- Which boiler is better to choose?

- Types of gas boilers

- Single and double circuit

- Wall and floor

- Condensing and convection (traditional)

- With open and closed type combustion chamber

- Advantages and disadvantages of wall-mounted gas boilers

- TOP-10 rating

- Buderus Logamax U072-24K

- Federica Bugatti 24 Turbo

- Bosch Gaz 6000 W WBN 6000-24 C

- Leberg Flamme 24 ASD

- Lemax PRIME-V32

- Navien DELUXE 24K

- MORA-TOP Meteor PK24KT

- Lemax PRIME-V20

- Kentatsu Nobby Smart 24–2CS

- Oasis RT-20

- Single and double circuit boilers

- Principle of operation

- Advantages and disadvantages

- Pros and cons

- Types of gas boilers

- With open combustion chamber

- With closed combustion chamber

- single circuit

- Dual circuit

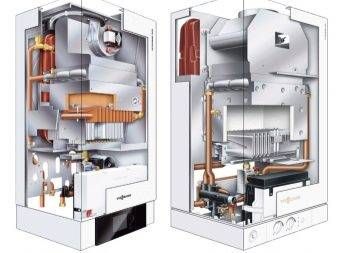

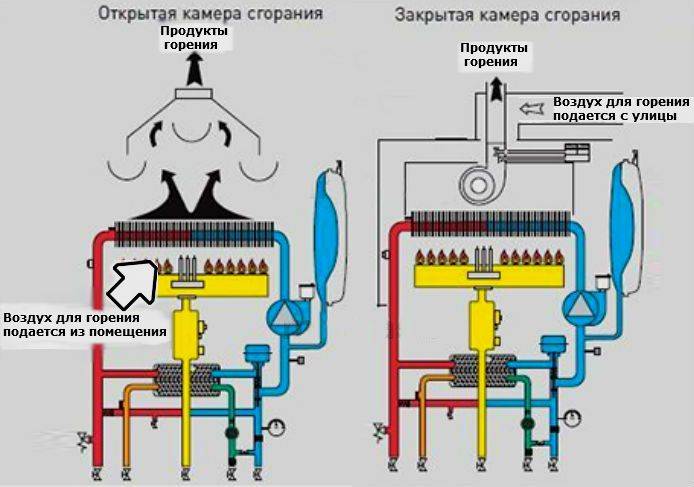

- Combustion chambers of gas boilers and their features

- Turbocharged gas boilers

- Traditional chimney gas boilers

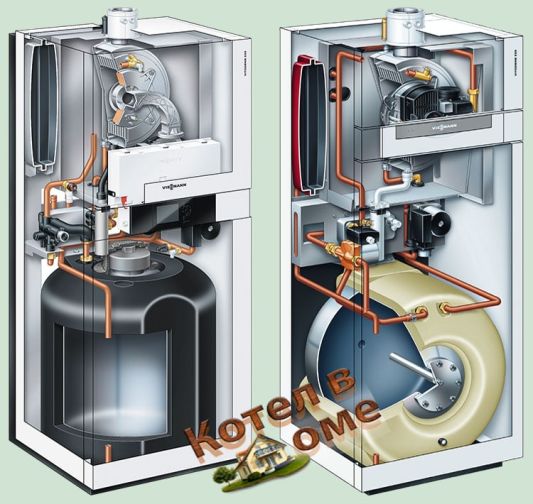

- Floorstanding turbocharged boilers

- The best wall-mounted atmospheric gas boilers

- BaxiECO4s

- Dakon

- NavienAce

Which boiler is better to choose?

In addition to the main technical characteristics and price, the choice of a heating unit is influenced by the operating conditions and recommendations of specialists who regularly service gas-using installations in private homes.

Taking into account practical experience in the field of heating private housing and reviews of various types of natural gas heating equipment, we give the following recommendations for choosing a heat source:

The most budget option for small houses (up to 150 m²) is a parapet non-volatile boiler with a straight chimney that goes through the wall. These are produced with limited power - up to 15 kW. Under it, you do not have to specially build a chimney.

