control

They fully confirm the opinion of consumers that the Dakon solid fuel boiler, which is reviewed on many sites, is one of the best in this market segment.

Gas

Dakon manufactures the following gas boilers:

- Wall gas;

- Floor gas;

- Pig-iron gas floor.

Dakon boilers of the DUA series are available in three types with a capacity of 24, 28 and 30 kW, while they are able to heat an area from 100 to 400 square meters. The temperature of the water in the system is between 40 and 90°C.

There are a lot of performance options. The Dakon company is constantly expanding models of gas boilers, and today there are 16 modifications, both for heating and for hot water supply, with and without chimneys, with boilers and running water.

When choosing a solid fuel boiler Dakon, we are guided, of course, by the technical characteristics of gas appliances. A good choice would be to purchase gas equipment with a boiler. But in the general case, it is better to purchase Dacon gas equipment with two circuits. This will ensure the availability of water for both heating and water supply. Gas heating is more common than other types of heating.

Tab. 3 Technical characteristics of gas, wall-mounted boilers DAKON

Tab. 4 Manufacturing options for DAKON gas wall-mounted boilers

Mounted single-double-circuit boilers

This Dakon line is represented by two modifications: DUA and KOMPAKT. Each of the series has its own characteristics and individual technical characteristics.

- Double-circuit wall-mounted gas boilers Dakon DUA are designed for heating relatively small residential premises. The advantage of the Dakon DUA modification is the possibility of precise heating of water and coolant to the required temperature. A gradual increase in power is carried out. An electric ignition system is provided. An ionization control of the presence of a flame is installed. The heating mode is automatic. It is possible to complete the wall-mounted boiler with a boiler.

- Autonomous 2-circuit hinged gas boiler from Dakon KOMPAKT. Unlike the previous model, Dakon KOMPAKT has a more compact size, so it can be installed even in small spaces. Modifications with closed and open combustion chamber are available. An anti-freeze system, smooth control of the temperature of the coolant and hot water is installed. For convenience, there is a touch control panel for the combustion mode. The Dakon KOMPAKT modification also includes wall-mounted single-circuit heating gas boilers. For the needs of domestic hot water in this case, an external BKN is connected.

Advantages of solid fuel boilers from the Czech Republic

The history of the Dakon trademark has been going on for more than a dozen years. And during this time, the company's specialists have learned to make really reliable and easy-to-use heating boilers.

After analyzing the reviews of people who have already bought and use the products of a Czech manufacturer, we can highlight the most strengths of these heaters:

- A special funnel-shaped opening and a wide flap that blocks access to the combustion chamber makes it easier to load firewood.

- The presence of special grates allows not only to burn fuel with a high level of humidity, but also to easily clean the combustion chamber from the ash accumulated there.

Special swivel grates make it easy to clean the combustion chamber

- The use of special asbestos-free insulation makes Dakon boilers safer for humans and the environment.

- Modern design meets the most progressive trends in this area.

- Automatic power control with the help of mechanical non-volatile thermal valves or high-tech electronic control systems for climate control equipment makes the use of boilers not only convenient, but also economical.

And last but not least, the cost. Despite the high technical characteristics and consumer properties, Dakon boilers belong to the middle price category.

The minimum cost of a steel boiler with horizontal fuel loading starts from 40 thousand rubles. More economical and reliable cast iron varieties will cost you from 65 to 95 thousand rubles.

Well, the most progressive pyrolysis models cost from 111 thousand rubles.

The low cost of boilers and moderate fuel consumption allow significant savings

This is much less than similar products from other European brands. Cheaper can be purchased only equipment of domestic manufacturers, and it, regrettably, is not yet very popular.

Atmospheric boilers floor type

Atmospheric volatile equipment is represented by two basic models with the possibility of additional configuration with the necessary equipment.

- Czech steel non-volatile floor gas heating boilers Dakon with one P Lux circuit. Maximum operating efficiency is achieved due to the unique internal structure of the heat exchanger, separated by water sections. As a result, both heat directly from combustion and from combustion products is accumulated. Gas burners are equipped with the function of automatic adjustment of the combusted air, complete and environmentally friendly combustion is ensured. The presence of a flame in the Dakon P Lux boiler is controlled by an ionization electrode. The steel heat exchanger is thermally insulated. Installation of a P Lux boiler independent of electricity takes only a few hours (provided that the heating system is ready). Dakon P lux - installation and operation data sheet.pdfDownload file(532.7 Kb) (downloads: 5)

- Stationary floor-mounted water-heating single-circuit gas boiler Dakon with a cast-iron heat exchanger GL EKO. Maximum performance and safety is achieved thanks to the installed safety group, compact gas fittings, unique atmospheric burner. Another feature of the Dakon GL EKO range is the possibility of conversion to liquefied gas. Automatic boiler GL EKO fully regulates the combustion process. For greater comfort, it can be connected to room thermostats. Models of the GL EKO series are designed for connection to a heating system with forced circulation of the coolant.

In the design of Dakon boilers, bithermic copper heat exchangers are widely used. Such a device significantly increases the efficiency of the equipment. Thanks to the temperature of the flue gases, it is possible to obtain an additional amount of thermal energy.

floor standing

There are 21 models of gas appliances in the range of Dakon floor boilers.Models are named Dakon P lux for steel execution, and Dakon GL EKO cast iron boilers. Minimum power 18 kW, maximum 48 kW. Non-volatile, have a two-stage power adjustment. The devices use HONEYWELL CVI electronics without a gas wick. Such devices are used in closed and open systems.

Dakon P lux have advantages over other systems:

- Operation at reduced power, fuel economy is achieved at the beginning and end of heating seasons;

- High safety, presence of the thermostat against freezing.

Advantages of gas boilers GL EKO:

- Reliability due to the use of a cast-iron body;

- Possibility of additional connection of gas equipment, draft damper, pump, thermostats and other elements;

- Power adjustment in different periods of the heating season;

- Reliable shut-off valves;

- Complete combustion of fuel due to the low emission level of the gas burner.

Rice. four

Boilers gas floor single-circuit steel Dakon