- Internal structure and principle of operation

- Manufacturing materials

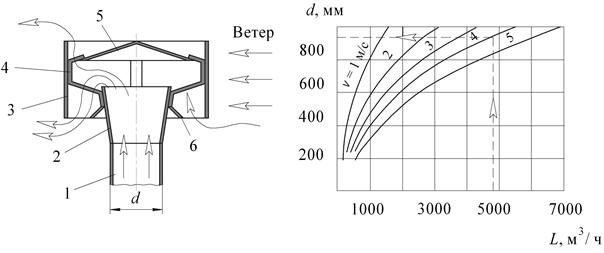

- Device selection

- Classification of wind nozzles

- Varieties of deflectors

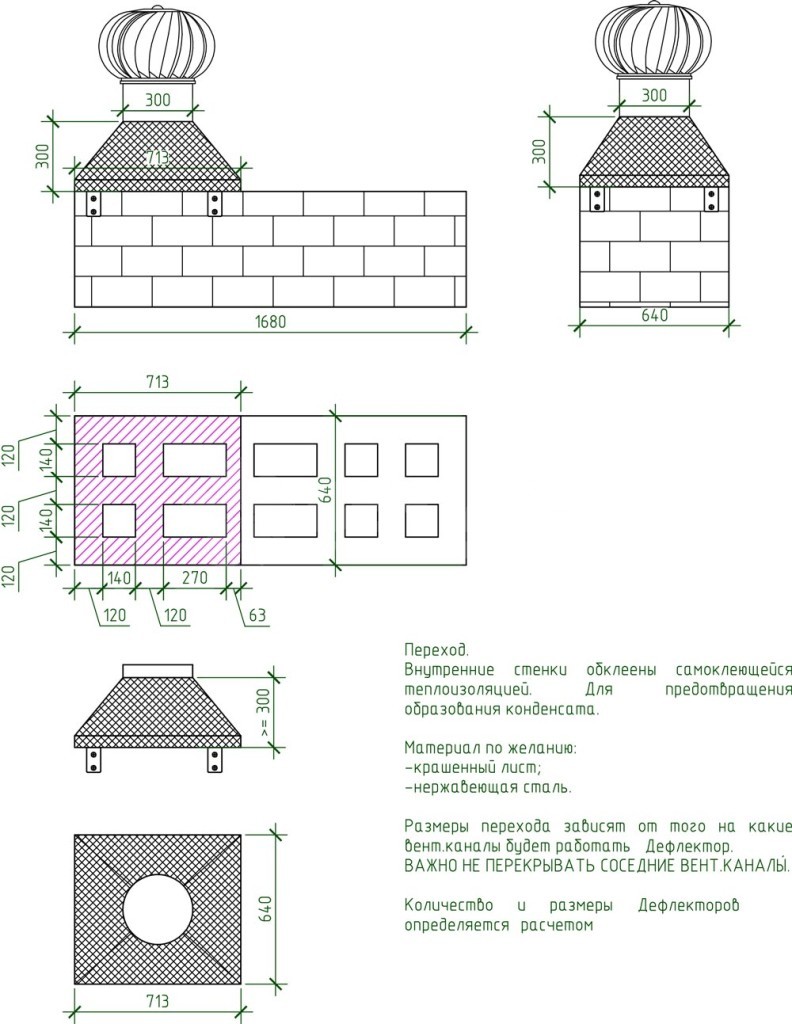

- Mounting Features

- Making a Grigorovich deflector with your own hands

- materials

- Stages of creation

- The need to install a chimney deflector

- Installation rules

- Possible problems and solutions

- Can it be installed on a chimney

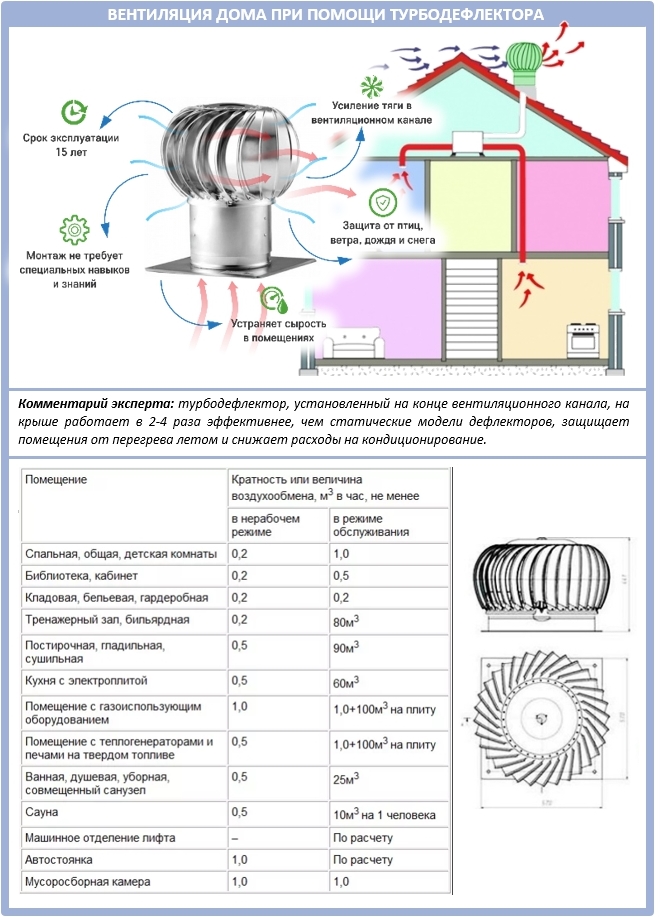

- Advantages and disadvantages of turbo deflectors

- Price

- The principle of operation of the ventilation deflector

- Types of deflectors

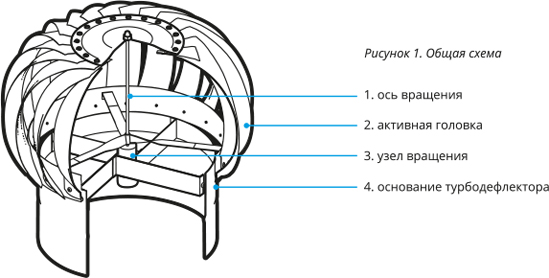

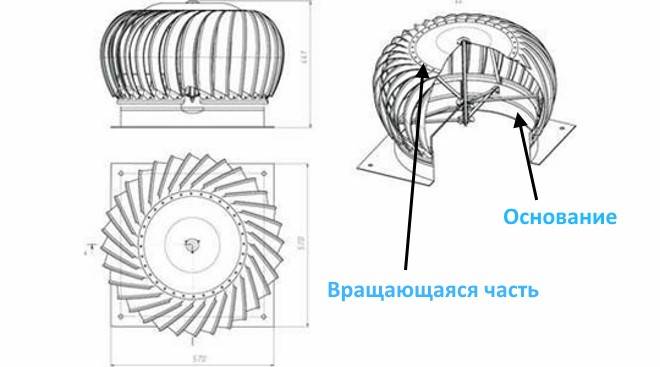

Internal structure and principle of operation

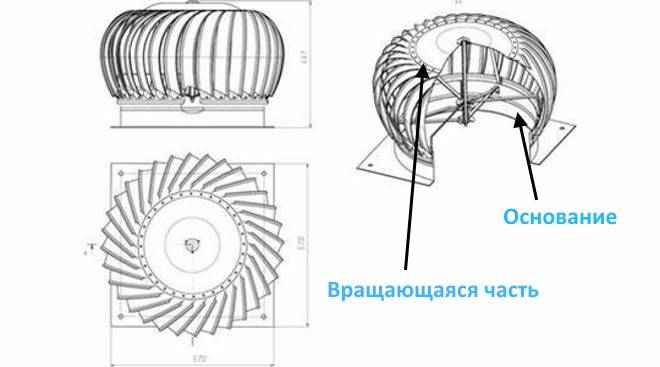

The deflector consists of two main parts:

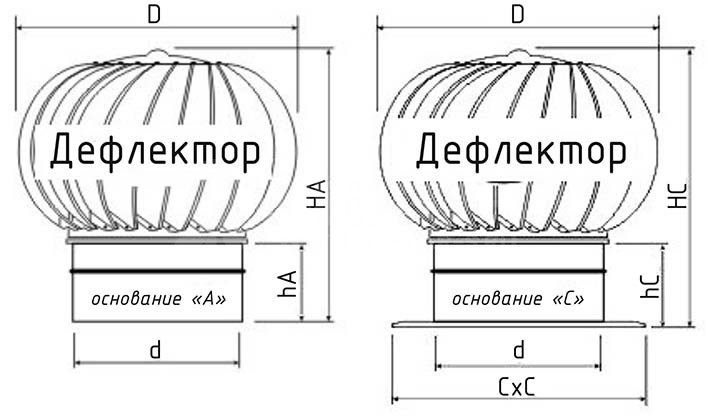

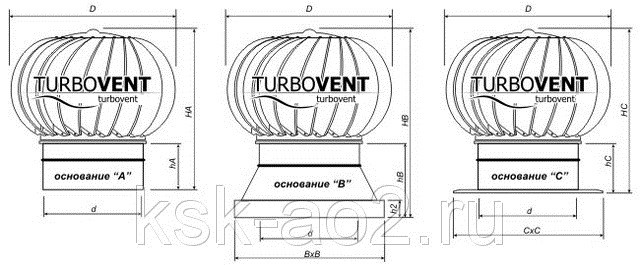

