- Advantages of PVC pipes

- Corrosion resistance

- Antibacterial properties

- Little chance of clogging

- Durability

- light weight

- Easy installation

- Low cost

- The choice of sewer pipes: the advantages and disadvantages of different materials

- Cast iron and metal pipes

- PVC and plastic sewerage

- The choice of pipes for use in conditions of increased loads

- Features of sewer pipes

- Proper laying of sewer pipes

- Installation of sewer pipes outdoors is carried out taking into account the mandatory requirements:

- The material used for the production of sewer pipes

- metal

- Steel

- Cast iron

- Ceramic

- Concrete

- Asbestos-cement

- PVC

- Polypropylene

- Main types and sizes

- Types of HDPE pipes for sewerage

- Kinds

- Advantages and disadvantages of asbestos cement

- Advantages and disadvantages of ceramics

- Advantages and disadvantages of metal

- Advantages and disadvantages of polymers

- Related video: Pipes for external and internal sewerage

- your plumbing

Advantages of PVC pipes

Competitors of plastic pipes are products made of cast iron, asbestos cement, ceramics, etc. All of them are good in their own way and have certain advantages.

And yet it is pvc pipe that is in great demand.They have advantages that are inherent only to them and are not available to other analogues.

Benefits include:

- Corrosion resistance;

- Antibacterial properties;

- Small chance of blockage;

- Durability;

- Light weight;

- Easy installation;

- Low cost.

Corrosion resistance

Since liquid is transported through the pipeline, anti-corrosion properties play an important role. Unlike metal, plastic is not subject to oxidation and rust formation. The metal pipe is covered with several protective layers against corrosion.

However, over time, these layers are damaged and the pipes begin to rust. This threatens to repair or even completely replace the pipeline. Polyvinyl chloride does not need additional treatment with protective agents.

Antibacterial properties

Another advantage of plastic is its resistance to microbial growth. Not pure water passes through the pipes every day, but drains with the presence of organic substances in them. Such an environment is an excellent breeding ground for bacteria.

In the course of their life, bacteria release substances that adversely affect the surface of pipes made of other materials. Bacteria practically do not multiply on plastic, and even if this happens, it still retains its original properties. This is due to the fact that polyvinyl chloride is not affected by acids and alkalis.

Little chance of clogging

Almost all sewer pipes are produced with a smooth inner surface. However, over time, roughness and irregularities may appear on their walls. Often this is due to the fact that there is garbage in the drains or household chemicals are used.

After some time, sediment begins to appear and they “overgrow”, that is, a blockage forms. Plastic pipes have a smooth surface that is not susceptible to chemicals.

And even if a blockage still forms, it can be safely dissolved by any means without fear of damaging the pipe.

Durability

Given the above advantages, we can conclude that PVC pipes will last longer than similar ones made from other materials. The average service life is more than 30 years. As practice shows, this period is much longer.

light weight

Plastic itself is a lightweight material and plastic pipes have the same properties. Their transportation does not require heavy vehicles. And loading and unloading operations can be easily carried out by one person, if the segments are long, then two.

Easy installation

Based on the fact that the weight of the products is small, and they themselves are equipped with a simple fastener system, even an unprepared person can cope with the installation of sewage.

Low cost

A PVC pipe is cheaper than its counterparts, for example, from metal, by 30-35 percent. This is due to the fact that the so-called recycled materials are most often used in their production.

The disadvantage is considered weak frost resistance. They do not tolerate frost below 15º C, but at temperatures down to -10º C, plastic is much more practical than metal.

All PVC pipes have these advantages for both external and internal sewerage. However, the external ones have a few more features, which will be discussed below.

The choice of sewer pipes: the advantages and disadvantages of different materials

When choosing which pipes are best to buy for assembling an external sewer, several factors must be taken into account:

