- What should be the surface temperature of the underfloor heating?

- Polymer pipes

- Polyethylene pipes

- Polypropylene pipes

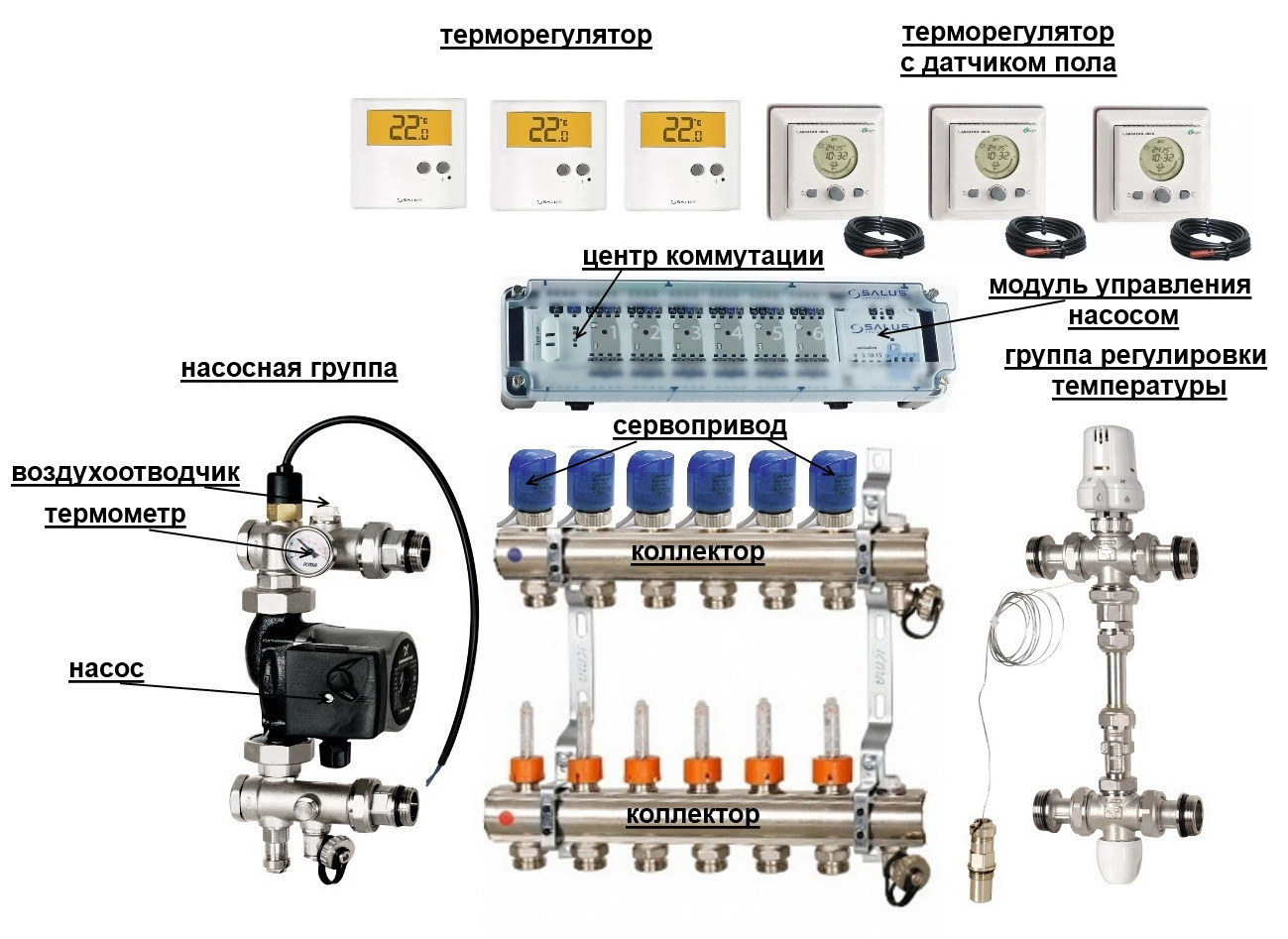

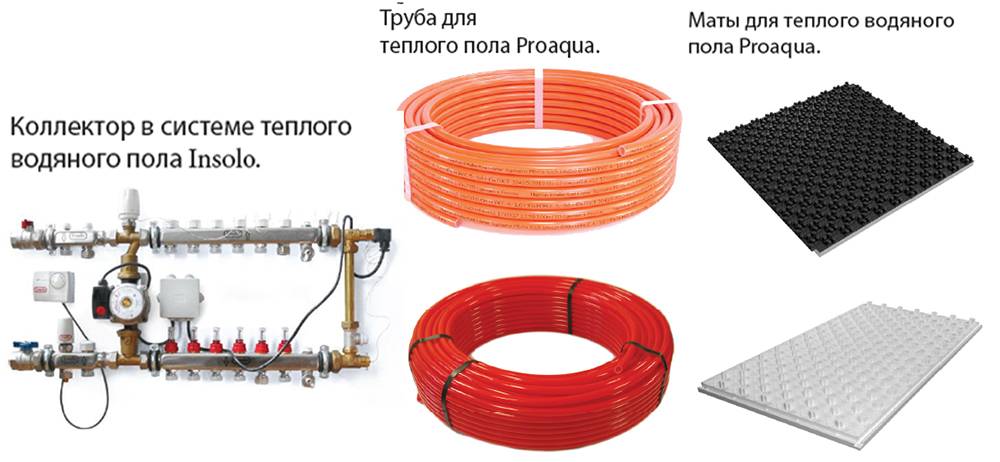

- The design of a warm water floor and how to lay it

- 7 Wavin Ekoplastik

- Which pipe is better to use for underfloor heating

- Number of pipes required for the system

- metal pipes

- Positive traits

- Mounting

- Wet floor

- dry floor

- Film

- Cable

- Infrared

- What are polyethylene pipes

What should be the surface temperature of the underfloor heating?