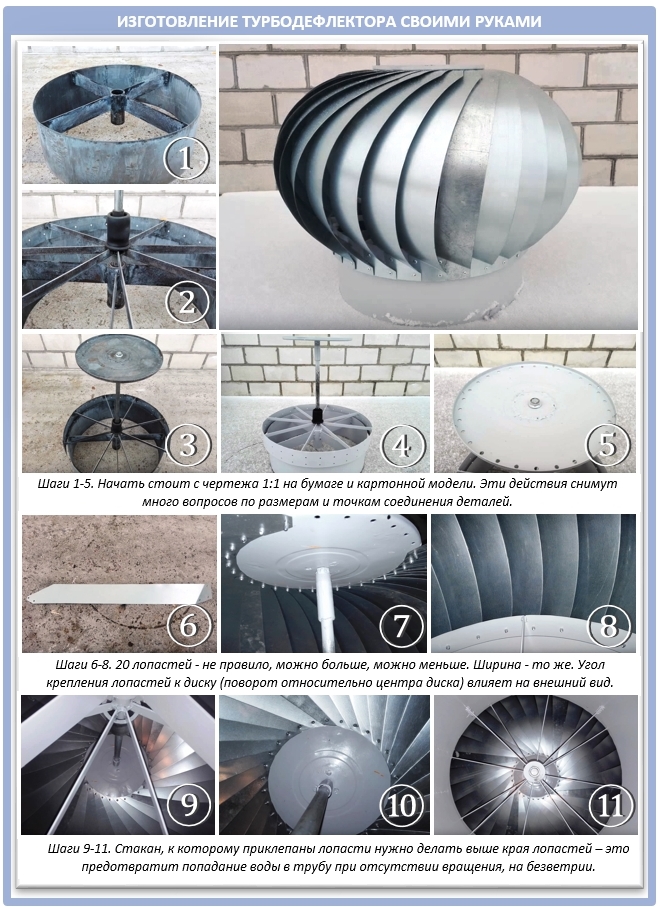

- The rotating head is the active part that directly rotates and creates a vacuum in the case. It consists of a base to which are attached special-shaped blades made of light materials, the thickness of which usually does not exceed 0.45-1.00 mm. The average number of blades is 20. The head is attached to the fixed body using a bearing with zero resistance. It is they who give the same rotation speed even with wind gusts.

- Fixed base. This is the part of the deflector that is the base for the head and at the same time is attached directly to the ventilation outlet pipe. It has a material wall thickness of 0.7-0.9 mm.

The mechanism begins its active work with a wind force of 0.5 m / s due to the use of light blades and high-quality bearings. The air flow, falling into the blades, causes the upper part to rotate. The higher the wind speed, the faster the head will rotate, increasing the overall efficiency of the ventilation system.