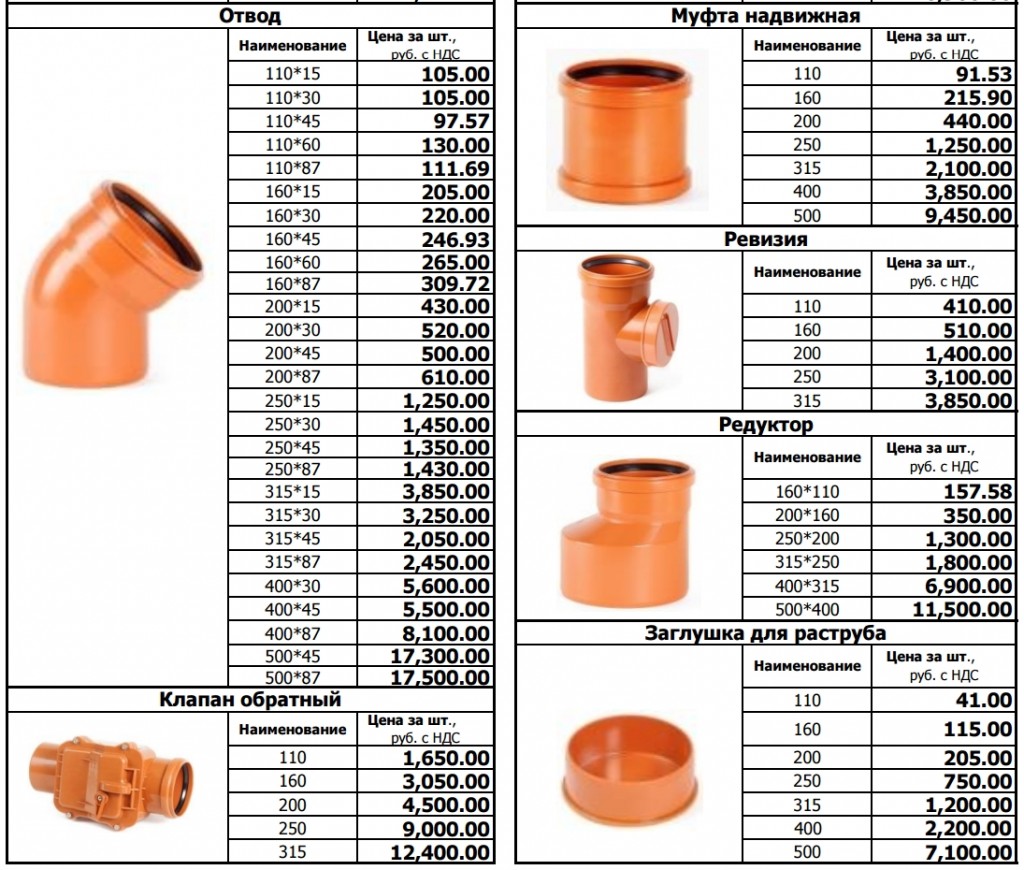

Details for the installation of a sewer pipeline

- Soil type, climatic conditions: In humid environments, a corrosion-resistant material must be used.

- Technical features of operation: products of increased strength and resistance to atmospheric and chemical influences are required, especially if the pipeline is laid in the area near roads, gas stations.

- Availability of special tools: some materials are joined by cold and hot welding and are not intended for self-assembly. If the master will be engaged in the sewerage, it is better to entrust the choice to him.

Cast iron and metal pipes

The only advantage of products made of cast iron and steel is the strength of the material and resistance to external mechanical stress, which is achieved by the maximum wall thickness. Cast iron is practically not used in the arrangement of private sewer pipelines.

Cast iron is strong, but heavy and short-lived material

Material disadvantages:

- Complexity of connections: welding is required. Welds are a weak point in the structure, subject to corrosion. It is at the joints that leaks and cracks occur.

- Structural heterogeneity and porous inner wall. On an uneven surface, a deposit of dense waste masses is deposited, which eventually narrows the inner diameter of the pipe.

- Susceptibility to corrosion. Metal pipes, even when treated with special anti-corrosion protective agents, are short-lived. The service life of the pipeline does not exceed 25 years.

Susceptibility to corrosion, difficulty in installation - disadvantages of cast iron pipes

In addition to operational disadvantages, cast iron products are too heavy. It is impossible to transport and install a cast-iron external sewage system with your own hands.

PVC and plastic sewerage

Instead of heavy and short-lived cast iron, light plastic pipes are used. Sewer products for outdoor use are color-coded: all products are painted orange. They produce pipes of different diameters, which are selected depending on the place of laying (inside or outside the residential building), the volume of drains (calculated based on the number of people living in the house).

PVC sewer assembly products

The main materials for the manufacture of external plastic sewerage:

- Polypropylene. The material is marked with the letters PP. This is the strongest and most durable material, but the cost of such pipes is higher than that of other materials.

