- Requirements for sewer pipes

- Outdoor piping

- Internal piping

- What material should you choose?

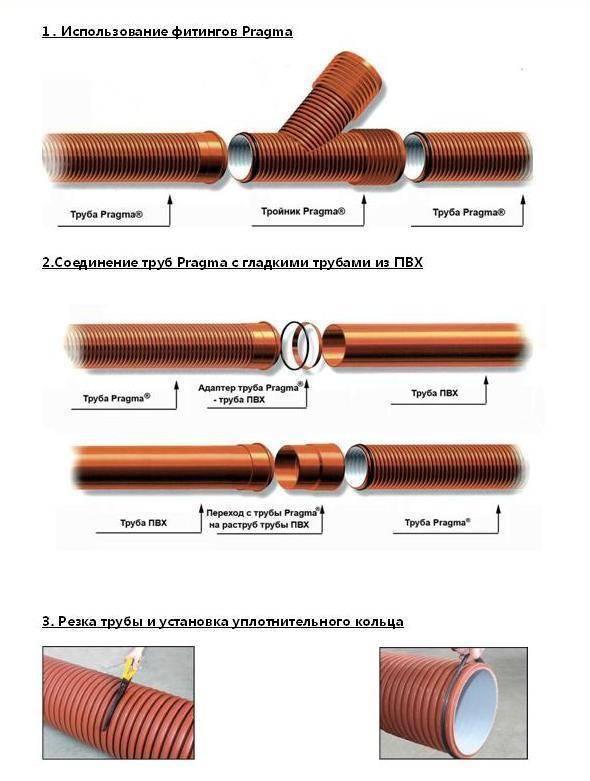

- Fitting

- Connection methods

- Cast iron parts: an overview of all the pros and cons

- Requirements for sewer pipes

- Requirements for pipes for internal sewerage

- Requirements for pipes for external sewerage

- Installation nuances

- PE pipes KORSIS and KORSIS Eco

- Selection of sewer products: manufacturers and prices

- Classification of pipes by type of material

- View # 1 - plastic products

- Option #1 - polyvinyl chloride (PVC) pipes

Requirements for sewer pipes

In the common sewer line, two interconnected systems are involved - internal and external. The choice of pipes for each of them has its own characteristics and requirements. Everything is based on building codes and regulations.

Outdoor piping

Due to the peculiarities of the location of the pipes of the external sewer system, they must have the properties of resistance to dynamic and static loading. In other words, they must withstand the deformations that occur when moving people, vehicles, and also withstand the load of the soil laid on top. The connection points must ensure that there are no displacements that can compromise the integrity of the entire line during the movement of groundwater.

In accordance with SNiP 2.04.03-85, pipes for sewerage of the external system must be laid below the freezing level of the soil in winter. It will be different for each region of the country. The value for your site must be specified on the Internet or the meteorological service. In general, for a private house, the laying level will be at the level of 0.5-2 m.

In those areas that are in the area of intersection with transport routes and increased load, corrugated pipes made of metal-plastic are laid. They are able to withstand high loads. This property is due to the ring stiffness. In addition, they have great flexibility. It also allows you to lay sewer pipes in particularly complex and non-linear areas.

Internal piping

Pipes that are used to create an internal system do not impose the above strength requirements on themselves. They can be laid in building structures or hidden under decorative elements. Whatever the laying scheme, the internal sewage system is not subjected to such loads as the external one. But still, to ensure the greatest duration of operation, the following properties should be provided:

- Resistance to mechanical damage;

- Resistance to aggressive environments - temperature, chemical and biological influences;

- Possibility of combining with elements of external sewerage;

- The polished internal surface which is not interfering with an output of sewage;

- If necessary, connect all necessary sanitary devices.

Separately, it is worth noting that a significant consumer factor is the ability to easily and simply carry out installation, as well as, if necessary, replace the damaged area. Given all the requirements, the majority of homeowners prefer to use plastic pipes or composite metal-plastic pipes.

Next, consider the possible options for materials for sewer pipes.

This is interesting: Professional sewer cleaning methods - an overview of methods

What material should you choose?

Since in the article we are considering the question of which pipes are better than a private house, we will summarize what to choose.

- Concrete and reinforced concrete - used in industrial construction. Of these, local sewer networks are being built. They differ in significant weight and dimensions.

- Cast iron - high strength, resistant to temperature, but heavy. Now they are not often used. Even in multi-apartment construction, the volume of their use is declining. Even in spite of the long service life.

