- What pipe diameter to choose

- Why is insulation necessary?

- Characteristics of plastic and polypropylene pipes

- Of the advantages of polypropylene pipes, there are:

- Reinforced polypropylene pipes are of 2 types:

- Which pipes to choose for plumbing: three main varieties and their features

- What you need to know about PVC pipes

- Determination of nominal pressure

- Which metal-plastic pipe to choose for water supply

- Steel pipes

- Pipe selection based on operating conditions

- Metal-plastic pipes

- What criteria should water pipes meet?

- Which column assembly option is better?

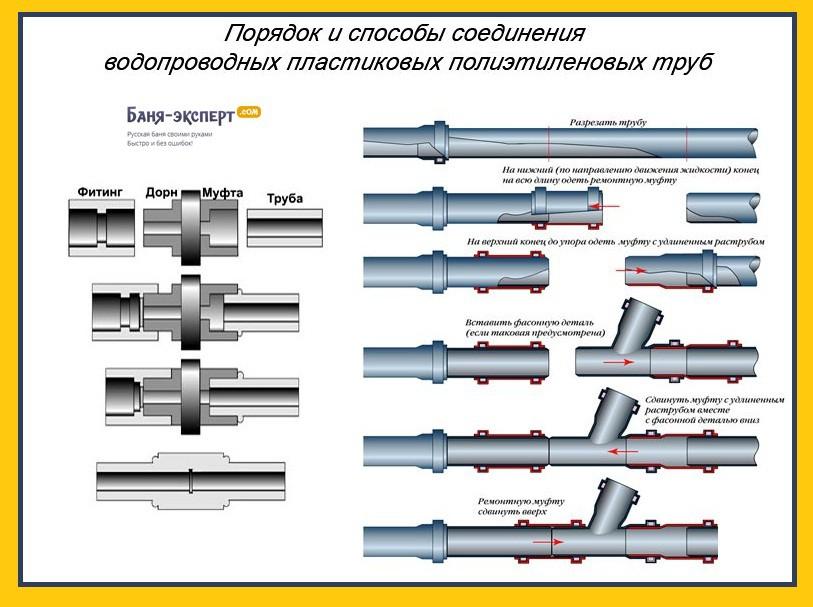

- No. 1 - one-piece contact of pipes for welding

- No. 2 - threaded water-lifting channels

- What pipes are better to use for plumbing in an apartment?

- Polypropylene pipes or metal - pros and cons

- Dimensions and diameter

What pipe diameter to choose

Another important indicator is the inner diameter. As a rule, for the main pipeline they choose with a diameter of 25-32 mm. This should be enough to reduce the pressure in the system. In the case when it is necessary to determine the exact indicator, a hydraulic calculation is carried out, taking into account the peculiarities of the operation of plumbing and other appliances, the power of the water supply source.

Summing up, we note the following points:

- The choice by type of material is carried out taking into account the easiest way to achieve sealed joints. For example, steel pipes can be connected qualitatively only by a 4th grade welder.

- Polymeric ones are suitable for giving, as they have sufficient strength and do not collapse when water freezes.

- When choosing, the likelihood of corrosion on the surface is taken into account.

When buying pipes, attention should be paid to their integrity. Quite often there is a situation when, due to improper transportation or storage, cracks and other defects appear on the surface, a curvature appears - all this can cause a decrease in the reliability of the pipeline being created

Why is insulation necessary?

There are several reasons why underground water supply should be insulated, all of them are related to the rules for laying communications and financial savings - it is obtained after the implementation of insulation work. The main reasons for conducting thermal protection of the water supply system:

- When laying an underground water line, the possibility of draining water from the system is taken into account; for this, the pipeline is laid with a slope of about 20 mm per linear meter towards the source. If the house or cottage is located at a great distance from the well or well from which water is taken, for example, 50 m, then when laying the pipeline near the house at an average freezing depth of about 1.5 m, at the entrance to the source, it will be necessary to bury the pipe by 2.5 m (0.02 x 50 = 1 m). This is economically impractical and rather difficult to implement technically.

-

To take water from wells, caisson wells are often used, in which pumping equipment is placed and maintenance of the electric pump is carried out.A standard caisson tank has a depth of submersion under the ground of about 2 m, while the upper pipe of the casing, according to the standards, is located 50 cm above the floor level. Thus, at the outlet of the caisson chamber, which is an unheated room, the pipeline is .5 m, and given that when connecting to the house through the basement, a slope is needed, the entire section of the water supply will be above the freezing point - accordingly, it must be insulated. Read more about plastic caissons.