There are situations when a suspended heat generator cannot be installed for various reasons, for example:

- in the kitchen, the walls are occupied by cabinets and household appliances;

- the building structure or its finish does not allow hanging a unit weighing 50 kg or more;

- there is no space on the walls in the boiler room or it is difficult to bring pipelines.

Then it remains to purchase a floor boiler of similar power and mount it in a convenient place. When we have decided on the installation method, we proceed to the choice of the heating installation according to the principle of operation.

Types of gas boilers

Heating units have individual parameters that will help you choose the perfect option. When choosing equipment, the area of \u200b\u200bthe heated room plays an important role.

Depending on this, specific models should be considered.

Single and double circuit

Single-circuit type heaters are designed specifically for small spaces. Thermal equipment is designed for heating the coolant with autonomous heating. A big advantage is that wall models take up little space. The system performs two important functions:

- heating of a private house;

- water heating.

Due to the presence of such capabilities in one device, a double-circuit boiler is in great demand and is considered the best-selling device. It is compact in shape and does not take up much space.

Wall and floor

Gas heating double-circuit boilers are found in two types:

- wall;

- floor.

They differ in parameters, and the functions remain almost the same. Wall-mounted double-circuit boilers are small, roomy and have a good ability to heat both housing and water. However, such a device is more suitable for an apartment or a cozy cottage.

Floor structures are large-sized units that require installation in a separate room. The connection of the boiler itself is simple, as well as operation. Typically, outdoor equipment is used only for heating a large private house, where water is heated using an additional boiler.

Condensing and convection (traditional)

The condensing double-circuit boiler is a relatively new piece of equipment. The principle of operation is the intentional formation of condensate. Moisture passes into a gaseous state, and the thermal energy released in this case is spent on heating the coolant. Thus, the cost of energy generation due to fuel combustion is significantly reduced.

The convection device works according to a simple principle: how much gas is burned, so much energy is released. Unlike a condensing boiler, in this model, the release of even a small amount of moisture can damage all equipment.