- Steel, ceramic and copper are too expensive and not very reliable for use in sewers. The process of installation and replacement is complicated.

- Asbestos-cement - resistant to biological and chemical influences. Suitable for sewers. However, fragility reduces their operational properties even before installation.

- Polymers are a relatively new type of product. There are models with different consumer characteristics. The class includes various plastic pipes for sewer networks. They are distinguished by significant strength, long service life, ease of installation and compatibility with other equipment.

- PVC pipes are the best choice for gravity sewerage.Suitable for indoor and outdoor installations. Resistant to mechanical damage and ultraviolet. Temperature has no effect on performance. They do not tolerate the effects of household chemicals very well.

- Polypropylene - not exposed to aggressive chemicals. Resistant to mechanical damage. Capable of passing high temperature liquids.

The sewer pipe market is much larger than described in the article. Here are the characteristics of the most common materials. It is impossible to say for sure that one of the options is better than the others. For each pipeline, it is necessary to take into account the specific operating conditions. It is taking into account all the nuances of the site, you can choose the best option.

Fitting

Fittings also influence the choice of pipes for sewerage, albeit to a lesser extent. Fittings are pipeline fittings that allow you to branch, close pipes or direct them in the other direction.

Plastic sewer fittings for indoor use

The most common fittings for plastic pipes. They are made of the same polymers: PVC, PP, PE - they have different diameters and sizes and are easy to install. The range of metal fittings is more modest. Mounting them is just as easy, but the parts themselves and their dimensions are smaller. The same is true for ceramic fittings. For other types of pipes, fittings are not sold at all, they are connected differently. In terms of fittings, polymer pipes are better for sewage.

Connection methods

Depending on the type of the selected sewer pipe and connecting fittings, the following connections are classified:

- Socket - the socket of the pipe is put on a fitting or other part. Fixed with a sealing ring. When socketing cast iron pipes, cement is used instead of an o-ring,

- For gluing (usually used for plastic pipe assemblies). Mounting adhesive is made from a mixture of PVC and tetrahydrofuran,

- With clamps and levers. This method allows you to increase the mechanical force,

- Threaded. Rarely used for joining cast iron parts.

Cast iron parts: an overview of all the pros and cons

Sewer pipes are made of gray cast iron by centrifugal casting, after which they are processed using cutting tools. The outer and inner surfaces of the elements are covered with a special bituminous composition. It protects the metal from corrosion, and also gives a greater smoothness to the surface, improving the throughput of pipes. The diameter of the elements varies from 5 to 15 cm, the wall thickness is 10-12 mm. For the arrangement of connections, sockets are provided, the length of which, depending on the diameter of the pipe, can be from 60 to 80 mm.

Traditional cast iron pipes are still widely used for arranging domestic sewers. This is a very reliable, durable and strong option.

Shaped elements are also produced: plugs, fittings and plugs designed for temporary or permanent blocking of pipeline branches, crosses for branching the direct direction of the main line, as well as tees or crosses that form various branched pipeline configurations. Fittings are used as connecting elements of the sewerage system. Are established on branchings, various turns and transitions from one diameter of a pipe to another.Transition elements are available for working with pipes of different diameters and straight for parts of the same diameter.

The advantages of cast iron parts include:

- High strength and reliability.

- The ability to withstand significant temperature changes, as well as long-term exposure to hot liquids.

- Service life reaching 90-100 years.

- Environmental Safety.

- Fire resistant.

- Good soundproofing.

You need to know that a long service life is due to the absence of defects in the production of pipes: fistulas, seams, slags present in the anti-corrosion coating. Therefore, before installation, it is imperative to check the quality of the products and tap each of them, so you can detect cracks and other hidden defects.

The disadvantage of cast iron products is their large weight, which significantly complicates transportation and installation. Also, the installation of such elements is also quite complicated.

It is extremely important to correctly connect the parts, the smooth operation of the sewer depends on this. The most common connection method is caulking or caulking the gaps between the socket and the shaped part installed in it with the help of a cable. Another disadvantage of cast iron drain pipes is the roughness of the inner surface, which contributes to the appearance of deposits.

Over time, they can completely block the lumen.

Another disadvantage of cast iron drain pipes is the roughness of the inner surface, which contributes to the appearance of deposits. Over time, they can completely block the lumen.

