- Recommendations for the selection of gas pipelines

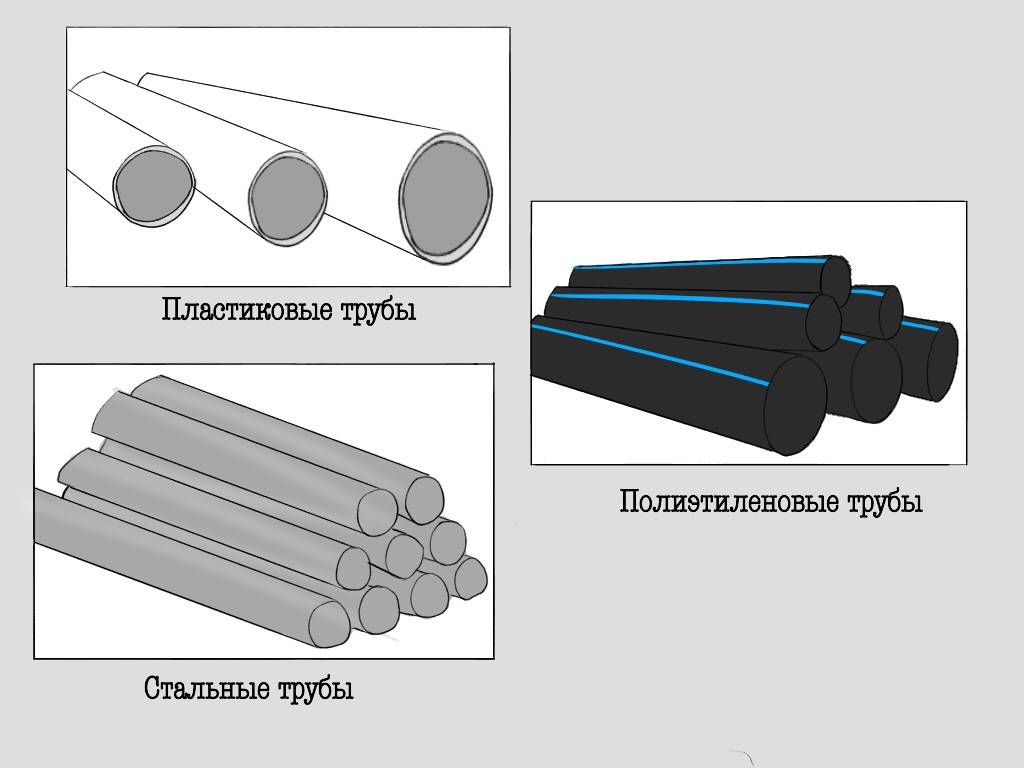

- Number 3. Gas pipeline material

- Criteria for choosing pipes for gas pipelines

- Varieties of pipes for gas pipelines

- Selection of pipe parameters

- No. 5. Pipes for a gas pipeline made of low-pressure polyethylene (HDPE)

- Pipe Installation Instructions

- How to cut and bend copper

- Connection methods: crimping and soldering

- How is the laying of communications in a private area?

- Metal-plastic pipes for gas supply

- Scope of a pipe from a metalpolymer

- Pros and cons of a metal-polymer pipe

- What are the positive features of gas communications based on plastic pipes?

- Features of installation work

- Options for gas ducts for a country house

- Selection Guide

- Chimney of solid fuel boiler

- Mounting Features

- Scope of application

- What does a quality gas pipeline consist of?

- Boiler structures and chimney outlet

- Methods for installing chimneys

- Conclusions and useful video on the topic

Recommendations for the selection of gas pipelines

Most often, gas pipelines for honest houses and apartments are equipped with metal products. Steel pipes for gas supply are characterized by their ability to withstand internal pressure perfectly. Such a pipeline is completely sealed, which reduces the risk of gas leakage to zero.The selection of pipes is carried out taking into account the working pressure in the gas line.

Conditions in gas pipelines can be as follows:

- With low pressure - up to 0.05 kgf / cm2.

- With an average pressure - from 0.05 to 3.0 kgf / cm2.

- With high pressure - from 3 to 6 kgf / cm2.

What pipes are used for the gas pipeline? The use of thin-walled metal pipes is only permitted on low-pressure gas pipelines. This material has an exceptionally light weight, which makes it possible to equip systems with a complex configuration from it. Also, thin-walled metal pipes are distinguished by good flexibility: if necessary, to give such a product a small angle, you can do without a pipe bender, doing everything by hand.