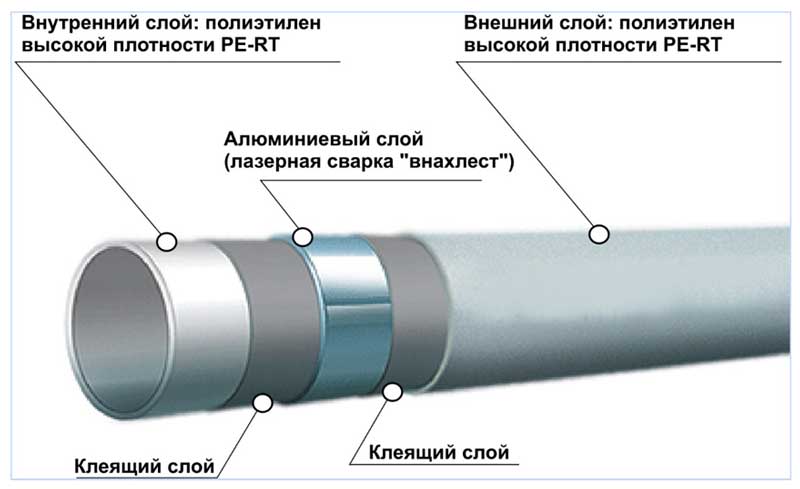

- Polyethylene. Marking - PE. The assembly of a polyethylene pipeline is carried out by hot welding with a special apparatus.

- Polyvinyl chloride. For self-assembly of external sewage, PVC pipes are the best choice. Products are inexpensive, produced with ready-made factory connecting elements, sealed with moisture-resistant gaskets.

In addition to pipes, you will need adapters, elbows, tie-in couplings, splitters and tees, and repair tanks. Additional parts and pipes must be made of the same material. It is advisable to assemble the entire system from products of the same brand.

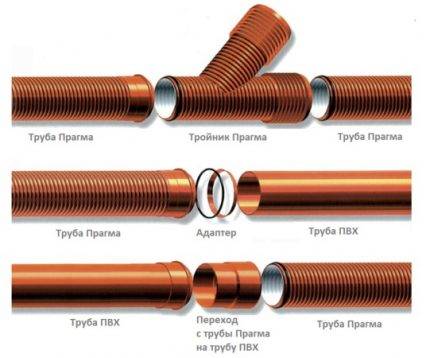

The choice of pipes for use in conditions of increased loads

There are special requirements for the material for the manufacture of pipes for external sewerage, carried out in difficult areas. The pipe wall for laying under the roadway must withstand significant weight loads, resist deformation and freezing.

Corrugated double-layer pipes for demanding applications

Use products from a combined material - metal-plastic. The inner surface is smooth, the outer surface is made in the form of corrugations with stiffeners for greater strength.

Metal-plastic pipeline of large diameter

Metal-plastic pipes can be used in separate sections where the pipeline is subjected to strong pressure and there are access restrictions for repairs.

Features of sewer pipes

A pipeline for a private or multi-storey building of an outdoor type must meet several parameters:

The pipe material must be well tolerated by temperature changes;

It is very important that the pipes were frost-resistant, and also tolerated high temperatures and direct sunlight normally;

Be sure to consider the stability of the system to work in aggressive environments;

The material must be wear resistant.

Previously, regardless of the type of sewage, metal pipes were used, but they are not suitable for outdoor installation due to the fact that they do not tolerate frost well and are susceptible to corrosion. At the moment, the building materials market offers pipelines from the following materials:

- Plastic;

- Cast iron;

- Reinforced concrete;

- ceramic compounds.

Despite external reliability, cast iron or reinforced concrete pipes are very fragile. They are rarely used in private construction, also because of their high weight. Therefore, for their installation, you need to use additional lifting equipment. Ceramics are known for their excellent durability and are not susceptible to corrosion. But at the same time, ceramic compounds become brittle under the influence of low temperatures. Also, ceramic pipes are sold only up to 2 meters long.For a standard sewer, you will need to use a large number of connections, which will significantly reduce the strength of the entire system.

sewer pipe

The most commonly used plastic pipes. There are the following types of plastic, which is used for the manufacture of gutters:

- PVC (polyvinyl chloride);

- Metal-plastic;

- Polypropylene;

- Polyethylene.