Actually, I already wrote about this in a separate article, but it will not be superfluous to repeat it. The following are the maximum floor surface temperature limits for rooms for various purposes:

- for residential premises and workrooms in which people mostly stand: 21 ... 27 degrees;

- for living rooms and offices: 29 degrees;

- for lobbies, hallways and corridors: 30 degrees;

- for baths, pools: 33 degrees

- for rooms in which vigorous activity takes place: 17 degrees

- in premises with limited stay of people (industrial premises), the maximum floor temperature of 37 degrees is allowed.

In the edge zones up to 35 degrees.

Polymer pipes

Plastic pipe can be made on the basis of:

- polyethylene;

- polypropylene.

Polyethylene pipes

Polyethylene as a pipe material for underfloor heating in its pure form is not used, since due to its physical properties it cannot be used at temperatures above 25ºС. However, on the basis of polyethylene are made:

- pipes made of cross-linked polyethylene. Products are labeled PEX;

- pipes made of high temperature resistant polyethylene (PE-RT).

Depending on the method of processing polyethylene, red PEX pipes are divided into the following types:

- PE Xa. Peroxides are used for production;

- PE-Xb. The crosslinking process occurs due to silane and additional catalysts;

- PE-Xc. Crosslinking of molecules is carried out with the assistance of electrons;

- PE Xd. Nitrogen is used for production.

For the manufacture of heat-resistant pipes, modified polyethylene is used, which, first of all, has high resistance to high temperatures and pressure. The distinctive characteristics of PE-RT pipes in relation to PEX are also:

- lower cost of products, which arises due to the absence of the need for additional processing of the material;

- the absence of any noise;

- extended period of use;

- possibility of connection by welding.

For higher stability, pipes can be reinforced:

aluminum (PEX-AL-PEX). The second name is metal-plastic pipes;

Metal-plastic pipe for underfloor heating

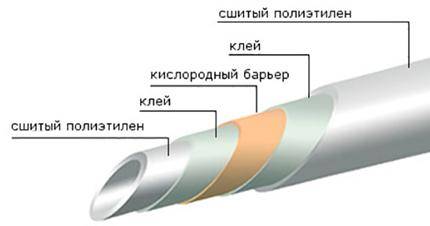

a special substance (polyethylvinyl alcohol) that creates an anti-oxygen barrier (PEX-EVOH).

Pipe with anti-diffusion protection

Pipes made of several types of material are absolutely not subject to delamination, therefore their technical characteristics and cost attract a large number of consumers.

How to choose the best option for polymer pipes? The video will help you decide on the choice of pipe.

Polypropylene pipes

Polypropylene pipe (PN marking) is available in the following types:

- PN10 - the maximum pressure that the pipe can withstand is 10 atmospheres. The temperature of the passed liquid is up to 45ºС;

- PN16 withstands a pressure of 16 atmospheres, and the water temperature rises to 60ºС;

- PN20 - at a pressure of 20 atmospheres, the maximum temperature is 95ºС;

- PN25 - the temperature remains at 95ºС, and the pressure increases to 25 atmospheres.

Thus, a warm floor made of polypropylene pipes can be made exclusively from two types - PN20 or PN25.

Polypropylene pipe of the third type

Distinctive features of pipes made of polypropylene are:

- relative durability. The service life of pipes reaches 25 years;

- low cost. Polypropylene pipes are the cheapest, and therefore are in demand on the market;

- high resistance to chemicals contained in water;

- strength, which is achieved by foiling the pipe.

Polypropylene pipe reinforced with aluminum foil

The disadvantages of this type of pipe are:

- low temperature level. The manufacturers state that the pipe can withstand temperatures up to 95ºС, but at the same time, the value at 80ºС is optimal. Reducing the recommended temperature regime leads to the need to install additional equipment;

- installation difficulty. As a rule, pipes are produced in small lengths. To connect individual pipes into a whole water circuit, welding is required. This reduces the service life of the finished structure.In addition, polypropylene pipes are characterized by low elasticity. It is impossible to bend them into a small radius;

- high degree of expansion when exposed to temperature. When using pipes for hot water supply, special expansion joints are installed on the surface, but in the manufacture of a water floor, the installation of expansion joints is not possible, which leads to a decrease in the service life of products.

The cost of polypropylene and polyethylene pipes is almost the same. Therefore, experts recommend using pipes with more reliable technical parameters.

The design of a warm water floor and how to lay it

Having fully prepared the required materials and armed with the necessary theoretical knowledge, you can proceed with the installation of a warm floor. And the following detailed instructions will help you understand the installation process more clearly.

So, the algorithm for creating a warm water floor includes the following sequence of actions:

Level the prepared floor surface with a special construction mixture.