Number 3. Gas pipeline material

Until quite recently, there was not much choice, and in all sections of the gas pipeline, from large nodes to points of consumption in homes, only steel pipes were used. Today, an alternative has appeared in the form of low-pressure polyethylene pipes. Copper pipes are also used. It is unlikely that you will have to suffer the pangs of choice, since each of these materials has strictly defined operating conditions:

- steel pipes can be with different wall thicknesses. Thick-walled products are used for arranging high-pressure gas pipelines. If we are talking about above-ground laying, then there is no alternative to steel pipes. These are strong, durable and reliable pipes that can handle a serious load. Thin-walled pipes are suitable for organizing a low-pressure gas pipeline, incl. for the arrangement of the gas supply system inside the house;

- polyethylene pipes are used for underground installation of a gas pipeline with different pressures. There are products that can withstand operation at a pressure of 1.2 MPa.They outperform the steel counterpart in terms of weight, price and ease of installation. Not suitable for above-ground and indoor installation;

- copper pipes are superior to steel pipes in many respects, but their mass use is impossible due to the high price. Above-ground installation with the help of such pipes is not carried out, but this is an excellent option for organizing a gas pipeline inside the apartment.

The network has information about the use of metal-plastic and even polypropylene products as pipes for a gas pipeline, but these are still far from the most suitable options.

Criteria for choosing pipes for gas pipelines

When choosing steel pipes for a gas pipeline, factors such as:

- type of pipe;

- specifications.

Varieties of pipes for gas pipelines

Steel gas pipe can be:

- seamless. Production of this type is carried out by "flashing" a metal cylinder (blank). The manufacturing method is labor intensive, which affects the cost of the resulting products. Seamless pipes are divided into the following subspecies:

- cold-rolled (the billet after the process is processed without exposure to temperature);

- hot-rolled (the billet undergoes further processing under the influence of high temperature).

High strength steel pipes

Hot-rolled pipes are produced with a larger wall thickness, which affects the strength of the gas pipeline. They are mainly used in construction in cold climates or for pipelines that require special strength and the passage of gas under high pressure.

The technology for the production of seamless steel pipes is presented in the video.

straight-line seam (the weld line runs parallel to the pipe).Pipes are characterized by low cost and acceptable technical parameters. The main disadvantage is a small margin of safety, since under the influence of pressure the seam can “burst” or deform;

Steel pipe with straight welding seam

spiral-seam (the seam line in the form of a spiral runs along the entire surface of the pipe). Such pipes are more durable than longitudinally welded products and practically do not differ in cost.

Spiral welded steel pipes

Selection of pipe parameters

How to choose pipe parameters, and what indicators should you pay special attention to? When choosing options, consider:

- diameter of pipes for gas;

- pipe wall thickness.

Basic pipe selection parameters

The choice of the diameter of gas pipelines is made after preliminary calculations, which take into account:

- gas consumption per hour;

- pipeline length;

- pipeline type (low, medium or high pressure).

It is almost impossible to make calculations using the formula on your own. Therefore, the calculation can be made using various online programs located on specialized sites.

For the construction of distribution gas pipeline systems, pipes with a diameter of 50 mm or more are used. Wiring inside the dwelling is carried out with products with a diameter of 25 mm.

Such a parameter as the thickness of the pipe wall is also essential in the construction of gas pipelines, since the strength index of the product depends on it. Manufacturers produce pipes with a wall thickness of 1.8 mm to 5.5 mm (GOST 3262 - 75).

Experts recommend choosing the wall thickness depending on the location of the gas pipeline:

- if gas supply is carried out underground (underground communications), then the thickness must be at least 3 mm;

- if an above-ground pipeline is being constructed, then less durable products with a wall thickness of 2 mm are used.

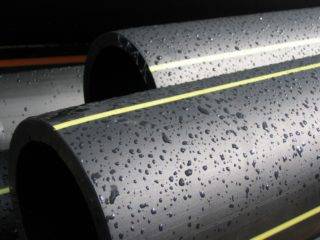

No. 5. Pipes for a gas pipeline made of low-pressure polyethylene (HDPE)

HDPE pipes have recently been in no less demand than steel pipes. It should be noted right away that the phrase "low pressure", which appears in the name of the material, refers to the features of the production of pipes, and not to the operating conditions of the gas pipeline. There are polyethylene pipes that can withstand pressure up to 1.2 MPa. What makes us abandon the proven option with steel pipes and use polymer ones? The answer to this question lies in the advantages of the material.

