- Installation nuances

- Cast iron pipes

- Asbestos cement pipes

- Ceramic pipes

- Pipes made of polymeric materials

- Metal-plastic pipes

- Sewer types

- What are there?

- Cast iron

- Plastic

- PVC and HDPE

- How to choose pipes for storm water

- Types of sewer pipes

- What material is used for manufacturing?

- Sewer pipe diameters

- Sewer pipes - how to choose them?

- Structural material

- Communications diameter

- Asbestos-cement pipes

- Types and characteristics

- PVC sewerage

- Polypropylene (PP)

- corrugated polyethylene

- Asbestos-cement

- Concrete

- metal

- Cast iron sewer

- Ceramic products

- The material used for the production of sewer pipes

- metal

- Steel

- Cast iron

- Ceramic

- Concrete

- Asbestos-cement

- PVC

- Polypropylene

- Requirements for outdoor piping

- No. 2. PVC pipes: advantages and disadvantages

- Peculiarities

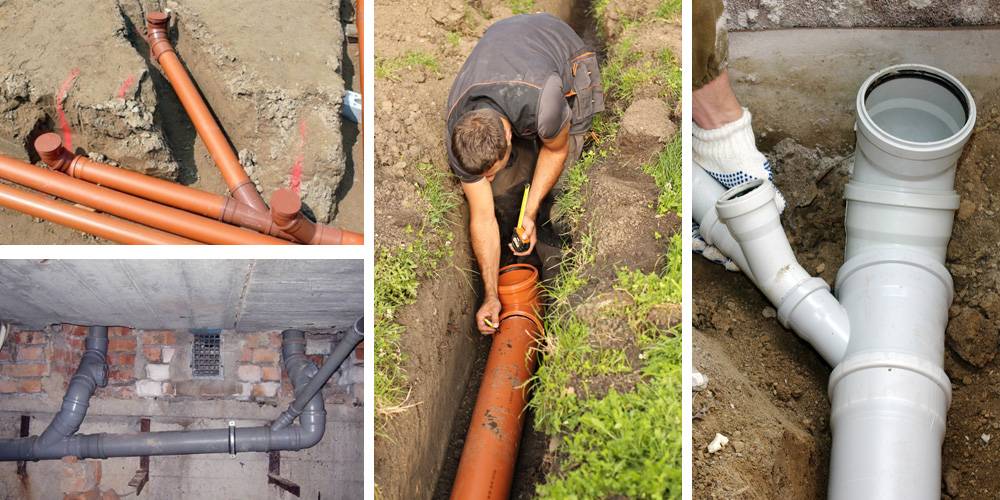

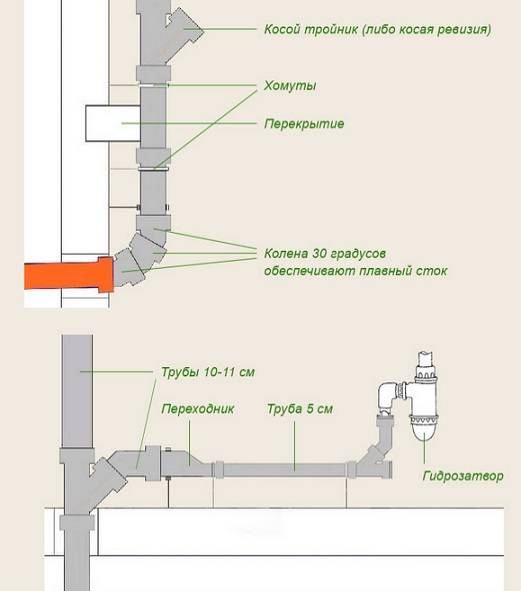

Installation nuances

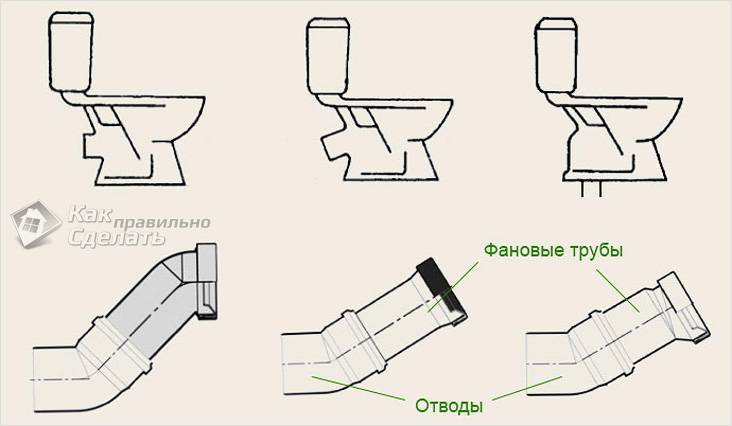

There are a number of nuances in the installation of sewage, ignoring which you can get not a good drainage and drainage system, but in Russian speaking, big hemorrhoids. So I will list as much as possible:

- When cutting pipes, the cut must be strictly perpendicular to the axis and must be processed with sandpaper;

- The elements to be glued must be degreased;

- Fittings with a rubber seal must be coated with silicone sealant;

- The cross section of the horizontal pipeline should not exceed the diameter of the sewer riser;

- In places where the pipeline turns, revisions are required - holes for cleaning with a cover;

- Horizontal connections must be assembled from angles and oblique tees;

- They fix the sewer at intervals equal to 10 x the diameter of the pipe;

- The slope of horizontal sections should not exceed 1-2 cm / 1 m; 9. The bell is located towards the moving fluid.

Cast iron pipes

Listing the types of metal pipes used for the installation of sewerage systems, one cannot fail to mention cast iron products. Since it was cast iron pipes for decades that were the main material for assembling sewer networks. The main advantages of this material are:

- Durability and long service life;

- Corrosion resistance.

The disadvantages of the material include:

- Large weight, which makes it difficult to transport the material and its installation.

- Relatively high brittleness. Pipes made of cast iron do not tolerate shock loads.

- The impossibility of using for laying an external pipeline in saline soils, since the soil brine quickly destroys the material.

- Rough inner surface, due to which the pipes become clogged faster.

Asbestos cement pipes

For the production of such pipes, a mixture of asbestos fiber with Portland cement is used. Advantages of these products:

- Resistance to corrosion processes.

- Ease of machining, which greatly facilitates installation.

- Long service life.

- Smoothness of the inner surface.

- Asbestos cement is a dielectric, so this material is not subject to electrochemical corrosion.

Asbestos-cement pipes have disadvantages, these are, first of all:

- Brittleness of the material. When working with pipes made of asbestos cement, you have to be extremely careful and accurate.

- Under the action of the soil, the outer surface of the pipes is quickly destroyed, so protective measures must be taken.

Ceramic pipes

Ceramic pipes in their properties resemble cast iron, however, they are lighter and one hundred percent resistant to corrosion. The undoubted advantage of ceramic pipes is their resistance to high temperatures and the effects of aggressive environments - acids and alkalis.

However, the material is quite fragile, so you need to carefully handle the pipes during loading, transportation and during installation. In addition, mechanical processing of pipes (cutting) is difficult; when trying to cut a pipe, it can simply split.

Pipes made of polymeric materials

Today, various types of plastic pipes for sewerage are widely used. For the manufacture of such products, three types of polymers are used:

- PVC.

- Polypropylene.

- Polyethylene.

PVC pipes are designed for gravity sewerage systems. The material is strong enough to withstand high loads. PVC pipes are widely used for the installation of outdoor systems, as they are inexpensive, able to withstand aggressive environments, and resistant to ultraviolet radiation. But the impact of temperatures above 70 degrees of the pipe does not tolerate, at very low temperatures PVC becomes brittle, so it is recommended to insulate them.

Various types of polypropylene pipes are widely used to assemble sewerage systems.These pipes have a long service life, they can be used for both gravity and pressure systems.

It is necessary to distinguish between types of propylene pipes intended for internal and external pipelines. The first type of pipes was created for use in the home, they are strong enough, but not able to withstand the effects of low temperatures and the load exerted by the soil.

For external pipelines, special types of pipes are produced - two-layer. Their inner layer is perfectly smooth, and the outer layer is corrugated, so the pipes are characterized by increased strength.

When assembling sewerage systems, different types of polyethylene pipes are increasingly being used. This material is mainly used for the installation of non-pressure systems. The great advantage of this material is its high elasticity, when the liquid in the pipe freezes, polyethylene does not collapse, but only deforms.

Metal-plastic pipes

For the assembly of various systems, including sewage systems, various types of metal-plastic pipes are widely used. These pipes have a plastic coating, so they are one hundred percent resistant to corrosion, chemically neutral and fairly easy to process.