Related video:

In general, experts recommend using polyvinyl chloride (PVC) or unplasticized polyvinyl chloride (UPVC). These polymers are obtained by processing vinyl chloride in a special way, their main difference is that the first version contains plasticizers, while the second does not. It should be noted that PVC can tolerate low ambient temperatures, while PVC-U is used only in the range from 0 to 45 degrees. If you have opted for PVC pipes, it is better to install them in thermal insulation.

pvc pipes

Polypropylene sewer pipes for outdoor sewage have a number of advantages: low price, easy installation, durability. Unlike PVC options, they perfectly tolerate sub-zero temperatures, while not cracking, but slightly expanding (even if water freezes in them).

Gray metal-plastic options are most often not suitable for outdoor work due to poor transfer of temperature changes. In addition, their cost is much higher than that of classic plastic pipelines. A good selection of such communications is provided by the Rehau catalog.

Plastic sewer polyethylene pipes for outdoor sewage are known not only for their low price and durability.In addition, they are well tolerated by chemicals, are used at low temperatures, and do not lend themselves to corrosive processes. Available options are offered by the domestic company Egoplast.

pipe

To connect plastic pipelines to each other, special fittings are used - fittings. They are used both for internal work and for external work, the main difference is the material and certain alloys. In order to install outdoor sewer pipes, you need to buy orange parts.

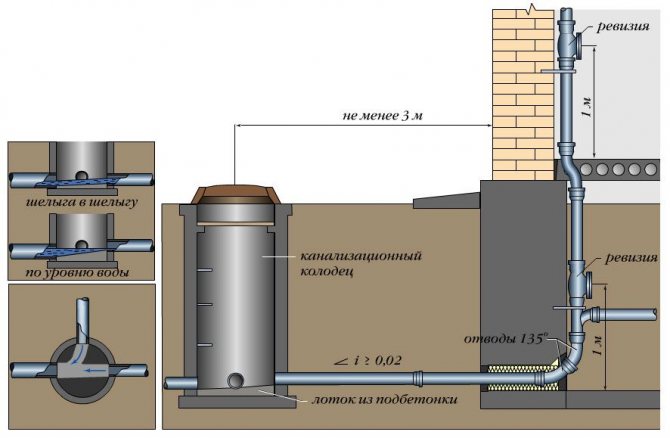

Proper laying of sewer pipes

Installation of sewer pipes outdoors is carried out taking into account the mandatory requirements:

- The pipeline must have a slope towards the septic tank, cesspool, bio-treatment station, etc. Norm: 2-3 cm per 1 running meter.

- Pipe laying is done in a trench below the freezing depth or with thermal insulation if the depth is small. The bottom of the trench is covered with a layer of crushed stone and sand, screening

- The device of revision wells every 25 meters is a prerequisite for the normal functioning of the system.

- The laid pipes are first covered with a layer of sand (screenings) 10 cm thick, without ramming it over the pipe, but only on the sides of it. Above is soil. If a little dry cement is added to the sand mixture, over time, under the influence of moisture, a strong box is formed above the pipe, which additionally protects the system from dynamic and static loads.

The wastewater disposal system will work smoothly and efficiently if all the necessary requirements and rules are taken into account and followed when choosing materials and installing pipes.

Posted in Sewer pipes

No "

The material used for the production of sewer pipes

Now consider the material of manufacture in order to assess how one or the other meets all the requirements. Today the market offers a wide range of pipe products for sewer systems:

- ceramic;

- metal;

- asbestos-cement;

- concrete;

- from polyvinyl chloride (PVC);

- from polypropylene.

And despite the large selection of products, only three are the most popular and most commonly used: cast iron pipes, PVC and polypropylene. Other species are less common, but still used.

metal

By metal pipes are meant cast iron and steel.

Steel

Steel products meet almost all requirements and have a lot of advantages:

- durable;

- withstand high temperatures;

- easy to process;

- low cost.

However, despite this, they have disadvantages that make their use in private housing construction unprofitable. Here are just some of them:

- large mass;

- corrosion.

The main scope of their application is the petrochemical and chemical industry, where they are actually and successfully used for transporting waste, etc.

