General sanitary requirements in GOST 30494-2011

A collection of state-approved standards for creating a comfortable living environment in residential facilities.

Indicators for air in residential apartments:

- temperature;

- movement speed;

- proportion of air humidity;

- total temperature.

Depending on the stated requirements, acceptable or optimal values are used in the calculations. You can get acquainted with their full composition in Table No. 1 of the above standard. A condensed example is shown below.

For the living room are allowed:

- temperature - 18o-24o;

- humidity percentage - 60%;

- air movement speed - 0.2 m / s.

For kitchen:

- temperature - 18-26 degrees;

- relative humidity - not standardized;

- the speed of advancement of the air mixture is 0.2 m/sec.

For bathroom, toilet:

- temperature - 18-26 degrees;

- relative humidity - not standardized;

- the rate of movement of the air medium is 0.2 m / s.

In the warm season, microclimate indicators are not standardized.

The assessment of the temperature environment inside the rooms is carried out according to the usual air temperature and the resulting temperature. The latter value is a collective indicator of tо air and radiation tо of the room. It can be calculated using the formula in Appendix A by measuring the heating of all surfaces in the room. An easier way is to measure with a balloon thermometer.

For the correct measurement of temperature data and sampling to determine the organoleptic indicators of the air mass, the direction of the flows of the supply and exhaust parts of the system should be taken into account.

Air pollution inside the home is determined by the content of carbon dioxide - a product exhaled by people during breathing. Harmful emissions from furniture, linoleum are equated to an equivalent amount of CO2.

According to the content of this substance, indoor air and its quality are classified:

- 1 class - high - carbon dioxide tolerance of 400 cm3 and below in 1 m3;

- Class 2 - medium - carbon dioxide tolerance 400 - 600 cm3 in 1 m3;

- Class 3 - permissible - CO approval2 – 1000 cm3/m3;

- Class 2 - low - carbon dioxide tolerance of 1000 and above cm3 in 1 m3.

The required volume of outdoor air for the ventilation system is determined by calculation using the formula:

L = k×Ls, where

k is the air distribution efficiency coefficient, given in Table 6 of GOST;

Ls – calculated, minimum amount of outside air.

For a system without forced traction, k = 1.

The following article will acquaint you in detail with the implementation of calculations to provide ventilation to the premises, which is worth reading both for construction customers and owners of troubled housing.

SNiP requirements for ventilation systems

The requirements of SNiP can be considered redundant, but they still need to be fulfilled. They clearly prescribe not only the minimum required air exchange for each of the premises, but also regulate the characteristics of each of the elements of the system - air ducts, connecting elements, valves.

The required air exchange is:

- for the basement - 5 cubic meters per hour;

- for living rooms - 40 cubic meters per hour;

- for a bathroom - 60 cubic meters per hour (plus a separate air duct);

- for a kitchen with an electric stove - 60 cubic meters per hour (plus a separate air duct);

- for a kitchen with a gas stove - 80 cubic meters per hour with one working burner (plus a separate air duct).

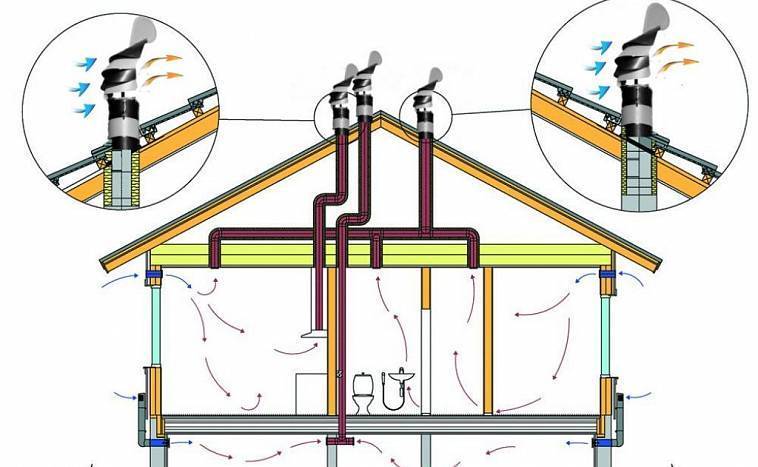

It is logical to equip the bathroom and kitchen with a forced ventilation system, even if it is natural enough for the rest of the house. The extraction of air from the basement, in order to avoid the concentration of carbon dioxide heavier than air, is also often provided by a separate duct.