At the same time, the presence of a metal core gives these products increased mechanical strength. The disadvantages of the material include their rather high cost.

Sewer types

According to the type of transportation of sewage sewage, there are:

- Gravity-flowing. Liquid and solid contents move through the pipes under the influence of gravity with their direction at a slope. In such systems there is no excess pressure, but blockages may form during operation.

- Pressure.The movement of drains from the bottom up is possible, naturally, such a system requires the mandatory installation of a pump.

For the first method, free-flow pipes for sewers are used. There are many varieties of such products according to the material of manufacture, which we will discuss a little further, as well as according to the type of the pipe itself - smooth and corrugated. However, the main difference between pressure sewer pipes and non-pressure ones is the ability of the former to work under conditions of high pressure.

This, of course, does not mean that ordinary free-flow pipes cannot withstand high pressure - on the contrary, they can be quite strong and reliable, however, this condition is simply not included in the technical specifications for such products.

What are there?

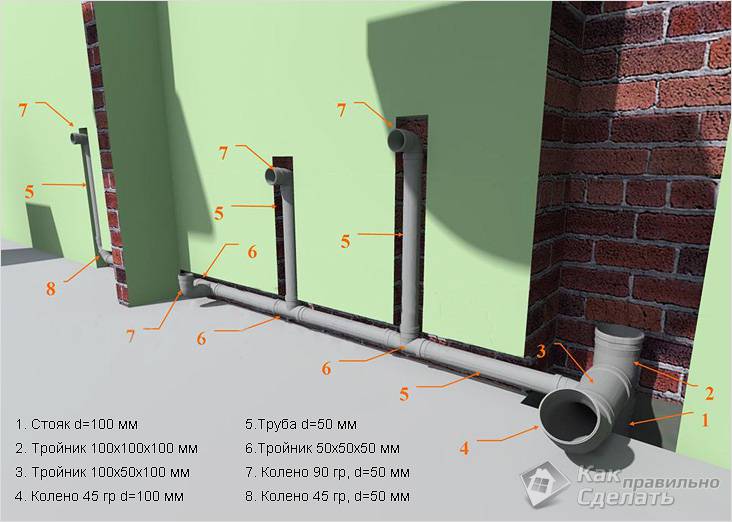

Most often, when repairing in apartment buildings and small cottages, standard sizes of outlet pipes are used. For internal networks, a diameter is selected in the range from 50 to 110 mm, and for external highways from 110 to 600 mm. All central pipes and risers are made of 110 mm pipes, as well as water drainage from the toilet. Pipes from sinks, bathtubs and showers have a diameter of 32 to 50 mm.

External sewerage is most often mounted from wide paths, however, products of 100–110 mm are quite suitable for a small private house. And in multi-apartment skyscrapers, pipes with a diameter of 160 mm are most often used to drain waste into the central sewerage system.

Cast iron

Cast iron products do not leave their positions in the construction market yet. Although they can rarely be found inside apartments and houses, they are still indispensable for highways on the scale of a district or an entire city. They are produced by casting by centrifugal force with the formation of sockets.Unlike their predecessors, modern cast iron products have a special coating on the inside for better water glide, and on the outside to protect against corrosion.

The advantage of cast iron over other materials is its strength, resistance to sudden temperature changes and long service life. They are inexpensive and successfully resist destruction under the influence of an aggressive environment, which is not uncommon in sewer systems. The disadvantages are the large weight and the cost of a large amount of material, the high risk of formation of build-ups inside the pipe and their high cost.

Cast iron pipes are produced with a diameter of 50 to 300 mm for use in the internal and external drainage system of apartment buildings and private houses. For large highways serving the entire city, huge cast-iron pipes with a width of 300 to 1200 mm are being laid.

Plastic

Plastic pipes are a popular alternative to bulky cast iron. They have a number of advantages, including ease of installation and resistance to freezing. Like cast iron, plastic is resistant to high temperatures, impervious to ice and allows mounting systems with high hydraulic pressure. Compared to metal products, plastic is a budget material.

With all its advantages, the choice of such a material will entail some features. Polyvinyl chloride, from which the pipes are made, is very noisy during the passage of water flows through it. And if the angle of the pipe is set incorrectly, then the risk of blockages and a water seal increases significantly.In addition, plastic does not withstand temperatures over 90 degrees.