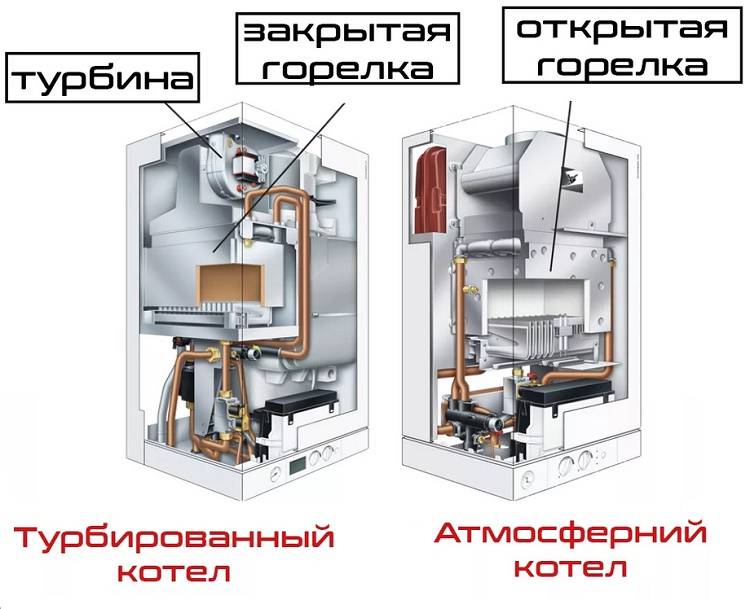

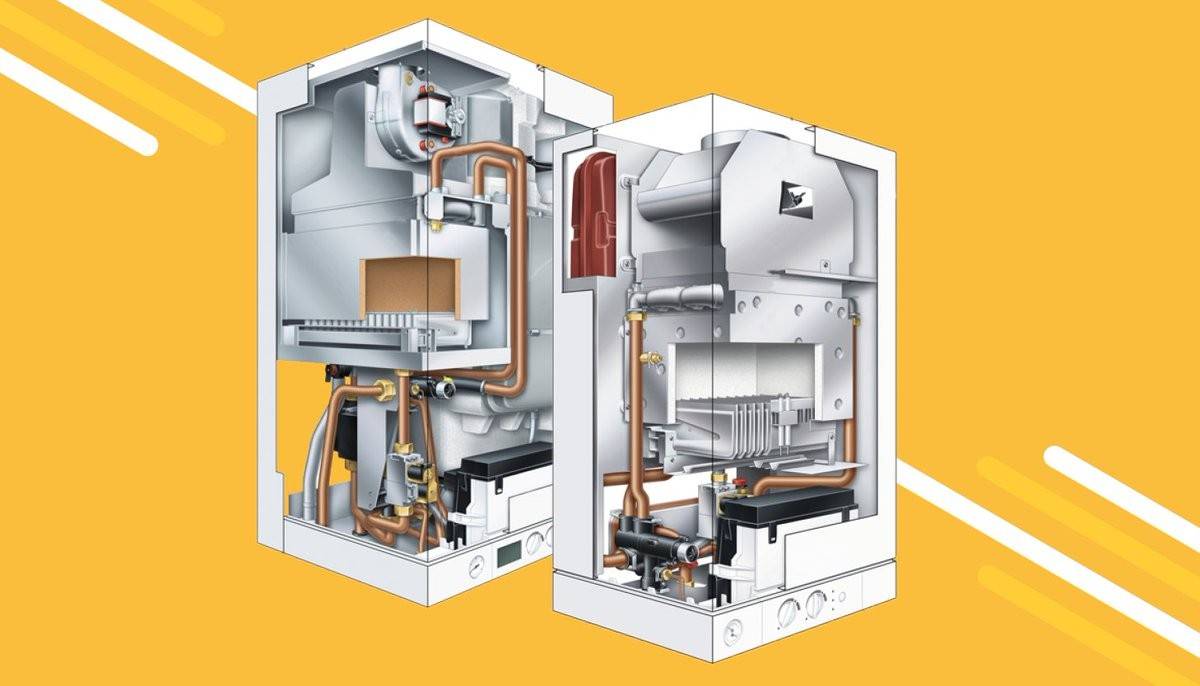

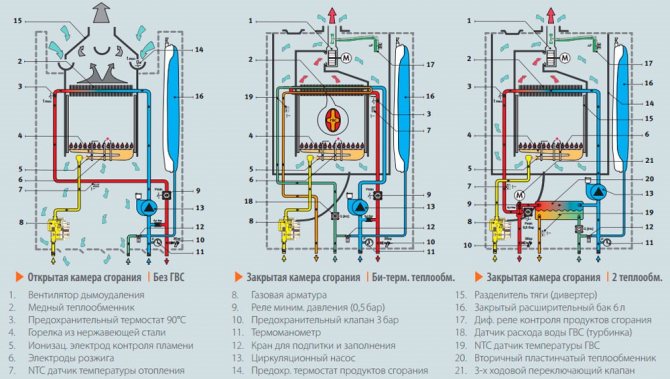

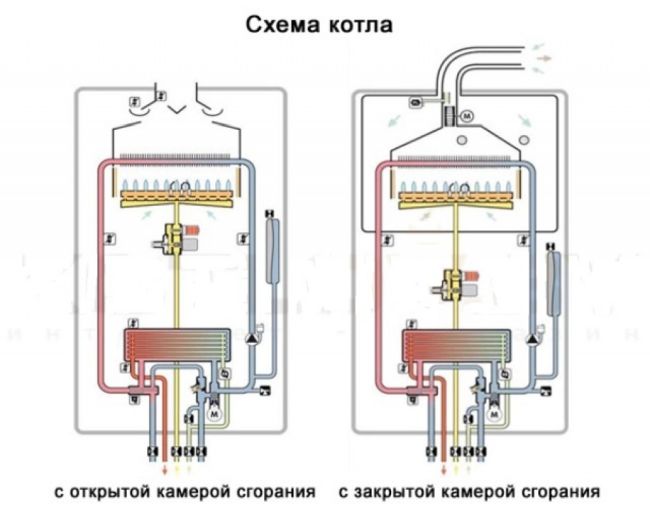

With open and closed type combustion chamber

Heating appliances with an open combustion chamber are called atmospheric burners.They have found application in boilers up to 70 kW. The heat exchanger is installed above the combustion chamber. Modern models are equipped with automation, which reduces the risk of fire. Wall-mounted double-circuit boilers are equipped exclusively with atmospheric burners.