The scheme of air circulation in the house, made in the style of infographics, gives an idea of the flow of air flows

It is very important to check the functionality of the system after installing the duct system. Homeowners who are not ready to turn the roof of the house into a palisade of air ducts often think about how best to equip ventilation communications within the attic.

After all, I would like the design to be not too cumbersome

Homeowners who are not ready to turn the roof of the house into a palisade of air ducts often think about how best to equip ventilation communications within the attic.After all, I would like the design to be not too cumbersome.

But is it possible to remove the exhaust air through the roof structure and its supporting frame - the truss system? And if this solution is acceptable, how best to implement it? What equipment will be required for the arrangement?

Installation of ventilation pipes on the roof

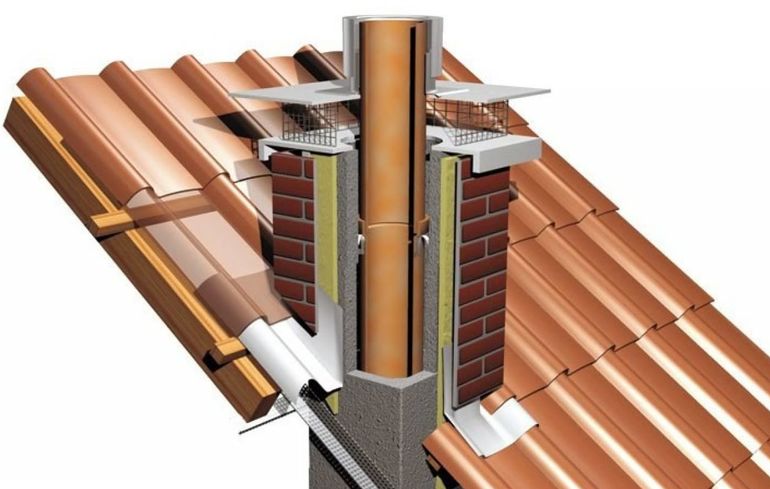

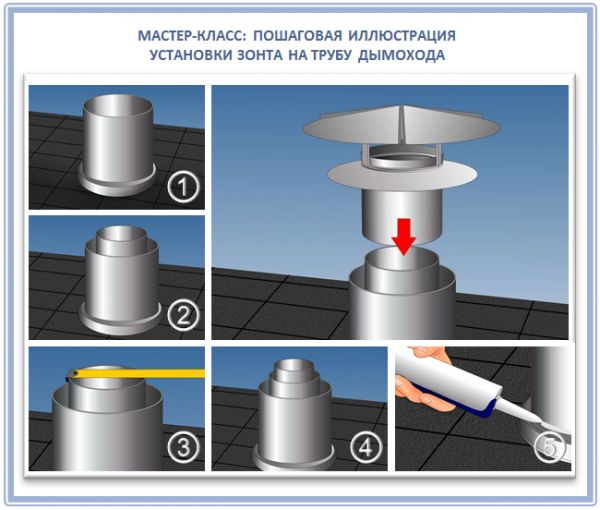

Installation of the ventilation pipe on the roof is carried out in several stages, regardless of what materials it is made of. A competent designer necessarily lays in the project a node of passage through the roof. The selection of the node of the passage through the roof is carried out depending on the type of roof. The structure is fixed on the glasses with anchor bolts.

For the manufacture of nodes for passage through the roof, black steel is used, up to 2.0 mm thick. It is possible to use thin-sheet stainless steel with a thickness of 0.5 mm. The type of roof and the type of ventilation system determine the configuration and dimensions of the passage through the roof, while in shape they correspond to the main sections of the ventilation system.

These are industrial products of domestic or foreign production.

Regardless of the country of manufacture, it is important to correctly mount it. . Prior to the start of all work, the workplace is cleaned of contamination, the moisture present on the roof is removed.

Prior to the start of all work, the workplace is cleaned of contamination, the moisture present on the roof is removed.