For internal sewage, pipes with diameters of 32, 50 and 110 mm are usually used, for external systems - 110 mm. The connection of the segments to each other occurs both by soldering the material, and with the help of various types of fittings.

PVC and HDPE

The most popular material for the installation of sewer systems in private houses and high-rise buildings are polymer pipes made of polyvinyl chloride and low-pressure polyethylene. Like any material, they have their advantages and disadvantages. The advantages include their low cost, elasticity (flexible pipes can be laid at any angle that does not pinch them), and ease of installation. They are silent and non-toxic, very resistant to corrosion and last up to 50-60 years.

Unfortunately, HDPE cannot be used to drain water hotter than 45 degrees, and PVC products do not tolerate high temperatures well. They are not very resistant to mechanical damage and can change their properties after a long stay in direct sunlight.

The minimum dimensions of pipes made of polymeric materials for the internal sewer system start from 32–40 mm and end at 90–110 mm. For the installation of external systems, HDPE pipes are practically not used, and the thickness of PVC products reaches 15 mm. The diameter of the pipes themselves ranges from 200 to 500 mm.

For greater convenience, special tables of standard sizes of PVC sewer pipes are used, since this material is used in more than half of the cases. They are used to select pipes for the internal sewerage system and such tables look like this.

| Nominal diameter DN, mm | Inner diameter ds min, mm | Wall thickness, mm | Bell length, mm | Free end length, mm | |||

| e | e2min | e3 min | Amin | Cmax | L1min | ||

| 32 | 32,3 | 1,8 | 1,6 | 1 | 24 | 18 | 42 |

| 40 | 40,3 | 1,8 | 1,6 | 1 | 26 | 18 | 44 |

| 50 | 50,3 | 1,8 | 1,6 | 1 | 28 | 18 | 46 |

| 75 | 75,4 | 1,9 | 1,7 | 1,1 | 33 | 18 | 51 |

| 110 | 110,4 | 2,7 | 2,4 | 1,5 | 36 | 22 | 58 |

How to choose pipes for storm water

Requirements that rainwater pipes must meet

As already mentioned above, storm sewer pipes can have both above-ground and underground laying, and must be resistant to the types of influences that are subjected to during operation.

In general, the list of requirements for pipe material looks like this:

Strength. This includes mainly resistance to mechanical stress: pressure, both external and internal, as well as shock loads. Storm sewerage is constructed in the calculation for several decades of use, and therefore, strength and durability are its essential properties.

UV resistant. Where pipes pass over the soil surface, they are exposed to sunlight, so the use of a material that is sensitive to this factor will lead to a decrease in the strength of individual sewer fragments.

Resistance to aggressive reagents. In precipitation, these substances are rare, and in melt waters they can be present in large quantities, since in winter they are actively treated with the roadway, so this moment should also be foreseen.

Resistant to temperature changes

Some types of plastic can withstand high temperatures well, and become brittle at sub-zero temperatures, such pipes can be used with great care, located where they are not threatened by mechanical stress.

Types of sewer pipes

For domestic needs, sewer pipes are made from various materials and different diameters.

Theoretically, the wider the diameter and the thicker the wall, the better the permeability and the less risk of pipe sagging. But the aesthetic appearance and price change the real choice of people when purchasing these products.

What material is used for manufacturing?

Their durability and peace of mind of residents depend on the material of sewer pipes.

The choice of material for sewer pipes is best done with a specialist. Cheap products can quickly leak or deform under their own weight.

The choice of material for sewer pipes is best done with a specialist. Cheap products can quickly leak or deform under their own weight.

Cast iron sewer pipes have not been used in domestic sewage for a long time, their place was taken by plastic counterparts, which can be made from the following materials:

- Polyethylene. Sewer pipes made of this material are flexible, sag, so their joints are difficult to seal. Polyethylene pipes are used in industrial sewers, where they are reinforced with transverse rings and used in areas with complex landscapes. They are not used in internal sewerage.

- Polypropylene. Quite expensive, but has good mechanical strength. Sewer pipes made of this material are heat-resistant, resistant to abrasive particles and perfectly tolerate cleaning with a cable.

- Polyvinyl chloride. PVC pipes almost do not differ from polypropylene pipes in their properties, but they are a little noisier and can sag when water flows through them over 70 degrees.

For apartment and domestic sewage, pipes made of PVC or polypropylene are sufficient, which, if properly installed, will last for several decades.

