- Some installation rules

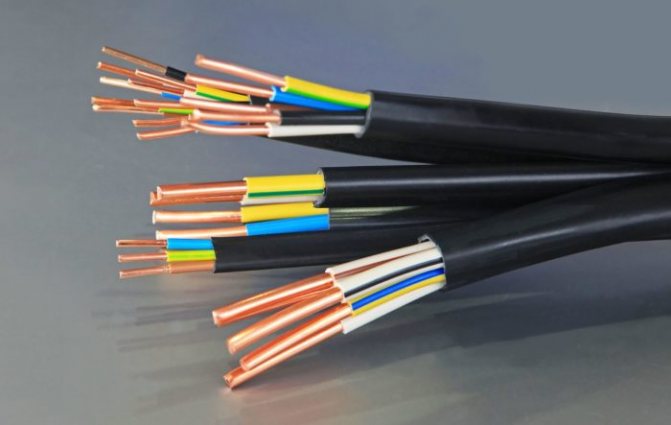

- Cable cross section for open wiring

- Scope of use

- Types of channels for electrical wiring

- What is a wiring box

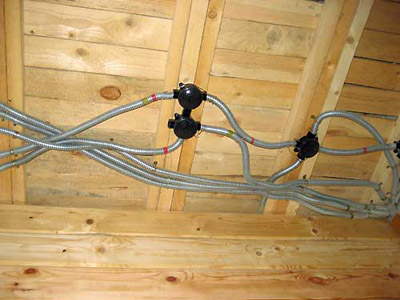

- Advantages of a tubular corrugated channel

- Tips for choosing a pipe for installation in different conditions

- Dimensions and approximate prices

- Advantages and disadvantages

- Advantages of PVC pipes over metal pipes

- Important aspects of grounding

- Technology for laying cables in metal pipes: installation process

- Trench construction

- Trenchless cable laying in the ground

- Cable laying under the road

- Requirements for PVC pipes for wiring

- GOSTs

- Which cables are allowed

- Advantages of metal cable channels

- Scope of pipes for electrical wiring

- Scope of HDPE pipes

Some installation rules

Before installing a cable route made of metal thin-walled pipes for electrical wiring, you should familiarize yourself with the following rules:

the ends of each piece of products need to be pre-cleaned from burrs and countersinking;

the maximum allowable bending angle of the steel channel is 90 degrees;

there is a restriction on the length of the segments: up to 10 meters in the case of a straight pipe, up to 5 meters - in the presence of 2 bends;

when performing bending, it is important to monitor the integrity of the cross-section of the product;

the metal channel must be carried out as part of the EMS (potential equalization system).

If it is impossible to fulfill the condition for choosing the length of the pipes, according to the rules, it is required to install a pull box without additional joints.

The physical essence of the EMS is the need to connect all the conductive parts into a single system in such a way as to minimize or completely eliminate the potential difference between them. To do this, it must include:

- grounding device;

- the main (G) grounding (Z) bus (W) mounted in the shield (Sch) for metering (U) electricity (E) or the input shield;

- all elements of the metal structure of the building.

If you follow these rules, you can greatly facilitate the installation and replacement of electrical wiring.

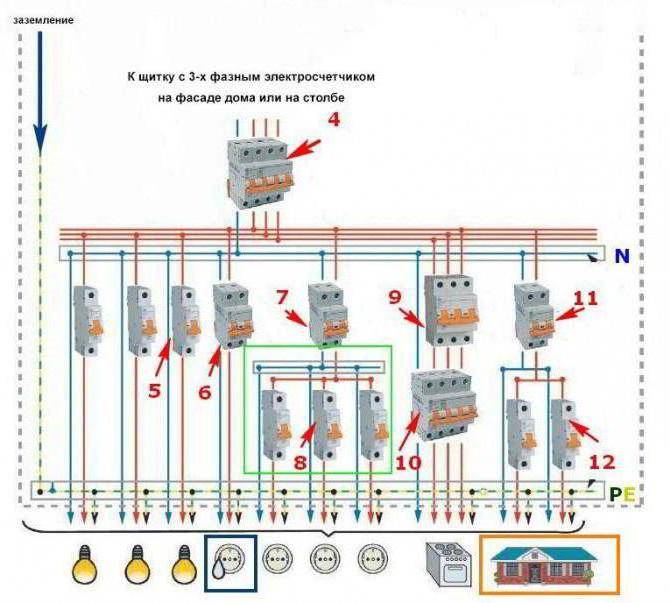

Cable cross section for open wiring

To use the tables and choose the right cable cross-section for a house or apartment, we need to know the current strength, or know the power of all household electrical receivers.