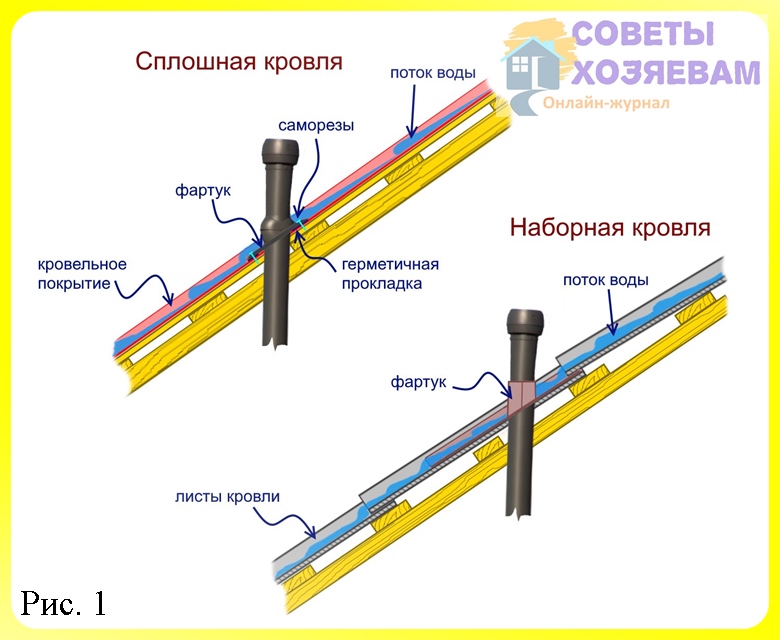

After determining the place of passage of the ventilation pipe through the roof, in accordance with the requirements of SNiP, markings are carried out on the roof. In each layer of the roof (roofing, waterproofing, insulation), a hole is cut out in accordance with the dimensions of the pipe to be installed. Then markings are made for the passage channel and fasteners.With the help of a sealant, a sealing gasket is fixed in this place, a passage unit through the roof is installed on the gasket and fixed with fasteners. Further, a ventilation pipe is passed through this node, fixing it with fasteners. The entire structure must be mounted strictly vertically, the efficiency of the entire ventilation system depends on this.

After completion of the installation work, they check how well the sealing of the duct elements is performed.

To provide the waterproofing function, the ventilation passage nodes through the roof are equipped with a special skirt. When water is released from the air mixture, it is necessary to install a condensate collector, which is attached to the nozzle.

It will be useful to insulate the duct. On sale there are products made with thermal insulation in the kit. Their cost is much higher. But you can insulate the ventilation structure yourself.

The cheapest material for pipe insulation is mineral wool. The disadvantage of its use is the ability to cake over time, which leads to a deterioration in its characteristics.

The most practical to use are shells made of polypropylene. For installation, simply put it on the pipes and fix it in the places of the seams. Some shells are equipped with special locks that ensure tight connections. For additional sealing, you can use a self-adhesive film, applying it in several layers. The insulation must be fastened securely so that weather conditions do not damage the structure.

The node of the passage through the roof of the profiled flooring has its own characteristics and is performed by additional elements.They help to ensure the reliability of sealed pipe outlets. To perform work on the profiled roofing, an apron is installed, it is located around the entire pipe. In places where the apron adjoins the corrugated board, sealing is carried out with roofing sealant. Also, waterproofing is carried out around the pipe. It is convenient to use a piece of roofing membrane for these purposes.

The node of the passage through the roof structure is a metal system that is used in the arrangement of ventilation shafts. If the system has a general purpose, then it is located on reinforced concrete cups, then it is mechanically fastened. The main purpose of such nodes is the transportation of air flows that do not differ in chemical activity. The humidity level of these streams does not exceed 60%.