Main advantages polyethylene gas pipes

light weight;

- faster and easier installation without the use of complex expensive equipment that requires special skills;

- strength, ductility and flexibility make it quite easy to bypass possible obstacles in the path of the gas pipeline. The maximum allowable bending radius is 25 pipe radii. Flexibility allows the pipeline to remain intact with small ground movements;

- the ability to withstand pressure up to 1.2 MPa, so that such pipes can be used in almost all sections of the gas pipeline;

- resistance to corrosion, the ability to withstand the effects of aggressive substances;

- high throughput, as the inner surface of the pipe is smooth. With the same diameter as a steel pipe, a polyethylene pipe will have a capacity of about 30% higher;

- HDPE pipes are produced of great length, which makes it possible to do with fewer connections, thereby achieving the integrity and reliability of the structure;

- polymer materials do not conduct stray current;

- low cost when compared with steel or copper counterparts;

- durability of at least 50 years, and under all conditions up to 80-90 years

There are also cons:

- polyethylene pipes cannot be used in areas where the temperature drops below -450C. Such a gas pipeline is located at a depth of at least 1 m, at winter temperatures of -400C, the depth increases to 1.4 m, and in some cases, laying HDPE pipes is completely impossible. At low temperatures, performance may deteriorate, and durability may decrease;

- pipes are also not suitable for seismically active areas;

- HDPE pipes will not withstand a pressure of more than 1.2 MPa - only thick-walled steel will help here;

- sensitivity to ultraviolet rays does not allow for above-ground installation - polyethylene pipes are only suitable for installation underground;

- due to the increased level of flammability of polyethylene, such pipes are not recommended for indoor use. Already at +800C, the material tends to deform and collapse;

- HDPE pipes are not suitable for laying gas pipelines in collectors and tunnels. In such places, a steel analogue is used;

- at the intersection of the gas pipeline with roads and other communications, the pipes must be hidden in a metal case.

It is better not to use polyethylene pipes for installing a gas pipeline indoors, but they are being used more and more often for underground installation.

For the production of pipes, special pipe grades of polyethylene are used:

- PE 80 - black pipes with yellow inserts, withstand pressure up to 0.3-0.6 MPa;

- PE 100 - pipes with a blue stripe, withstand pressure up to 1.2 MPa. During their installation, more serious efforts are made, since the material has to be heated to higher temperatures, but the quality of the connection in this case is at its best.

The diameter of HDPE pipes can vary from 20 to 630 mm or more, even pipes with a diameter of 1200 mm are used. When choosing, it is also worth taking into account such an indicator as SDR - this is the ratio of diameter to wall thickness. The smaller this value, the thicker the walls and the more durable the product in front of us. SDR ranges from 9 to 26.

The connection of polyethylene pipes is carried out in one of the following ways:

- butt welding. The edges of individual elements are heated with a special soldering iron until a viscous consistency is reached, which allows you to safely connect two pipes into one;

- electrofusion welding involves mounting the edges of the pipe into a special coupling, to which voltage is applied, due to which heating and connection of two segments occurs. Such a connection is stronger than the pipe itself and can withstand a pressure of 16 MPa.

With an individual connection to the network, butt welding will be enough, and if, for example, gasification of an entire area takes place, then it is better to use electrofusion welding - it is more reliable and tight.

To connect a section of a steel and polyethylene gas pipeline, special elements are used, one side of which is welded to steel, and the other to polyethylene.

Pipe Installation Instructions

The installation of the gas pipeline includes 3 stages:

- design;

- pipe preparation;

- mounting.

At the end, a test run is made and the pipeline is checked for leaks.

We will analyze the main methods of preparing parts for installation - bending and cutting, as well as two popular methods of connecting pipes - pressing and soldering.

How to cut and bend copper

Before starting installation work, it is necessary to prepare pipes. Completely straight gas pipelines are rare, more often they consist of combinations of straight and bent elements. This means that the pipe material must be cut, and some parts must be carefully bent at a given angle, 90° or obtuse.

For cutting, you can use a hacksaw for metal, a circular electric saw, but a pipe cutter is considered the most acceptable tool.

Pipe cutters are distinguished by the fact that they make a perfectly even cut perpendicular to the direction of the pipe. Cutting is done quickly and accurately, and the smooth edge of the workpiece does not require additional processing.

Pipe cutters are distinguished by the fact that they make a perfectly even cut perpendicular to the direction of the pipe. Cutting is done quickly and accurately, and the smooth edge of the workpiece does not require additional processing.

During the cutting process, make sure that the pipe is not deformed - any bulges, cracks or dents will pose a threat to the tightness of the gas pipeline.