Fan burners or those with a closed combustion chamber can be used for heating residential and industrial buildings. Water flows between the walls of the tank (burner). Thanks to the complete isolation of the flame, the device becomes safer. A large amount of energy is expended on the operation of the fan, so boilers of this type will increase material costs.

Advantages and disadvantages of wall-mounted gas boilers

Being interested in which boiler is better, you need to study all the pros and cons of wall-mounted devices. Their key advantage is the almost complete automation with the help of volatile systems.

The design provides for the presence of a pump and an expansion tank. There are many small elements and parts that contribute to the efficient and economical operation of the equipment.

Wall mounted boiler option in the kitchen

The units are highly economical, and the difference in energy savings with wall-mounted boilers reaches 10-15%. Similar results are typical for models operating on the principle of condensation and equipped with a turbocharger. Other benefits include:

- Compact overall dimensions and weight. The medium power model weighs no more than 50 kg and has small dimensions, which simplifies the installation and maintenance process. The presence of an installation in the bathroom or in the kitchen does not impair the organic style of the interior, since it does not differ from a simple wall cabinet.Modern products have a presentable design and fit into any style of the room.

- Possibility of mounting the unit with a closed combustion chamber in any part of the outbuilding.

- Good work productivity. The main market share is occupied by double-circuit boilers, which are able to heat the building and at the same time solve the problems of hot water supply.

- Ease of choice. Even an inexperienced consumer can calculate the kW power for every 10 m².

- Optional installation of additional devices. Modern manufacturers market products with a closed combustion chamber, so coaxial chimneys are already included. They are a small carbon monoxide exhaust pipe that does not take up much space, but demonstrates high performance.

- Wide functionality - modern units operate on the basis of weather-dependent automation, are able to connect to the Internet and are controlled by a remote control or a smartphone.

Among the shortcomings, there are a number of costs for arranging a complete set and using automation with a microprocessor chip. Because of this, a wall-mounted boiler is used less often than a floor-standing one, because. For many consumers, cost is a key selection criterion.

When choosing between wall and floor units, it is necessary to take into account such disadvantages of the first type of systems:

- Energy dependence. There are 1-2 circulation pumps installed in the boiler, which work non-stop. Another design provides for the presence of sensors and automation, which require a constant voltage.

- The microprocessor reacts negatively to interference in the network.Any jumps or failures contribute to the combustion of the controller, which entails the need for expensive repairs.

- The equipment is equipped with complex automation systems, which often fail and fail. Restoring them with your own hands is problematic, and there are few experts involved in setting up and repairing equipment.

TOP-10 rating

Consider the most popular models of double-circuit gas boilers, recognized by experts and ordinary users as the most successful in terms of design and operation:

Buderus Logamax U072-24K

Gas double-circuit boiler designed for wall mounting. Equipped with a closed-type combustion chamber and a separate heat exchanger - primary copper, secondary - stainless.

Heating area - 200-240 m2. It has several levels of protection.

Models with the index "K" perform heating of hot water in flow mode. It is possible to connect a room temperature controller.

Federica Bugatti 24 Turbo

Representative of Italian heat engineering, wall-mounted double-circuit gas boiler. Designed to work in a cottage or public space up to 240 m2.

Separate heat exchanger - copper primary and steel secondary. The manufacturer gives a 5-year warranty period, which indicates confidence in the quality and operational capabilities of the boiler.

Bosch Gaz 6000 W WBN 6000-24 C

The German company Bosch is known all over the world, so it does not need additional introductions. The Gaz 6000 W series is represented by wall-mounted models designed for operation in private homes.