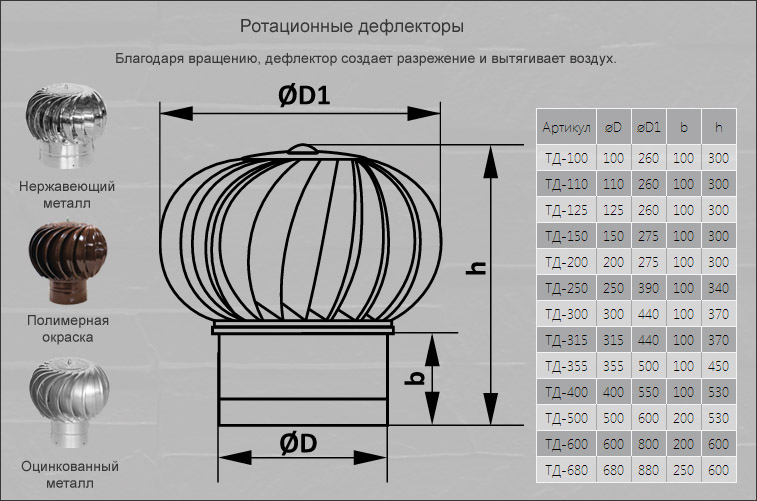

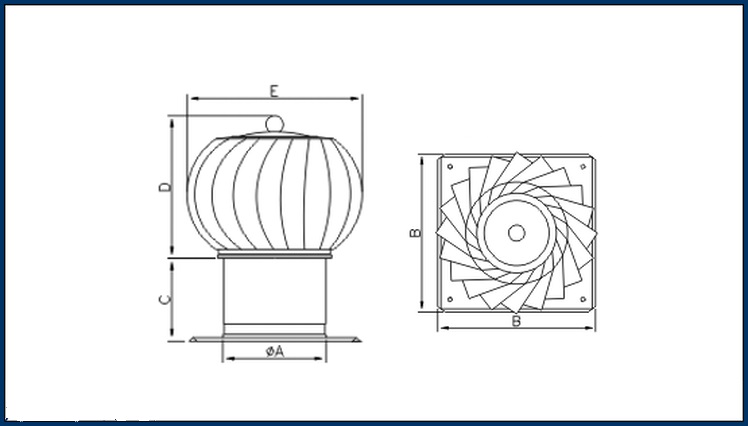

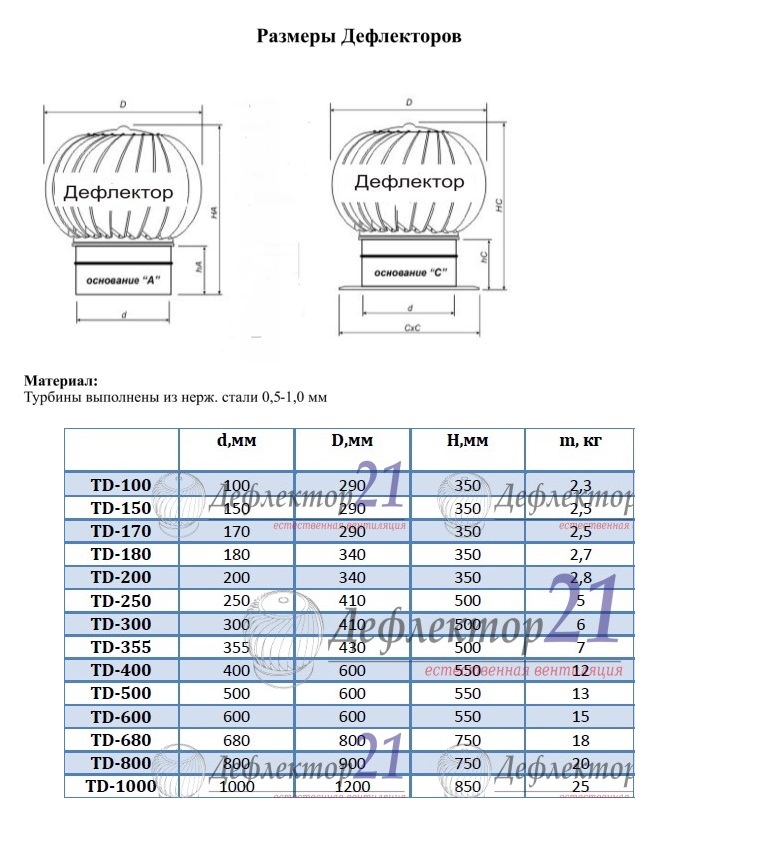

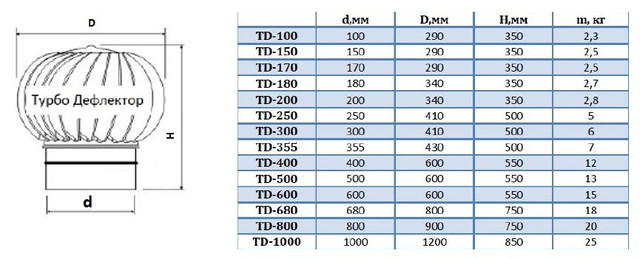

Products are produced by several companies and have a different designation. The marking often indicates the landing diameter or dimensions in the case of a rectangular ventilation shaft.

Frequently used diameters: from 100 mm to 200 mm - in increments of every 5 mm, as well as 250, 300, 315, 355, 400, 500, 600, 680, 800 mm.

The delivery set may also include a roof passage, under the slope level from 15° to 30°.

The marking and designation of turbo deflectors are individual for each manufacturer, for example:

- Production in the Karachay-Cherkess Republic. Made from stainless steel. It has the designation as ABT-xxx. See the table below for more details.

- Production from Arzamas, Nizhny Novgorod region. It has three letter designation markings - TA (for a round pipe), TV (square) and TC (flat square base). Further, the landing diameter or size of the rectangular channel is usually indicated.

Manufacturing materials

The bulk of finished products are made from three main materials:

- Galvanized or chromium-nickel sheet steel. Has a matte finish. The cheapest option.

- Stainless steel. It costs 1.5-2 times more expensive than galvanizing. Can be powder coated to match common roof colors (green, blue, brown and red).

- Structural steel coated with a protective polymer.This option is suitable for cottages, as the mechanism can be matched to the color of the roof or facade of the building.

The choice of material will depend mainly on your budget and personal preferences.