Bending can be done cold or hot. The first is used for thin pipes, more often used in everyday life, with a diameter of up to 22 mm. The hot method is used for products with a large diameter. The pipe is heated by filling the bend with sand. This is necessary so that there are no creases.

For cold bending, pipe benders are used - special machines. In everyday life, spring devices are used, into which thin pipes are first inserted, and then they are gently bent

For cold bending, pipe benders are used - special machines. In everyday life, spring devices are used, into which thin pipes are first inserted, and then they are gently bent

For heating, experienced craftsmen use a burner, acetylene-oxygen or acetylene-air. Working temperature – from +650°C. The readiness of copper is determined by its shade: as soon as it becomes dark red, you can bend.The procedure is carried out quickly, but carefully.

Connection methods: crimping and soldering

If you have time, developed skills and experience, you can try to solder copper pipes yourself. This method is longer than crimping, but it is inexpensive and reliable.

Soldering should be carried out under certain conditions: in a ventilated room, at a temperature from -10 ° C to + 40 ° C, and preferably at room temperature.

Soldering should be carried out under certain conditions: in a ventilated room, at a temperature from -10 ° C to + 40 ° C, and preferably at room temperature.

Procedure:

- Preparation of parts: cutting and bending pipes, if necessary - expanding and calibrating.

- Cleaning the ends of the connected segments, eliminating any defects.

- Inserting the end of one pipe into the expanded end of another.

- Heating the soldering area to the melting temperature of the solder.

- Feeding solder into the gap between two parts.

- Cooling the soldering area and cleaning the joint to a shine.

After soldering, diagnostics are performed. Testing for the tightness of the system is carried out by a special commission.

Connection using press fittings is a reliable modern method, the main advantage of which is the fast assembly speed of the gas pipeline.

Connection instructions pipeline elements by pressing:

If the hand is full, then when assembling a small fragment, several elements are first connected to the fittings, and then they are pressed in one go. It is recommended to assemble the in-house gas system in parts - first separately complex sections with a large number of bent elements, and then them together.

In the connection of copper pipes, collet (crimp) fittings are also used, which are practically not used in the assembly of gas lines due to the not very high reliability of the collapsible assembly. The connections formed by soldering are recognized as the most reliable.

However, to implement the soldering of copper pipes, experience and the appropriate tool are needed: a blowtorch for a low-temperature connection, a propane or acetylene torch for a high-temperature one.

How is the laying of communications in a private area?

If we are talking about the gasification of a private (low-rise) house, then the described process and the use of PVC structures will have their own specifics. It should be assumed that all gas transmission communications collected on the basis of the material under discussion and passing outside the premises (along the street) must be placed under the ground surface, these are the requirements of modern safety standards

It is impossible not to understand that this is an important advantage, because the pipes, being underground, will be reliably protected from the destructive influence of any specifics, and in the event of an explosion (an undesirable option, but it would be careless to exclude it), the soil layer will act as a reliable protection against damage to people and property . At the same time, any person who evaluates the situation from the point of view of logic is aware that in order to place plastic pipes for gas in a private house underground, it will often be necessary to damage sections of the transport infrastructure, which in itself is troublesome and undesirable

Which of the considered aspects is more important - each person will have to decide individually.

It is interesting to note that there are aluminum and fiberglass reinforced pipes, both inside and out. Such products differ only in heat dissipation. The most efficient for heating are fiberglass pipes. They have minimal heat output. You can find information about the connection of such materials here.

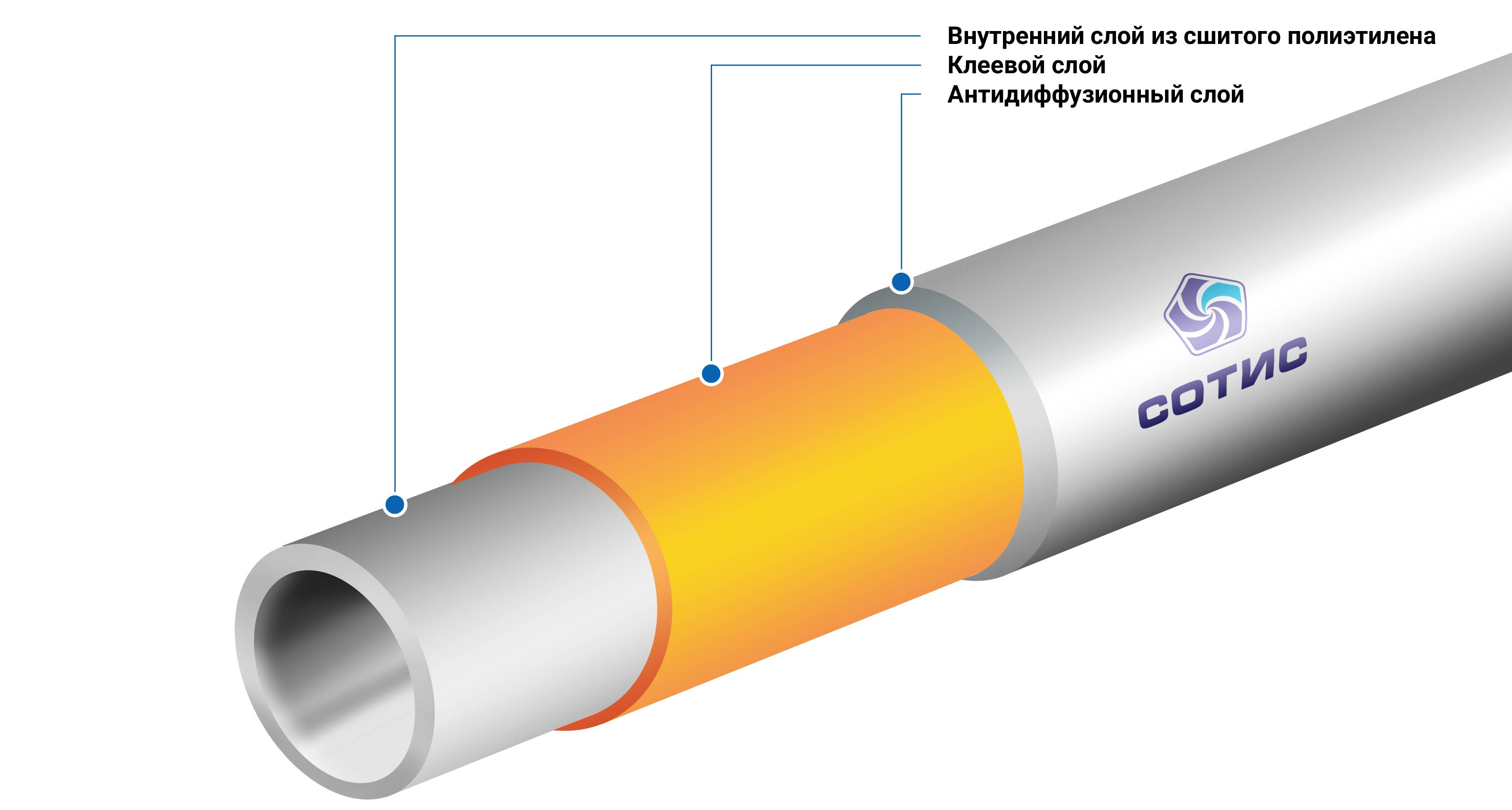

Metal-plastic pipes for gas supply

For the implementation of gasification of a private house, metal-plastic pipes PEX-B-AL-PEX-B are used. The sleeve of the product is protected by a polymer composition. The pipe is used for laying inside buildings, including the hidden installation method.

Installation of fittings, adapters and installation of joints are carried out using crimping. Press fittings provide sufficient sealing. The pipe can be laid through living quarters.

Scope of a pipe from a metalpolymer

Polymer-coated metal pipes are mainly used for laying pipelines inside residential premises and connecting household heating appliances and gas consumption sources. A set of fittings allows you to connect to pipes made of other materials (PE, steel, etc.). Polymer-metal pipes are made from the following materials:

- The outer and inner layers are made of PEX-b polyethylene.

- Adhesive layer - connects plastic and aluminum

- The middle layer - the core is made of aluminum, welded by TIG welding.

Metal-polymer products are not recommended for installation outside the building. Under the influence of ultraviolet rays, the upper polymer layer is rapidly destroyed. The pipe loses its tightness and cannot be used for gas supply.

Manufactured standard sizes and basic parameters of pipes are made in such a way as to ensure the most convenient installation. The consumer is offered a pipe of 16, 20, 26, 32 mm sizes. The material is supplied in coils of 50, 75, 100 m.

Pros and cons of a metal-polymer pipe

Multilayer metal-polymer pipes have a number of advantages over analogues:

- Ease of installation - the crimping mechanism allows you to quickly mount the gas pipeline without the involvement of specialists and expensive equipment.

- Profitability - the pipe bends well, which allows you to get by with a minimum number of fittings when laying a gas supply system.

- Possibility of piping indoors. Good appearance and good tightness of the product make it possible to install even in living rooms.

The disadvantages are the following:

- Limited prospects for the use of metal-plastic pipes - polymer products are intended for laying inside the building.

- Low heating temperature - the product maintains tightness at temperatures from -15 to +40°C.

Metal-plastic pipes are suitable for domestic gas supply; for laying on the street, it is better to use polyethylene products.

What are the positive features of gas communications based on plastic pipes?

Such a gas pipeline is better than a metal one in that:

- The service life of the structure under discussion significantly exceeds the similar parameter of the metal structure.

- Products of this type do not conduct electricity, which in the context of many situations plays an extremely important role.

- Due to the low weight of PVC structures, the construction of various objects with their use is carried out quite quickly.

- The construction of any communications using the pipes in question in domestic and industrial conditions is an optimization of the estimate, the use of the same number of metal parts will cost much more.

For a more in-depth study of the characteristics, it is best to read the article on this issue on our website - Temperatures, pressure, what it consists of and more.

Features of installation work

Installation is carried out by butt or electrofusion welding using fittings with embedded heaters. The choice of welding method is determined by the diameter of the pipes, the availability of access to the installation site, and budget requirements. Welding equipment can be rented, which reduces the cost of the finished pipeline if the project is one-time.

The manufacturer offers a wide range of complete shut-off and control valves and fittings for gas pipelines of any diameter, which allows you to easily mount any section, including with connection to existing steel pipes. If the technology is followed, the strength of the joints exceeds the strength of the pipe itself and guarantees the exclusion of ruptures and other joint defects.

Qualified personnel who have been trained and regularly certified to work with welding equipment in accordance with the fixed work schedule are allowed to install.

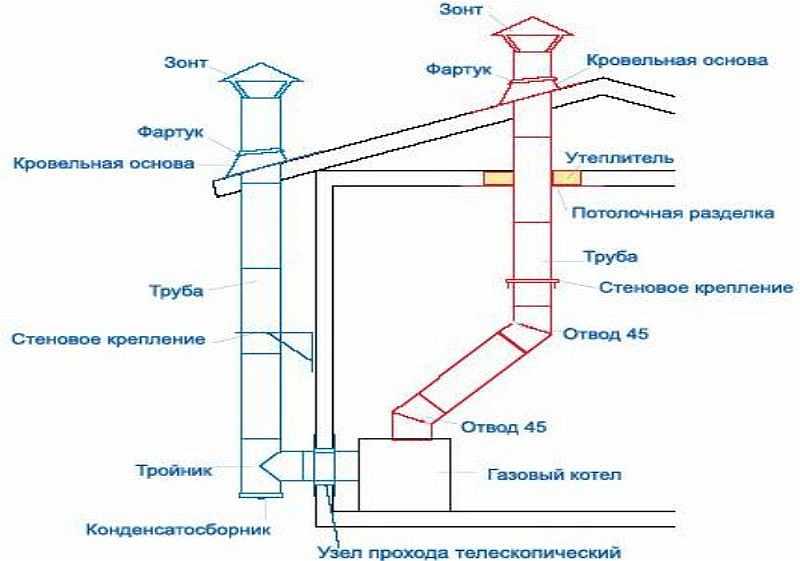

Options for gas ducts for a country house

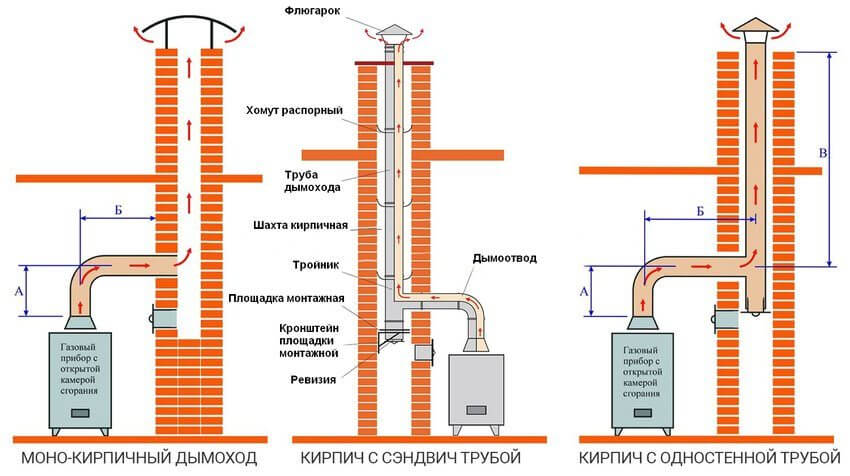

To discharge combustion products with a relatively low temperature (up to 120 ° C) emitted by gas boilers, the following types of chimneys are suitable:

- three-layer modular stainless steel sandwich with non-combustible insulation - basalt wool;

- a channel made of iron or asbestos-cement pipes, protected by thermal insulation;

- ceramic insulated systems such as Schiedel;

- brick block with a stainless steel pipe insert, covered from the outside with heat-insulating material;

- the same, with an internal polymer sleeve of the FuranFlex type.

Three-layer sandwich device for smoke removal

Let us explain why it is impossible to build a traditional brick chimney or put an ordinary steel pipe connected to a gas boiler. The exhaust gases contain water vapor, which is a product of the combustion of hydrocarbons. From contact with cold walls, moisture condenses out, then events develop as follows:

- Thanks to numerous pores, water penetrates into the building material. In metal chimneys, condensate flows down the walls.

- Since gas and other high-efficiency boilers (on diesel fuel and liquefied propane) operate periodically, frost has time to grab moisture, turning it into ice.

- Ice granules, increasing in size, peel the brick from the inside and out, gradually destroying the chimney.

- For the same reason, the walls of an uninsulated steel flue closer to the head are covered with ice. The passage diameter of the channel decreases.

Ordinary iron pipe insulated with non-combustible kaolin wool

Selection Guide

Since we initially undertook to install an inexpensive version of the chimney in a private house, suitable for do-it-yourself installation, we recommend using a stainless steel pipe sandwich. Installation of other types of pipes is associated with the following difficulties:

- Asbestos and thick-walled steel pipes are heavy, which complicates the work. In addition, the outer part will have to be sheathed with insulation and sheet metal. The cost and duration of construction will definitely exceed the assembly of a sandwich.

- Ceramic chimneys for gas boilers are the best choice if the developer has the means. Systems such as Schiedel UNI are reliable and durable, but too expensive and out of reach for the average homeowner.

- Stainless and polymer inserts are used for the reconstruction - lining of existing brick channels, previously built according to old projects. Specially fencing such a structure is unprofitable and pointless.

Flue variant with ceramic insert

A turbocharged gas boiler can also be connected to a conventional vertical chimney by organizing the supply of outside air through a separate pipe. The technical solution should be implemented when a gas duct has already been made in a private house, brought to the roof. In other cases, a coaxial pipe is mounted (shown in the photo) - this is the most economical and correct option.

Noteworthy is the last, cheapest way to build a chimney: make a sandwich for a gas boiler with your own hands. A stainless pipe is taken, wrapped in basalt wool of the required thickness and sheathed with galvanized roofing. The practical implementation of this solution is shown in the video:

Chimney of solid fuel boiler

The mode of operation of wood and coal heating units involves the release of hotter gases. The temperature of the combustion products reaches 200 ° C or more, the smoke channel warms up completely and the condensate practically does not freeze. But it is replaced by another hidden enemy - soot deposited on the inner walls. Periodically, it ignites, causing the pipe to heat up to 400-600 degrees.

Solid fuel boilers are suitable for the following types of chimneys:

- three-layer stainless steel (sandwich);

- single-wall pipe made of stainless or thick-walled (3 mm) black steel;

- ceramics.

Brick gas duct of rectangular section 270 x 140 mm is lined with an oval stainless pipe

It is contraindicated to put asbestos pipes on TT-boilers, stoves and fireplaces - they crack from high temperatures. A simple brick channel will work, but due to roughness it will become clogged with soot, so it is better to sleeve it with a stainless insert. Polymer sleeve FuranFlex will not work - the maximum operating temperature is only 250 ° C.

Mounting Features

Having bought pipes for the heating system, it is necessary to properly install

Features to pay attention to:

- To correctly calculate the number of pipes, fittings, and other elements of the pipeline, you need to draw the location of the main elements on a piece of paper.

- Consider what connections are best to make - detachable or soldered. The former are better suited for open systems, the latter for closed ones.

- In a private house, a separate room should be equipped in which a heating boiler, overhead taps, and pipeline openings will be located.

- Choose in advance the radiators that will be located in the rooms. Their choice depends on the diameter of the tubes, the heated area.

- Do not tighten the fixing nuts during installation. This will break connections.

- Threaded fasteners are covered with FUM tape before tightening.

Before putting the pipeline into operation, a test run is carried out to avoid leaks.

Scope of application

Pipes for gas pipelines made of HDPE are used in almost all areas of business:

- small construction: for the gasification of individual buildings and entire settlements on a turn-key basis, including new and existing facilities;

- rehabilitation of existing highways;

- capital construction: to connect new houses and social facilities;

- industry: to meet the needs of production of various types and scales;

- agriculture: to meet the needs of crop and livestock heating kits;

- strategic objects: maintaining the functionality of storage facilities, creating an auxiliary infrastructure for transport gas pipelines.

What does a quality gas pipeline consist of?

Permissible material for a gas pipeline directly depends on the pressure in the pipes

Permissible material for a gas pipeline directly depends on the pressure in the pipes

There are 4 types of pipelines:

- Main - gas pipeline of the 1st category. The gas pressure here is 0.6–1.2 MPa. Liquefied gas is transported under pressure from 1.6 MPa and above.

- High pressure gas pipeline - 2nd category. The pressure is lower - from 0.3 to 0.6 MPa.

- Medium pressure pipelines - from 0.005 to 0.3 MPa. These are systems that serve urban areas.

- Low pressure - with indicators below 0.005 MPa. Blue fuel is supplied to the dwelling without pressure.

The lower the pressure, the less strong the material can be. Characteristics are regulated by GOST R 55473-2019 and GOST R 55474-2013. For gas supply it is allowed to use:

-

Steel pipes - seamless from cold-rolled steel for high pressure systems, with a straight seam for high and medium pressure communications and gas pipes for gas distribution in residential buildings. Their advantages are strength, high tightness of pipes and joints, and the absence of linear expansion. At the same time, steel products are very heavy, are connected only by a weld, and are prone to corrosion.

- Plastic - able to withstand a pressure of up to 1.6 MPa, however, it is forbidden to use them for laying liquefied gas lines.The plastic pipe for gas is flexible with high strength: communication can have a very complex shape. The material is resistant to chemically aggressive substances and does not corrode at all. However, the gas pipeline can only be carried out underground. Operation in areas with temperatures below -45 C is prohibited.

- Copper - the metal is resistant to corrosion, strong, ductile and very durable. However, it is only suitable for low pressure gas pipelines.

The circuit is assembled from pipes of different materials. Often, the base of the highway is made of steel, and in an apartment building, gas is supplied to dwellings through plastic gas pipelines.

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through the nozzles, and a heat exchanger, which is heated by the energy obtained during the combustion of gas. The gas burner is located in the combustion chamber. The movement of heat occurs with the help of a circulation pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules that allow the equipment to be used offline.

When choosing a chimney, pay attention to the type of combustion chamber of the boiler. It is from its design that the method of taking in the air necessary for the combustion of gas will depend, and as a result, the optimal type of chimney

Different types of chimneys are suitable for different types of combustion chamber

The combustion chamber for gas boilers is of two types:

- open - provides natural traction. The air is taken from the room where the heating equipment is installed.The removal of combustion products is carried out by means of natural draft using a chimney with an exit through the roof;

- closed - provides forced draft. The intake of air for combustion of fuel occurs from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. For the simultaneous removal of flue gases and intake of fresh air, a coaxial type chimney is used, which is led out through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or make a chimney that is suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross section is fixed inside a pipe with a larger diameter by means of special racks. Through the inner channel, carbon dioxide and other combustion products are removed, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

- internal - chimneys made of metal, brick or ceramics. They are both single-walled and insulated double-walled structures. Arranged vertically upwards. Perhaps the presence of several knees with an offset of 30o;

- outdoor - coaxial or sandwich chimneys. They are also located vertically upwards, but the chimney is brought out horizontally through the load-bearing wall.After the pipe is removed, a 90° swivel elbow and support brackets are installed to allow installation in the desired direction.

The chimney can be led outside through the wall in the immediate vicinity of the boiler or in the traditional way through the roof

When choosing a chimney device, the dimensions of the building in which the equipment is located should be taken into account. For small buildings, it is more advisable to use external chimneys, as they allow you to bring the chimney outside the room.

In other cases, one should build on personal capabilities. If space permits and it is possible to perform high-quality insulation in the places where the pipe passes through the floors, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.

Conclusions and useful video on the topic

More about the main types of flexible eyeliners in the video:

Video instruction for connecting the stove to gas:

Scheme for connecting a gas column in a video clip:

Thanks to universal flexible hoses, it became possible to refuse to connect household appliances to gas pipes "tightly". The mobility of such devices greatly simplifies the life of the owners of kitchen facilities, allowing you to easily move equipment for cleaning, rearrangement or repair.

And what type of hose did you choose to connect the gas at home? Tell us, which of the advantages of eyeliner was the main reason for choosing? How long have you been using this flexible hose?

Or maybe you noticed an inaccuracy in the reviewed material or want to supplement the above with your own opinion? Please leave your comment below our article.