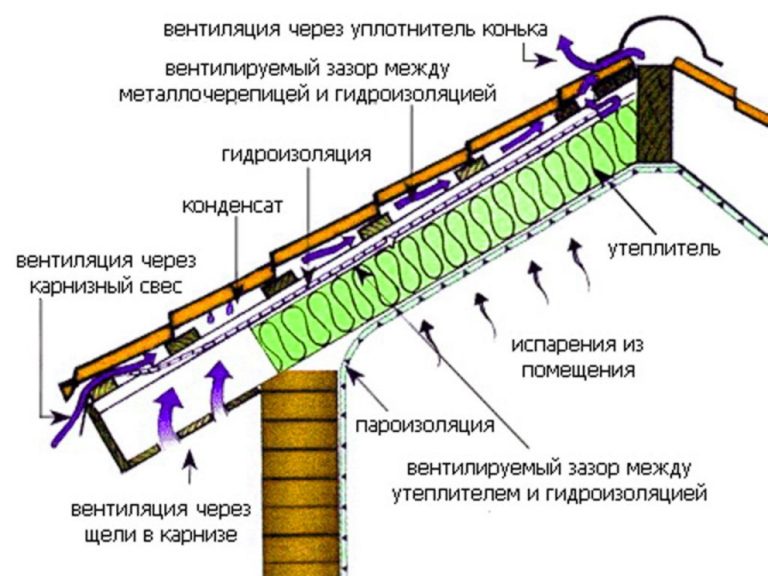

How to equip attic ventilation?

During construction, roofers, as a rule, lay 50-60 mm of free gap under the deck when installing the roof. The optimal distance is equal to the width of the laths of the crate. If the roofing materials are solid, such as corrugated board or metal tiles, air can freely enter the building and under the roof

Air currents cool the roof, which is important for bituminous formulations

For a soft roof, another method is effective - small gaps are left in the crate. Penetrating the entire roof, they serve as channels for the passage of air into the room. In difficult parts of the roof, spot ventilation is done or additional turbines are installed for aeration.

For a cold attic

Attic equipment requires considerable investment and labor, so most pitched roofs have a cold attic type. The air temperature in it is much lower than in the residential parts of the building. Therefore, a spacious intermediate zone makes it easy to solve the issue of ventilation.

the roof in this case consists of the following elements:

- cover layer;

- External walls (in the case of pitched roofs with gables);

- Insulation in the form of an overlap between the walls and the attic space.

Ventilation of the cold attic is provided by holes in the eaves and ridge of the roof. Through the cornice there is an influx of air, through the ridge - an extract. Dormer ventilation windows can be located on opposite slopes or stone gables of the roof. Thus, all areas are ventilated equally. Regulate the strength of ventilation with built-in blinds.

The ventilation window in the attic prevents condensation from accumulating on the roofing pie. It can also be used as access to the roof to inspect the elements of the system and the chimney. A popular solution is to install perforated soffits on the eaves of the roof. Soffits perform two functions - they allow air to flow freely under the roof, while preventing insects from flying into the building.

For a warm attic

Traditionally, the attic is made cold, warm is mounted if they plan to use it in the future as a residential attic. The main task is to remove vapors and excess moisture, leading to the loss of the properties of the internal insulation. Her solution lies in the arrangement of a ventilated roof.

A warm attic in a building structure is usually designed for the entire upper floor above the living space.Unlike a cold counterpart, the room is sealed, has fences from the outside. Stagnant air from the building is drawn out into the street through channels on the roof ridge. Fresh air is blown through the windows. For the winter they are insulated, protecting them from ice and icicles.

As an element of the ventilation system, a warm attic appeared in the late 70s. The use of the attic has become relevant, mainly for multi-storey buildings. A warm attic has the following advantages over a cold attic:

- Provides the proper temperature level on the ceiling of the upper residential floor of the building. At the same time, the rafter space of the roof is also insulated;

- Reduces aerodynamic resistance when air is released from the ventilation system in a natural way;

- Reduces heat loss and the risk of water leakage.

How to avoid mistakes when creating ventilation?

There are a number of misconceptions about attic ventilation. It is usually assumed that:

- It is necessary to ventilate the attic in the summer, in the heat, to avoid overheating of the roof. In fact, in winter, the ventilation system is needed no less, since water and snow cause fungus and mold to form, and ice to freeze.

- An air-blown attic interferes with the preservation of heat in the house. In fact, it does not interfere, it all depends on the thermal insulation. At the same time, a high-quality ventilation system does not allow cold and humid air to linger in the attic.

- The dimensions of the air vents in the attic can be chosen arbitrarily. On the contrary, dimensions are important, since the efficiency of the process depends entirely on maintaining the correct proportion. There should be one meter of ventilation holes per 500 square meters of roof.

According to the recommendations of experts, the owner of the house chooses in advance what type of attic space will be in the building - warm or cold. For construction, it is important to properly design the ventilation system in order to achieve effective ventilation of the room.