Device selection

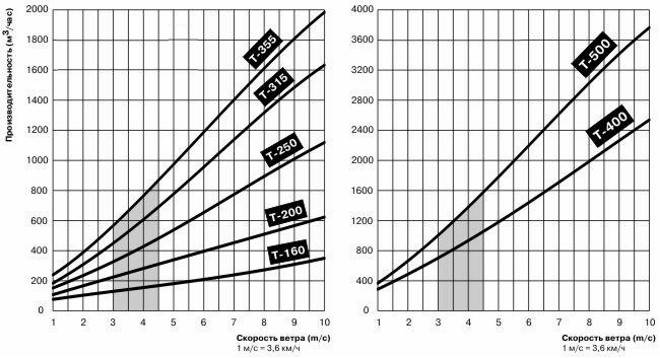

It is possible to select the product required in size, firstly, by the diameter of the base (depending on the air duct used), and secondly, by its performance. Each manufacturer presents the characteristics of their products. Consider them on the example of graphs:

As you can see, the required performance depends on the speed of the air masses. Knowing this speed in your location, choose the appropriate type of device.

Classification of wind nozzles

Despite the same purpose, exhaust hoods differ from each other.

When determining the optimal device model, it is necessary to evaluate:

- material of manufacture;

- principle of operation;

- structural features.

Manufacturing material. The production uses aluminum, stainless steel, galvanization, copper, plastic and ceramics.

Steel and aluminum products are considered the best solution in terms of cost/quality balance. Copper deflectors are rarely used due to their high cost.

Plastic models differ from their counterparts in a lower price, a variety of colors and shapes. Disadvantages of polymers: susceptibility to high temperatures and limited service life

A symbiosis of strength and decorativeness - combined caps made of metal, covered with plastic.

Principle of operation. Based on the functional features, ventilation devices are divided into 4 groups.

Types of deflectors:

- static nozzles;

- rotary deflectors;

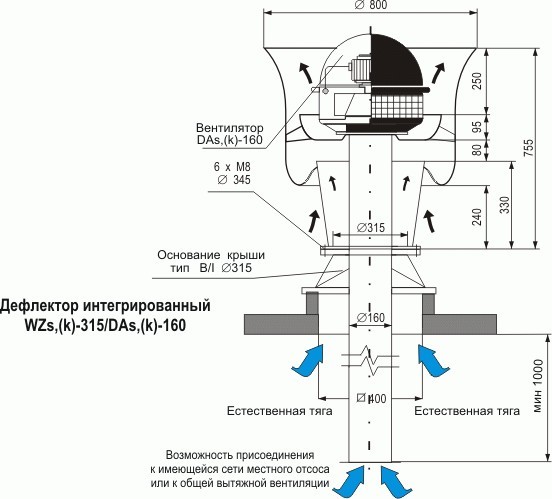

- static installations with an ejector fan;

- swivel models.

The first group includes models of the traditional type. Static deflectors are simple in design and can be self-assembled. The dampers are mounted on the exhaust shafts of residential and industrial aeration ducts.

The second group (rotary deflectors) are equipped with a system of rotating blades. The complex mechanism consists of an active head and a static base.

Gusts of wind cause the paddle drum to rotate. During operation, a vacuum is created at the mouth of the mine, preventing the appearance of reverse thrust.

Gusts of wind cause the paddle drum to rotate. During operation, a vacuum is created at the mouth of the mine, preventing the appearance of reverse thrust.

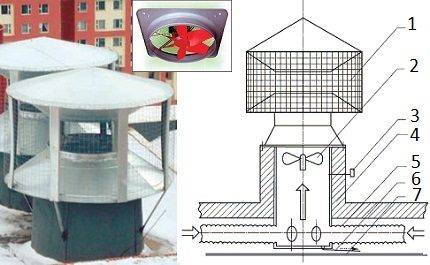

A static exhaust deflector with an ejector fan is a state-of-the-art technology. A fixed cap is installed at the end of the ventilation duct, and a low-pressure axial fan is mounted directly under it inside the shaft.

The device of the static-rotary model: 1 - static deflector, 2 - fan, 3 - pressure sensor, 4 - heat-insulated flask, 5 - noise-absorbing ventilation duct, 6 - drainage, 7 - false ceiling

Under normal ambient conditions, the system functions like a traditional static deflector. As the wind and thermal pressure decrease, the sensor is triggered - the axial fan is turned on and the thrust returns to normal.

An interesting development that deserves attention is an ejection-type deflector with a swivel body. The rotating cap is installed above the shaft.

The model consists of a horizontal and a vertical pipe, which are interconnected by a hinged mechanism. On top of the deflector there is a partition - a weather vane.

The horizontal pipe turns in the direction of the wind. The flows rush into the inner part and create a vacuum - the thrust at the mouth of the mine increases

Design features.Models with the same principle of inducing natural ventilation have some differences in the device.

Deflectors are open or closed, square or round, with one cap or several cone umbrellas. The characteristics of the most popular and effective modifications are described below.

Varieties of deflectors

To improve the operation of the ventilation system, there are many varieties of deflectors on the market. Some of them are static, others are rotational. It is the latter that include turbines, in which the impeller head rotates, functioning due to the force of the wind.

Note! Regardless of whether the deflector has a static body or a rotational one, they are all made to improve draft in a chimney or ventilation duct. They protect the system from precipitation and debris.

However, the turbo deflector can be called the most effective device with confidence.

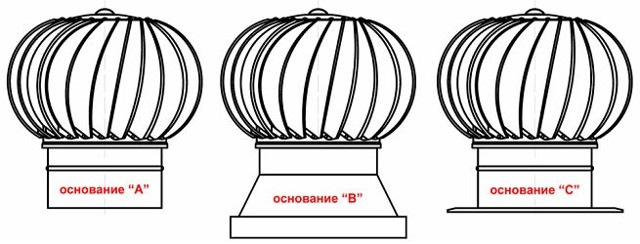

Rotary turbines can be classified according to the following parameters:

- Manufacturing material. Deflectors are made of stainless steel, galvanized or painted metal, aluminum.

- The diameter of the nozzle or connecting ring is at least 110 mm and maximum 680 mm. It is clear that the dimensions are identical to the diameter of the sewer pipes.

Despite the fact that manufacturers produce modifications of turbo deflectors, which outwardly practically do not differ from each other, their characteristics are different. Below is some information about these products:

- Turbovent. The company of the same name is engaged in the production of rotary ventilation products made of aluminum. Products have a thickness of 0.5 to 1 mm.The base is made of galvanized steel, 0.7 to 0.9 mm thick. The turbo deflector can be painted in any of the colors according to RAL standards;

- Turbomax. Manufacturers are selling, calling the products a natural traction supercharger. To create a deflector, steel is required, grade AISI 321, the thickness of which is 0.5 mm. Scope of use: both for natural ventilation systems, and for stove and fireplace chimneys. And this is not in vain, since the turbo deflector is able to withstand temperatures up to +250 ℃. The products are made from high quality stainless steel.