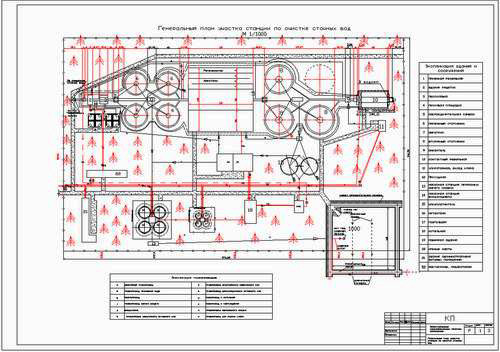

Requirements for sewer pipes

Structurally, the sewerage system is an extensive network of pipelines going from plumbing fixtures to a treatment plant.When thinking about which pipes are best for sewage, you need to remember that in the sewer network they will be divided into two components that work together - the external and internal system.

At the same time, pipes for internal sewage and pipes for external sewage must be different, since they are operated in different conditions.

Requirements for pipes for internal sewerage

The interior of the system includes all plumbing fixtures and sewer pipes connecting them. Since the networks are located in the apartment, the sewer pipes will be operated in gentle conditions.

In an apartment, pipes for sewerage can be laid secretly (in walls, under floor coverings) or openly. In the latter case, provide for fastening sewer pipes to the wall.

Fasteners for sewer pipes are represented by clamps screwed to the wall. For indoor sewer pipes, the characteristics should be as follows:

- Be durable.

- Do not interact with the transported medium.

- Be resistant to thermal, chemical and biological influences.

- Have the smoothest possible inner surface.

- Provide the ability to connect various plumbing fixtures.

What pipe diameter should be chosen? The diameter of the sewer pipes is chosen according to building codes. The dimensions of the sewer pipes differ depending on which device you plan to connect the pipe to. Recommended sewer pipe diameter for drainage from:

- bathtubs - 40 mm;

- shower cabin - 40 mm;

- washbasin - 40 mm;

- bidet - pipe 32 mm;

- toilet - pipe 110 millimeters.A 90 mm pipe can be used to install wall hung toilets.

The central riser in the apartment is made of a 110 mm pipe, and the outlets from it can have a diameter of 75 mm. When building an internal sewerage system for a private house, the diameter of the sewer pipe is selected according to the same standards.

In addition to pipes, fittings are needed to assemble pipelines. What are the fittings? These are various couplings, tees, spurs, corners, crosses. So, when assembling internal networks, tees for pipes are often used.

Tees are used to connect an additional branch pipe to the line. Oblique tees are used to assemble the sewerage system, since if you install tees with a right angle, the risk of blockages will increase. Such a detail as spurs is used to assemble metal pipes. Spurs are threaded pipes; spurs are used where non-rotating parts need to be connected.

Requirements for pipes for external sewerage

Special requirements apply to materials for mounting the outer part of the sewerage system. It is clear that underground sewer pipes must be especially durable. Previously, pipes for sewerage into the ground were made only of cast iron or asbestos cement.

Now more often used plastic red sewer pipes. The red pipe is a model designed for assembling outdoor networks. Red coloring, of course, is optional.

It's just that the manufacturer in this way makes it easier for customers to choose, the orange sewer pipe is intended for external networks, the gray one is for internal ones.If not a red, but a gray pipe intended for internal networks is chosen for laying in the ground, then the system will soon become unusable and sewer pipes will need to be repaired.

The red pipe is resistant to soil pressure and the effects of negative temperatures. For the installation of outdoor systems, you need to choose the appropriate fittings, so the tees for the sewer pipe should also be designed for use in outdoor networks, they are also distinguished by a red color.

For the installation of an external pipeline, large diameter pipes are used, most often a sewer pipe of 160 mm or 150 mm is used. With a large flow of water, a sewer pipe of 200 mm is chosen.

When building a collective drainage system for several houses, a 200 mm pipe may not be able to cope with the load. Therefore, it is worth choosing a sewer pipe of 250 or even 300 mm.

Installation nuances

There are a number of nuances in the installation of sewage, ignoring which you can get not a good drainage and drainage system, but in Russian speaking, big hemorrhoids. So I will list as much as possible:

- When cutting pipes, the cut must be strictly perpendicular to the axis and must be processed with sandpaper,

- Elements to be glued must be degreased,

- Fittings with a rubber seal must be coated with silicone sealant,

- The cross section of the horizontal pipeline should not exceed the diameter of the sewer riser,

- In places where the pipeline turns, revisions are required - holes for cleaning with a cover,

- Horizontal connections must be assembled from angles and oblique tees,

- Fix the sewer at intervals equal to 10 x pipe diameter,

- The slope of horizontal sections should not exceed 1-2cm/1m.9.The bell is located towards the moving fluid.