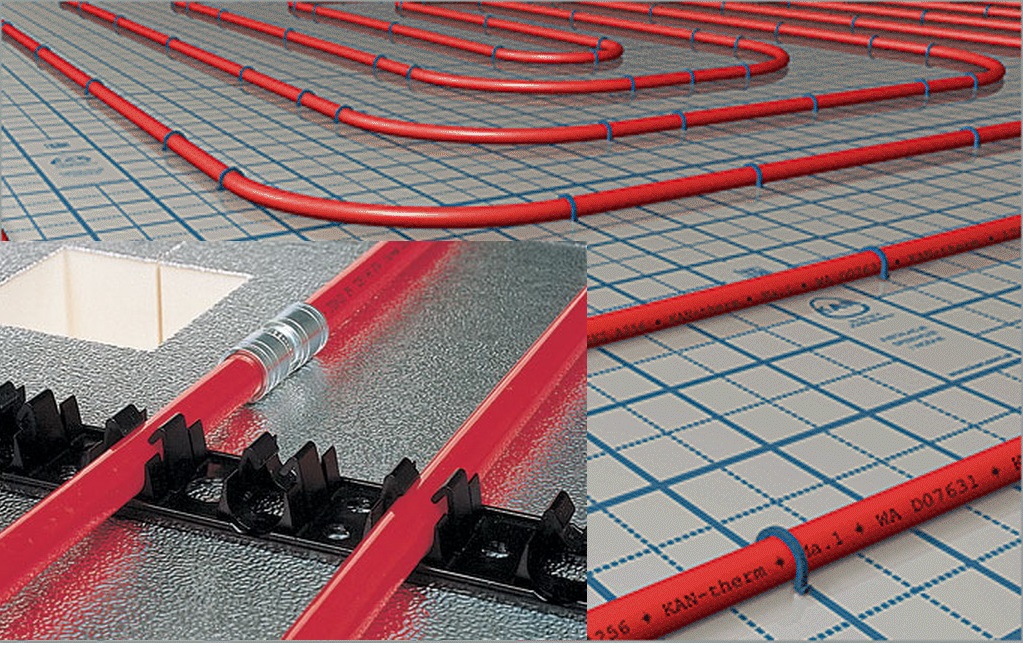

Next, lay a layer of heat-insulating foil material that will reflect heat, preventing it from going down and to the sides.

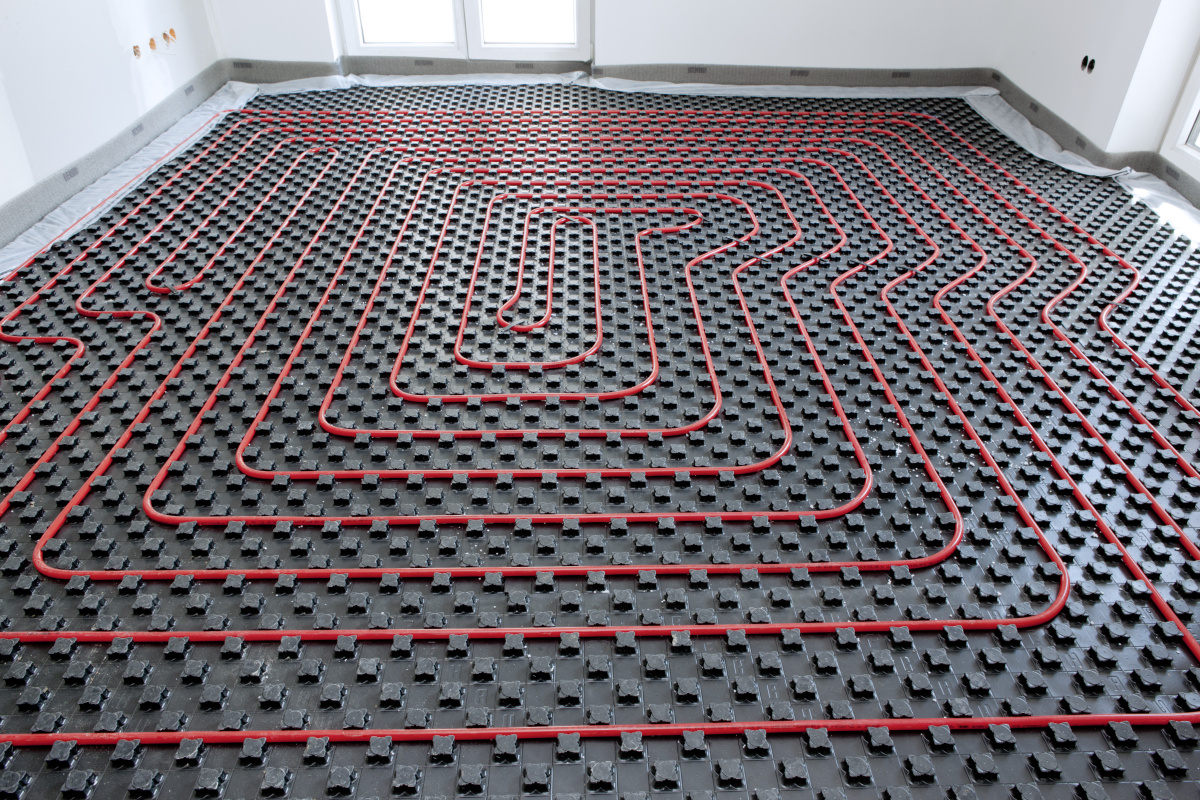

Lay the selected pipes in the required order, fix them with heat-insulating elements.