Sewer pipe diameters

There are standard sewer pipe diameters that allow you to combine products from different manufacturers.

The thicker the wall, the less the pipes bend, therefore, with their long length, it is recommended to purchase thickened products with increased rigidity

The thicker the wall, the less the pipes bend, therefore, with their long length, it is recommended to purchase thickened products with increased rigidity

The most common when installing internal sewage pipes with a diameter of 40 mm and 50 mm.

For risers, a pipe with a diameter of 110 mm is used, but in multi-storey cottages its size can be increased. For joining pipes of different clearances, adapters and branch pipes of the appropriate sizes are used.

The minimum values are indicated. If there is a large amount of fat and waste in the drains, it is recommended to increase the diameters of the pipes to the next standard size

Sewer pipes - how to choose them?

The search for a quality sewer pipe begins with a study of the catalog of manufacturers of similar products. All ideal pipes are hidden from buyers there

And in the process of searching for the really best option, you need to pay attention to two criteria: the material and the diameter of the product.

Structural material

Before choosing pipes - sewer, drainage or drainage - the buyer must imagine the conditions in which such a product will work. And if you need a pipe for an internal pipeline, then a polyvinyl chloride product would be the best option for you. These products are characterized by a minimum wall thickness and, as a result, the minimum cross-sectional dimensions of the entire pipeline. In conditions of eternal shortage of internal space, this quality will be very useful.

If you intend to mount an external section of the pipeline, then the best option is in this case, there will be a product made of polyethylene.Moreover, for external lines, you should choose only a corrugated pipe, sewn from several layers of polymer. This option is able to endure both a huge amount of drains (the diameter of such products starts from 250 millimeters), and significant ground pressure.

in this case, there will be a product made of polyethylene.Moreover, for external lines, you should choose only a corrugated pipe, sewn from several layers of polymer. This option is able to endure both a huge amount of drains (the diameter of such products starts from 250 millimeters), and significant ground pressure.

Even the weakest corrugated pipe of class SN2 can be buried 2 meters, and rigid pipes of class SN16 are immersed in the ground by 15-16 meters.

Well, cast iron should be used only in one case - when repairing an old pipeline line from a similar material. In all other cases, you need to use a more durable and cheap material - plastic.

Communications diameter

When deciding which sewer pipes are best, one must take into account such an important criterion as the throughput, which depends on the diameter of the communications. The choice of the optimal diameter for the sewer line depends on the average daily volume of water consumed. Next, using well-known formulas, you need to calculate the diameter of the pipe that can pass a specific volume of fluid moving at a speed of 0.7 m / s (natural free flow velocity)

Next, using well-known formulas, you need to calculate the diameter of the pipe that can pass a specific volume of fluid moving at a speed of 0.7 m / s (natural free flow velocity).

However, when installing sewer systems for a private house, there is no need for such calculations, in this case, choose:

- 50 mm pipes for drainage from sinks,

- 110 mm pipes for draining waste from the toilet,

- 250 mm pipes for central line.

And as practice shows, pipes with such dimensions will really be the best.

Asbestos-cement pipes

They are made from a mixture of cement and asbestos fiber. Among the advantages are the following:

- Long service life (50-100 years);

- Resistance to aggressive influences. Capable of passing any type of liquid;

- Minor weight. This property can facilitate installation;

- The inner surface is resistant to clogging. This means that the internal lumen decreases very slowly.

- Ease of installation. The installation process can be carried out without the use of any special tool.

But there are also disadvantages. These include significant fragility and instability to mechanical stress. Most often problems occur at the ends of pipes

Therefore, when buying, pay attention to them.

Types and characteristics

For laying sewer systems, manufacturers offer finished pipes, tees, corner products, adapters, crosses. The materials used in production determine several varieties of products. These can be polymer, metal or ceramic components.

PVC sewerage

PVC pipes have a smooth surface, sufficient strength for internal and deep sewerage, are not afraid of ultraviolet radiation, can last more than 50 years and are inexpensive. The classification of types of PVC sewer pipes is based on strength indicators:

- SN2 - lungs.

- SN4 - medium.

- SN8 - heavy.

Regarding the application, there are restrictions due to poor resistance to low and high temperatures exceeding +40 degrees Celsius. The material becomes brittle and elastic, which leads to cracks and deformations. During combustion, toxic substances are released.