The 24 kW model is the most common, it is optimal for most residential and public buildings.

There is a multi-stage protection, the copper primary heat exchanger is designed for 15 years of service.

Leberg Flamme 24 ASD

Leberg boilers are usually referred to as budget models, although there is no noticeable difference in cost with the products of other companies.

The Flamme 24 ASD model has a power of 20 kW, which is optimal for houses of 200 m2. A feature of this boiler is its high efficiency - 96.1%, which is noticeably superior to alternative options.

Works on natural gas, but can be reconfigured to liquefied gas (replacement of burner nozzles is required).

Lemax PRIME-V32

Wall-mounted double-circuit boiler, the power of which allows you to heat 300 m2 of area. It is suitable for two-story cottages, shops, public or office spaces.

Produced in Taganrog, the basic technological principles of assembly were developed by German engineers. The boiler is equipped with a copper heat exchanger providing high heat transfer.

It is calculated on operation in difficult technical conditions.

Navien DELUXE 24K

Korean boiler, the brainchild of the famous company Navien. It belongs to the budget group of equipment, although it demonstrates high performance.

It is equipped with all necessary functions, has a self-diagnosis system and frost protection. The power of the boiler is designed to work in houses up to 240 m2 with a ceiling height of up to 2.7 m.

Mounting method - wall, there is a separate heat exchanger made of stainless steel.

MORA-TOP Meteor PK24KT

Czech double-circuit gas boiler, designed for hanging installation. Designed for heating 220 m2. It has several degrees of protection, blocking in the absence of liquid movement.

It is possible in addition to connect an external water heater, which greatly expands the possibilities of supplying hot water.

Adapted to unstable power supply voltage (permissible fluctuation range is 155-250 V).

Lemax PRIME-V20

Another representative of domestic heat engineering. Wall-mounted double-circuit gas boiler, designed to service 200 m2.

The modulating burner makes it possible to distribute fuel more economically by changing the gas combustion mode depending on the intensity of the coolant circulation. It has a separate stainless steel heat exchanger, can be connected to a room thermostat.

There is a possibility of remote control.

Kentatsu Nobby Smart 24–2CS

Japanese wall mounted gas boiler providing heating of 240 m2 and hot water supply. Model 2CS is equipped with a separate heat exchanger (primary copper, secondary stainless).

The main type of fuel is natural gas, but when changing jets, it can be converted to the use of liquefied gas. Most of the performance characteristics correspond to European boilers of similar power and functionality.

It is possible to use several design options for the chimney.

Oasis RT-20

Wall-mounted double-circuit gas boiler of Russian production. Designed to work in rooms of about 200 m2. Equipped with an efficient copper heat exchanger and a stainless secondary assembly.

The combustion chamber is of a turbocharged type, there is a built-in expansion tank and a condensate trap.

With an optimal set of functions and high build quality, the model has a relatively low price, which ensures its demand and popularity.

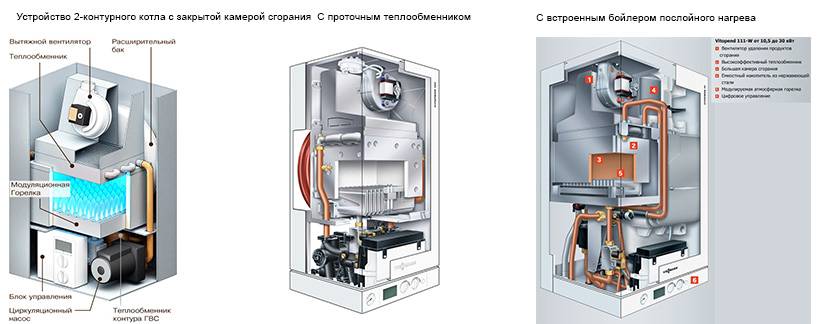

Single and double circuit boilers

By the number of circuits, gas boilers are: single-circuit and double-circuit.

Single-circuit boilers are designed for heating an apartment or house. They are connected to a battery system and the devices heat water exclusively for them. Such a unit is not capable of heating water for washing dishes or taking a shower, this will need to be taken care of separately.