- Insulation of water supply pipes in a private house, passing underground, saves significant funds that are spent on heating cold water for household needs. It is clear that less chilled water after flowing through an insulated water supply system will require less electricity for heating than chilled water after passing through a non-thermally insulated main.

- It is known that the thermal insulation of an underground water supply system from contact with the ground does not heat the pipes, but prevents heat loss, therefore, insulated pipes for water supply can be effectively operated in the summer - they prevent water from heating when the main line is shallow.

- To prevent freezing, not only the water pipes are insulated in the ground, but also on its surface at the exit from the well and the entrance to the house, if it is located on piles, for this they often use thermal insulation methods and materials similar to underground utilities.

Self-regulating electrical cable device

Characteristics of plastic and polypropylene pipes

Products from the latter material can be used for plumbing and heating systems.If you need to supply hot water, reinforced pipes are used, and for cold water, ordinary products are used. Polypropylene lasts longer than 50 years, during which the pipeline is able to easily withstand temperatures up to +90 degrees.

Of the advantages of polypropylene pipes, there are:

- low price;

- durability;

- good tightness of connections;

- wide application;

- high quality and easy installation.

If you need to lay a pipeline for supplying cold water in an apartment, then any plastic pipes are used. This is due to the fact that there are no temperature effects and differences in the room. To supply hot water, it is better to lay non-reinforced or reinforced products.

Propylene is a material with a high thermal elongation, unlike other types of material under consideration. For non-reinforced products, the value of this indicator is 150 mm per 10-12 m of pipe, provided that temperature differences range from 95-100 degrees.

From a physical point of view, this value is considered huge, therefore, if there are discrepancies equal to the parameters of the pipe, indents are made, special loops are used. To reduce this value to zero or to minimize it, reinforcement is used. In this case, a fiberglass pipe is laid. In this case, thermal elongation is 1.5 cm per 10-11 m, in contrast to unreinforced material.

Reinforced polypropylene pipes are of 2 types:

- with fiberglass - stripping is not required. Products consist of 3 layers. Two layers - polypropylene, and one layer - a mixture of fiberglass with a polymer;

- with aluminum foil - the product is equipped with an aluminum layer of different sizes - 0.1-0.5 mm.Aluminum foil is located inside or outside the pipe, between the plastic.

Reinforced aluminum pipe is a foil sealed inside (without soldering inside). The product helps to reduce thermal elongation. Reinforced pipes have different strengths. Fiberglass has the lowest warm elongation value. For internal and external aluminum reinforcement, the value of this indicator is the same. It is greater than the value corresponding to fiberglass, but less than that of a pipe without reinforcement.

Before laying, it is cleaned, otherwise, during soldering, aluminum will prevent the pipe itself from melting. For cleaning work, a special tool is used - a shaver. It comes in several types:

- manual - used for one-time work;

- automatic - used for processing products in industry.

If the reinforced layer is outside, a shaver is used, with which aluminum is removed from the pipe to a depth that ensures a quality connection with the fitting.

If the foil is inside the product, a shaver is used to perform cavity work. In this case, stripping prevents metal from contacting water at the points where the pipe connects to the fitting.

Experts advise using non-reinforced material for supplying cold water. It's easy to install, and it's cheap. If it is necessary to organize hot water supply, a reinforced pipe with fiberglass is used. It is convenient, practical and reliable in operation. Reinforced pipes are less subject to thermal elongation.Products with aluminum reinforcement and combined pipes have their drawbacks, so they are less often used to supply hot water.