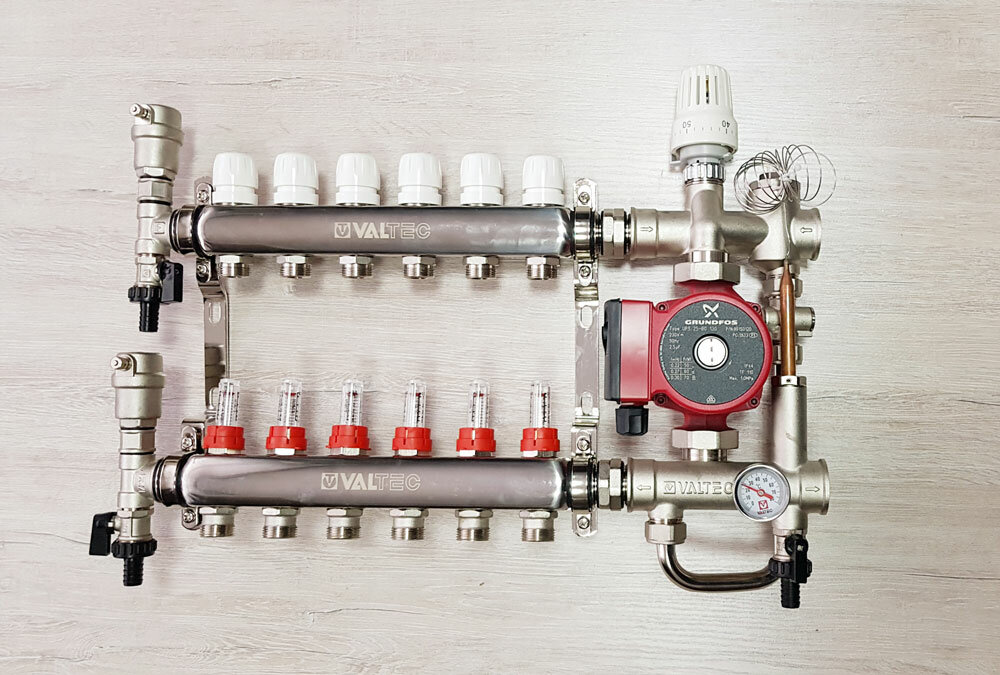

Connect the pipes to the pump and check the operation of the system, paying attention to a thorough inspection for possible damage and leaks.

After a few days, make a concrete screed (taking into account the linear expansion of polypropylene pipes and the creation of special channels for them), and level the floor surface.

Install the final floor covering.

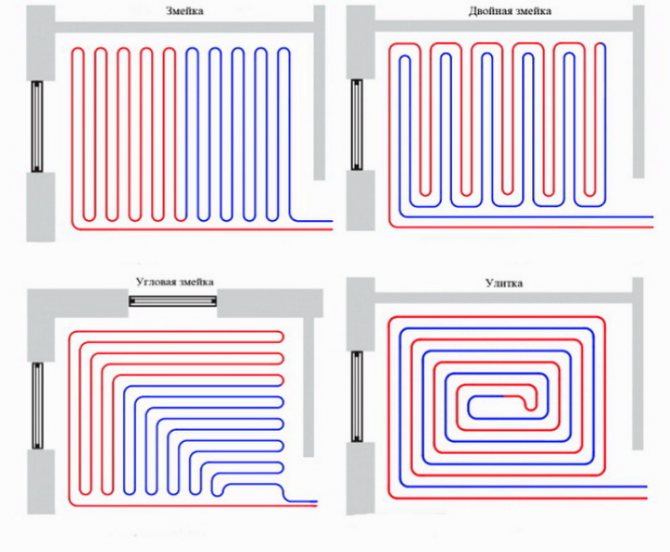

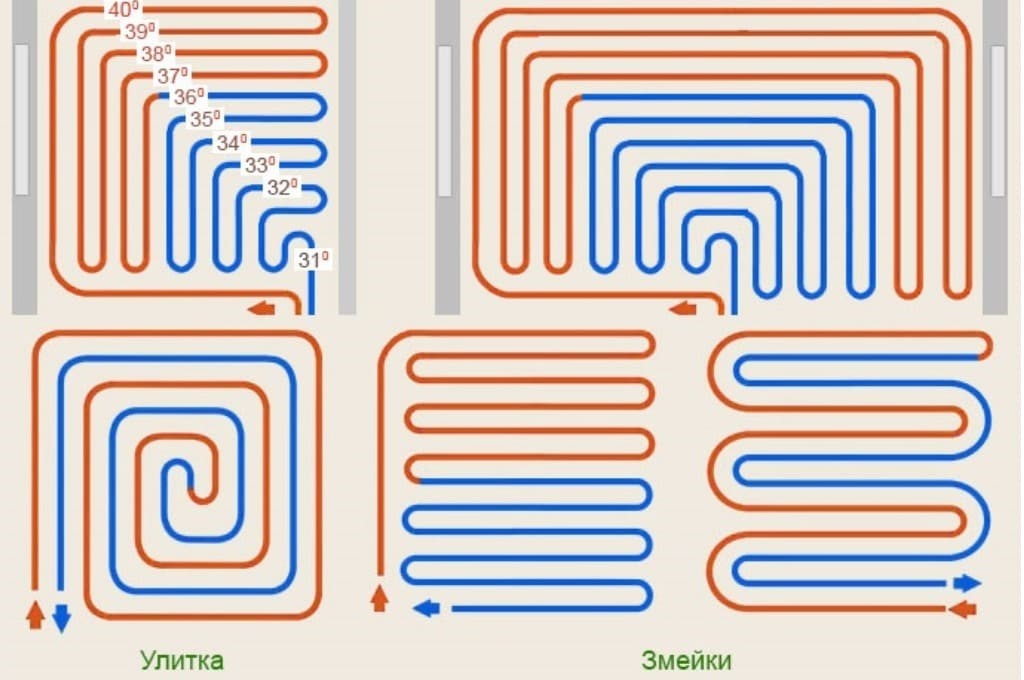

To ensure the best heat transfer and maximum efficiency of the underfloor heating system, there are several pipe laying options.

These include:

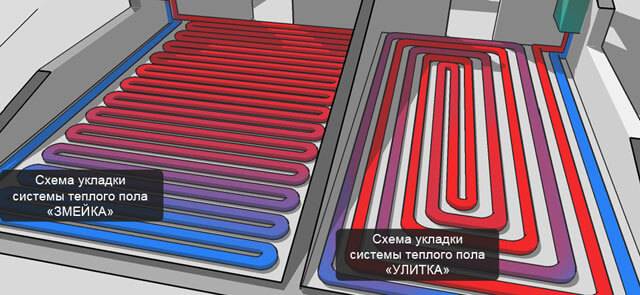

- placement in a spiral (or snail), due to which there is a more uniform and high-quality distribution of heat over the entire surface;

- placement in the form of a zigzag (or snake) allows you to quickly install the system, but contributes to uneven distribution of heat;

- the combined version combines the advantages of the two previous methods and is most often used in fairly large rooms with a significant surface area.