Double-circuit boilers can be used both for heating your home and for heating water for various domestic needs, since they have an additional heat exchanger. This device also comes in two types:

- Flow type heat exchanger - they have a "DHW priority" mode. If you want, for example, to take a shower, then you just need to set this mode and the boiler will switch to the second DHW circuit. In such instances, heat exchangers with low power, so they are only suitable for small houses and apartments.

- Boilers with a built-in storage boiler - in such devices, the tank volume is from 160 to 180 liters, so they can heat water both in storage mode and in flow mode.

You can read about the types of heat exchangers for a gas boiler here.

Principle of operation

In single-circuit boilers, there is only one heat exchanger, which heats water only for the heating system of your home.

In units with one circuit, the main part is the combustion chamber, it contains a coil and a burner. Above the coil is directly the heat exchanger itself. The liquid can circulate naturally or with the help of a circulation pump.

The double-circuit heat exchanger is initially equipped with an auxiliary boiler for domestic hot water. Water from the cold water supply system is heated thanks to the hot coolant of the primary circuit responsible for heating. The device has a special valve that monitors the direction in which the coolant moves.

The operation of all double-circuit boilers is based on the principle of priority of the DHW system. This means that the moment you open a hot water tap, the boiler will immediately stop heating water for heating and start heating it for hot water supply.

It follows from this that two circuits cannot do work at the same time. During water heating, the circuit that is responsible for heating does not work. And it will start functioning only at the moment when you close the tap with hot water.

Advantages and disadvantages

When choosing units with one or two circuits, it is worth familiarizing yourself with the advantages and disadvantages of each of the devices.

Advantages of single-circuit boilers:

- lower price than double-circuit;

- operation does not depend on the pressure in the water supply;

- high power and efficiency;

- consume significantly less gas than double-circuit ones.

Heating and hot water supply system with single-circuit gas boiler and indirect heating boiler

Cons of boilers with one circuit:

- are intended only for space heating; in order to heat water, a special indirect heating boiler must be installed;

- it is necessary to equip a special place where the boiler will be installed;

- more complex binding.

Boilers are indirect, direct and combined heating.

Advantages of double-circuit boilers:

- not bulky, so there will be no difficulties with installation;

- ease of use;

- economical, because heat exactly the amount of water that is required.

Cons of boilers with two circuits:

- Inconsistency in the temperature of the water in the hot water supply. This is due to the fact that when the tap is opened, the water will only begin to heat up, so you will have to wait for some time until the water of the required temperature begins to flow. In addition, the device does not have high power, due to which the water pressure may be weak. Units with one circuit and a boiler do not have such difficulties.

- More expensive than single-circuit boilers WITHOUT a boiler.

- Not economical, since the second circuit is turned on only at the moment when the water flow is very noticeable.

Pros and cons

The advantages of floor boilers include:

- no restrictions on the power of the unit;

- strength, reliability of all components and parts;

- ease of installation;

- stability of work, the ability to maintain a given mode regardless of external conditions;

- lack of unnecessary additions;

- powerful models can be connected in a cascade of up to 4 units, forming high-performance thermal units.

The disadvantages of floor structures are:

- large weight, size;

- the need for a separate room;

- for atmospheric models, connection to a common house chimney is required

IMPORTANT!

In addition to a separate room, for floor-standing boilers, it is necessary to provide the possibility of connecting to a vertical chimney or leading a horizontal pipe through the wall.

Types of gas boilers

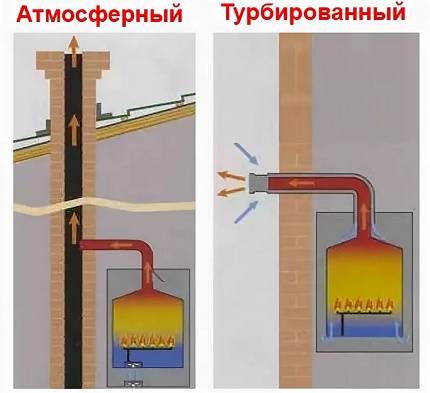

With open combustion chamber

Boilers with an open combustion chamber use air to maintain the fire, which comes directly from the room with the equipment located there. Removal is carried out using natural draft through the chimney.

Since a device of this type burns a lot of oxygen, it is installed in a non-residential specially adapted room with a 3-fold air exchange.

These devices are absolutely not suitable for apartments in multi-storey buildings, since ventilation wells cannot be used as chimneys.

Advantages:

- simplicity of design and, as a result, low cost of repair;

- no noise during operation;

- a wide range of;

- relatively low cost.

Flaws:

- the need for a separate room and chimney;

- unsuitable for apartments.

With closed combustion chamber

For units with a closed firebox, there is no need for a specially equipped room, since their chamber is sealed and does not come into direct contact with the internal air space.

Instead of a classic chimney, a horizontal coaxial chimney is used, which is a pipe in a pipe - one end of this product is attached to the appliance from above, the other goes out through the wall. Such a chimney works simply: air is supplied through the outer cavity of the two-pipe product, and exhaust gas is removed through the inner hole using an electric fan.

This device can be installed both in apartments and houses, and in any room convenient for operation.

Advantages:

- no need for a special room;

- operational safety;

- relatively high environmental friendliness;

- simple installation;

- ease of use.

Flaws:

- dependence on electricity;

- high noise level;

- High price.

single circuit

A single-circuit boiler is a classic heating device with a local purpose: preparation of a coolant for a heating system.

Its main feature is that in the design, among the many elements, only 2 tubes are provided: one for the entry of cold liquid, the other for the exit of the already heated one. The composition also includes 1 heat exchanger, which is natural, a burner and a pump that pumps the coolant - in the case of natural circulation, the latter may be absent.

When installing hot water, an indirect heating boiler is connected to the CO system - given the possibility of such a prospect, manufacturers produce boilers that are compatible with this drive.

Advantages:

- relatively low fuel consumption;

- simplicity in design, maintenance and repair;

- the possibility of creating hot water using an indirect heating boiler;

- acceptable price.

Flaws:

- used only for heating;

- for a set with a separate boiler, a special room is desirable.

Dual circuit

Double-circuit units are more complicated - one ring is intended for heating, the other for hot water supply. The design can have 2 separate heat exchangers (1 for each system) or 1 joint bithermic. The latter consists of a metal case, an outer tube for CO and an inner tube for hot water.

In the standard mode, water, heating up, is supplied to the radiators - when the mixer is turned on, for example, washing, the flow sensor is triggered, as a result of which the circulation pump turns off, the heating system stops working, and the hot water circuit starts to function. After closing the tap, the previous mode resumes.

Advantages:

- providing hot water to several systems at once;

- small dimensions;

- simple installation;

- affordable cost;

- the possibility of local shutdown of heating for the season "spring-autumn";

- a large selection, including design;

- ease of use.

Flaws:

- DHW flow diagram;

- accumulation of salt deposits in hard water.

Combustion chambers of gas boilers and their features

The combustion chambers of these types of boilers have significant differences in their design. This determines the way carbon monoxide is removed from them.

Turbocharged gas boilers

Here, “closed” combustion chambers are used to burn gas. Their peculiarity is that the cavity of the chamber does not communicate with the air of the room in which the boiler is installed. What does it give? The fact is that for normal gas combustion, air oxygen is needed in the required amount (for normal combustion of 1 m3 of gas, 10 m3 of air is needed) and it must be taken somewhere. So in this case, it is taken forcibly not from the room, but directly from the street it is sucked in by a fan. This allows not to arrange an influx of fresh air for the boiler and not to place it in a specially allocated and equipped with ventilation room. That is, in accordance with the technical requirements, such a gas boiler has more opportunities at the place of its installation in a house or apartment.