You can also find products from unknown brands on store shelves.

Such products must be purchased carefully, paying attention to the certificate. Better yet, make a turbo deflector for ventilation with your own hands. Need drawings and related instructions

Need drawings and related instructions.

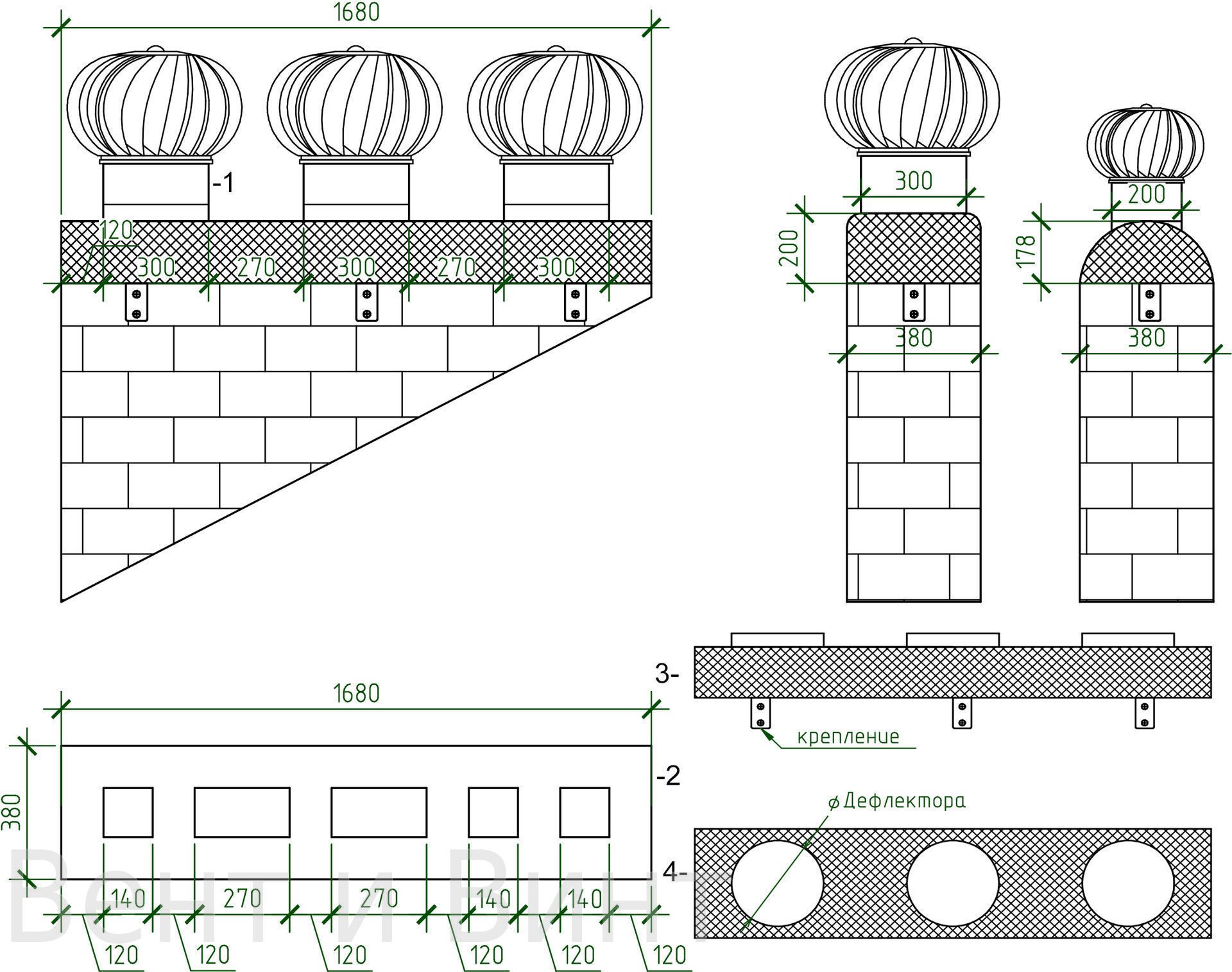

Mounting Features

The factory turbo deflector is a one-piece design, ready for installation. It has an active moving top and a base that includes zero drag bearings. The product is thought out in such a way that even with a strong gusty wind it will not tilt and will not be blown down.

Attention! During installation, it is important to take into account that the deflector of any modification should rise 1.5-2.0 m above the roof. If this device is observed, the draft in the ventilation duct will increase even more.

In conclusion, we want to note that rotary deflectors in their segment are the most expensive

In conclusion, we want to note that rotary deflectors in their segment are the most expensive

At the same time, the consumer is invited to choose a suitable design made of stainless steel, galvanized or structural steel with a protective polymer coating, the color of which can be matched to the facade design. Of course, the type of material from which the deflector is made is reflected in its cost.

In conclusion, we want to note that rotary deflectors in their segment are the most expensive. At the same time, the consumer is invited to choose a suitable design made of stainless steel, galvanized or structural steel with a protective polymer coating, the color of which can be matched to the facade design. Of course, the type of material from which the deflector is made is reflected in its cost.

Often, residents of private houses are faced with the problem of inefficient removal of combustion products in stoves, fireplaces or boilers. In such situations, there is a high risk of poisoning by combustion fumes, as a result of the cessation of the outflow of smoke. In most cases, this problem occurs due to strong gusts of wind, an incorrectly selected pipe diameter, or a clogged chimney. Such problems can be solved by a well-made and correctly installed deflector. It makes it possible to increase the efficiency up to 20%.

Before proceeding with the manufacture of a ventilation deflector, it is necessary to understand the principle of operation of this device. It consists in the occurrence of a low pressure zone as a result of the flow around the diffuser, in other words, in the redirection of air flows, due to which the intensity of the air masses increases and, accordingly, the thrust increases.

Making a Grigorovich deflector with your own hands

materials

For the manufacture of the Grigorovich deflector, it is necessary to prepare the following materials:

- A sheet of galvanized or stainless steel, the thickness of which should reach up to 1 mm.