When installing a warm water floor, experts recommend:

- start laying pipes in the area with the lowest temperature (sides near the window or door);

- during the installation of pipes, extreme care should be taken and mechanical damage should not be allowed (for example, you should not step on them);

- make the optimal step between the pipes, which, as a rule, is 100–400 mm;

- take into account that with an increase in the step, it becomes necessary to increase the temperature of the coolant;

- take into account the manufacturer's data on the maximum permissible temperature values in the system in order to avoid damage to the floor covering or cracking of the concrete screed;

- comply with the normative temperature regime of underfloor heating, which is 25ºС for rooms with permanent stay of people, and 32ºС for rooms with periodic stay;

- in order to avoid damage to the furniture, it should not be placed directly above the warm floor.

This article describes in detail which pipe to use for a warm water floor, as well as what you should pay attention to when choosing and installing it. After studying the detailed descriptions and instructions, you can safely proceed to the next stage - the arrangement of a warm floor

Excellent quality of components and the whole system is guaranteed!

7 Wavin Ekoplastik

In reviews of the possibility of using polypropylene pipes in water-heated floor systems, we often met negative opinions - they say that the thermal conductivity of polypropylene is too low, and its flexibility leaves much to be desired. This is absolutely true for conventional polypropylene. However, Wavin Ekoplastik produces pipes from 4th generation polypropylene, which is marked as PP-RCT and is characterized by high strength, heat resistance and a melting point increased to 170 °C.

As a result, pipes from a Czech manufacturer can withstand more stringent temperature conditions (the maximum continuous temperature is 110° with an allowable short-term increase of another 20°). The unique strength properties of the material allow you to set a smaller circumference and wall thickness, and thereby increase their throughput without compromising the durability of the system. Remains pleasant and its cost. The only thing is that PP-RCT pipes look no different from ordinary polypropylene pipes, so we recommend buying underfloor heating in a trusted store.

Which pipe is better to use for underfloor heating

When choosing pipes, many are wondering what material is better to buy pipes for underfloor heating. The choice of purchase will be influenced not only by price and quality, but also by the ease of installation of the selected product.

It is also worth paying attention to the advantages and disadvantages of a particular type of material from which the coolants are made.

When choosing between copper and stainless steel corrugated pipes, you need to compare their positive and negative qualities. For example, copper pipes are durable and reliable. They have good heat conductivity. You can pour into the system not only water, but also antifreeze or antifreeze. With great strength and resistance to temperatures, they can be used almost anywhere. The low coefficient of resistance of the inner layer allows the liquid to circulate freely within the system. This allows you to choose coolants with a minimum diameter (16 mm).

Corrugated stainless products are just as strong, flexible and durable. However, choosing from these two types, which pipe is better, you need to know:

- Copper materials are afraid of acidity and water hardness. These factors significantly reduce the service life.

- The price of copper and stainless pipes is quite high.

- The installation of such pipes requires considerable financial costs. You need to hire specialists, have special equipment. True, these costs are paid off due to the long-term operation of these systems.

- The main condition for the operation of corrugated stainless steel coolants is the absence of electric current on them.

- The combination of copper and steel can lead to negative electrochemical processes.

Choosing between metal materials and metal-plastic, which pipes are better, preference is given to the latter. This is due to the lower price of the product.

Layout example

Metal-plastic, also durable in use. Unlike copper and stainless, water flows through these pipes almost silently.This material does not react with various chemical elements of water. Metal-plastic pipes are much lighter than copper and stainless pipes. Their installation is quite simple and does not require special technical skills. The heating system can be installed independently and quite simply.

The disadvantages of metal-plastic products include

- Short-term exposure to temperatures above +100°C.

- This material is susceptible to open fire.

- When crushed with a mounting nut, a notch may appear on the pipe, and subsequently leak.

- Poor-quality connection of pipes with fittings, at the joints, a lime layer will form.

You also need to pay attention to the large number of Chinese fakes of these products. Polypropylene coolants, although they do not have a high cost, are used less frequently.

This is due to the large bending radius (8 - 9 pipe diameters). During installation, additional special connections must be used.

Polypropylene coolants, although they do not have a high cost, are used less frequently. This is due to the large bending radius (8 - 9 pipe diameters). During installation, additional special connections must be used.

Their advantage is a fairly simple and reliable method of connection (soldering). The joints are strong, monolithic.

Which polyethylene pipes are better to choose for underfloor heating can be determined by product labeling, knowing the minimum crosslink density. The price will depend on the value of this indicator. But it will be significantly lower than that of pipes made of metal material.

The main disadvantage of polyethylene products is the need for rigid fixation during installation.

It is also worth paying attention to a careful attitude during the delivery and installation of such coolants. Defects in the anti-diffuser protective layer will lead to a reduction in the service life

Having studied all the advantages and disadvantages of various types of material, everyone chooses which pipes are best used for warm water floors. It is more expedient to make a complete re-equipment of the heating system in a private house. For multi-storey buildings, additional permits will be required, which will entail unnecessary expenses.

Polyethylene is made up of hydrocarbon molecules that are not linked together. However, new developments have made it possible to connect molecules through the interaction of carbon and oxygen atoms. Such technologies have made it possible to create a new material - cross-linked polyethylene (PEX). With additional processing (under high pressure), it acquires greater strength.