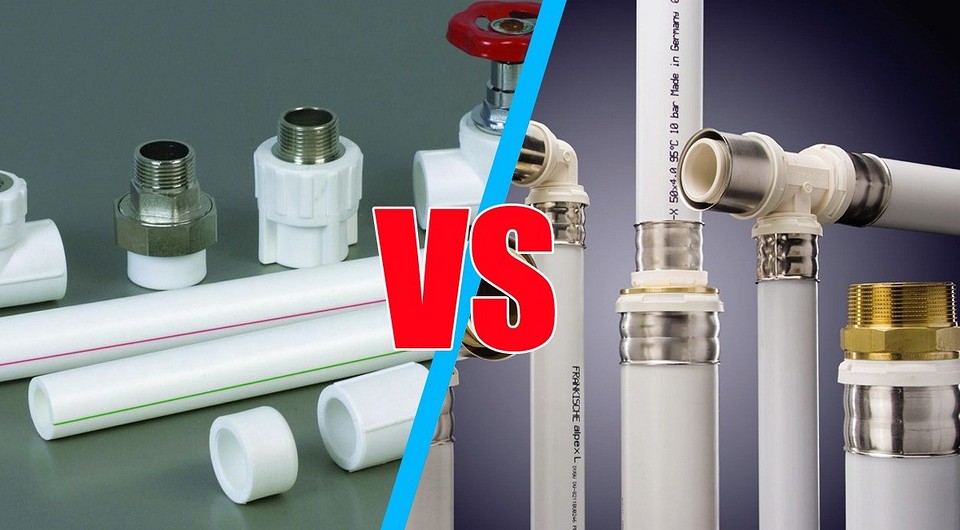

Which pipes to choose for plumbing: three main varieties and their features

Let's not go back to the past and deal with obsolete iron or stainless steel - although these materials are still used for laying water pipes, they are gradually becoming a thing of the past and their age is short. Let's focus on such modern plumbing systems as metal-plastic, polypropylene and copper pipes - the future lies with these materials, we will try to make friends with them.

-

Metal pipes. For a self-taught master, this is ideal, since such a water supply system is assembled with little or no use of sophisticated equipment. If desired, you can even get by with just keys and a puncher - it is assembled using the so-called fittings on compression nuts. The manufacturer took care of the installers and manufactures all kinds of tees, turns, limit switches and other connectors for ease of assembly. The pipe itself has a white color and is made in layers - plastic inside and out, and an aluminum layer is placed between it.

- Copper pipes. Non-ferrous metal has always been expensive, and products made from it are even more expensive. This is the most expensive plumbing system, which is assembled by welding (or soldering - as you please). As in the previous case, this water supply system consists of a mass of individual elements that are soldered with a pipe into a single system. To assemble copper pipes for plumbing into one system, you will need a gas welding machine and the ability to use it.

- Polypropylene pipes.With this plumbing system, just like with the previous one, you can’t figure it out without special equipment; you need a soldering iron for pipes here. In fact, in some way, the polypropylene water supply system can be compared with metal-plastic - the difference between them lies in the plastic itself and, as a result, in the assembly method. Such a seemingly insignificant difference entails serious differences between these systems of water pipes.

So, we already know what types of water pipes are, now we will deal with them in more detail and study their advantages and disadvantages.

Which pipes to choose for plumbing

What you need to know about PVC pipes

Under the concept of plastic pipes, many of their varieties are understood. There are a large number of varieties of plastic, each with its own special performance characteristics. PVC pipes are quite popular. They are the optimal solution at the time of the creation of a water supply or sewer outlet. As previously noted, an increase in temperature can cause an increase in the flexibility index. That is why manufacturers indicate:

- For cold water choose PVC.

- For hot water only CPVC can be installed.

In addition, CPVC is also used for cold water.

Determination of nominal pressure

If metal pipelines can withstand a sufficiently large pressure indicator, then with plastic ones everything is a little different.

When purchasing plastic pipes, pay attention to the nominal pressure indicator, which is denoted by PN. It is recommended to purchase PN 10 and PN16 for cold water, PN20 and PN25 are suitable for hot water

For hot, versions with a higher nominal pressure are installed due to a decrease in strength due to heating of the material.

Which metal-plastic pipe to choose for water supply

The choice of metal-plastic pipes also depends on several parameters. First of all, when choosing, their structure should be taken into account. They consist of five layers: three main and two binders. Main:

-

Internal (consists of a polymeric material);

-

Reinforcing (made of aluminum);

-

External (also polymeric).

The reinforcing layer should cope with the main load:

-

Prevent unacceptable linear expansion that occurs when plastic is heated;

-

Create an oxygen barrier;

-

Protect from damage possible from external or internal influences.

Metal-plastic pipes differ from each other in the thickness of the aluminum layer (0.15-0.6 mm). Metal-plastic products are in the greatest demand, in which the reinforcing layer is from 0.3 to 0.55 mm. They are quite flexible, which is convenient for installation, but at the same time quite durable.