Traditional chimney gas boilers

Boiler with an open combustion chamber

These designs have an "open" (sometimes called "atmospheric") combustion chamber. It communicates with the air in the room where the gas boiler is located and the necessary amount of air for burning gas will be absorbed naturally during the operation of the gas burner of the boiler. That is, the oxygen of the air will gradually be consumed and its constant replenishment is necessary. For this, supply and exhaust ventilation is needed.Its device must solve this problem, otherwise the normal operation of the gas boiler is both impossible and dangerous.

When there is a lack of oxygen, the following happens:

1) the gas ceases to burn completely, and we do not receive the amount of heat that we should receive in the normal process;

2) carbon monoxide (CO) is formed, which is life-threatening in certain concentrations (the presence of only 1% carbon monoxide in the air when inhaled can lead to fatal poisoning of the body).

Therefore, the operation of such gas boilers is considered more dangerous, and even with automatic protection, it requires periodic monitoring of the process.

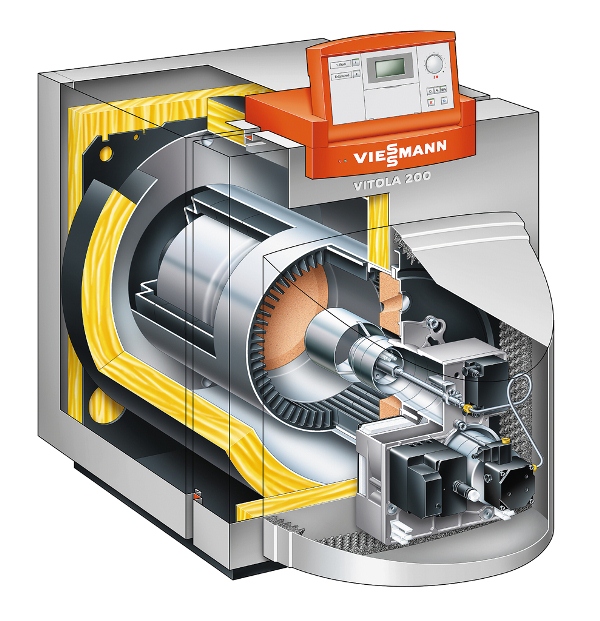

Floorstanding turbocharged boilers

Floor standing turbo boilers generally have high power and are reliable in operation.

When choosing a floor option, you should analyze the following characteristics:

- heat exchanger material (cast iron or steel). Cast iron is more reliable and durable (up to 35 years), but steel is cheaper;

- number of circuits: can be single-circuit and double-circuit. Some models have a built-in hot water tank. If there is no need for hot water, then you can use a single-circuit floor boiler, which copes well with heating large areas, since there are no energy costs for hot water.

The disadvantage of floor turbocharged boilers is the size. This is important when placing it in a small area.

The advantage is reliability, all components and parts of the boiler are made of durable materials due to the absence of weight restrictions. Such boilers are operated for about 5 years longer than wall-mounted ones.

The best wall-mounted atmospheric gas boilers

Lines from Italy, Korea, the Czech Republic are considered industry leaders, world-famous brands provide a wide range of items.

BaxiECO4s

The Italian brand offers a range of wall-mounted atmospheric boilers with advanced electronic filling. Heating equipment is made in accordance with the requirements of environmental safety. Baxi units are ergonomically designed, reliable, easy to install and maintain.

Dakon

The products of the Czech manufacturer are designed to help solve problems with home heating and hot water supply. Cast iron DakonGLEco models with an atmospheric ejection burner are of particular consumer interest. The equipment is equipped with Honeywell electronics, a draft interrupter, additions are provided in the form of room thermostats, outdoor sensors, anti-freeze devices.

NavienAce

The Korean brand offers wall-mounted atmospheric boilers that do not respond to voltage drops and function perfectly in the range of 155-220 volts. The unit is able to operate at low pressure gas fuel (within 4-16 mbar) and water (0.1 bar)

Also draw attention to the minimum dimensions and relative availability of equipment. Double-circuit wall-mounted boilers NavienAceATMO are equipped with a natural system for removing combustion products, a chip that is triggered by changes in mains voltage, and automatic equipment that turns on the pump when the temperature drops to 10 ° C