Current calculated by the following formulas:

- for a single-phase network with a voltage of 220 Volts:

where P is the sum of all the powers of household electrical receivers, W;

U - voltage of a single-phase network 220 V;

cos(phi) - power factor, for residential buildings it is 1, for production it will be 0.8, and on average 0.9.

- for three-phase network voltage 380 volts:

in this formula, everything is the same as for a single-phase network, only in the denominator, because the network is three-phase, add root 3 and the voltage will be 380 V.

To select the cable cross-section for a house or apartment, according to the above tables, it is enough to know the sum of the capacities of the electrical receivers of a given cable line (group).We will still need to calculate the current when designing an electrical panel (selection of automatic devices, RCDs or differential automatic devices).

Below are the average power values of the most common household electrical receivers:

Knowing the power of electrical receivers, you can accurately select the cable cross-section for a specific cable line (group) in a house or apartment, and therefore an automatic machine (difavtomat) to protect this line, which has a nominal the current must be below the continuous current cable of a certain section. If we choose a copper cable cross section of 2.5 sq. mm., which conducts current up to 21 A for as long as we like (hidden laying method), then the automatic (difavtomat) in the electrical panel for this cable should be with a rated current of 20 A so that the machine turns off before the cable starts to overheat.

Typical sections of cables for electrical installation in everyday life:

- In apartments, cottages or private houses, a copper cable of 2.5 sq. mm is laid on the socket groups;

- For the lighting group - a copper cable section of 1.5 sq. mm;

- For a single-phase hob (electric stove) - cable cross-section 3x6 sq. mm., For a three-phase electric stove - 5x2.5 sq. mm. or 5x4 sq. mm. depending on power;

- For other groups (ovens, boilers, etc.) - according to their power. And also on the connection method, through a socket or through terminals. For example, if the oven power is more than 3.5 kW, then a 3x4 cable is laid and the oven is connected through the terminals, if the oven power is less than 3.5 kW, then a 3x2.5 cable and connection through a household outlet are sufficient.

In order to correctly choose the cable cross-section and the ratings of the machines for the electrical panel of a private house, apartment, you need to know important points, not knowing which can lead to sad consequences.

For example:

- For socket groups, a cable cross-section of 2.5 sq. mm is selected, but the machine is selected at the same time, with a rated current of not 20A, but 16A, because. household sockets are designed for a current of not more than 16 A.

- For lighting I use a cable of 1.5 sq. mm., But the machine is not more than 10A, because. switches are designed for current not more than 10A.

- You need to know that the machine passes current up to 1.13 times its nominal value, for as long as you like, and if the nominal value is exceeded up to 1.45 times, it can turn off only after 1 hour. And all this time the cable will be heated.

- The cable cross-section should be correctly chosen according to the hidden laying method so that there is a necessary margin of safety.

- PUE p.7.1.34. prohibits the use of aluminum wiring inside buildings.

Thank you for your attention

Scope of use

Open cable and wire routing on walls and ceilings, behind false walls and inside plasterboard partitions and behind suspended ceilings in accordance with regulatory documents is not allowed. In such cases, the wiring should be additionally isolated and protected from mechanical damage, exposure to aggressive environments, ultraviolet radiation, and precipitation. The most versatile and practical way to insulate and protect wires is to use pipes. A variety of their types helps to choose the right pipe for any situation that has arisen in the process of building and repairing your home.

But the favorite of all types of pipes for laying electrical wiring are their PVC products - durable, non-conductive, non-flammable, aesthetic, easy to install.

Scope of PVC pipes:

- Installation of electrical wiring indoors and outdoors, underground.

- Installation of telephone lines.

- Installation of telecommunication cables, fiber-optic communication.

- Installation of alarm systems, including fire.

- Installation of various local communication systems, computer networks, etc.

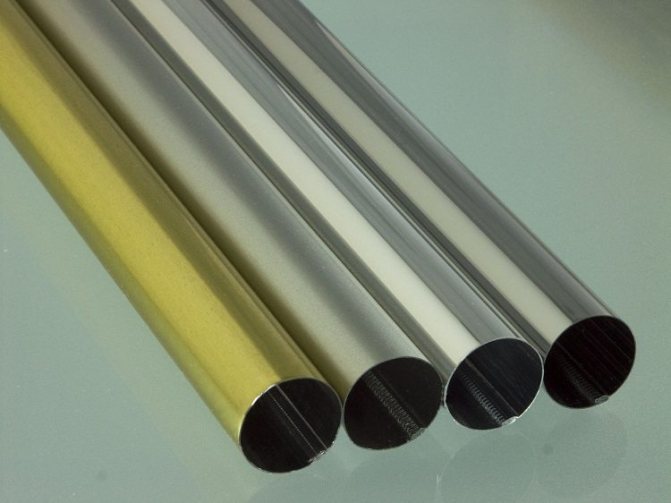

Types of channels for electrical wiring

The choice of tube material depends on the type of room where the wiring is performed, its conditions and features. Among the main materials of channels for such purposes are:

- plastic;

- steel;

- copper;

- brass.