If the thickness of the reinforcing layer is less than 0.3 mm, there is a risk that the pipes will not withstand the load and break even during installation. And a thicker layer of aluminum, on the contrary, complicates the task, and it costs an order of magnitude more expensive.

During the production of metal-plastic pipes, the metal is connected by welding. There are two methods: laser and ultrasonic. As a result of the first method, the pipes at the outlet are seamless, in the second option they are overlapped, which means that a seam is obtained.

Pipes made of metal-plastic with a laser welding method come with different thicknesses of the inner layer.In the second method, manufacturers reduce the thickness of the weld. Accordingly, such pipes lose strength and ease of installation.

It should be noted that when choosing metal-plastic pipes, both the outer and inner layers are also important - that is, the polyethylene from which they are made. Most often it is a cross-linked polyethylene PEX or a linear polymer PE-RT. Such materials are characterized by excellent properties. Pipes are durable, reliable, resistant to the environment, able to withstand high temperatures. Pipes made from PEX and PE-RT will serve you for a long time and without fail.

Other types of polyethylene such as PE, PEHD, HDPE, PE-RS are not as reliable in use. They lack strength and heat resistance. Direct sunlight has a great influence on these materials, while the material tends to age and collapse. PE-RS pipes can withstand only 75 degrees. Hotter temperatures can melt this polyethylene, and therefore the pipes themselves become unusable.

Many European manufacturers produce metal-plastic pipes at a low price. This factor suggests that they are made of just such plastic and are suitable for use only at low pressure. At the same time, firms do not expect to sell low-quality goods for little money. The fact is that such metal-plastic pipes deserve attention, you only need to follow the rules for their operation.

As mentioned above, in addition to the three main layers in metal-plastic pipes, there are also two bonding layers.Their main function is clear from the name - to fasten the main layers together. The quality of the tie layers also affects the overall result.

Therefore, when choosing such products, you should pay attention to this aspect. By the way, to determine how good the bonding part is, you can try to separate one layer from another.

In order to choose the right metal-plastic pipes, it is necessary to carefully consider whether there are delaminations in them. If such a factor is present, this is a sure sign of poor quality, which means that such pipes will quickly fail.

Let's define the basic rules for the purchase of metal-plastic pipes:

-

Connections must be made by butt welding.

-

The thickness of the reinforcing layer is from 0.3 to 0.6 mm.

-

Pipes are most durable if they are made from PERT or PEX plastic.

-

Layers are not separated from each other.

Information regarding the first three points can be obtained from the consultant. The delamination will be noticeable when inspecting the products. By following these rules, you can choose the right pipes that will last a long time.

Read the material on the topic: Metal-plastic pipes: types, sizes, operation

Steel pipes

Such pipes are used in the construction of a water supply system, heating, and partially in the sewerage system. In the houses of the old building, they accounted for almost one hundred percent of the length of the water supply.

Types of steel pipes.

- high resistance to mechanical damage;

- relatively low cost;

- a lot of fittings necessary for the installation and wiring of pipes are manufactured. therefore it is possible to make a complex and reliable system.

- Susceptibility to rapid corrosion is the main disadvantage of steel.Protective coatings, coloring protect only the outer surface. At the slightest violation of the protective layer, corrosion begins, which, spreading under the coating, destroys it from the inside.

- Installation of pipes is laborious, requires welding equipment. Threaded connections are used, which partially, and sometimes completely replace connections by metal welding. But this method is also labor intensive.

- Pipes with cold water become clogged, which narrows their clearance.

- Good electrical conductivity can also be attributed to disadvantages: in the event of an accident, they can cause electric shock.

- Cannot be used with aluminum and copper radiators. The resulting galvanic couple leads to the appearance of weak currents, and consequently, the corrosion process is accelerated at the joints.

In modern capital construction, unprotected steel pipes are almost never used for water supply. During repairs, they are usually replaced with other types of pipes.

Pipe selection based on operating conditions

Plumbing is needed to supply water to plumbing equipment (faucets, toilets, etc.). The main parameter that should be considered in the selection process is the working pressure. It depends on the material of manufacture of the product and varies between 2.5 - 16 kg / cm2. For internal plumbing, steel pipes can be used without restrictions. Polymer and metal-plastic products have certain restrictions on pressure and water temperature.