Polypropylene (PP)

Compared to PVC pipes for sewerage, plastic polypropylene pipes are inferior in strength, therefore they are used only for laying inside the building without external mechanical load. The permissible drain temperature is +80 degrees Celsius. The smooth surface contributes to the free flow of the medium, which is important for the circulation of drinking water. Inside the dwelling, it is better to lay noise-absorbing products (for example, under the rehau or politek brand).

corrugated polyethylene

Structurally, HDPE pipes are represented by a solid corrugation and a built-in smooth-walled channel. This design provides increased rigidity of products, which is important for deep laying (up to 16 m.). According to the technical characteristics, the material is similar to the plastic counterpart. It is used more often for the construction of engineering communications for the transportation of hot waste.

Asbestos-cement

Asbestos in the composition of the cement mortar plays a reinforcing role. Products belong to the most budget option for a sewerage device. Contact with water has a positive effect on the strengthening of the walls. Pipes have a low coefficient of thermal expansion and do not corrode. The characteristics are relevant for pressure systems and outdoor laying.

Concrete

For the manufacture of pipes, as a rule, M350 concrete is used. It is characterized by water absorption up to 3%, 200 cycles of freezing and thawing and high compressive and tensile strength. The material does not rot, does not burn, does not corrode, is resistant to chemical environment and low temperatures. It is used in the industrial, hydrotechnical and urban planning sectors with a low degree of aggressiveness.

metal

Such products are represented by steel-rolled products with a galvanized anti-corrosion coating. The material has high strength, long service life, withstands temperature extremes in a wide range and is relatively inexpensive. However, it is rarely used in the private sector due to its heavy weight. More often, a sewer pipeline of this nature is laid at industrial enterprises of the chemical and oil refining type.

Cast iron sewer

Cast iron is an alloy of iron and carbon. The material is characterized by higher strength, pressure endurance and corrosion resistance compared to steel. It also has a service life of over 80 years.

For laying sewers, a negative fact is the rough inner surface, which makes it difficult to transport wastewater and contributes to the formation of plaque. In the private sector, cast iron is rarely used due to its significant weight, high cost and the need to additionally resort to sealing agents. More often, such pipes are used for the internal construction of risers and sewers in multi-storey buildings.

Ceramic products

The production of ceramic pipes is based on the processing of clay. The raw material has water resistance, resistance to aggressive environment in terms of temperature, chemicals, corrosion. Among the advantages, an unlimited service life is also noted. However, brittleness complicates installation work, the installation of fittings and limits the installation in places of increased mechanical stress. The use of ceramic pipes is relevant for sewerage in industrial areas, at strategic sites.

The material used for the production of sewer pipes

Now consider the material of manufacture in order to assess how one or the other meets all the requirements. Today the market offers a wide range of pipe products for sewer systems:

- ceramic;

- metal;

- asbestos-cement;

- concrete;

- from polyvinyl chloride (PVC);

- from polypropylene.

And despite the large selection of products, only three are the most popular and most commonly used: cast iron pipes, PVC and polypropylene. Other species are less common, but still used.

metal

By metal pipes are meant cast iron and steel.

Steel

Steel products meet almost all requirements and have a lot of advantages:

- durable;

- withstand high temperatures;

- easy to process;

- low cost.

However, despite this, they have disadvantages that make their use in private housing construction unprofitable. Here are just some of them:

- large mass;

- corrosion.

The main scope of their application is the petrochemical and chemical industry, where they are actually and successfully used for transporting waste, etc.

Cast iron

Compared with the previous ones, cast iron pipes are less afraid of corrosion, but the cost of this option will be higher. Most often used when installing a riser in apartments of high-rise buildings, as well as for diverting wastewater to a collection point.

Advantages:

- high strength;

- long service life - more than 80 years, and this is a theory, but time-tested data;

- good plastic properties;

- resistant to heavy loads.

Cons that significantly limit its use:

- rough inner surface makes it difficult to transport wastewater;

- big weight;

- the need to use additional materials for sealing joints;

- price.

Ceramic

The main scope of ceramic pipes is external sewerage. They transport household, industrial and rainwater. They are resistant to chemicals and corrosion, not afraid of fire, strong and durable.

However, complex installation, fragility and a number of other disadvantages led to the displacement of this material by others, more modern and practical. You can learn more about them from this article: Ceramic pipes.

Concrete

The reinforced concrete pipe is used in hydrotechnical, civil and industrial construction, for the transportation of non-aggressive effluents by gravity. In their production, heavy concrete of the following grades is used: W6, F200, B25, M350.