- Metal rivets or bolts.

- Paper or thick cardboard to create a drawing of a future product.

- Scissors for cutting metal.

- Drill and drill bits for metal.

- Riveter.

Stages of creation

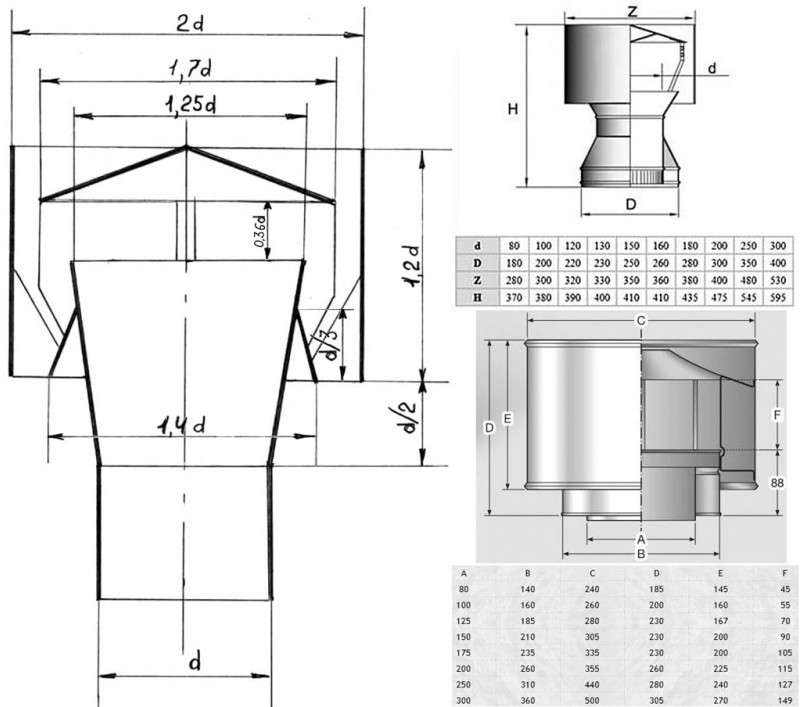

First you need to prepare a drawing on a sheet of drawing paper. As in the previous version, the inner diameter of the chimney is taken as the basis. Next, you need to calculate the following parameters in the ratios:

- The height of the structure should be approximately 1.7 times the diameter.

- The width of the protective Santa should be 2 times the inner diameter of the chimney.

- The width of the diffuser should be approximately 1.3 diameters.

After that, you need to prepare a drawing, which should look something like this:

Next, you need to cut out each piece of paper. Having previously fixed them on a steel sheet, circle the blanks and cut out the parts with metal shears.

Bend about 5 mm from each edge to secure the parts. Beat off each bend with a hammer, reducing its thickness by about 2 times. Drill 2-3 holes in them and connect the parts together so that the diffuser has the shape of a cylinder, and the protective umbrella is a cone.

As in the previous instructions, make several strips and use them to connect the cap and the diffuser itself.

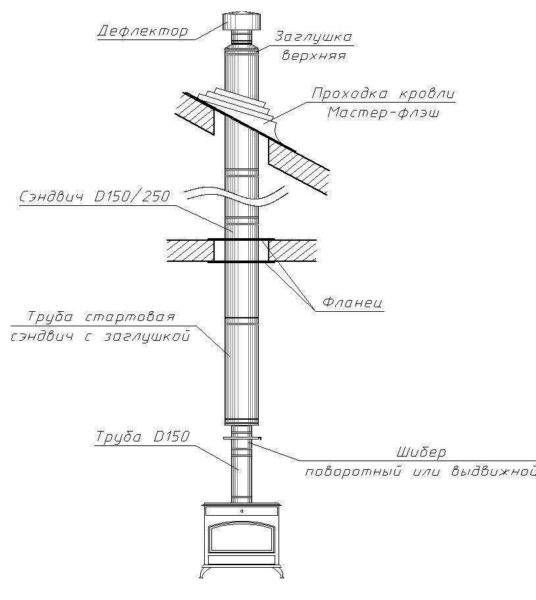

The need to install a chimney deflector

The functioning of the heating equipment is reflected in how air circulates in the system and smoke is eliminated. If these mechanisms are not debugged, then the process of fuel combustion is disturbed, carbon monoxide enters the room and causes serious damage to health.

Each part of the chimney must be installed correctly, otherwise the draft will be bad.

Each part of the chimney must be installed correctly, otherwise the draft will be bad.

It happens that the correct parameters of the chimney, that is, the cross section, height and configuration, are not able to normalize the operation of the stove or fireplace. In such a situation, they resort to a deflector installed on the upper section of the chimney.

An important mission is assigned to the deflector - to equalize or increase traction in heating equipment. The device’s assistant in this matter is the wind, which creates a space with rarefied air and pushes into it the combustion products that could not leave the smoke channel.

The deflector often saves the situation if traction cannot be improved by any other means.

The deflector often saves the situation if traction cannot be improved by any other means.

The deflector is also entrusted with some other tasks that contribute to improving the operation of the chimney as a whole. The device blocks the access of rainwater and snow to the heating equipment. Thanks to the deflector, the oven functions without interruption even on a rainy day.

Installation rules

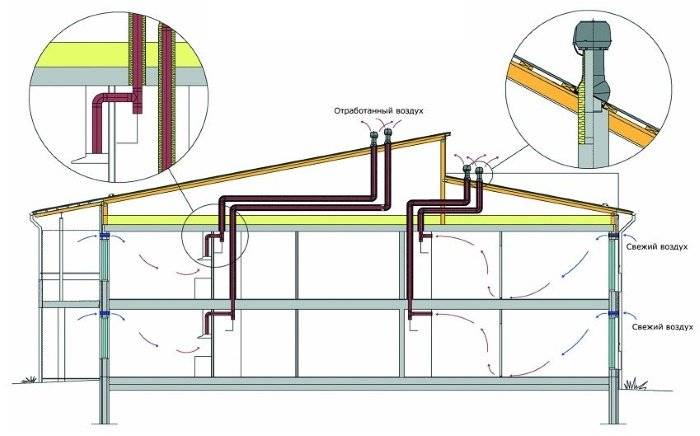

Installation of the turbo deflector is simple: first, the lower fixed part is attached to the clamp on the ventilation outlet (or chimney). Then a rotating head is attached from above. The process is simple, it’s realistic to do it with your own hands (neither an expensive tool is needed, nor specific experience either), the only difficulty is that it will be necessary to carry out installation on the roof.