If they equip cold water in a private house or apartment, then today plastic is most often chosen. This material is excellent for cold water with threaded and welded connections. You can install these products yourself.

It is better to equip the external pipeline with an outer protective layer in order to increase the anti-corrosion properties of the material, prevent freezing of cold water and reduce heat loss in hot water.

To determine the choice of pipes for water supply, you need to consider that they are low-temperature or for hot environments

At the same time, take into account the fact that the latter have a service life of 2 times less

If steel products are replaced with polymer ones, then it is important to take into account the pressure and throughput of the network.

Metal-plastic pipes

Metal-plastic pipes are also quite popular among summer residents. Their peculiarity lies in the following points:

- The structure is three-layer, each layer performs its task.

- The inner and outer layers are polymer. This material withstands exposure to high humidity and temperature extremes, a low roughness index does not lead to blockages.

- The layer between the plastic is made of aluminum. This metal has high ductility and does not corrode.

They are aesthetically pleasing and light weight. The ductility of aluminum and the properties of plastic allow some versions of multilayer pipes to be bent, which reduces the number of connections due to the absence of the need for rotary elements. However, the multilayer structure and the use of aluminum significantly increase the cost of the product.

What criteria should water pipes meet?

Regardless of the material, the pipe must have a smooth surface inside and out. There should be no cracks, bubbles, foreign bodies and chipped places in the walls. Withstanding limit pressure should not be less than 1 MPa.

Additional requirements are imposed on water pipes that supply drinking water. Most importantly: a guarantee of environmental safety of the supplied water.

Such pipes are always accompanied by a certificate of conformity. It confirms that the material from which they are made does not contain components harmful to humans and the environment.

Pipes for an external network are different from pipes for indoor water supply. Suitable for cold water are not suitable for hot, different types are used under different pressures.

Pipes made of steel, copper, with a protective coating are considered a universal option. They meet all the listed requirements, but they are used very rarely. The main disadvantage is the high cost and complex installation, which requires additional equipment.

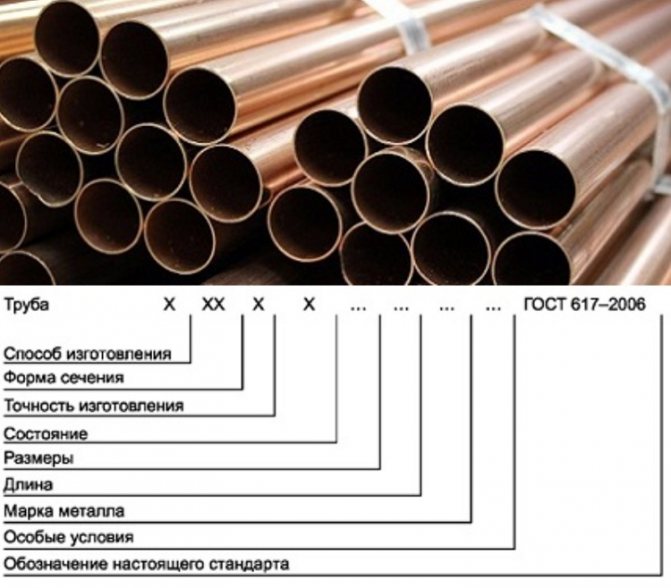

Which column assembly option is better?

A set of requirements for casing pipes and technologies for connecting well string segments is displayed in GOST 632-80. Regulations allow the use of different assembly methods.

Based on the docking method, the appropriate type of pipe is selected, so this issue must be resolved at the well design stage.

No. 1 - one-piece contact of pipes for welding

Welding provides the most rigid connection of metal pipes. The main advantage of the method is now being questioned by representatives of a number of drilling companies.

Arguments against using welding:

- the probability of insufficient tightness of the weld;

- the possibility of deflecting the pipe along the vertical axis, which makes it difficult to install the string in the well;

- insufficient corrosion protection of the seam.

However, with a high level of professionalism of the welder, there will be no listed defects.Most building structures (bridges, trusses, oil pipelines) are made of steel and, as a rule, they are welded.

Another issue is that high-quality work requires welding equipment and the involvement of a qualified electric welder. These measures increase the cost of work performed, reducing the profit and competitiveness of the executive organization.

In welding electrodes, a protective coating is used, which provides alloying of the weld. This increases the strength of the metal and increases the corrosion resistance of the joint.