Cast iron

Compared with the previous ones, cast iron pipes are less afraid of corrosion, but the cost of this option will be higher. Most often used when installing a riser in apartments of high-rise buildings, as well as for diverting wastewater to a collection point.

Advantages:

- high strength;

- long service life - more than 80 years, and this is a theory, but time-tested data;

- good plastic properties;

- resistant to heavy loads.

Cons that significantly limit its use:

- rough inner surface makes it difficult to transport wastewater;

- big weight;

- the need to use additional materials for sealing joints;

- price.

Ceramic

The main scope of ceramic pipes is external sewerage. They transport household, industrial and rainwater. They are resistant to chemicals and corrosion, not afraid of fire, strong and durable.

However, complex installation, fragility and a number of other disadvantages led to the displacement of this material by others, more modern and practical. You can learn more about them from this article: Ceramic pipes.

Concrete

The reinforced concrete pipe is used in hydrotechnical, civil and industrial construction, for the transportation of non-aggressive effluents by gravity. In their production, heavy concrete of the following grades is used: W6, F200, B25, M350.

Main advantages:

- compressive and tensile strength;

- water resistance;

- not afraid of low temperatures;

- low price - compared to steel pipes;

- chemical resistance;

- are not subject to rotting and corrosion.

The depth of laying reinforced concrete products varies from 2 to 6 meters.

Asbestos-cement

Asbestos-cement sewerage - products of Russian manufacturers. It is considered the cheapest of all types. Asbestos cement is one of the varieties of reinforced concrete, where evenly distributed asbestos fibers play the role of reinforcement.

This material is tensile, so it can also be used for pressure systems. It is not afraid of corrosion, and when exposed to water, it compacts and becomes stronger.

PVC

According to experts, PVC pipes are strong enough and durable, they are not afraid of UV radiation.They are distinguished by an affordable price, ease of installation and an almost perfectly smooth inner surface of the walls.

Minuses:

- When the temperature rises above 70 ° - deformed.

- They become brittle at low temperatures.

- They are afraid of fire, when burning, it releases a dangerous gas.

PVC pipes, depending on their strength, are divided into several classes:

- lungs - SN2;

- medium - SN4;

- heavy - SN8.

The permissible temperature regime of the passing liquid should not exceed 40 ° C, the service life is reduced from high temperatures.

Polypropylene

To date, it is this material that is considered the most optimal for the construction of a sewer pipeline inside a building. This conclusion can be reached by evaluating the advantages of polypropylene pipes:

- high strength;

- long service life;

- resistance to aggressive influences;

- simple installation;

- perfectly smooth inner surface;

- low cost.

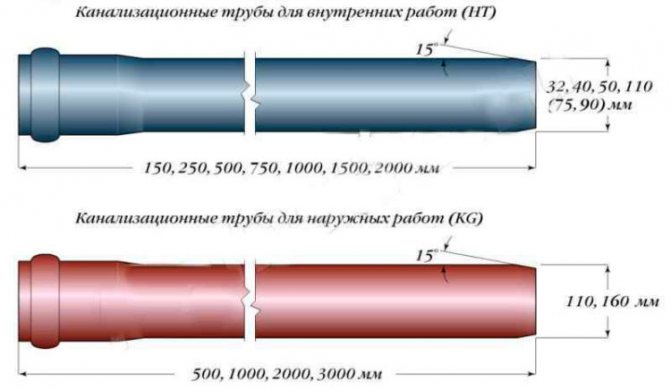

Main types and sizes

Depending on the conditions of use, PVC pipes are produced in three versions, which correspond to the main standard sizes:

- SDR51; SN-2; row S25 - light type products are laid under the sidewalk, green area and in places where traffic loads are not expected.

- SDR41; SN-4; series S20 - products of the middle type are chosen for laying in places where traffic is not so great.

- SDR34; SN-8; series S16,7 - heavy-duty products are chosen for laying in industrial areas and places with a saturated traffic flow.

Pipes used for laying outdoor pipelines are one-, two- and three-layer. In the latest version, the inner layers of the product are made of foam material with a porous structure, which is obtained by recycling.And the top layer is made of primary unplasticized PVC.

The most widespread when laying on the street are two-layer corrugated pipes. The outer layer of such products has a corrugated surface with stiffeners. Due to this, the corrugation acquires increased strength.