Number of pipes required for the system

Scheme of the device of a metal-plastic pipe.

In addition to the material, when calculating, it is necessary to take into account the water pressure in and the heated area of \u200b\u200bthe room.

Based on the data obtained, the optimal pipe diameter is selected. Typically, pipes having a diameter of 1.60 are used; 2.0 or 2.5 cm. If you install pipes that have a diameter smaller than the required one, this will lead to a violation of the circulation of water in the system.

Water pressure can be measured with your own hands by connecting a pressure gauge to the riser. After that, you can begin to determine the required length of the pipe.

This is done so that the coolant first heats the cooler air and then distributes it throughout the system.Places in the room where built-in or heavy furniture will be located are not equipped with underfloor heating. To obtain more reliable results at this stage, it is necessary to choose a method for laying pipes in the floor. To date, the most popular are two underfloor heating circuits with water:

- zebra or snake;

- snail or spiral.

"Zebra" is widespread in the west of Europe and is good for ease of calculation and device. However, such a circuit cannot boast of a uniform distribution of heat and is characterized by significant temperature differences between individual sections of the floor corresponding to the output or input of the circuit. Often the floor temperature can exceed the maximum allowable rate. Convenience is not added from this, and heat losses increase. "Snake" is advisable to use in rooms with small heat losses and temperature amplitude of water fluctuations at the outlet and inlet within 5 ° C.

Scheme of installation of a warm floor using the "zebra" method.

In the CIS, the “snail” contour is more common, although it is characterized by more complex design and installation in comparison with the “snake”. This method of installation ensures uniform distribution of heat over the entire area of the heated room. This happens due to the alternation of parallel-laid supply and return pipes. In such a floor heating system, the return point of the coolant is located in the middle of the pipe, and the average temperature is constant anywhere. Everything, you can start the calculation.

Taking a sheet of graph paper or any other paper with divisions, it is necessary to draw a plan of the room on a scale of 1:50, taking into account all doors and windows on a scale of 1:50.The plan shows the contour of the proposed warm floor, and it should start from the wall adjacent to the riser, which has windows. According to the current building codes and regulations, there should be at least 25–30 cm between the underfloor heating pipe and the wall, and the distance between the pipes to be laid depends on the diameter and usually ranges from 35–50 cm. Having drawn a drawing, it will not be difficult to measure the length of the pipes. Multiplying the result by 50 (scale factor) gives the actual length of the contour. Do not forget that you need to add another 2 m to connect to the riser. You can also calculate the quantity using the following formula: S / n + 2 x lpt, where

- S is the area of the room (m2);

- n is the distance between the pipes;

- lpt is the length of the supply pipes.

Any of the values \u200b\u200bcan be measured using a tape measure.

Scheme of laying a warm floor "snail".

The area of the room can be found from the plan or you can multiply the width of the room by its length. If the room is equipped with overall furniture or appliances, then under it the warm floor does not fit, which means that the area will also decrease. In addition, as mentioned above, it is necessary to observe the distance between the walls and pipes, which should be at least 30 cm. The distance between the pipes to be laid is the step between the axes of the underfloor heating pipes. This value, depending on the characteristics of the room, ranges from 5 to 60 cm, that is, it depends on the humidity and temperature in the room.

The colder the room, the smaller the pitch between the pipes. The main thing here is not to get carried away, it may happen that the floor will be too hot, and operation will become simply impossible.The length of the supply pipeline is characterized by the distance between the collector and the beginning of the pipes that form the underfloor heating system. In this case, some part may be recessed into the wall. It is also necessary to take into account all the bends. If it turned out that the length of the pipe is more than 70 m, then it would be better to divide it into two circuits, and in each circuit the length of the supply and return pipes should be taken into account.

metal pipes

The water floor from metal pipes differs in the big durability and service life. Metal is more expensive than plastic, but in some cases there is no alternative to it. Its final cost is higher than that of a warm water floor made of polymer pipes, but this is offset by good performance.

The metal perfectly withstands temperature changes, is not very susceptible to deformation, and has good thermal conductivity. Thanks to this, a warm water floor made of metal pipes quickly and efficiently warms up the room.

A warm water floor made of copper pipes has a long service life. It is advisable to equip it in houses with central heating, where the water does not differ in quality.

Upon contact with water, a corrosive film forms on copper, which prevents water from penetrating deep into the copper. Thanks to it, the metal is protected not only from water, but from any chemical attack.

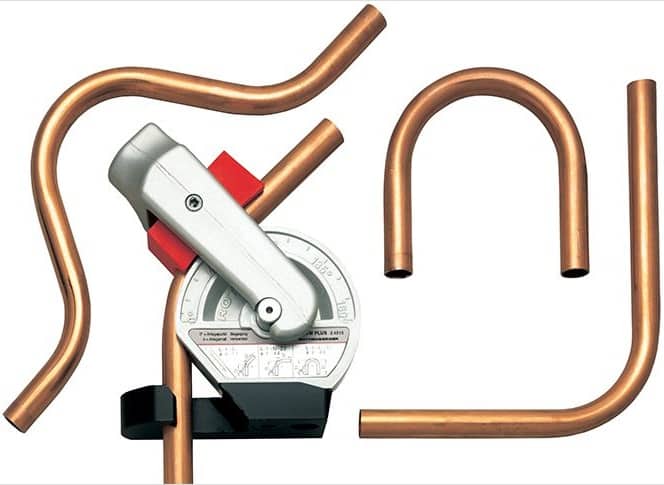

When installing copper pipes, it is necessary to use a pipe bender to prevent cracks when bending. Copper soldering is carried out with a special flux, the quality of which significantly affects the service life of the system.