No. 2 - threaded water-lifting channels

When casing a well with rolled metal, 90% of drilling companies use a threaded connection, pointing to the GOST standards. It sounds convincing enough, but managers of organizations often keep silent about the fact that the standards are relevant for pipes with a diameter of 146 mm and a wall thickness of at least 6 mm.

The use of threaded technology significantly reduces the life of the casing string.

In a pipe with a thickness of 4.5 mm, the thread size does not always reach 1.2-1.5 mm. Knowing the rate of corrosion (0.1 mm/year), it can be assumed that in 12-15 years the pipe will rot at the junction

The use of a threaded connection on plastic lines does not have such deplorable consequences, but, on the contrary, is considered the most reliable.

There are several options for joining polymer pipes:

- Nipple. The thread is cut from the inside of the plastic pipes. The two elements are connected through a nipple with an external thread. The hole diameter does not increase.

- Coupling. Both ends of the pipe have external threads.Docking takes place with the help of an overhead coupling, which increases the diameter of the penetration.

- Threaded socket. Segments with threads on the outer and inner surfaces are used - docking is carried out without additional elements.

In the case of a socket joint, a slight expansion of the diameter at the joints is permissible.

The socket method of docking without a thread is not used in wells - it is impossible to control the process of installing a pipe into a pipe. In addition, the connection does not provide the necessary tightness of the column and eventually sags.

What pipes are better to use for plumbing in an apartment?

A wide range of water pipes. presented on the shelves of stores, is able to provide the creation of any water supply. Whether you are doing a major overhaul in an apartment or re-creating a water supply, sewerage system, you will surely be able to find the necessary pipes.

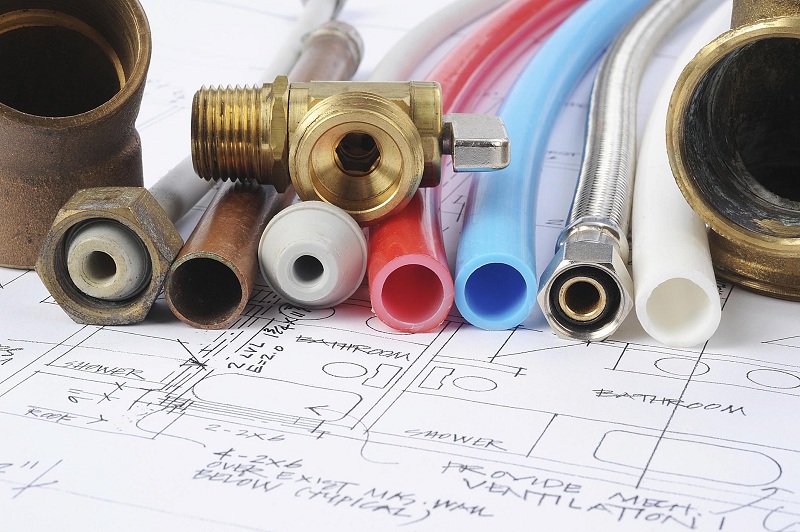

Types of pipes for water supply: 1-steel, 2-plastic, 3-metal-plastic, 4-copper.

The external diversity, the number of similar, but somewhat different pipes, is sometimes confusing when it comes to choosing which pipes are best for water supply. The problem is not as complicated as it seems at first glance. All types of pipes popular today in construction can be divided into only five categories:

- steel;

- steel galvanized;

- copper;

- metal-plastic;

- polypropylene.

The characteristics of the materials from which the pipes are made affect the technique of working with them and the methods of connection, reliability and durability. The price range is quite large. Therefore, you need to select the type of pipes for specific purposes, then the purchase will turn out to be rational.

Polypropylene pipes or metal - pros and cons

More recently, plumbing was assembled exclusively from metal pipes, made mainly of steel. Billets made of copper, stainless steel, aluminum were not popular because of the high cost. To get rid of numerous shortcomings, steel pipes were modernized. For example, they were galvanized to reduce corrosion. But improvements raised the price, and not all users could buy them.

Polypropylene pipes are devoid of most of the shortcomings of metal products, so they quickly replaced them in such a household sector as a plumbing system. In addition, the price of polypropylene pipes for plumbing is lower than that of metal ones.