The inner surface of profiled products, created by extrusion, is ideally smooth, which minimizes wall resistance when moving drains

Both walls of profiled products are produced simultaneously. Due to the fact that they are connected by a "hot" method, the finished cylindrical products are an integral structure. The cavities formed between the inner and outer walls lighten the weight of the structure, and the wavy wall on the outer side gives the necessary annular rigidity.

If we take the ring stiffness class as the basis for the classification of polymer products, then PVC pipes are of three types:

- "L" - light pipes for laying in ditches, the depth of which does not exceed 0.8-2.0 meters.

- "N" - medium-hard products are designed for laying to a depth of 2-6 meters.

- "S" - rigid with a maximum wall thickness that can be laid in trenches up to 8 meters deep.

The ring stiffness parameter of products is denoted by the abbreviation "SN". It is a significant value because it determines the initial deformation during laying and lateral support.

In the private construction sector, products of the “SN2” stiffness class are most in demand, which can be laid in trenches up to 2 meters deep.

In systems that provide for the forced removal of effluents, where pumping equipment is involved, pressure PVC pipes are installed.The basis for their manufacture is unplasticized PVC-U polyvinyl chloride, which is famous for its highest performance.

The main difference between pressure pipes is that they are able to withstand significant loads on the walls. There are three types of pressure pipes on sale that can withstand pressures of 6, 10 and 12.5 kg / cm2.

In gravity sewer systems, the movement of effluents is carried out under the influence of gravity. For the arrangement of such systems, ordinary PVC pipes are used, created on the basis of a simpler PVC polymer. The temperature range of these products is from 0 °С to +45 °С.

The depth to which it can be laid directly depends on how rigid the walls of a polymer sewer pipe are.

The size range of PVC pipes for external sewerage is also quite wide:

- 110 mm - products with a minimum diameter are intended for the disposal of domestic wastewater in suburban construction.

- 315 mm - pipes of this size are used when it is necessary to build a common sewer system that unites several houses.

- 630 mm - pipes of maximum diameter are used for the construction of a general village sewer line.

Cylindrical products are produced in segments 500/1000/2000/3000/...6000 mm. Some sizes can also be produced in 12-meter lengths. We talked in more detail about the characteristics of PVC pipes in this article.

Types of HDPE pipes for sewerage

Since non-standard solutions and ideas are used in construction, manufacturers of polymer products work in close cooperation with engineers.The HDPE sewer pipe is best suited for use in arranging multi-storey buildings, laying a route in unstable ground, creating temporary and permanent pipelines for transporting drinking water and technical liquids, wastewater, gases and compressed air.

Produce polyethylene pipes of this type:

- Non-pressure. They are used in ventilation and drainage systems moving by gravity. They serve as channels for placing telecommunication and power cables. They are characterized by thin walls and increased flexibility. Due to this property of pipes, it is possible to lay routes with smooth bends without the use of fittings and welding. In addition, small-diameter products are wound into coils up to 50 m long. The diameter varies between 50-110 mm. For laying air ducts, links up to 12 m long and up to 120 cm in diameter are produced.

- Pressure. Products have found application in the construction of water pipelines, gas pipelines and sewer systems operating with forced pumping. The line is designed for a pressure of 2-5 MPa. The connection is carried out by welding - the use of glue and sockets is excluded. Depending on the tasks to be performed, builders make tracks with a diameter of 50-110 mm.

According to the composition, links from HDPE are divided into standard ones, which can be laid underground and inside buildings, and protected from ultraviolet radiation - they are used to make open-type sewer systems and sections of pipelines that go to the surface.

Kinds

To understand which pipes to use in the sewer is better, you need to consider what the construction market offers consumers. They are made from the following materials:

- asbestos cement;

- ceramics;

- metal;

- polymers.

Advantages and disadvantages of asbestos cement

The advantages of a mixture of asbestos fiber and cement include the following:

- service life up to 100 years;

- immunity to aggressive environmental influences and the type of liquid;

- lightness of the material;

- ease of installation;

- no blockages.

Asbestos cement is not without drawbacks. It is quite fragile, so it should be protected from mechanical stress. Such sewer pipes are good to use in an apartment.

Advantages and disadvantages of ceramics

Ceramic pipelines were laid in antiquity. But even now they are in demand due to their high performance. These include:

- immunity to chemical and temperature effects;

- no blockages;

- ease of installation and replacement.