For the manufacture of plastic models, polyvinyl chloride, polyethylene (P) of high (V) and low (H) pressure (D) are used. PVC products are most popular due to affordable price, good indicators of heat resistance and strength. Common diameters are from 1.6 to 6.0 centimeters.

Plastic pipes are characterized by a smooth surface, which makes it easier to replacement work conductors, low weight, resistance to corrosion.

For laying wires, thin pipes are used that are easy to bend

Metal pipes for electrical wiring, made of steel, have a significant mass, however, they are characterized by particularly high strength. Such products are recommended for use in wooden buildings. Since the material is a good conductor, then, to ensure electrical safety, all such channels must be grounded. Thin-walled brass or copper tubing is excellent for both wall mounting and concealed installation. It bends easily and does not always need decor.

What is a wiring box

An electrical box, or cable channel, is an electrical product designed for installing cables and wires on walls, floors or ceilings. The shape of the cable channel can be rectangular or triangular, the cross section looks like a closed profile, inside which power or low-current wires are laid. Unlike the corrugation, which performs similar functions, the wiring box is collapsible and consists of the inner cavity of the channel and the cover. The main place of application of the electrical box is the organization of network provision where internal wiring is not considered appropriate.

Power or low-current cables are bred in ducts in cases where installation of hidden wiring is not advisable

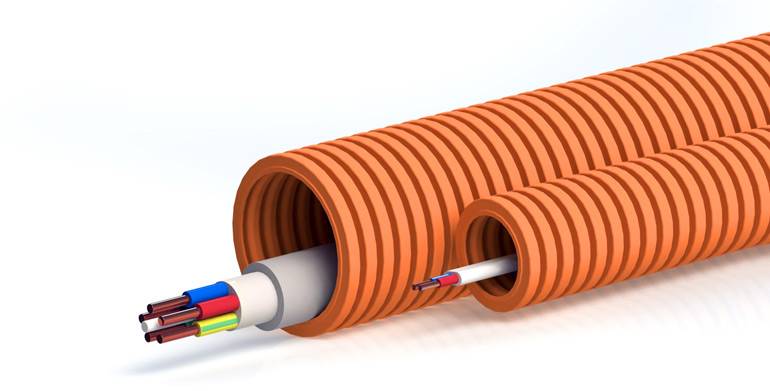

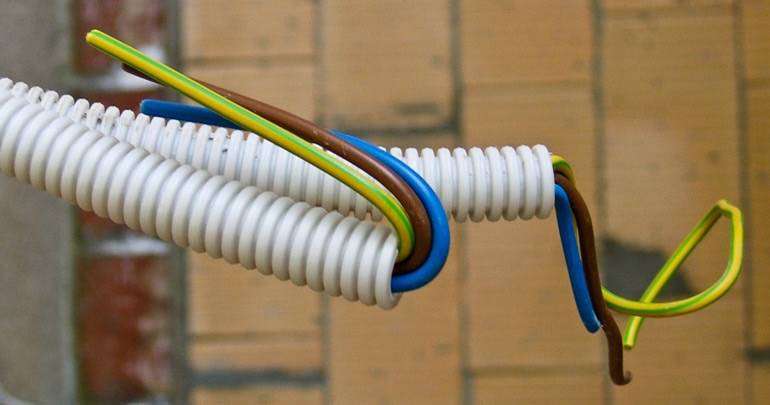

Advantages of a tubular corrugated channel

Professional specialists prefer to lay electrical cable in corrugated PVC or HDPE pipes. This is justified by the undeniable advantages of products compared to other materials:

- The corrugated pipe perfectly protects the wiring from mechanical damage;

- Safety against electric current due to short circuit due to reinforced insulation;

- Special additives do not allow the pipe to catch fire, but only melt, which prevents a fire in case of an emergency in the electrical system;

- The ability to create designs of complex configurations without additional fittings, which is explained by the elasticity of the material.

Corrugated pipes are easy to stock, store and move due to their low weight. Dielectric properties make it possible to refuse grounding.Anti-corrosion characteristics and resistance to negative external influences extend the period of trouble-free operation up to 50 years.