Features of copper pipes for water floor:

- Service life of 50 years;

- The minimum bending radius is equal to two diameters;

- Connection with brass and steel fittings only through a threaded connection.

Stainless steel is the most expensive, but high-quality material for a water floor line. Due to the corrugated surface, it has high strength and a minimum turning radius of 1-1.5 diameters.

Stainless steel is not susceptible to corrosion, acid and alkali, and lime formations are not deposited on it. Experts say the minimum service life is 50 years, but in reality it is much higher.

Positive traits

A set of unique characteristics refers to the number of pipes made of cross-linked polyethylene

The main attention is paid to high heat resistance, which allows the use of coolant in the pipeline up to a temperature of 120 degrees. When compared with other products made of polymer material, they are able to fully function at a coolant temperature of no more than 80 degrees

In addition, they are characterized by reverse shrinkage, excellent elasticity, which allows you to create different radii and bends of the contour of the warm water floor system.

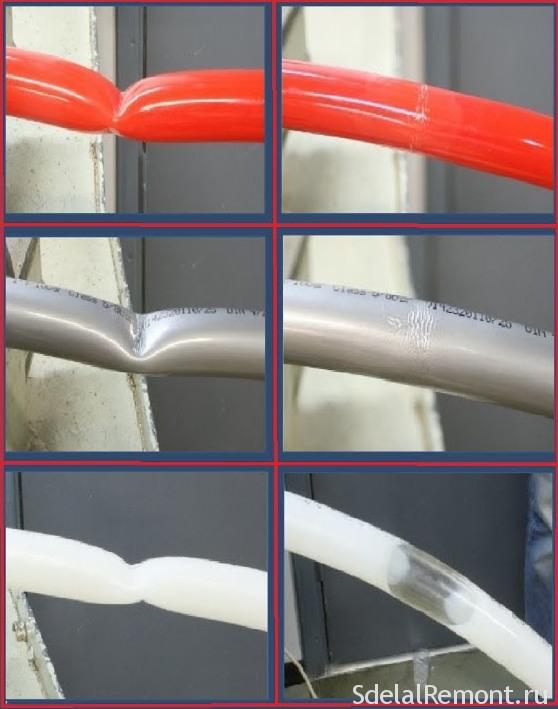

Pipe bending is strictly prohibited.

Pipe bending is strictly prohibited.

One very interesting quality of cross-linked polyethylene is the ability to recover from significant stress. If in this case other products similar in composition were used, then they would simply stretch or even break. All this leads to the speedy repair work.

During the installation of a water floor heating circuit, pipes made of cross-linked polyethylene can be located on the base with a different radius. In this case, a fracture can be easily avoided due to the presence of the properties and qualities of the material itself.It is worth noting that for the floor screed itself, as well as for the environment, polyethylene does not have any negative impact. No emissions of harmful substances are carried out even after the expiration of a long operating period. The quality of the material allows the system to work for a longer time fully in comparison with similar materials and products. During the entire time, no one will encounter rotting of the material, the appearance of corrosion, both inside the pipe and outside.

If cross-linked polyethylene is used when installing a warm water floor, then it allows you to absorb incoming vibrations. This reduces the level of noise coming into the room.

But no material can boast only positive qualities. There can be no ideal variant of a pipe for a warm floor. There are, albeit minor, but disadvantages that should be remembered when buying such material. In some cases, even they can lead to more serious consequences.

The main disadvantage is oxygen permeability. This factor can cause corrosion of those components that are located next to the pipeline. But even this point can be almost completely avoided. In this case, special spraying should be carried out on pipes made of cross-linked polyethylene.

Since such pipes retain their shape very poorly, it is best to fix them immediately securely using appropriate fasteners (rails, clips). The fasteners almost always have mounting grooves, where the pipes are placed.

Mounting

Before carrying out it, you should check the sealing of walls, window openings and doors. Then you need to prepare the base, it should be even.Using the level, check the flatness of the base, if there are deviations, then eliminate them by performing a screed.

Initially, a place is chosen for installing the thermostat and access to communications, if we are talking about electric heating, in the case of water heating, the location of the boiler, pipes and taps should be provided.

The installation work for each heating system is different and is described in more detail below.