Before installing the product, read the installation rules:

- After unpacking, you need to check how the device works. To do this, you need to put the turbo deflector on the street on any surface. When the wind blows, the turbine should spin.

- You need to check the work again after installation. After the deflector is mounted on the ventilation shaft. Wait for the wind to blow and see if the head spins.

Otherwise, the rules are the same as when installing a ventilation duct without a turbo deflector:

- If the ventilation duct is located at a distance of more than 3 meters from the ridge: its opening must be no lower than the conditional line passing from the horizontal line of the ridge down with a slope of 10º.

- If the ventilation duct is located at a distance of 1.5 to 3 meters from the ridge: its opening can pass at the level of the ridge.

- If the ventilation duct is located at a distance of up to 1.5 meters from the ridge: its opening should be at least 50 cm higher above the level of the ridge.

Possible problems and solutions

Despite the fact that the turbo deflector is extremely simple, it also needs maintenance and can also break.

Here are the main problems and how to fix them:

- Deterioration of work: slowdown of rotation, extraneous noise during rotation. A possible reason is mechanical damage (for example, if a tree grows near the house, a branch may fall on the deflector, or strong hail may bend the plates). In this case, you need to inspect the turbo deflector, if possible, dismantle and repair it.

- A sharp drop or complete absence of draft in the duct in severe frost. Possible cause is freezing. This can only be noticed during inspection (either climb to the roof, or from the ground - if the deflector is clearly visible). To solve the problem, you will either have to wait for the temperature to rise, or go upstairs and clean the product from ice.

- Full stop of rotation, slowdown of rotation.A possible reason is that the bearings are jammed (if no other damage is visually visible). In this case, the turbine will have to be removed and the bearings lubricated or replaced.

Litol is suitable for lubricating bearings. To update the lubricant, you need:

- Remove turbine.

- Using a puller, loosen the retaining ring.

- Bearings - lubricate (or replace, if necessary), and assemble and install the product in place.

Can it be installed on a chimney

By installing a deflector, unlucky homeowners are trying to solve the problem of lack of traction. This happens when the chimney is not made correctly - the head has fallen into the area of \u200b\u200bthe wind support of the roof, raised to a low height, or a neighbor built a tall building nearby.

The best solution for insufficient draft is to raise the chimney to the desired height. Why it is undesirable to put various nozzles on the head:

- It is forbidden to put umbrellas and other exhaust devices on the pipes that discharge the products of combustion of gas boilers. These are safety requirements.

- During combustion, stoves and solid fuel boilers emit soot that settles on the inner surfaces of chimneys and hoods. The deflector will have to be cleaned, especially the rotating one.

- At the bottom of a properly constructed smoke channel, there is a pocket for collecting condensate and excess moisture. It is pointless to close the pipe from precipitation; it is enough to attach a nozzle to the end that protects the sandwich insulation.

The heads of furnace gas ducts can be equipped with umbrellas, but a turbo deflector is definitely not needed there. The topic of mounting caps on chimney ducts is described in detail in a separate material.

Advantages and disadvantages of turbo deflectors

What will a user get who makes a ventilation turbo deflector with his own hands or buys it? A lot of advantages and only positive impressions about his work. Here are the advantages that a product for ventilation or a chimney has:

- The head of the turbo deflector, which rotates, enhances the air exchange in the ventilation or chimney. There is no reverse draft, and the under-roof space does not accumulate condensate. In addition, the rotary device works much better than a conventional deflector.

- The product runs exclusively on wind energy, without consuming electricity. Therefore, there will be no extra costs, unlike the use of electric fans.

- If the equipment is properly cared for and installed correctly, the service life will be 10 years, or 100,000 hours of operation. If you take stainless steel turbo deflectors, then their service life is 15 years. In comparison, the fans work 3 times less.

- Snow, hail, rain, foliage, rodents will not get into the ventilation duct. The turbo deflector is used in areas with strong and frequent gusts of wind.

- The design of the equipment is light, convenient and compact. Turbo deflectors with a diameter of 20 cm or more have a weight slightly less than that of the TsAGI deflector. Products of large size, which is 680 mm, have a weight of approximately 9 kg. To understand the difference, let's say that a TsAGI deflector of the same diameter has a weight of up to 50 kg.

- Ease of installation. Even a beginner can handle this task. You only need instructions and a standard set of tools.

This is why turbo deflectors are so commonly used.But along with the advantages, the products also have some disadvantages:

- when compared with other types of deflectors, the turbo deflector is somewhat more expensive. True, if you do it yourself, then it will be cheaper;

- under adverse atmospheric conditions, for example, if there is no wind, low temperature or high humidity, the device may simply not work and stop. But if the deflector is constantly in motion, then it is less susceptible to icing;

- the use of a deflector for rooms with increased ventilation requirements, such as a medical laboratory, production rooms, buildings with chemicals, cannot be considered the only remedy. You still need to install fans.

Depending on the material of manufacture, the price of the device can be quite high. Yet these shortcomings are very few, so many people prefer to use a deflector for their ventilation system.

Price

The cost of a turbo deflector directly depends on the material from which it is made and the size of the connecting channel. Devices made of galvanized steel are somewhat cheaper than models made from stainless steel. The average cost of a galvanized rotary turbine starts from 2 thousand rubles, and stainless - from 3 thousand rubles.

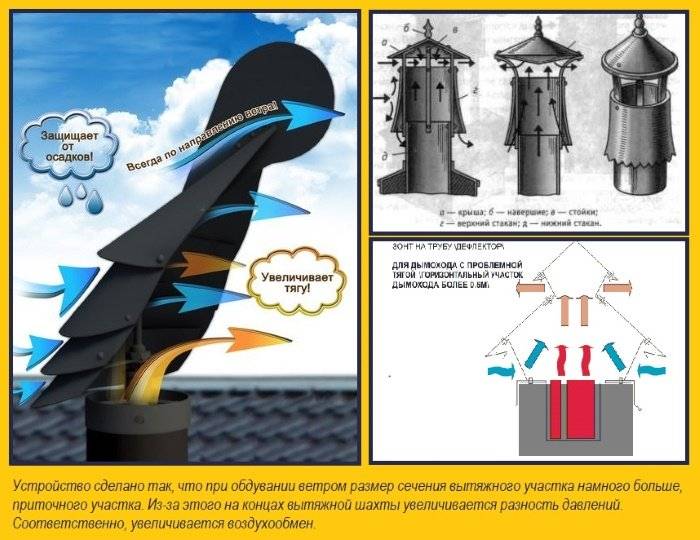

The principle of operation of the ventilation deflector

The ventilation deflector works according to a simple principle, regardless of the design and model of the device:

- directed wind currents hit the metal hulls;

- due to diffusers, the air branches, as a result of which the pressure level decreases;

- in the pipe of the system, the thrust increases.