In damp rooms, as well as in places located in the area of action of chemically active compounds or explosive mixtures, electrical wiring needs additional protection. HDPE pipes will help protect the cable from mechanical destruction and the negative influence of the environment.

It is recommended to install channels for polyethylene wires in two stages. First, the exit points of the pipes to the power panels, receivers and control equipment are determined. Then mark the trajectory of the electrical wiring with the places of fixation of the boxes, the angles of the bend of the channels and the attachment points.

A temperature of 100 - 130 degrees allows you to bend a smooth HDPE pipe without damage.

A necessary condition before cable laying is channel check and air purge.

Pipe sections are connected with special fittings like standard plumbing fittings such as elbows or crosses.

Tips for choosing a pipe for installation in different conditions

The most important parameter that is taken into account when choosing a method of protecting electrical wiring is the location: indoors on the wall, behind a false ceiling, plasterboard false wall; up to 2 m at floor level or plinth, above 2 m; in a damp room, in the open air or in the ground. The second parameter is the required degree of protection, which directly depends on the location of electrical networks.

For laying wires and cables on the street, steel smooth and corrugated pipelines are more often used. They are somewhat stronger. PVC structures. In addition, although PVC is considered UV-resistant, PVC corrugation will not last very long under direct sunlight - 15-20 years. PVC pipe will last a little longer. But it all depends on the purpose of laying the wire and the potential service life of the entire structure - if it is a power cable, then it is laid reliably and for a long time, and if it is wiring to the lamp, then just in 15-20 years it will be time to update both the lamp and the wiring.

It is desirable to ensure the tightness of the wiring outdoors - both for the safety of wires and insulation, and for the safety of pipes - when water freezes in them, they can break or deform. When using a metal corrugation, you should choose a corrugation with an inner layer of plastic. Joints of pipes and sleeves with boxes or fittings should preferably be greased with sealant or sealed with seals.

HDPE and polypropylene are not UV resistant, so they are not used outdoors. Although they will stand for 2-3 years, they are suitable for temporary laying of electrical networks.

In the ground, the laying of communications is carried out using HDPE and a two-layer PVC corrugation. Gasketing in metal has almost become a thing of the past due to the tendency of steel to corrode.

For pouring into the screed and concrete walls and floors, the passage of walls must be used strong smooth steel or plastic pipes or reinforced heavy corrugation. In production and storage areas, robust, smooth cable ducts are also required. In public buildings, entrances and in some other places, smooth, durable pipes will also have to be used, based on public safety (or anti-vandal resistance) considerations.

In wet rooms, a two-layer corrugation is used, which reliably seals the wires.

The thinnest and lightest corrugated hoses are used when laying electrical networks under wall and ceiling sheathing, suspended ceilings, and in plasterboard partitions.

When laying openly, the location of the wiring should be taken into account - if there is a possibility of damage by objects, bags, arms and legs and other parts of the body, either smooth pipes or strong corrugations with a thick wall should be chosen. This danger should be especially taken into account when laying the wire near the floor and above the plinth, at the height of the hips (0.8-1.2 m)

When buying a corrugation, you should choose products with a probe (wire) for pulling the cable. The absence of a probe will complicate your work and raise doubts about the quality of the corrugated hose.

It is desirable to buy in large stores and hypermarkets. When buying, be sure to require a check and a certificate, especially for plastic products. For internal wiring, the plastic must be self-extinguishing! If possible, it is advisable to buy a small piece of pipe and check it - try to set it on fire.