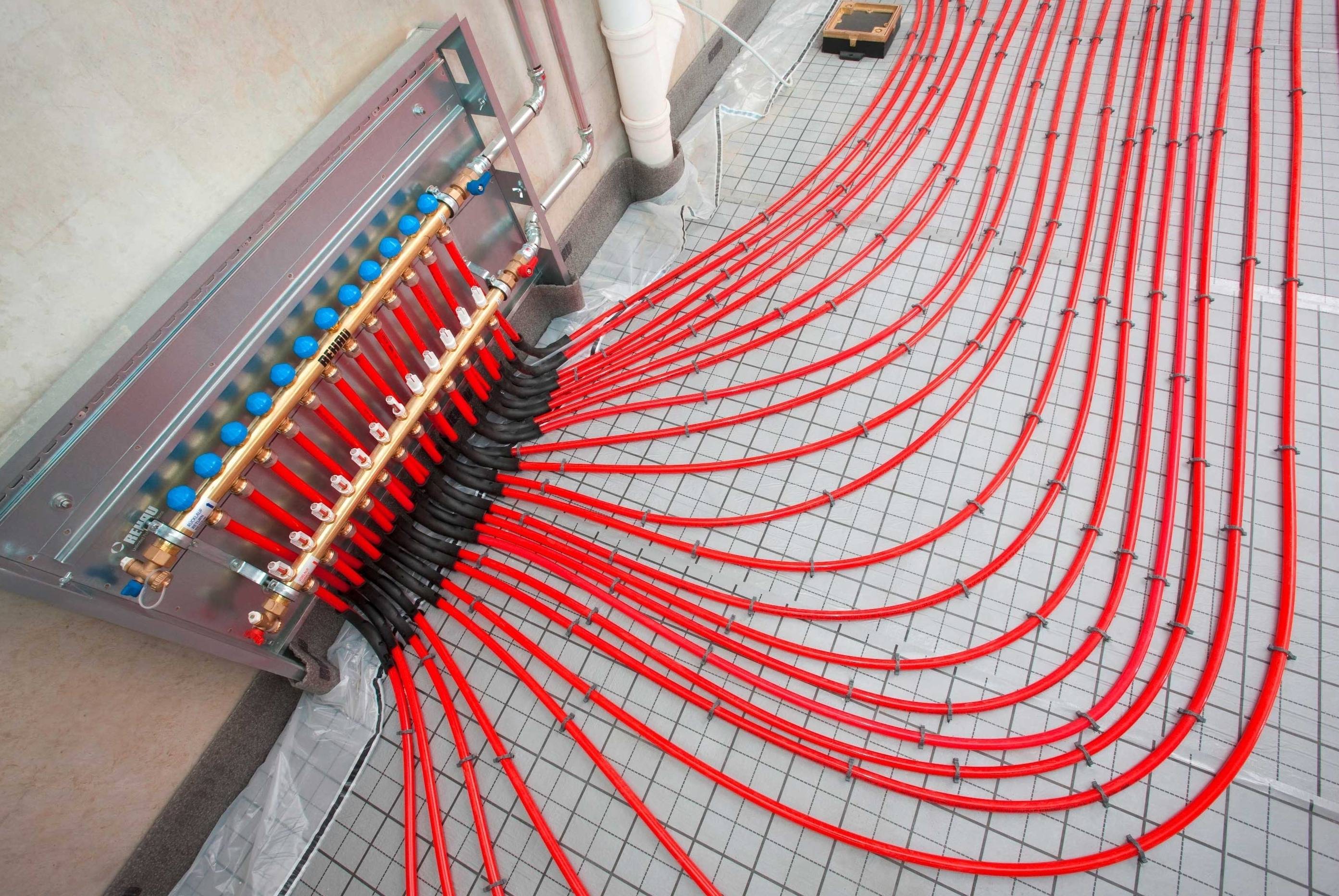

Wet floor

Installation begins with the selection and organization of the place for supplying the coolant. Holes should be made in the walls through which the pipes will pass and the necessary floor cranes should be installed.

It is best to provide a free niche in the bath for arranging the outlet of such heating, which can be converted into a closet so that communications are invisible.

A mesh is laid on the pre-leveled floor for fastening pipes, which are fixed with the help of screeds. The pipe must be folded in half in order to organize not only the input of the coolant, but also its output.

After checking the laying of water heating, you can connect it to the taps (supply and return).

After that, a test run of the system is performed, which will help identify a leak, if any, wait for the maximum pressure of the network, which will depend on the heating of the coolant.

At the end of the installation, the screed is poured and the subsequent laying of the floor material.

The entire design of water heating is multi-layered:

- waterproofing material;

- insulating;

- foil;

- pipes;

- screed with reinforced elements;

- clean floor.

Pipe laying patterns can be different, and although a spiral is often used, a snake or its double version is sometimes used.

The pouring of the concrete screed along the laid pipes starts from the far wall and ends at the door.

It is imperative to provide for the zoning of the room according to the beacons, and the concrete mixture poured over the pipes is leveled with the rule in order to avoid warping the base of the new floor.

If semi-dry mixtures are used for pouring, then after about 6 hours the surface must be sanded so that it does not completely harden.

dry floor

Its installation will depend on the choice of the type of electric floor, and it can be:

- film;

- cable;

- using heating mats.

Film

It is made of thin strips that emit infrared radiation, it is similar to the sun, only unlike the latter, it excludes the influence of harmful ultraviolet radiation. Flexible strips are made of carbon and sealed in a polymer film.

When laying such a floor in a bath, you should first lay an isolon - the material will reflect the resulting heat up. Then the heating elements are laid out, which are covered with a plastic film.

The latter serves as a waterproofing for heating elements. At the end of the installation process, the finishing coating is laid.

Cable

The convection type of underfloor heating consists of a heating cable that is laid on a mesh base. The cable floor is sold in rolls.

Installation of such a variant of the electric floor is a rather laborious process, it is better to entrust it to specialists. It can be used under different floor coverings.

Infrared

The bar elements are called mats. Their name comes from the heating rods that are connected to the power wires. They are connected in parallel, so you should not worry if one element fails.

When considering infrared mats, they can be compared to a rope ladder. They are mounted in tile adhesive or cement screed, protected by isolon.

Read more about the installation of the infrared floor in the article - How is the installation of the infrared floor heating under the tile? Overview of ways

What are polyethylene pipes

In the manufacture of polyethylene pipes for underfloor heating, the polyethylene cross-linking method (PEX pipes) or the new PERT technology can be used.

At the same time, pipes sewn from polyethylene can be processed in different ways, which is the determining factor for the following varieties:

- PE Xa.

- PE-Xb.

- PE-Xc.

- PE Xd.

To determine the type, products are marked with appropriate designations. Water floors are equipped with PE-Xa and PE-Xb pipes: they contain only virgin material, which guarantees high durability of the product.

The use of the latest PE-RT technology allows you to provide products with certain advantages compared to polyethylene pipes:

So that oxygen does not act on polyethylene in a destructive way, pipes made of this material began to be equipped with a special oxygen barrier along the inner surface. It makes sense to use polyethylene pipes in underfloor heating in cases where the system is mounted inside an apartment or a residential country house. Freezing the system in this case is best avoided.