Main advantages:

- compressive and tensile strength;

- water resistance;

- not afraid of low temperatures;

- low price - compared to steel pipes;

- chemical resistance;

- are not subject to rotting and corrosion.

The depth of laying reinforced concrete products varies from 2 to 6 meters.

Asbestos-cement

Asbestos-cement sewerage - products of Russian manufacturers. It is considered the cheapest of all types. Asbestos cement is one of the varieties of reinforced concrete, where evenly distributed asbestos fibers play the role of reinforcement.

This material is tensile, so it can also be used for pressure systems. It is not afraid of corrosion, and when exposed to water, it compacts and becomes stronger.

PVC

According to experts, PVC pipes are strong enough and durable, they are not afraid of UV radiation. They are distinguished by an affordable price, ease of installation and an almost perfectly smooth inner surface of the walls.

Minuses:

- When the temperature rises above 70 ° - deformed.

- They become brittle at low temperatures.

- They are afraid of fire, when burning, it releases a dangerous gas.

PVC pipes, depending on their strength, are divided into several classes:

- lungs - SN2;

- medium - SN4;

- heavy - SN8.

The permissible temperature regime of the passing liquid should not exceed 40 ° C, the service life is reduced from high temperatures.

Polypropylene

To date, it is this material that is considered the most optimal for the construction of a sewer pipeline inside a building. This conclusion can be reached by evaluating the advantages of polypropylene pipes:

- high strength;

- long service life;

- resistance to aggressive influences;

- simple installation;

- perfectly smooth inner surface;

- low cost.

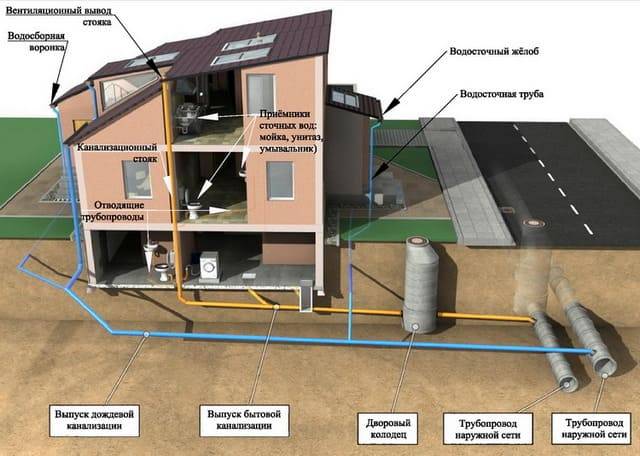

Requirements for outdoor piping

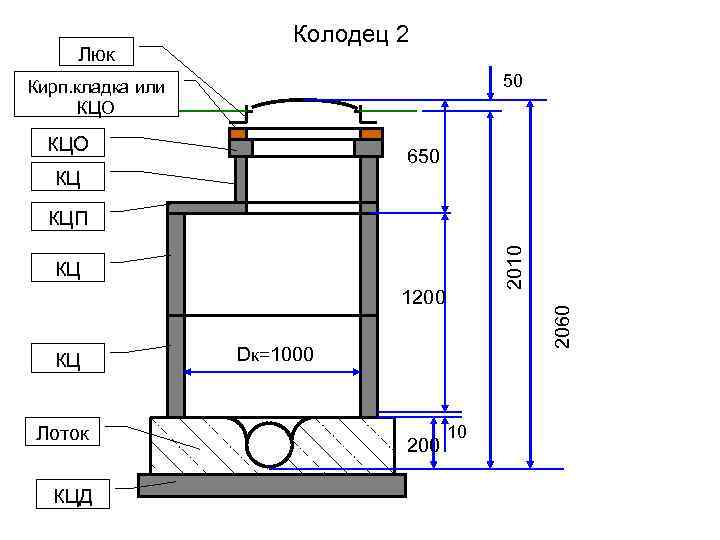

The external sewage pipeline is a system of channels that divert effluents from structures to tanks. Laying is carried out under a slope (0.7-3 cm per 1 m, depending on the diameter of the pipes) to ensure independent movement of the transported medium. Otherwise, a pumping or pressure system is installed.

Regarding the device, external sewerage has 3 types of execution:

- Separate has different tanks for collecting domestic and rainwater.

- Semi-separate are equipped with different channels, but one collection point.