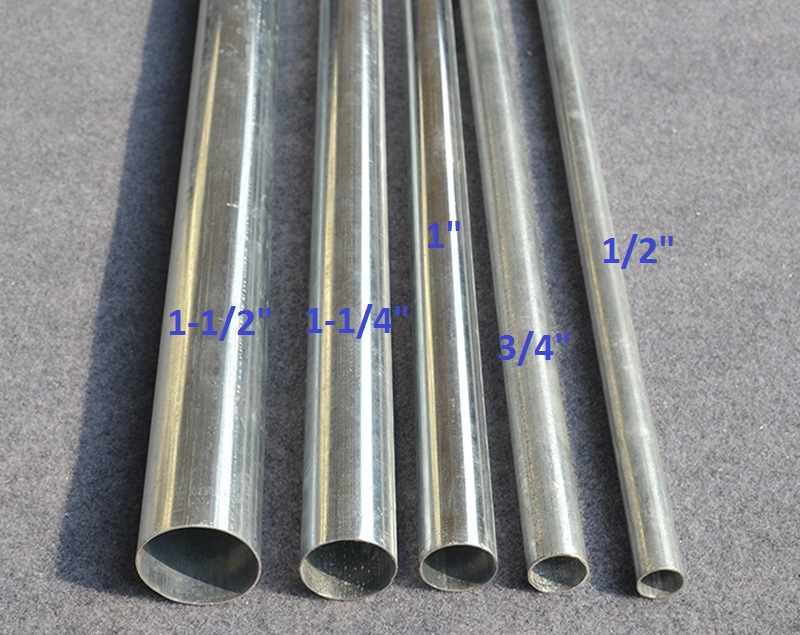

Dimensions and approximate prices

When choosing pipes, it is necessary to choose the right diameter. For lighting networks, telephone or computer networks, a pipe with a diameter of 16 mm is sufficient. For the supply of wires to switches and sockets, a diameter of 20 mm is suitable. For small cables (for example, for connecting powerful equipment in the kitchen), a diameter of 25 mm is suitable. Power cables are best laid in pipes with a diameter of 25-50 mm.

Prices for PVC corrugation:

- Diameter 16 mm - from 4.7 to 9 rubles. and higher.

- Diameter 20 mm - from 6.5 to 11 rubles. and higher.

- Diameter 25 mm - from 10.8 to 18 rubles. and higher.

Prices for smooth PVC products:

- Diameter 16 mm - from 12 rubles. and higher.

- Diameter 20 mm - from 18 rubles. and higher.

- Diameter 25 mm - from 35 rubles. and higher.

The price is very different from different manufacturers.

Advantages and disadvantages

Advantages:

Durability - the first products have already worked for more than 50 years and are approaching 60 (although the service life of the wires is half as long).

Small cost.

Incombustibility is especially important for electrical networks, PVC also has the property of self-extinguishing.

Easy installation - easy to cut, there are many types of connecting elements; there is no need for complex expensive equipment for installation.

No corrosion.

Strength and at the same time high impact strength - pipes resist mechanical damage well; products are not fragile, can be restored after deformation.

Frost resistance - withstand freezing - thawing and return to their original shape.

Flexibility - plastic is easy to bend when heated, even with your hands, the corrugation is generally easy to bend;

Harmless to humans and animals.

Chemical inertness, resistance to acids and alkalis;

Smooth walls facilitate the tightening of wires;

No need for regular maintenance (cleaning, anti-corrosion environmental friendliness - fairly harmless production, easy disposal.

aesthetic qualities.

Easy care - the stainless surface is easy to wash, clean from dirt.

Light weight, lack of fragility facilitate transportation and storage.

Polyvinyl chloride is UV resistant.

Flaws:

- Low heat resistance of polyethylene and polyvinyl chloride - their operating temperatures are practically limited to 60 ° C.However, such a temperature practically does not occur when laying wires in a residential building (only near heating systems).

- Brittleness in the cold.

- The strength of plastic is still lower than that of metal.

Advantages of PVC pipes over metal pipes

The most significant drawback of common steel pipes is their susceptibility to corrosion. Copper and stainless steel pipes do not rust, but their price for wiring under normal conditions is simply unacceptable. Yes, steel pipes are more expensive than PVC pipes.

The second advantage of PVC is light weight and easy installation - PVC is easy to cut, weighs less, it is easier to fasten to walls and ceilings.

The third advantage is that PVC does not conduct electricity. Fourth, PVC systems do not require grounding.

Important aspects of grounding

The main task of protective grounding is to ensure human safety from contact with electric current (ET). Its impact is as follows:

- at a current of 0.6-1.5 thousand μA, the effect of electricity on the body is felt;

- at 2-4 thousand μA - fingers begin to tremble;

- at 5-7 thousand μA, hand cramps may occur;

- at 10-15 thousand μA - it is difficult to open the hand with the conductor on your own without help;

- at 20-25 thousand μA - severe pain is felt, breathing is difficult and it is impossible to separate the hand from the wire;

- at 50-80 thousand μA - there are malfunctions in the work of the heart, respiratory paralysis occurs.

The critical current that causes heart fibrillation and cessation of breathing is 100 thousand μA. 1 uA is a millionth of an ampere.

Any electrical system must be equipped with a residual current device.

In relation to the conductor of a constant ET or a phase conductor, the earth has a zero potential, which explains the use of grounding.The value of the resistance of the grounding device, equal to the ratio of the voltage on it to the current that goes into the ground, should be no more than 4 ohm.

Modern electrical wiring is carried out only with the use of a residual current device, which is almost instantly triggered by any leakage (unauthorized) current. There are such types of grounding systems: TN-C; TN-S; TN-C-S; TT; IT.

Explanation of letters in the first position: T - grounded neutral IP (power supply); I - all current-carrying elements of the equipment (including the working neutral wire) are isolated from the ground. Symbols in the second position mean: N - open conductive elements of grounded devices are connected to the SP neutral; T - conductive parts of devices and electrical installations are grounded through a separate circuit. Letters separated by a hyphen: C - functions of zero protective and zero working conductors are combined in a single conductor; S - working and protective zero provide different conductors.

Metal corrugated pipes and smooth types of such pipes are great for laying hidden communications. Although alternative corrugated or smooth polymer cable channels are increasingly being used today, steel / copper products surpass their characteristics in terms of strength and degree of mechanical protection.

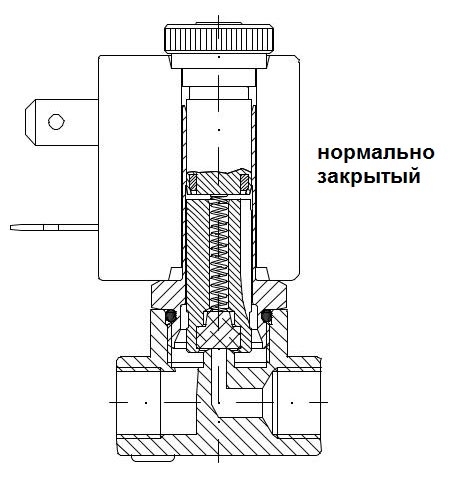

Technology for laying cables in metal pipes: installation process

Installation of a cable in pipes is quite laborious and expensive, therefore it is used when it is necessary to protect the cable from mechanical stress. Bookmarking is carried out in several stages:

- marking of the upcoming route;

- preparation and installation of pipes;

- cabling.

To fulfill the first point, the place of laying is determined, and preparatory work is carried out. When mounting on the walls of buildings, in the foundation, partitions, strobes, holes for electrical appliances, transitions, etc. are made. Lengths and bends are measured, the necessary documentation is compiled and transferred to the electrical workshop. There the pipes are cleaned, painted, cut to size. Joints must be processed so that there is no burr. Make bends if necessary. Finished products are labeled, packaged and sent to the customer.

Installation is carried out in such a way that dust, oil and other substances do not get inside. To prevent water from accumulating, the gasket is made at an inclination of at least 2 degrees towards the boxes. Fastening by welding is prohibited, for this you need to use brackets, clamps, linings, clamps. The distance between the fasteners must be no more than indicated in the table.

| Outer diameter of pipes, mm | Distance between mounts, m |

|---|---|

| 18-26 | 2,5 |

| 30-42 | 3,0 |

| 45-90 | 4,0 |

All connections and entries must be sealed. After that, the installation of electrical equipment is carried out.

At the final stage, tightening is performed. They check the cleanliness of the pipes, if necessary, they are blown with compressed air, plastic bushings are put on the ends. Wires and cables are assembled in groups, the cores are tied to a steel wire with a diameter of 2-5 mm and stretch.

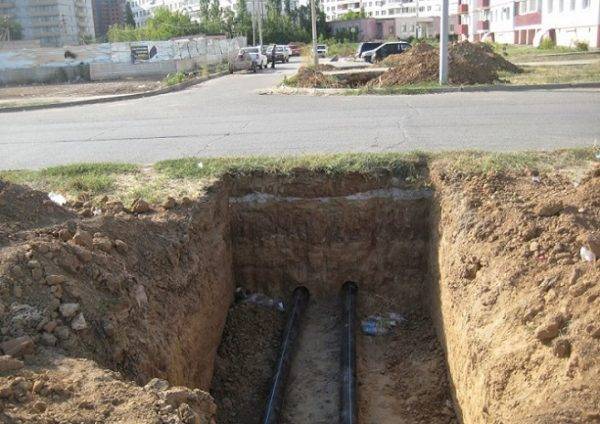

Trench construction

First, the terrain is marked, the future route must be removed from the foundation, gas pipeline, etc. to the distance indicated in the PUE. Then the land is cleared of plants and debris. Earth-moving equipment is used to dig a trench, where this is not possible, they dig it manually. The depth is determined by the operating voltage.The bottom is cleaned, if necessary, of debris, leveled and lined with a sand cushion. A signal tape must be laid over the track.

Trenchless cable laying in the ground

This is a complex and expensive method, carried out by specialized equipment. It is produced in places where it is impossible to dig a trench due to any circumstances, for example, laying under a reservoir. The bottom line is that horizontal drilling is performed using an adjustable drill head. Then the channel expands, a HDPE pipe is pulled, in which there is a steel cable, and a cable is already laid through it with the help of a cable.

Cable laying under the road

In the case when the route must pass through an asphalt road, in order not to disturb its cover, another method of passage is used - a puncture. A rod with a tip is pushed through the ground under the road with the help of technology. The tip, passing through the thickness, compacts the earth around itself, preventing it from crumbling. Such a pass is called a start pass. After the rod has reached the surface, an expander is attached to it and pulled in the opposite direction. The passage widens, and the earth around is even more compacted. A cable line is pulled through it.

Requirements for PVC pipes for wiring

PVC pipes used for laying electrical networks must have the following qualities:

- Sufficient strength.

- Durability.

- Fire damping.

- chemical inertness.

GOSTs

In the production of PVC pipes, the following GOSTs are used:

- GOST 32415-2013 Thermoplastic pressure pipes and fittings for them for water supply and heating systems. General specifications.

- GOST R 54475-2011 Polymeric pipes with a structured wall and fittings for them for external sewage systems. Specifications.

Special standards for PVC pipesused for laying electrical systems have not been developed.

Which cables are allowed

There are no special requirements for wires and cables. According to 2. 3. 42. PUE, it is permissible to lay cable lines in rubber and plastic insulation without additional protection, since pipes perform this function. The number of shells is also not regulated. The cores can be copper or aluminum. Each conductor can consist of one or several lived.

When servicing a four-wire network, the cable to be laid must be four-core (p. 2. 3. 52). This applies to HDPE pipes (low pressure polyethylene) if steel is used, and voltage up to 1 kV, then according to 1. 7. 121. the pipe can play the role of a neutral conductor. This is provided that it does not have an electrical break throughout the route.

It is forbidden to place nearby (clause 2. 1. 16.):

- working and backup network;

- working and emergency line;

- circuits up to and above 42 V.

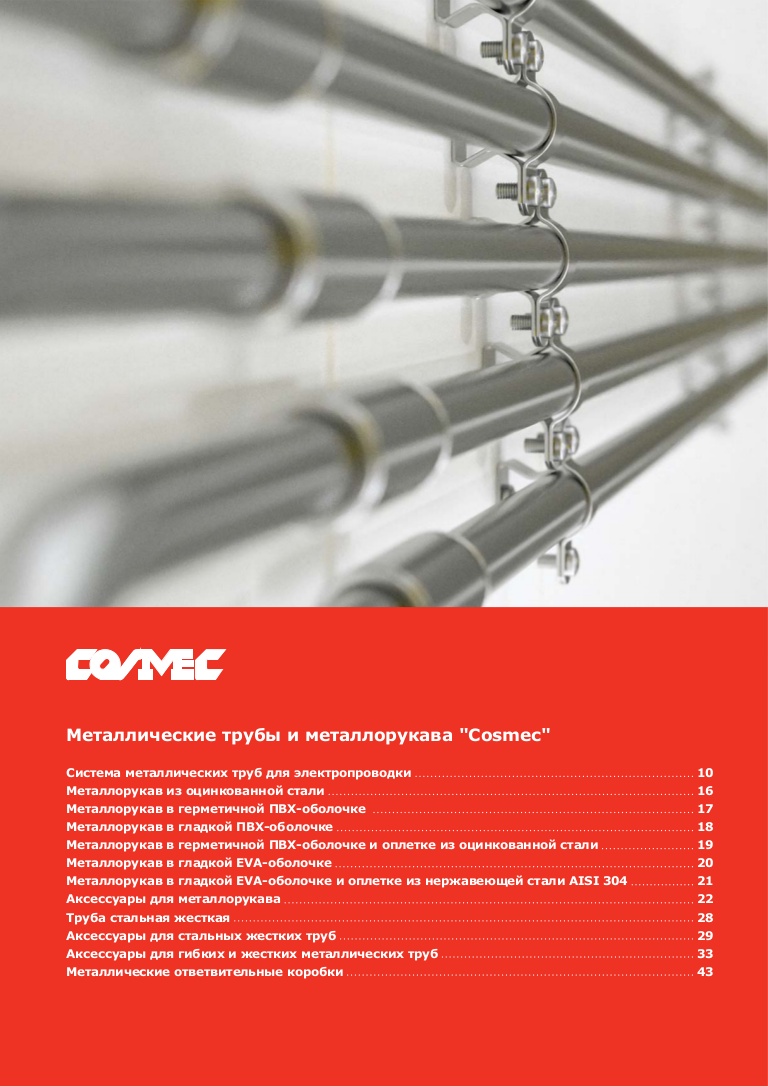

Advantages of metal cable channels

The main advantages of metal channels for electrical wiring are:

- reliability;

- wear resistance;

- practicality;

- variety of solutions;

- parameter stability;

- UV resistance;

- resistance to low / high temperatures.

The resistance of metal pipes to damage allows them to be laid openly without additional protection.

Metal cable channels are able to provide stable protection of wiring from moisture, rodents, mechanical stress and temperature extremes. They can be used for a long time, especially if covered with a protective layer. Such pipes do not require special maintenance.

Metal pipes do not change size and shape, subject to the rules of operation, are suitable for both hidden (internal) and open (external) wiring, and can also be used in unheated rooms.

Scope of pipes for electrical wiring

- Details

- Category: Electrical wiring in pipes

Pipes are used to protect wires from mechanical damage, as well as to protect wire insulation from destruction by the environment. In the first case, the pipeline is allowed leaky, in the second - only sealed, moisture-, dust-tight. The tightness of the pipeline is ensured by sealing the junctions of the pipes with each other and the places where they are connected to devices and devices.

The degree of sealing of pipes can be different. In an explosive environment, the seal must provide sufficient tightness to withstand the norms established by the rules for testing the pipeline with increased pressure. In rooms with a chemically active environment, the seal protects against the penetration of gases and liquids aggressive to the wires into the pipeline.

Ordinary unsealed pipelines protect the wires from possible mechanical damage and direct moisture ingress. Steel pipes for electrical wiring should be used as an exception when laying wires and cables without pipes is not allowed and is limited to the use of non-metallic pipes.Usually, light water-gas and thin-walled electric-welded pipes are used for electrical wiring, and ordinary water-gas pipes (gas) are used only in explosive zones.

Lightweight and electric-welded thin-walled pipes used as protective shells are laid: openly without sealing joints in dry normal rooms; hidden and open with sealing of pipe joints and places of their entry into boxes (walls, ceilings, grouts and floor preparation, in other building elements of structures, in foundations), as well as in all cases in damp, hot, dusty and fire hazardous areas, except for the exit of pipes to the outside.

Substitutes for steel pipes for electrical wiring are polymer pipes (vinyl plastic, polyethylene and polypropylene), which have high corrosion and chemical resistance, moisture resistance, sufficient mechanical strength, smooth surface, while increasing the reliability of electrical wiring in an aggressive environment, reducing the likelihood ground fault, labor costs are reduced both at installation and in workshops due to the exclusion and simplification of a number of technological operations (threading, painting).

Vinyl plastic pipes can be used in dry, damp, damp, especially damp and dusty rooms, rooms with a chemically active environment, in outdoor electrical wiring: with open and hidden laying directly on fireproof and slow-burning walls, ceilings and structures, with hidden laying along combustible walls, ceilings and structures on a layer of sheet asbestos with a thickness of at least 3 mm or basting of plaster up to 5 mm, protruding from each side of the pipe by at least 5 mm, followed by plastering with a layer up to 10 mm thick, as well as in aggressive soil to protect cables. It is forbidden to use these pipes for open and hidden laying in explosive and fire hazardous premises, in hospitals and nursing homes for the elderly and disabled, and for open laying in auditoriums, on stages and in movie booths of entertainment enterprises and clubs, in nurseries, kindergartens and pioneer camps, in attics, in residential and public buildings with a height of more than 10 floors and computer centers.

Polyethylene and polypropylene pipes are allowed to be used in dry, damp, damp, especially damp and dusty rooms and rooms with a chemically active environment for hidden installation on fireproof bases, in external electrical wiring - directly on fireproof bases, in floor grouts and equipment foundations (subject to protection pipes from mechanical damage), as well as in aggressive soil to protect cables. It is forbidden to use these pipes in explosive areas and fire hazardous rooms, in buildings below the second degree of fire resistance, in livestock buildings, as well as in rooms specified for vinyl plastic pipes.

Industrial preparation of pipes and pipe wiring >

Scope of HDPE pipes

The water resistance of the products explains the use for the transportation of drinking and domestic water and for land reclamation activities. Since polyethylene does not emit harmful compounds, HDPE pipes do not pose a danger to the human body.

Anti-corrosion properties allow the use of products in order to lay electrical cables in the ground.Seasonal independence of the material, resistance to the influence of low temperatures makes it possible for a 50-year period of trouble-free operation not to worry about the integrity and safety of underground utilities. The mechanical endurance of products is also taken into account, which does not affect the quality in the event of landslides, subsidence of the soil and other troubles created by nature.

Pipes made of low-pressure polyethylene are used in the construction of wooden structures. In buildings built according to the shield method, in which the walls are insulated with specialized combustible materials, professionals recommend using closed tubular channels for the installation of an energy supply system. Refractory HDPE products will protect the premises from accidental fire in case of involuntary short circuit of electrical wires.