A ceramic sewer pipe can pass any type of liquid. It cannot be damaged by chemicals. The smooth inner surface eliminates the formation of mechanical and biological blockages.

Ceramics have one drawback - fragility, which complicates the task of transportation and installation.

Advantages and disadvantages of metal

Among metal products, pipes made of steel and cast iron are the most popular.

Steel has the following advantages:

- strength;

- ease of processing and installation;

- ability to withstand high temperatures.

However, it is not recommended to use it for laying water pipes due to its impressive weight and susceptibility to corrosion.

Cast iron has the same advantages as steel. It is not subject to corrosion and is able to withstand significant loads. However, cast iron is very heavy, and many consumers note its fragility.The inner surface of cast iron products is rough, which contributes to the formation of blockages.

Advantages and disadvantages of polymers

Now consumers rarely have to think about which pipe to choose for sewage. Most often, preference is given not to heavy metal, but to light polymeric materials (plastic). They are used for laying internal and external pipelines due to their high strength characteristics.

You have to choose from three polymers:

- PVC (polyvinyl chloride);

- PVC np (unplasticized polyvinyl chloride);

- PP (polypropylene);

- (PET) polyethylene.

Plastic products have the following advantages:

- have high strength;

- UV resistant;

- do not deform under temperature changes.

Polyvinyl chloride is used in gravity sewer lines. Exposure to low temperatures leads to a loss of elasticity, making it brittle. High temperatures cause deformation. Polyvinyl chloride is destroyed by chemicals.

The service life of polypropylene is up to 100 years. It is strong, light, elastic and withstands high temperatures without being deformed. However, it is not recommended to use it for laying outdoor plumbing.

For the installation of external sewerage, it is recommended to choose materials from polyethylene. They are durable, polished inner surface eliminates the formation of blockages. The only drawback is the sensitivity to ultraviolet radiation. Therefore, they are used under the condition of absence of exposure to the sun.

Related video: Pipes for external and internal sewerage

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

your plumbing

Coupling Assembly

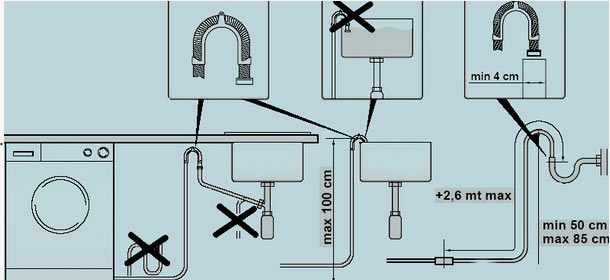

Soldering Polyethylene models are mounted by soldering or using couplings/fittings (coupling assembly). How to solder plastic pipes for plumbing?

For new water supply networks, PVC and polyethylene products without reinforcement and reinforcement are suitable. Preparation requires creating a diagram of the future water supply with the designation of the lengths of the branches, its position and all the fittings necessary for installing the structure. The correct calculation of the lengths and number of bends will simplify the technology, increase the speed of the task and prevent rework.

soldering iron

pipe cutter

For soldering polyethylene joints you will need:

- Soldering iron.

- pipe cutter

- Trimmer for cutting pipes and cutting off the edges of the cut ends.

- Fine sandpaper for sanding edges

- Coupling (if coupling assembly)

The heating device is a special device with a sole with attachment to it of special nozzles of various diameters. There are devices that come with two or more nozzles at the same time.

The stages of the technology for laying hydrocommunications will tell you how to learn how to solder:

- We measure the desired length with a tape measure.

- Cut off the measured length with a pipe cutter.

- Trim the cut ends. This is an important step in soldering. Sections should be smoothly ground and deburred.For greater certainty, you can additionally degrease with an alcohol solution.

- We solder the ends. If a coupling connection is used when installing life support networks, then we install a coupling / fitting at one end of the building and heat it together with the future return line in the nozzle of the desired diameter of the soldering iron. After warming up, we immediately connect the ends and wait for the assembly to cool completely. The presence of a shoulder indicates the quality of welding.

Attention! When installing heat and water supply with a soldered seam, it is strictly forbidden for water or moisture to fall into the cavity or onto the surface. When heated, water, turning into steam, deforms the plastic structure, as a result of which it loses its strength.