- All-alloy are represented by a single system.

According to the purpose, external sewage is distinguished as follows:

- Intra-apartment, intra-yard is called tracing, excludes connection to an autonomous sewer. The end point is located 3 meters from the facade of the building.

- The street network is represented by pipelines and wells leading to the central collectors.

- Collectors are nodal wastewater collection points.

The end point of the collection is the treatment plant. They are autonomous for private use and centralized for processing wastewater from enterprises and urban buildings.

Requirements for pipes for external sewerage are based on the following criteria:

- the condition of the soil and the level of groundwater flow, the climatic features of a particular area;

- volume and chemical composition of the transported medium;

- distance from the object to the treatment plant, the need for pumping or pressure equipment.

Regardless of the drains, the material must be corrosion-resistant, rigid and strong in accordance with the ground investigations and the mechanical load exerted on the pipe route.

The conditions regarding the temperature regime of the environment and external operating conditions, the chemical composition of the effluents and the pressure inside the channels are also observed. All standards are prescribed in SNiP under the number 2.04.03-85.

No. 2. PVC pipes: advantages and disadvantages

Before choosing anything, every sane person weighs all the pros and cons. Sewer pipes are no exception.

Advantages of PVC sewer pipes:

- democratic value. The arrangement of sewage using PVC pipes will cost several times cheaper than the organization of the same pipeline made of cast iron;

- corrosion resistance.Plastic does not rust, unlike the same cast iron, which means that PVC will create a more durable sewer system;

- resistance of both external and internal surfaces to aggressive environments;

- high tightness. Since the material is not afraid of corrosion and other negative factors, you can not be afraid that the pipe will lose its integrity underground, and sewage will fall into the ground;

- a smooth inner surface minimizes the likelihood of pipe overgrowth and clogging with fecal fractions;

- resistance to low temperatures. PVC pipes do not deform even with prolonged exposure to negative temperatures;

- light weight, which greatly facilitates the transportation and installation of PVC pipes;

- sufficiently high strength and environmental safety;

- durability. Manufacturers talk about a service life of up to 50 years;

- plastic does not conduct stray currents, and this is another plus in terms of your safety;

- a huge selection of pipes of different diameters and lengths, there is also a sufficient number of adapters and mounting elements, so the arrangement of a sewer system made of PVC pipes is a relatively simple task.

Not without drawbacks:

sensitivity to high temperatures. The maximum operating temperature for PVC pipes is +40C. Products withstand heating up to + 80C, but such exposure should be rare and short-term. With prolonged contact with hot liquids, the material loses a number of useful performance qualities and quickly fails;

PVC pipes behave better than cast iron pipes, but over time, plaque begins to form even on their smooth walls.With regular, albeit short-term exposure to high temperatures, the pipe from a round one begins to turn into an elliptical one.

All this together can lead to a decrease in throughput or even the formation of a leak, so it is important to follow the rules during the installation and operation of pipes;

low fire resistance;

despite the fact that manufacturers talk about the complete inertness of PVC to aggressive substances, individual compounds can still gradually corrode the pipe walls. In fairness, we note that such connections are not commonly found in domestic sewer systems.

Peculiarities

For arranging a sewage drain, pipe structures made of polyvinyl chloride are often used, displacing cast iron and steel. Plastic sewer pipes are made of ordinary and unplasticized PVC. The composition of the material includes vinyl chloride and additional additives. High strength properties make it possible to use unplasticized PVC for the organization of a pipeline with pressure.

Sewer pipes are designed to drain wastewater from a plumbing drain, to install a drainage channel, to install indoor and outdoor sewerage. The use of PVC products for sewerage is justified due to the technical characteristics of the material. The long service life of sewer pipelines will allow the system to operate up to 50 years. The tensile strength reaches 50 MPa, so the street sewer section will withstand the laying to the depth of soil freezing. The pipeline is capable of operating under pressure from 6 to 16 bar.

The use of PVC pipes for sewerage has the following advantages:

- A variety of sizes and shapes of pipes and fittings will allow you to assemble sewers of any complexity.

- Smooth inner walls do not allow sewage to settle, preventing the formation of blockages in a small diameter and preventing the pipe passage from overgrowing from deposits.

- The low weight of the products and the ease of cutting ensure quick and easy assembly and disassembly without additional tools.

- Inert to chemicals and corrosive attack.

- Affordable price of pipeline elements.