- The main advantages of chimneys made of corrosion-resistant steels

- Stainless steel grades for the production of chimneys

- Pipes wallpapers, pipes pictures, pipes photo

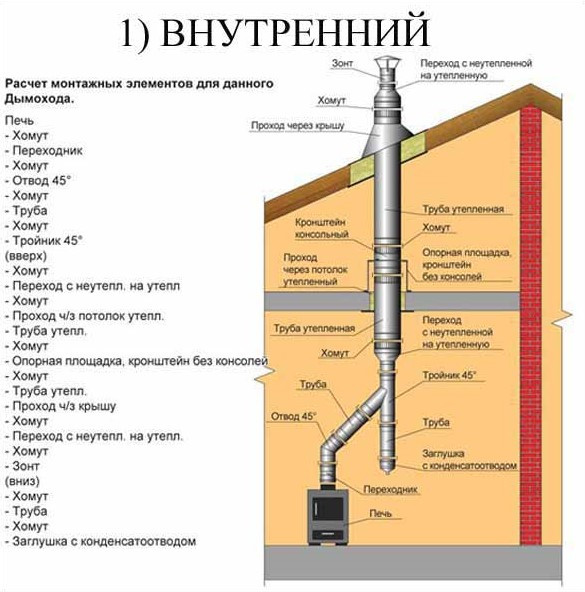

- The nuances of the device and installation

- brick chimneys

- Selection principles

- Dimensions

- Life time

- How to calculate the diameter of the chimney

- Swedish method

- Accurate calculation

- Design of galvanized products

- Varieties of sealants for chimneys

- How to calculate the diameter of the chimney

- For sauna stove

- For boiler gas equipment

- Calculation of a chimney for a wood-burning stove

- Ceramic chimney

- Tips on how to choose

- approximate price

- Typical mistakes of beginners and self-taught

- How to choose a chimney - tips

- Chimney material

- No. 5. Vermiculite chimney pipes

- Regulatory requirements for the installation of chimneys

- Norms for the installation of a smoke exhaust system

The main advantages of chimneys made of corrosion-resistant steels

A metal chimney made of steel has advantages not only in ease of installation, but also in the operation of the entire heating system. Chimneys made of bricks have a significant mass, therefore, they require a foundation. Unlike them, metal chimneys weigh much less, so they do not require a foundation.

The connection of metal elements into a single system is incomparable in complexity with the construction of traditional brick chimneys.Any person with elementary engineering skills can mount metal chimneys. Significant operational advantages of stainless steel pipes are their resistance to corrosion, mechanical strength, long service life.

With the right choice of steel grade, the mounted chimney will have an almost unlimited service life.

An additional advantage is the round profile, which steel chimneys have,

since it is this sectional shape that is optimal from the point of view of aerodynamics for the removal of combustion products. Unlike a rectangular brick chimney, a round pipe does not have local turbulences that reduce draft and prevent the movement of gases.

The smooth walls of metal pipes, unlike the walls of a brick chimney, are not prone to soot accumulation. Therefore, the operating instructions for stainless steel chimneys do not require such frequent cleaning as in the case of brick channels.

Metal pipes are universal, they can be adapted to almost any type of heating appliances. In addition, such a chimney can be easily mounted in an already operated building. When installing a boiler or furnace in a place not provided for by the project, the installation of metal chimneys is, as a rule, the only possible way out.

Industrial smoke metal pipes made of stainless steel are designed for:

- providing the necessary traction force,

- removal of combustion products into the upper atmosphere,

- dispersion of flue gases to concentrations allowed by sanitary standards.

Stainless steel grades for the production of chimneys

The specific operating conditions of chimneys dictate harsh conditions for the steel from which they are made. The material used for the production of chimneys must withstand significant chemical and thermal influences.

However, not all grades of stainless steel (and there are more than two thousand of them) can be used for the manufacture of chimneys.

The most commonly used materials are:

- Steel 430 according to the AISI system is similar to grade 12X17 in the classification of the CIS countries. It is used for the manufacture of outer casings and other elements of chimneys that are not exposed to chemicals. It is not recommended to use this steel grade in the production of internal parts of smoke channels, since high temperatures and acidic environments can quickly disable such a pipe.

- Steel 409 (analogue - grade 08X12T1), due to the content of titanium in it, can be used for the manufacture of internal chimney pipes installed for solid fuel heating units - boilers, stoves, fireplaces, furnaces. Since this steel has low acid resistance, it is not applicable to liquid fuel equipment at all.

- Steel grades 316, 316 L (08X17H13M2, 03X17H13M2) is optimal for the production of chimneys for liquid fuel heating units. Additives of nickel and molybdenum give this steel high acid resistance. They also provide significant heat resistance of steel.

- Grade 304 (08X18H10) is similar in properties to the previous steel, but has a lower nickel content and the absence of molybdenum additives, therefore it is a cheaper material.

- 321 and 316 Ti (08X18H12T and 08X17H13M2) are a universal material used in the production of pipes capable of withstanding temperatures up to 8500C. Chimneys made of stainless steel of these grades have high heat resistance, acid resistance, plasticity.

- 310 S (20X23H18) - steel with high heat resistance, capable of withstanding temperatures up to 10000C. The high content of chromium and nickel makes such pipes almost eternal.

Pipes wallpapers, pipes pictures, pipes photo

- 4.3 1280×720 5504 pipes, poppies, field

- 3.4 1280×720 5631 pipes, shape, curly

- 3.1 1280×720 6511 pipes, evening, sunset

- 2.6 1280×720 7843 pipes, device, forms

- 6.5 1280×720 13662 shape, pipes, lines

- 5.3 1280×720 5895 gold, pipes, circles

- 5.2 1280×720 7868 dizzy gillespie, pipes, performance

- 3.0 1280×720 4143 light, pipes, shape

- 3.4 1280×720 4704 shape, lines, pipes

- 2.9 1280×720 7312 plumber, gas wrench, pipes

- 1.9 1280×720 4303 gleen miller, orchestra, pipes

- 3.1 1280×720 7382 scorpions, group, members

- -1.4 1280×720 3594 dog, flight, flask

- 6.3 1280×720 7632 living room, art, concrete

- 3.4 1280×720 9935 destruction, band, rockers

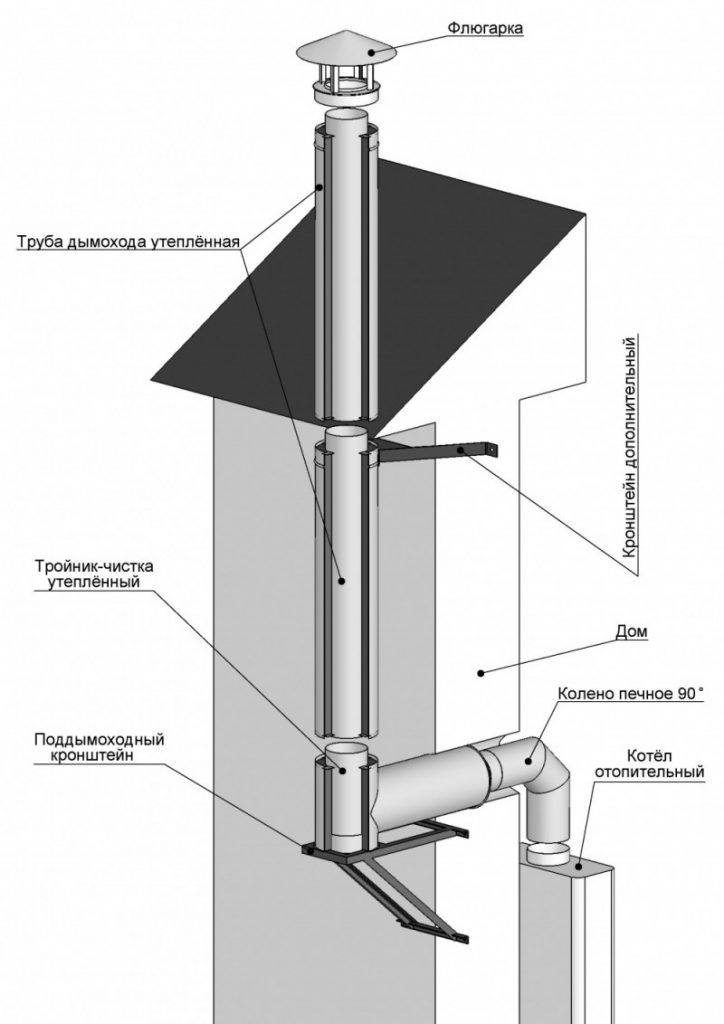

The nuances of the device and installation

The device of the pipe, as such, does not really matter. The number of bends, turns and other obstacles in the way of flue gases only worsens the draft, so you should try to make the pipe as straight as possible.

However, the main qualities of draft are determined by the height of the pipe, which is measured from the outlet of the boiler to the head of the pipe. The head of the pipe is called the end of the pipe, which is hidden under an umbrella. By the way, the existence of an umbrella is obligatory, it is protection intended, first of all, for the boiler itself.Moisture entering the combustion chamber can lead to damage to all boiler equipment.

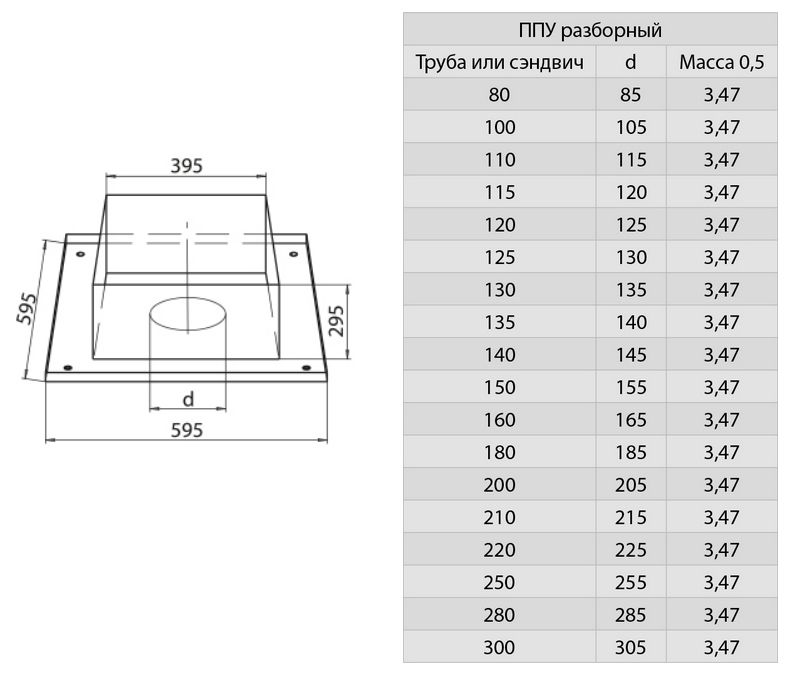

Another point worth noting is the welding seams and places of passage through the building envelope, that is, the walls, ceiling or roof surface. Welding seams must be made with the utmost care.

Steel pipe chimney

All passages through the enclosing structures must be made in the form of a sleeve. A sleeve is a pipe with a section larger than the section of the chimney itself. The space between the sleeve and the chimney is clogged with sealant. This is done in order to protect the space surrounding the pipe from rising temperatures.

To summarize the features of the chimney installation:

- The height of the pipe must be selected in accordance with the power of the boiler. Special tables will help you choose the height, but it’s easier to just look at the boiler passport, as a rule, you can find the required pipe height there.

- All welds must be neat and without breaks.

- The places of passage through the fences are sleeved and sealed.

- The chimney must not be laid near the place where the wiring and other communications pass. The outer part of the pipe should be at a remote distance from the trees.

Chimney pipe through the ceiling

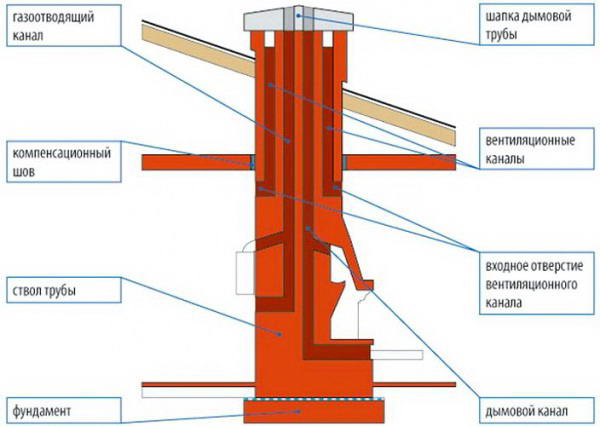

brick chimneys

When it comes to the classic version of the chimney, first of all, the masters call the brick version. The first stoves and fireplaces invented by man were equipped with smoke exhaust channels made of this material. For the manufacture of the pipe, burnt solid bricks are used, which have high heat resistance. Brick chimneys have the following advantages:

- Aesthetics.The chimney pipe made of red oven brick looks expensive, elegant and presentable. It perfectly decorates the roofs of luxurious mansions, cottages and modern townhouses.

- Fire safety. Perhaps the main advantage of brick is that it protects against fires better than other materials.

- High temperature resistance. Brick perfectly tolerates high temperatures without losing its operational properties. Brick chimneys can even be used for solid fuel stoves and fireplaces, in which the temperature of the outgoing gases is 500-700 degrees.

- Long service life. A well-laid brick chimney lasts at least 50 years, and proper care and maintenance extends the life of a chimney to 100 years or more.

Scheme of the device of the smoke exhaust channel made of bricks

Scheme of the device of the smoke exhaust channel made of bricks

from brick it is better to entrust an experienced master, since it is difficult for a person without experience to choose the required diameter that maintains the traction force necessary to maintain combustion.

Selection principles

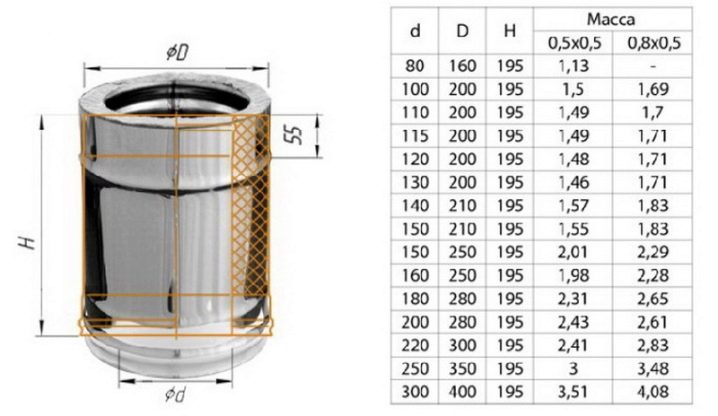

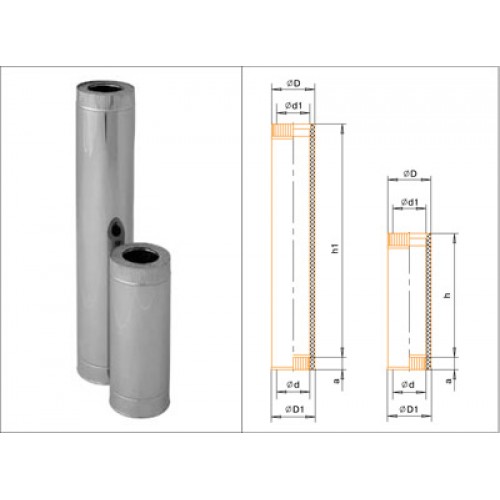

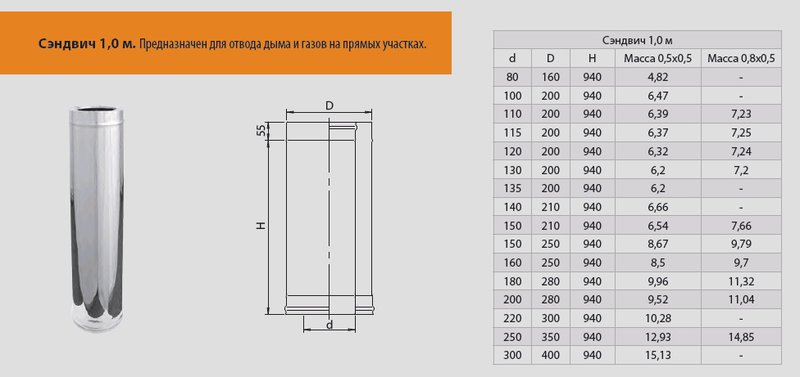

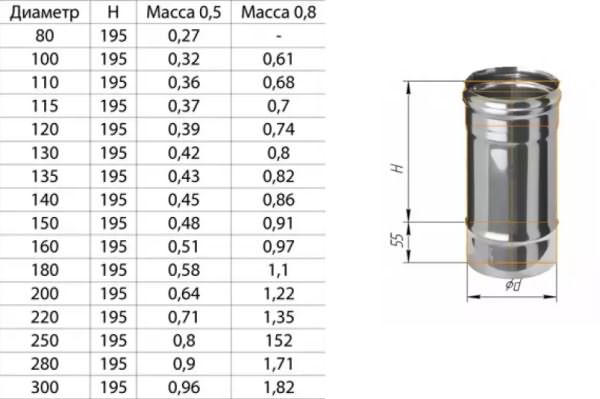

Sandwich pipe and accessories for it should be selected according to the following criteria:

- The type and number of modules.

- Thickness, brand of insulation.

- The wall thickness of the pipes, the material from which the protective casing is made.

- The material from which the inner pipe is made, the wall thickness.

Smoke sandwich pipes are made from different grades of alloy steels, which determines their technical characteristics.

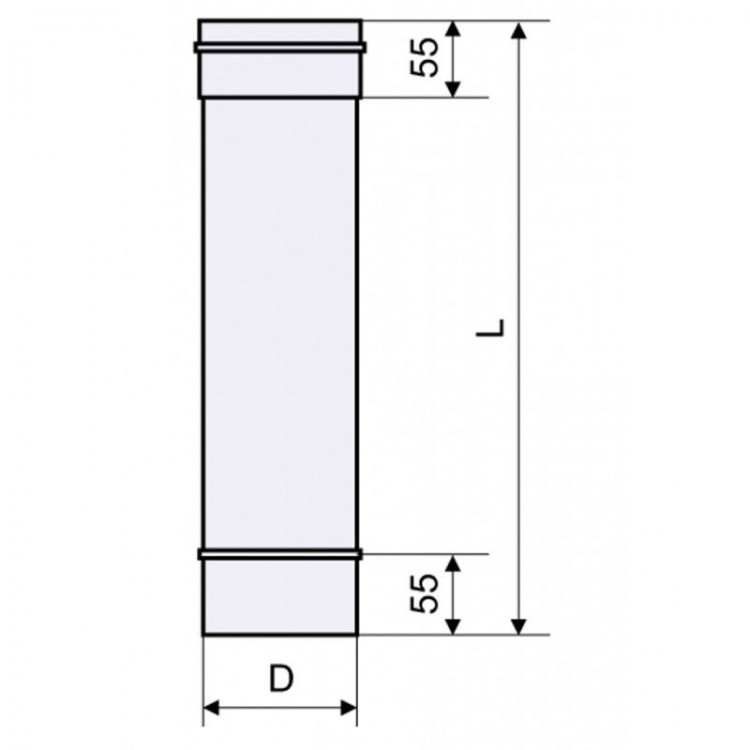

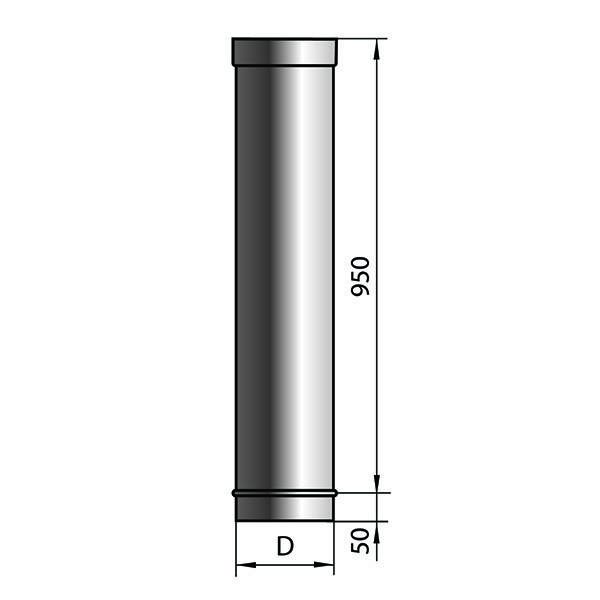

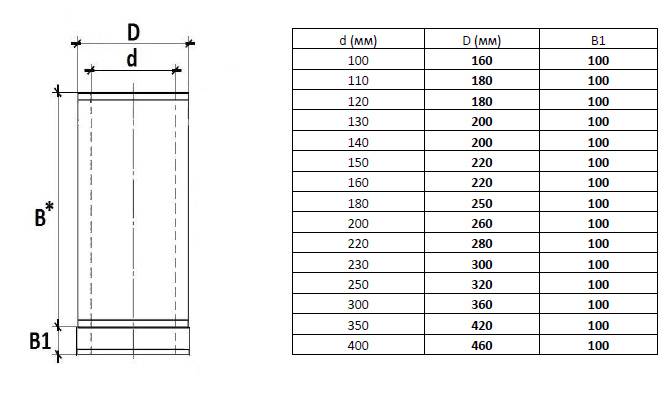

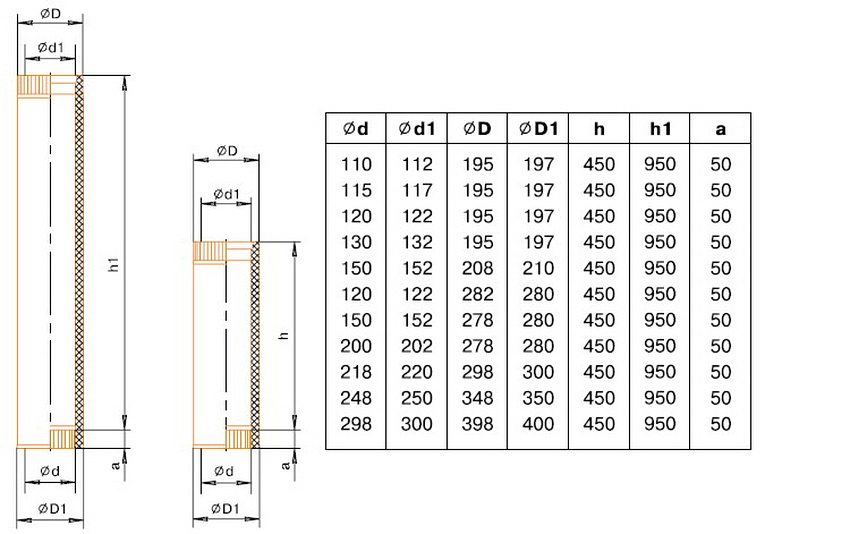

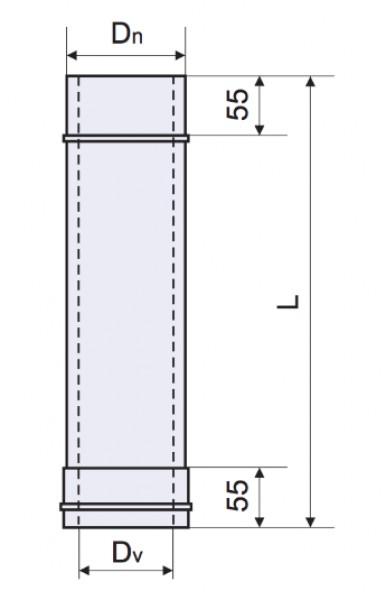

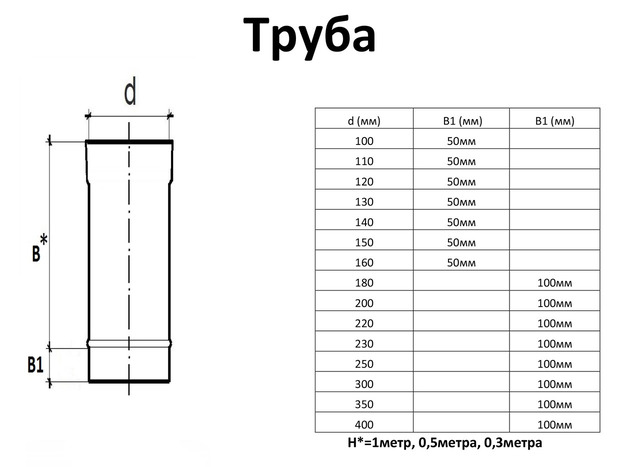

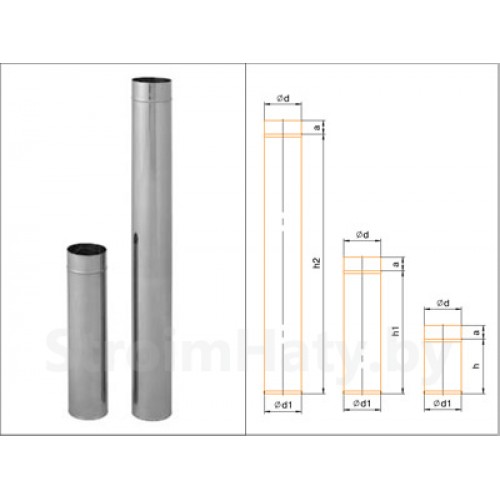

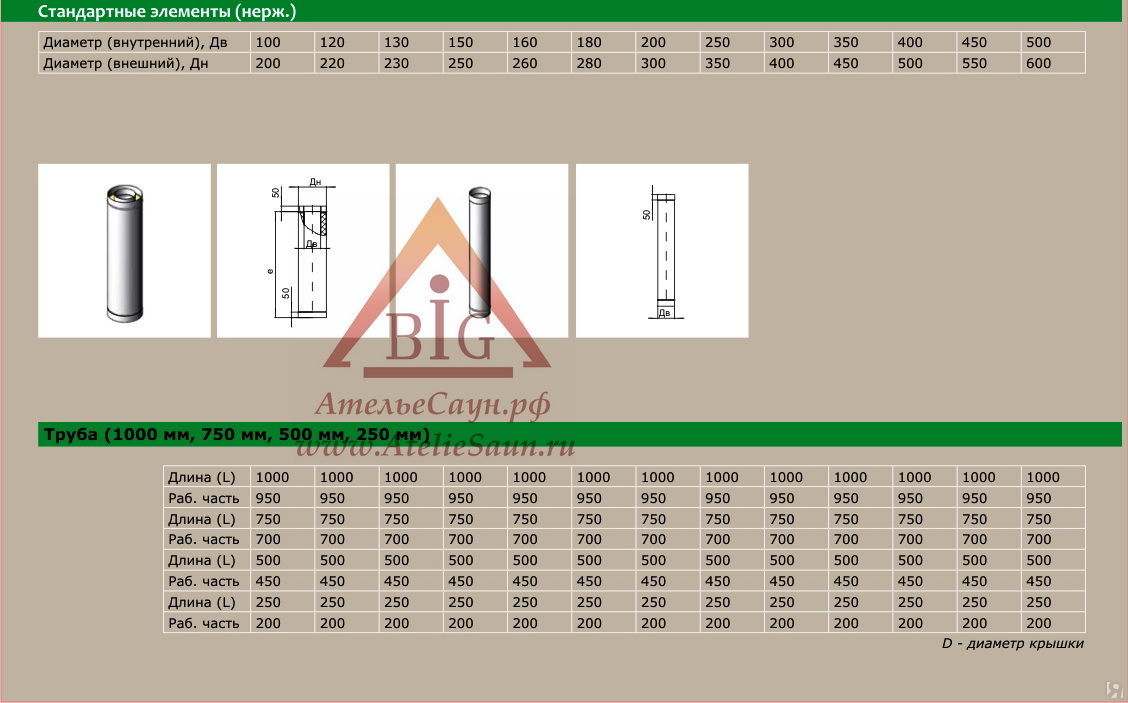

Dimensions

Particular attention must be paid to the size of the sandwich pipes for the chimney. It should be selected depending on the power of the heating equipment. The classic size of the cross section of the tubes is 120 mm

The optimal power in this case is up to 3.5 kW. If more powerful furnace equipment is used, the pipe diameter must be increased. Diameter of sandwich chimneys for boilers or furnaces with a power of 5 kW - 180 mm, 7 kW - 220 mm

The classic cross-sectional size of the tubes is 120 mm. The optimal power in this case is up to 3.5 kW. If more powerful furnace equipment is used, the pipe diameter must be increased. The diameter of the sandwich chimneys for boilers or furnaces with a power of 5 kW is 180 mm, 7 kW is 220 mm.

Life time

The service life of a sandwich chimney depends on several factors:

- exploitation activity;

- type of fuel burned;

- grade of steel from which the inner part of the part is made.

For example, a product made of AISI 316L steel with a thickness of not more than 0.5 mm can withstand about 10 years of active operation. If the part is made of AISI 310 steel, the thickness of which is 0.8 mm, the service life will be doubled.

Stacked firewood for the stove

How to calculate the diameter of the chimney

When designing a chimney, it is necessary to choose the material to be used. And the material largely depends on what fuel will be used for heating. After all, the chimney is designed to remove the remains of the combustion of one fuel, and will not work with another. For example, a brick chimney works great with wood, but is not suitable for gas-fired heaters.

In addition, a correct calculation of the diameter of the duct pipe is required. If the chimney is used for one heating appliance, the problem can be solved by reviewing the technical documents provided by the manufacturer of the appliance.And if several different systems are connected to one pipe, then to calculate the chimney, you need knowledge of the laws of thermodynamics, professional calculation, especially the diameter of the pipe. It is wrong to assume that the diameter is needed more.

Swedish method

Among the different methods for calculating the diameter, the optimally suitable scheme is important, especially if the devices are low-temperature and long-term burning.

To determine the height, the ratio of the cross-sectional area of the chimney pipe to the internal combustion chamber is taken into account. The height of the pipe is determined according to the schedule:

Where f is the area of the chimney cut, and F is the area of the furnace.

Let, for example, the cross-sectional area of the furnace F is 70 * 45 \u003d 3150 square meters. cm, and the section of the chimney pipe f - 26 * 15 = 390. The ratio between the given parameters is (390/3150)*100%=12.3%. After comparing the result with the graph, we see that the height of the chimney is approximately 5 m.

In the case of installing a chimney for complex heating systems, it is important to calculate the parameters of the chimney

Accurate calculation

To calculate the desired section of the chimney, be sure to take into account all its characteristics. For example, you can perform a standard calculation of the size of a chimney connected to a wood-burning stove. They take the following data for calculations:

- the temperature of the combustion waste in the pipe is t=150°C;

- the speed of passage through the waste pipeline is 2 m/s;

- the burning rate of firewood B is 10 kg/h.

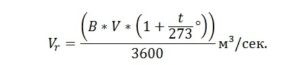

If you follow these indicators, you can do the calculations. For this purpose, the amount of outgoing combustion products is calculated according to the formula:

Here V is equal to the amount of air required to burn the fuel at a rate of v=10 kg/h. It is equal to 10 m³ / kg.

It turns out:

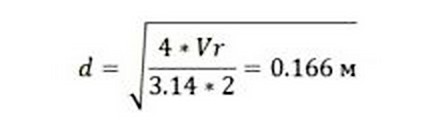

Then calculate the required diameter:

Design of galvanized products

Manufacturers produce single- and double-circuit modifications of these chimneys.

In order to avoid the formation of condensate, it must be insulated. It is not recommended to use single-circuit chimneys made of galvanized steel without insulation from the outside.

You can put it on your own in a barbecue or barbecue room.

The double-circuit modification (galvanized sandwich pipe) is so named because of the multilayer. It consists of three components, two pipes, internal and external, which are insulated with mineral wool or other refractory insulation.

This design quickly heats up, which activates the operation of heating devices and minimizes the amount of moisture that accumulates on the walls.

Having given preference to a galvanized sandwich pipe, we can talk about an aesthetic appearance that harmoniously fits into the overall exterior design. In addition to the technology described above, structures are created from the so-called black steel.

Since the sauna device is different from an ordinary house, in order to maintain a high temperature in the steam room, sandwich structures are used, and the space between them is filled with mineral wool, which is thermal insulation of an environmentally friendly composition and at the same time it is not subject to ignition at high temperatures.

Varieties of sealants for chimneys

Heating communications in a residential building are often subjected to all kinds of temperature, mechanical and other damage. In particular, this applies to brick structures, to a lesser extent - steel, polymer and other communications. The use of sealants gives chimney structures not only tightness, but also significantly strengthens them in relation to mechanical and other loads.

Sealing materials have different properties depending on the places of use. In the case of chimneys, sealants that are resistant to thermal stress are required for operation at high temperatures.

The basis of most sealing compounds and products are polymeric materials. In most cases, sealants for chimney pipes are one-component, in more rare cases - two-component. Two-component pipe sealants require high-precision mixing before use, where overdosing by even a few grams can lead to loss of important properties. Therefore, one-component sealing materials, which usually have a paste-like consistency, are mainly popular. It is better to use quality materials so that you don't have to think about it later than to seal the pipe on the roof from leaking, which will inevitably happen when using low-quality sealant.

High temperature sealants fall into two main categories:

- Heat-resistant, resistant to temperatures up to 350 °C. Such materials are used for the construction of the outer surfaces of stoves or fireplaces, especially brick ones. In addition, they are suitable sealants for chimneys on roofs, with the exception of metal ones.

- Heat-resistant pipe sealants withstanding temperatures up to approx. 1500 °C. They are used for metal chimneys, as well as for joining metal and brick parts. In particular, the use of such sealants for chimneys made of stainless steel or other types of steel is acceptable.

In general, the choice between heat-resistant and heat-resistant sealants depends on the location of the mounted area and the temperature in it.

You should also pay attention to sealing materials based on polymer SMX

They are not classified as high-temperature sealants, but are specifically distinguished as a sealing adhesive suitable for operation at temperatures up to 200 ° C. One of its advantages is that installation work with it can be carried out even at sub-zero temperatures in winter.

Some features of heat-resistant and heat-resistant sealants should be discussed in more detail.

How to calculate the diameter of the chimney

Different heating devices have their own requirements for traction. It is impossible to apply the same calculation method for a fireplace, stove and gas boiler, since the volume and design of the furnaces are different, the amount of combustion products and the rate of their formation are different. For the practical determination of the pipe diameter for all types of equipment, their own formulas and rules have been developed.

For sauna stove

The minimum diameter for a sauna stove is 14 cm

The minimum diameter for a sauna stove is 14 cm

Since the bath stove being designed has a firebox, it is easiest to calculate the diameter of the chimney for it, starting from the size of the furnace compartment. A regularity was experimentally derived that during the combustion of fuel a certain amount of gases is released, the volume of which will effectively go outside if the proportion of 10 to 1 is observed, where the first number of units characterizes the size of the furnace, and the second number characterizes the cross-sectional area of the round pipe.

If we are talking about a smoker built of brick, no matter square or rectangular, its internal passage should be larger than the blower door or ash chamber. Exceeding should be somewhere in 1.5 times

The minimum allowable size of a square channel for a low-power firebox should be 140 mm / 140 mm. The length of the chimney for a wood-burning stove in a bath can be arbitrary.

For boiler gas equipment

A gas boiler, like other heating installations, is characterized by a power expressed in kilowatts of thermal energy per unit area. The diameter or internal size of the pipe directly depends on this power.

The chimney rate for a gas boiler of a rectangular channel shape must comply with the rule that there are 5.5 cm² of passage per 1 kilowatt of unit power. The diameter of the round chimney must not be narrower than the diameter of the combustion chamber outlet on the gas appliance.

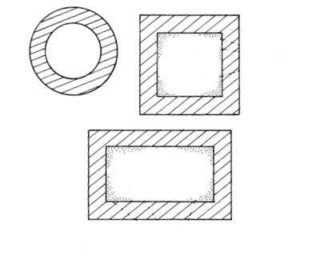

Calculation of a chimney for a wood-burning stove

The cross section of the chimney is greater than or equal to the cross section of the blower

The cross section of the chimney is greater than or equal to the cross section of the blower

First, find the volume of combustion products entering the chimney using the formula

where, B is the speed at which firewood burns (depends on the type of wood and is determined from the tables), V is the volume of air required for the combustion process, t is the temperature of the gases in the pipe;

Then carry out the calculation of the chimney, according to the formula:

Having determined the total area of the passage, based on the diameter obtained, it is easy to calculate the inner sides of a square or rectangular smoker.

Ceramic chimney

Recently, stove masters have been actively introducing things that differ from classic brick ones. They are ceramic pipes up to 3 m long, light blocks with a hole, the diameter of which corresponds to their size, are supplied in combination with them. Compared to other materials, ceramics has the following advantages:

- High temperature resistance.Ceramic pipes "lock" the heat coming from the mixture of smoke with combustion products inside, preventing the external units from heating up. Therefore, they are considered the safest and most reliable. A ceramic chimney does not require additional thermal insulation due to the high heat absorption of the material.

- Resistant to moisture, corrosion and aggressive chemical compounds. They began to use ceramics for the construction of the chimney, noticing how inert the material is. Pipes from it serve at least 50 years without requiring special care.

- Easy assembly. You can install a chimney from ceramic pipes, unlike brick, by yourself. The main thing is to choose the right diameter of the additional elements that you are going to use. Reinforcement bars and cement mortar are required for installation.

- Versatility. Thanks to the variety of ceramic products, it is easy to choose the appropriate diameter for connecting to the inlet pipe of the heater. Therefore, chimneys made of this material are used for all types of stoves, fireplaces, gas boilers and boilers.

- Ease of care. The inner surface of the ceramic pipe has a dense, smooth structure, so that soot does not accumulate on it. The chimney of their ceramics is easy to maintain, as it does not require frequent cleaning.

Scheme of the smoke exhaust channel from ceramic pipes

External smoke exhaust channel made of ceramic pipes

Tips on how to choose

Heating equipment and chimneys are a very important and unsafe part of home engineering. The life and health of residents depends on their serviceability. Therefore, saving on heat-resistant sealants is not worth it. It is best to buy materials from well-known brands and in large stores with a receipt.

Silicone is expensive and sometimes counterfeited.If several bottles are purchased, then you can squeeze a little polymer out of one, wait for curing and set it on fire. Silicone ignites heavily, will emit a mixture of black and white soot (hydrocarbons and silicon oxide). Fake (most commonly used acrylic polymers and PVC) will burn with the release of black soot.

It is also worth mentioning that heat-resistant oven sealants and chimneys are sold in tubes for a construction gun. If sellers advise polymer in ordinary tubes, be aware that most often it is a sealant for cars, it contains acid and is completely unsuitable for heating equipment and chimneys, so carefully read the labels on the package before buying.

When choosing, be sure to read the label. The operating temperature must correspond to the operating conditions, this is the most important criterion for choosing a heat-resistant sealant for the chimney. The sealant should be neutral, not acidic.

approximate price

Below is information on how much the most common brands of heat-resistant polymers cost. Silicone polymers are much cheaper than silicate ones.

Typical mistakes of beginners and self-taught

In the first place among the oversights is the wrong height of the chimney. A setting that is too high creates excess draft, which increases the chance of tipping over and drawing smoke back into the firebox and oven room. 5–6 meters are considered optimal, but much here depends on the size of the combustion chamber and the configuration of the chimney.

A constant flow of air into the furnace is a prerequisite for good draft in the chimney, which is why it is so important to equip high-quality ventilation in a room with a fireplace or stove

Overcooling of the chimney and its excessive heating as a result of intensive combustion of fuel in the furnace must not be allowed. Everything must be in moderation, otherwise the pipe may crack. To make it easier for yourself to identify these cracks, you should whitewash the chimney section in the attic. On a white background, all the “streaks” of soot will be noticeable.

Often, when installing a steel chimney, beginners forget to ensure the removal of condensate. To do this, you need to make a special collection and insert hatches into the pipe for revision. Mistakes are also made in the choice of steel grade.

During normal combustion of wood, gas or coal in a fireplace or heating boiler, the chimney warms up to 500-600 ° C. However, the temperature of the fumes, albeit for a short time, can rise to 1000 °C. At the same time, after a few meters from the furnace, they cool down to 200–300 degrees and do not pose a threat to the pipe.

But its initial meter section from the boiler manages to heat up very strongly. The steel must be heat-resistant and able to withstand these loads. And the steel pipe should be insulated only a couple of meters from the firebox to prevent overheating of this segment of the chimney.

To increase fire safety, passages through ceilings and walls are made through special non-combustible inserts; direct contact between hot pipes and flammable building materials is unacceptable

When laying bricks, an inexperienced master often allows their rows to shift vertically relative to each other. When building walls, this is allowed, but in the case of a chimney, it is absolutely unacceptable. This greatly reduces the efficiency of the chimney channel, as flow turbulence and soot deposits on the walls begin to form in it, which will eventually require cleaning.And how to do it right you can read in this material.

The foundation under the brick chimney must be ultra-reliable, otherwise the pipe can be led to the side with its subsequent partial or complete destruction. And if the removal of smoke is done for a gas boiler, then it is better to exclude bricks. It quickly breaks down under the influence of the alkaline environment formed during the combustion of natural gas.

How to choose a chimney - tips

The first recommendation is that if the budget and installation conditions allow, it is always better to build a ceramic shaft inside the house. For stability, you can make a frame of hollow bricks or lean the chimney against a building structure - a partition, a wall. Ceramics will work successfully with any heating equipment - a stove, a diesel boiler or a fireplace.

Scheme of the external laying of the chimney system

How to choose the right chimney material depending on the specific conditions:

- The cheapest option from finished products is a three-layer stainless steel + stone wool + galvanized sandwich. The material is perfect for working with efficient gas boilers that emit low temperature smoke.

- When locating the flue inside the dwelling, try, again, to purchase and install ceramics. Another way is to build a brick shaft, insert a stainless sleeve inside.

- For outdoor laying, use a sandwich, this is the most practical option. When choosing products from a particular manufacturer, examine the seams of the inner inserts - they must be welded into a solid one. Spot welding and seam connection is not suitable.

- If you are limited in funds, make a sandwich yourself - purchase a stainless pipe, dense basalt insulation and bend the galvanized casing.

- When building a fireplace or stove according to a finished project, it is not necessary to drive a brick pipe to its full height. Go through the ceiling (in a wooden house, do a fire cut) and go to the metal with a diffuser, as shown in the photo.

- If the section of the already constructed brick channel does not allow the insertion of an iron sleeve, connect the boiler directly. But remember - from a gas heat generator, the mine will begin to collapse, a wood-burning one - clogged with soot. The way out is the insulation and cleaning of the pipe.

- For a turbocharged gas-fired boiler, you do not need to buy any natural draft chimneys. Install the coaxial pipe horizontally and bring it outside through the wall.

Conclusion. The most reliable and durable chimney is ceramic. The second place in the ranking is firmly occupied by a metal sandwich, the third - by a traditional brick. Simple iron pipes, asbestos and aluminum corrugations are not suitable for residential premises.

More tips on choosing a smoke exhaust system will be given by a representative of a trading company in the video:

Chimney material

In modern heating systems operating on gas and liquid fuels, the temperature of the exhaust gases has decreased significantly. Under such conditions, a brick chimney cannot warm up quickly, and at the time the heating system is started, this leads to the appearance of a large amount of condensate in the chimney. He, in turn, gathering on the walls of the smoke channels and mixing with the combustion products of natural gas, forms a liquid with acidic properties that destroys the brick.

Problems with condensate do not have modular chimneys. These are structures assembled from individual elements.Various materials are used for their manufacture: carbon and polished high-alloy stainless steel, aluminum alloy and ceramics. Such devices can be mounted inside existing brick pipes during their reconstruction or be independent systems that operate inside or outside the building.

When assembling a steel chimney, it is important that the modules are assembled with the socket up, the joints are smeared with sealant, and a condensate trap is installed at the bottom. The main features of a good chimney are high-quality fuel combustion, ideal draft, quick heating of the walls and quick dew point threshold.

The second condition is met if the smoke exhaust system is well insulated. To do this, when installing a steel liner inside a brick channel, it is advised to wrap it with special mineral wool, or leave an air gap around. Do not fill the space between the insert and the brick with mortar. In this case, in addition to the steel liner, it will also be necessary to warm the solution, which, moreover, when heated, the concrete will expand and press from the inside against the wall

The main features of a good chimney are high-quality fuel combustion, ideal draft, quick heating of the walls and quick dew point threshold. The second condition is met if the smoke exhaust system is well insulated. To do this, when installing a steel liner inside a brick channel, it is advised to wrap it with special mineral wool, or leave an air gap around. Do not fill the space between the insert and the brick with mortar.In this case, in addition to the steel liner, it will also be necessary to warm the solution, which, moreover, when heated, the concrete will expand and press against the wall from the inside.

Before you install the chimney yourself, carefully read the recommendations. The operating parameters of your heating system are the basis from which you need to build on when calculating. If desired, you can use specialized programs. But, the best option is to trust competent specialists.

No. 5. Vermiculite chimney pipes

Not so long ago, vermiculite chimney pipes appeared on sale. These are stainless steel pipes coated inside with a 5 cm thick layer of vermiculite mineral. This mineral has low thermal conductivity, therefore, in fact, it is a natural heat insulator. Moreover, vermiculite is absolutely inert to aggressive combustion products.

Among other advantages of vermiculite pipes are high durability, relative ease of installation, no need for chimney insulation. The main disadvantage is the ability to accumulate soot, so you will have to clean the chimney often.

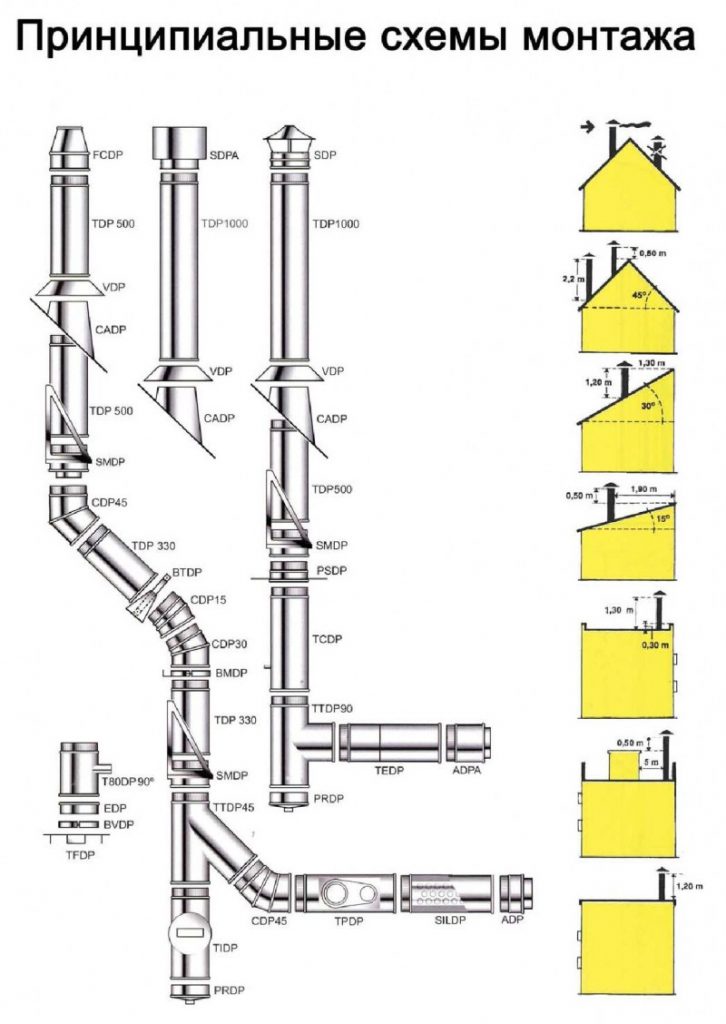

Regulatory requirements for the installation of chimneys

The main and only purpose of the chimney is to remove exhaust gases from the heating boiler into the atmosphere outside the building where the stove, boiler or fireplace is installed. At the same time, the efficiency of the heat-generating equipment directly depends on its proper installation.

You can put a boiler in the house with excellent efficiency, but make miscalculations when installing the chimney. The result is excessive fuel consumption and lack of comfortable air temperatures in the rooms.The chimney must have the correct section, location, configuration and height.

If the house has two boilers or a stove and a fireplace in different rooms, then it is better to make separate smoke exhaust pipes for each of them. The option with one chimney is allowed by SNiPs, but only a professional stove-maker can correctly calculate it.

The diameter of the chimney is selected depending on the heating equipment used. When installing the boiler, it is already set by the manufacturer with a drain pipe. It is forbidden to connect pipes of a smaller section to it, and it is simply not necessary to connect a larger one. In the second case, to increase traction, you will have to mount a gearbox, which costs a lot of money.

In the case of a fireplace or a Russian brick oven, everything is somewhat more complicated. Here you will have to make engineering calculations, taking into account the fuel used and the size of the furnace. It is much easier to take a ready-made brick oven project that has been tested by time. Fortunately, there are many options with a well-defined order of brickwork.

The height of the chimney pipe above the roof is determined by its distance from the roof ridge

The higher and longer the chimney, the stronger the draft. However, this can lead to overheating and destruction of its walls. Plus, a strong increase in draft is a prerequisite for the occurrence of turbulence in the chimney, which is accompanied by a hum and low-frequency noise.

If the pipe is too low, the ridge can turn into an insurmountable obstacle to the smoke coming out of it. As a result, a reverse draft effect will occur with the flue gases tipping back into the furnace. How to normalize it will be discussed in this material.

During normal operation of the chimney, the horizontal wind flow, flowing around the section of the pipe above the roof, turns up.As a result, rarefied air is formed above it, which literally “sucks” smoke from the exhaust. However, the ridge of a pitched roof and even a tall tree in the immediate vicinity of the house can interfere with this process.

Norms for the installation of a smoke exhaust system

Building codes prescribe the chimney to be done as follows:

- Its length from the grate to the top point should be from 5 meters (an exception is possible only for buildings without attics and only under conditions of stable forced draft).

- The optimal height, taking into account all possible bends, is 5–6 m.

- The distance from a metal chimney to structures made of combustible building materials should be from a meter.

- The horizontal outlet immediately behind the boiler must not exceed 1 m.

- When passing roofing, walls and ceilings inside the house, a channel made of non-combustible materials should be equipped.

- To connect the metal elements of the pipe, the sealant should be used exclusively heat-resistant with a working temperature of 1000 ° C.

- The chimney must rise at least 50 cm above the flat roof.

- If a non-brick chimney is built 1.5 meters or more above the roof level, then it must be strengthened without fail with stretch marks and brackets.

Any slopes and horizontal sections will inevitably reduce the draft in the chimney pipe. If it is impossible to make it straight, then bends and displacements are best done from several inclined segments at a total angle of up to 45 degrees.

In addition to observing purely building rules that guarantee the high efficiency of the chimney and stove, it is also necessary to take care of fire safety, for which special indents and screens are made

When arranging ventilation and chimney shafts in parallel in one structure above the roof, in no case should they be covered with a common cap. The outlet from the stove must necessarily rise above the ventilation pipe, otherwise the draft will decrease, and the smoke will begin to be sucked back into the house. The same applies to individual, but adjacent hoods and chimneys.