The principle of operation of the device

The greater the resistance created by the base of the case, the more efficient the outflow of air in the channels of the systems. It is generally accepted that the device installed on the roof at a slight inclination to the horizontal plane works better. Experts state that the effectiveness of these devices is determined by 3 factors:

- the design and shape of the hull;

- unit size;

- installation height.

No matter how reliable and high-quality ventilation deflectors are, they have both advantages and disadvantages, which I would like to dwell on in more detail.

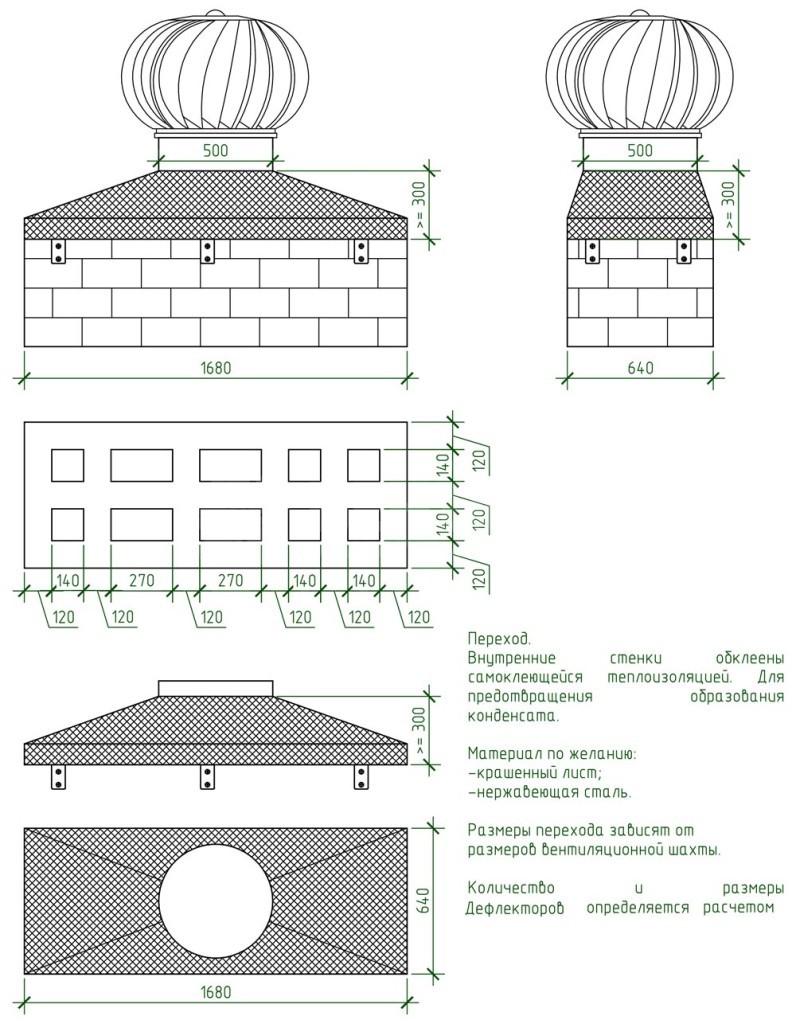

Mounting ventilation passage through roofing

2.1

About the "pros" and cons of deflectors

As mentioned above, umbrella solutions can effectively prevent dirt and precipitation from entering the air ducts. With proper selection and professional installation of the deflector, ventilation improves. The efficiency of the system as a whole is increased by 20%.

The ventilation device helps to create or increase air draft in the exhaust ventilation ducts

The devices are not without drawbacks: with a vertical wind direction, the flow comes into contact with the upper section of the structure, while the air cannot be fully discharged into the street. To eliminate such an effect, designs with 2 cones were invented. In winter, frost appears on the base of the pipes, so it is necessary to regularly carry out preventive examinations.

Cellar ventilation

Types of deflectors

There are several types of deflectors. They differ from each other in form and number of details. In this case, the materials that are used to create them, you can choose to your taste. It could be:

- Copper

- Cink Steel

- Stainless steel

Their shape can be very diverse: from cylindrical to round. The upper part of the deflector structure can have a cone-shaped umbrella or a gable roof. Also, the device can be equipped with various decorative elements, for example, a weather vane.

Let's take a closer look at a few varieties:

TsAGI deflector

A structure whose parts are connected by a flange or otherwise. Such a device is made of stainless steel, less often - of galvanized. Its feature is a cylindrical shape.

Round Wolper

In its form it resembles the TsAGI deflector, but its main difference is the upper part. Such a device is most often installed on chimneys in small outbuildings, for example, in baths.

Grigorovich deflector

If the facility is located in an area with low wind, then such a device will provide excellent traction for many years. Experts call it a modified version of the TsAGI deflector.

Poppet Astato

This type of device is distinguished by its simplicity and efficiency. Such an open type deflector is made of galvanized or stainless steel, which improves the efficiency of traction in any wind direction.

H-shaped deflector

Its design is particularly reliable, as the deflector is made of stainless steel, and all parts are connected by a flange method. It can be installed in areas with any wind direction.

Weather vane-deflector

This version of the device is the most popular and widespread. It has a rotating body, on which a small weather vane is fixed. Manufactured from stainless steel construction.

Rotating deflector

Such a device allows you to provide maximum protection of the channel from clogging with debris and precipitation. Rotation is in one direction only. It is worth noting that it is necessary to monitor its condition, since during icing, as well as in calm, the deflector will not work. Therefore, many install it on gas boilers. It is also used as a rotary turbine, which is necessary for the ventilation of residential and office visits.

In addition, there is a Khanzhonkov deflector. However, it is not currently used, as more modified device models can be found on the market.