Chimney Ventilation

Fan pipe indoors with a conclusion through overlappings

The fan pipe is used to connect the pipeline to the exhaust pipe (ventilation duct). Fan pipes are divided by shape and material. The choice of one or another product depends on the configuration of sewer communications and the place of their withdrawal from the building.

Principle of operation

If the drainage system is not equipped with a ventilation duct, then the sewage entering the sewer riser creates a "rarefaction" of the air. The lack of air is partially replaced by water in the siphons of sinks, bathtubs and other equipment.

With simultaneous draining, especially in multi-apartment and multi-storey private houses, a vacuum is created in the sewer pipe, which “breaks” the water seal. Therefore, unpleasant odors and harmful gases freely enter the room.

In sewer communications, where the installation of a fan pipe was carried out, the process is different. The air entering through the ventilation duct during the "discharge" in the riser protects the integrity of the water seal and normalizes the pressure inside the pipeline.

Mounting Tips

Accessories for assembling a ventilation pipe

When installing the exhaust pipe and sewage, it is recommended to use products from similar materials.This will allow for reliable sealing of joints due to the same fasteners and fittings. It is not recommended to use pipes made of various materials (plastic, cast iron), as the connection will not have sufficient strength.

Ideally, if design work has been carried out earlier and a place is provided for the installation of an exhaust pipe. Before starting work, it is advisable to prepare all the necessary materials and tools.

If installation work is carried out in old houses where a sewer system based on cast-iron pipes already exists, then you will need to purchase a fan pipeline from a similar material. When using plastic products, the existing system is completely dismantled and new communications are laid.

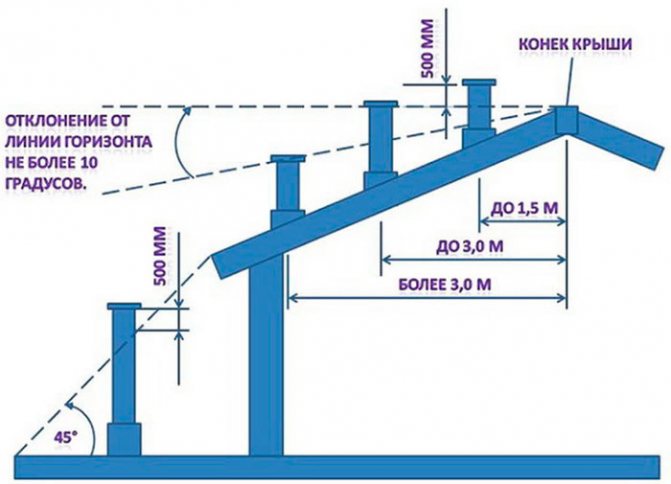

Exhaust pipe outlet through interfloor ceilings and roof

With independent installation of ventilation based on fan pipes should adhere to certain rules:

- According to the project, the end of the exhaust fan pipe is led to the roof of the house through interfloor and attic floors. The height above the roof level is at least 50 cm. When passing through the attic, the height from the ceiling to the end of the vent pipe is at least 300 cm.

- When the exhaust pipe is led through the ceiling, the interface is insulated with sound-absorbing material. If necessary, a steel box is mounted, the space inside of which is filled with heat-insulating material.

- When constructing ventilation for sewerage at an already operated facility, the outlet of the vent pipe is carried out through the bearing wall. Laying through the floors is undesirable, as this can lead to a decrease in their strength.

- The cross section of the exhaust pipe must be equal to the cross section of the riser pipe.As a rule, in multi-storey private houses, a pipe with a cross section of 110 mm is selected.

- If there are several risers, they can be connected to one exhaust pipe at the top. The connection of sewer ventilation with a stove chimney and an exhaust hood is not allowed.

- The length of the pipe from the plumbing equipment to the exhaust pipe should not exceed 6 m. The connection is made by connecting the siphon of the equipment to the socket adapter.

- For laying and exiting the pipe, special couplings and bends with the desired angle of rotation are used. The connection of various elements of the exhaust pipe is carried out using crimping metal clamps, seals and silicone-based sealant.

If during the process of output through the roof the fan pipe hits the floor beams, then a bend with the required angle of rotation (30–45) is installed for displacement. In multi-storey private houses, it is recommended to install an element with a plug (revision) on each floor. If blockages occur, this will quickly eliminate the problem without dismantling the ventilation duct.