The main reason for the popularity of plastic products lies in the properties of the material from which they are made. Polypropylene is obtained from petroleum products and their derivatives. There are several varieties of material for use in certain conditions.

The most popular pipes are made of static propylene copolymer (PP-R). They belong to products of the middle price category and are most often used in plumbing systems. These are single-layer pipes that are used in cold water supply systems. Monolithic products cannot be used to supply hot water, only multilayer products in which other materials are present. But they cost much more.

Why users prefer polypropylene pipes to metal ones can be found out by comparing the characteristics of pipes made of polypropylene (PP-R) and metal (steel).

| Pipe material | Advantages | Flaws |

| Polypropylene | Flexible enough to regain shape after being deformed | Cannot tolerate sunlight |

| Withstand high temperature and pressure | Not for use in hot water systems | |

| Resistance to aggressive chemical elements | Change their size greatly with temperature | |

| Installation does not require special skills | It is impossible to clean the line due to one-piece joints | |

| Salt deposits do not form on the surface | ||

| Can be installed closed | ||

| Environmentally friendly | ||

| Low price | ||

| light weight | ||

| Well absorbs sounds from the flow of water | ||

| Long service life | ||

| Pipe connections are one-piece and very reliable | ||

| Supplied in large cuts, which reduces the number of joints | ||

| When freezing water does not burst | ||

| Metal | Great strength | Corrosion resistant |

| low cost | Dirt and deposits build up on the walls | |

| Very small coefficient of linear expansion | Joints are made detachable, they require constant monitoring | |

| Actively react with various chemical elements | ||

| Large weight, which complicates installation and transportation | ||

| Supplied in small pieces | ||

| Highly qualified specialists are required for installation | ||

| High thermal conductivity | ||

| Relatively short service life |

The most popular pipes are made of static propylene copolymer (PP-R).

Dimensions and diameter

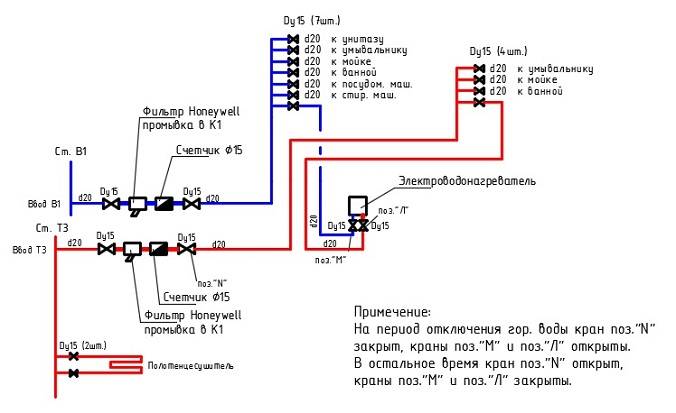

When choosing a diameter, one should be guided by the principle "the farther from the water supply to the house, the thinner the pipe." At the same time, in an apartment, usually all tubular products are mounted the same size across. The length of the water supply in it from the riser to plumbing fixtures is not too great. In this case, it is not difficult to plan the layout of pipelines for cold water and hot water, the scheme can be completely thrown on its own.

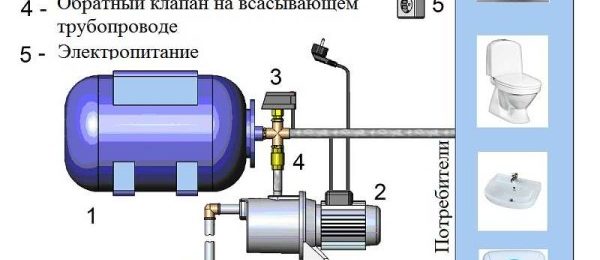

Wiring diagram of the house plumbing

For a cottage with several floors and with a lot of plumbing, a plumbing system project should definitely be ordered from a specialist. Here it is better to trust a professional who is able to competently make the necessary pipe calculations in all respects. Otherwise, then you can get a situation where, when you open the tap in the kitchen, water will not flow in the bathroom due to lack of pressure.

How to calculate pipe diameter

For intra-house wiring in diameter, pipes for water supply are most often used with an internal section of 15–32 mm. It is not recommended to install less, the pipeline will make noise or the pressure will be too low. For a street section from a cottage to a well or a centralized water main of the village, it is customary to use larger products - 32–50 mm.