PE pipes KORSIS and KORSIS Eco

Polyethylene is another polymer. KORSIS and KORSIS Eco pipes are made from high density polyethylene (PVP) and an outer corrugated layer is added. It increases the ring stiffness, so the products are suitable for outdoor sewage.

Polyethylene pipes KORSIS

Advantages:

- durability,

- ease,

- elasticity,

- frost resistance down to −60°С,

- resistance to acids and alkalis,

- soundproofing,

- polished inner surface.

Flaws:

- sensitivity to sunlight

- maximum temperature of the transported substance: 80°C.

High-density polyethylene pipes, unlike PVC, tolerate low temperatures. At the same time, they are also light, have elasticity and are more reliable for the external pipeline.

The company "Modern Identification Systems" sells polymer pipes made of PVC and high-pressure polyethylene. SIS is the official distributor of Polyplastic Group, a manufacturer of plastic pipes for sewerage, water supply, and heating. SIS sells products of Polyplastic Group at manufacturer's prices, and also helps to choose material for pipelines.

Selection of sewer products: manufacturers and prices

On the Russian market, you can find products from both foreign and local companies. The number of domestic pipe manufacturers is growing due to the constant growth in demand. Enterprises master the latest technologies and produce products of excellent quality (confirmed by a certificate) at an affordable price.

In the field of view of many owners of suburban housing who want to lay (or replace) an external sewer, products of Spanish, Italian, German brands fall into the field of view. Consumers are also familiar with the products of Turkish and Chinese firms. The best manufacturers of sewer pipes offer products that meet modern requirements for the installation and operation of a drainage system.

Crash test of sewer products on video:

Despite the excellent quality, the segment of foreign companies is small, since their prices are on average 15-20% higher than for similar domestic products.

-

Diameter 110 mm. 160-170 rub. (domestic), 220-260 rubles. (import).

-

Diameter 160 mm. 290-320 rubles, respectively, 345-289 rubles.

-

Diameter 200 mm. 465-535 rubles, 570-650 rubles.

-

Diameter 250 mm. 730-838 rubles, 885-930 rubles.

Pipes of external sewerage in a warehouse of materials

Classification of pipes by type of material

The most popular among users are plastic pipes for sewerage. But, in addition to plastic, external sewer pipes can be made from other materials. Let's look at the features of each type of pipe, highlighting their advantages.

View # 1 - plastic products

Sewer polymer pipes appeared not too long ago, but they have become widespread, displacing traditional analogues in the profile market.

Such components have a number of undeniable advantages:

- light weight, facilitating transportation, storage, laying;

- a smooth inner surface that facilitates the unimpeded passage of runoff water and prevents the settling of salts and other deposits.Due to this feature, with proper installation and operation, blockages almost never form in plastic pipes;

- wear resistance - plastic pipes do not rot, do not corrode;

- operation - such products have a sufficient service life, although less than their cast-iron counterparts (maximum 50 years).

Most often, for the manufacture of external sewer systems, components made of the following materials are used.

Option #1 - polyvinyl chloride (PVC) pipes

Polyvinyl chloride (PVC) is an affordable popular plastic that is widely used for the production of various products, including pipes for internal / external networks.

Such components are especially recommended for sewer systems that require a large flow area (collector, culvert, storm).

Among the most significant disadvantages of PVC pipes are:

- Sensitivity to aggressive materials. If it is planned to remove acids and oils through such components, it is better to purchase special PVC-U pipes with special properties.

- Thermal elongation of the material. Because of this property, it is not advisable to install such parts for transporting hot liquids (over 60 degrees C).

PVC pipes have the following positive properties: good resistance to mechanical stress, high strength and UV resistance, making such products suitable for open areas.

There are two types of PVC pipes:

- Pressure, high pressure (

According to the stiffness class, PVC components are divided into the following categories:

- Rigid pipes (class S) with a maximum wall thickness, designed for installation at a depth of up to 8 meters. This type can be used for any work, but is most often used in industry.

- Medium-hard products (class N) are used at a depth of 2-6 meters. They are suitable for pipeline installation under not too busy roads.

- Light components (class L) sufficient to create systems that are laid at shallow depths (0.8-2 m). Not suitable for laying under the roadway.

The most common pipe for external sewage is a product with a diameter of 10-11 cm. In this case, sewage from a country house is easily transported through the network.

Pipes made of unplasticized polyvinyl chloride are used in underground laying of external communications where it is known that there will be no significant load on communications.

If this factor is taken into account, then the scope of PVC products is quite wide: