- Selection criteria for natural draft flues

- Asbestos-cement pipes - the generosity of the USSR

- Base for chimney insulation

- Is it possible to paint a galvanized chimney

- Why is chimney insulation necessary?

- The nuances of the device and installation

- How to install a chimney?

- Mounting Features

- brick chimney

- How to calculate the diameter of the chimney

- Swedish method

- Accurate calculation

- What should be the height of the chimney pipe for the furnace

- SNiP requirements

- Self-calculation technique

- Table "Height of the chimney above the ridge"

- How and how to insulate a galvanized chimney

- Pipe height

- Brick chimneys - pros and cons

- How to choose a pipe and not make a mistake

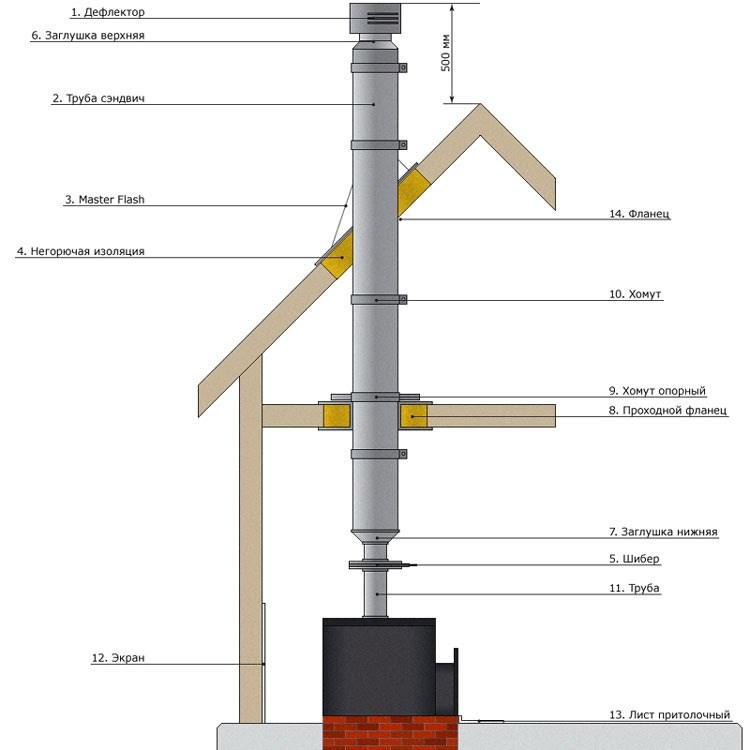

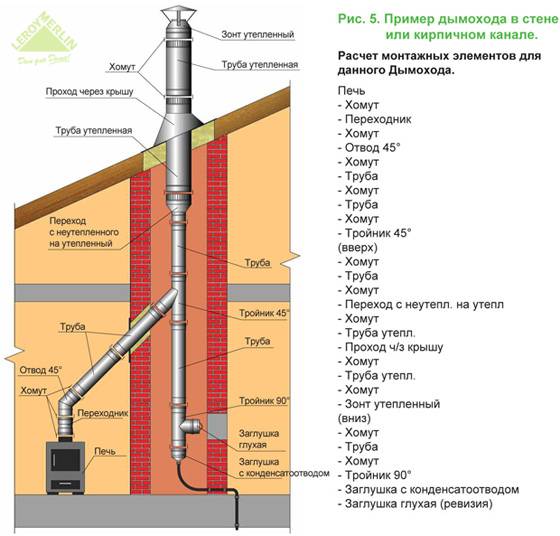

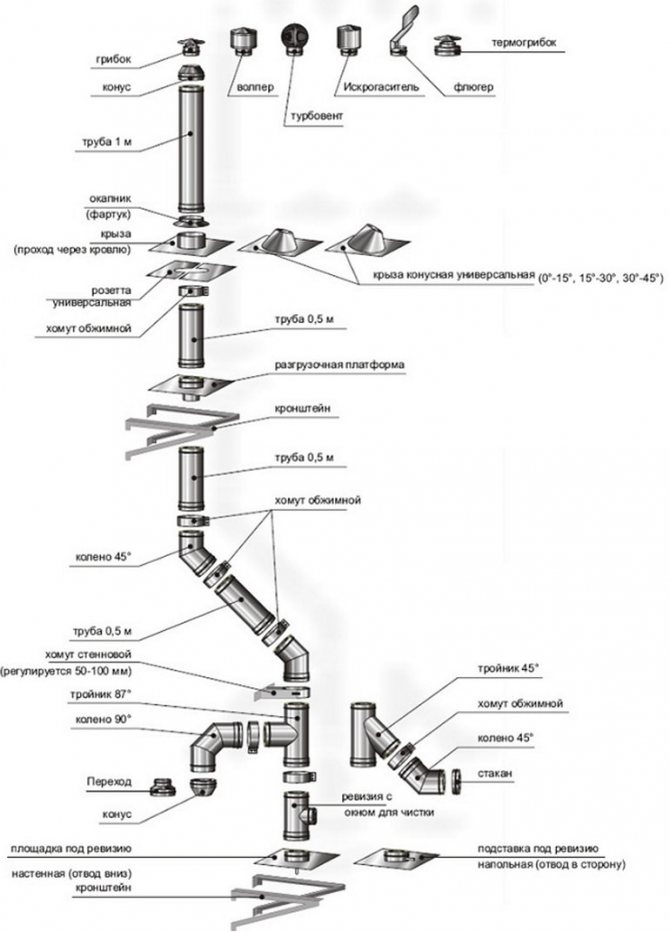

- What you need to purchase in addition to the pipes themselves: additional elements

- Material selection

- Cons of a steel chimney

- Box manufacturing

- Conclusion

Selection criteria for natural draft flues

When choosing the material for a future chimney, most homeowners focus on the price of products and the cost of installation. For reliable and safe operation of heating equipment, other factors will have to be taken into account:

- Chimney compatibility with boiler type. Units with high efficiency (gas, diesel) emit smoke with a temperature of 70 ... 120 ° C, brick stoves and solid fuel heat generators - 150 ... 200 ° C, steel and cast iron potbelly stoves - up to 400 degrees.

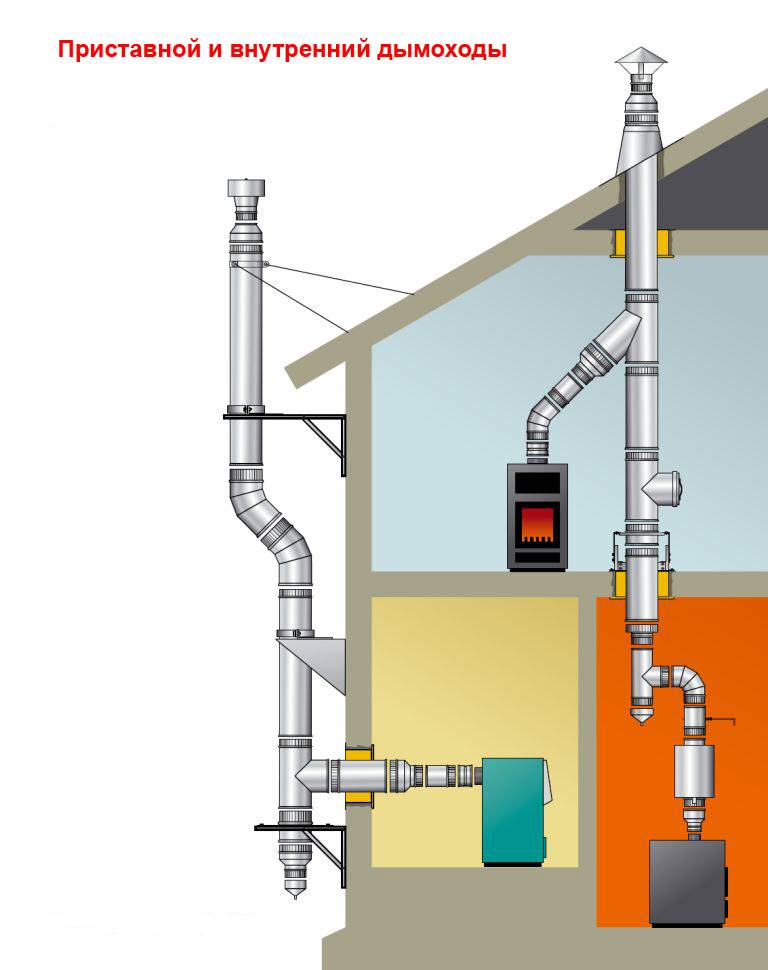

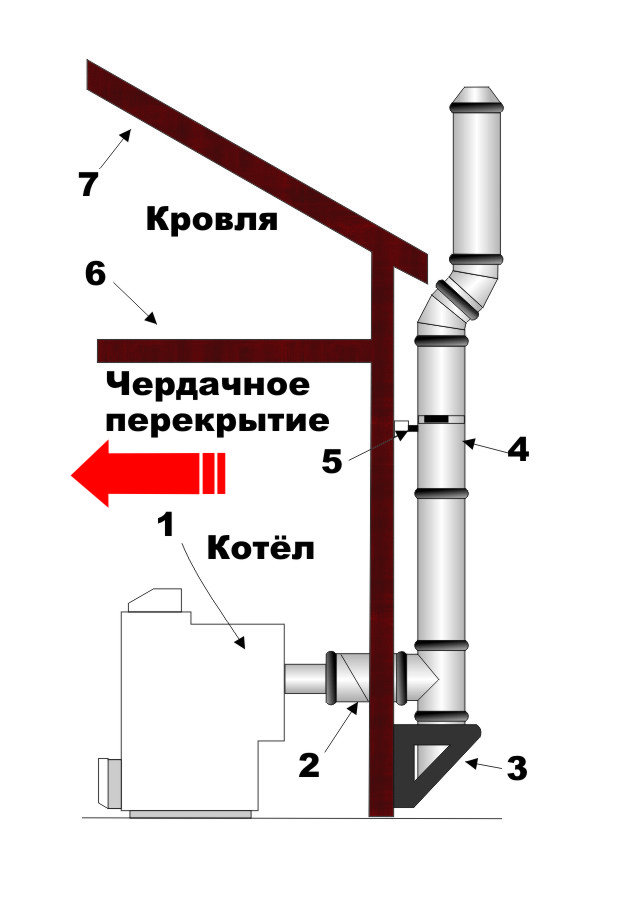

- The method of arranging the gas duct is internal laying with a passage through the ceilings and the roof, or external installation along the wall.

- The flammability of the material from which the building is built.

- The ability to repeatedly withstand an increase in the temperature of the outgoing combustion products up to 1000 degrees. Such emergencies occur when the soot accumulated inside the pipe ignites.

- Corrosion resistance, durability.

Wooden structures located next to the red-hot chimney of a wood-burning stove must be protected with non-combustible materials.

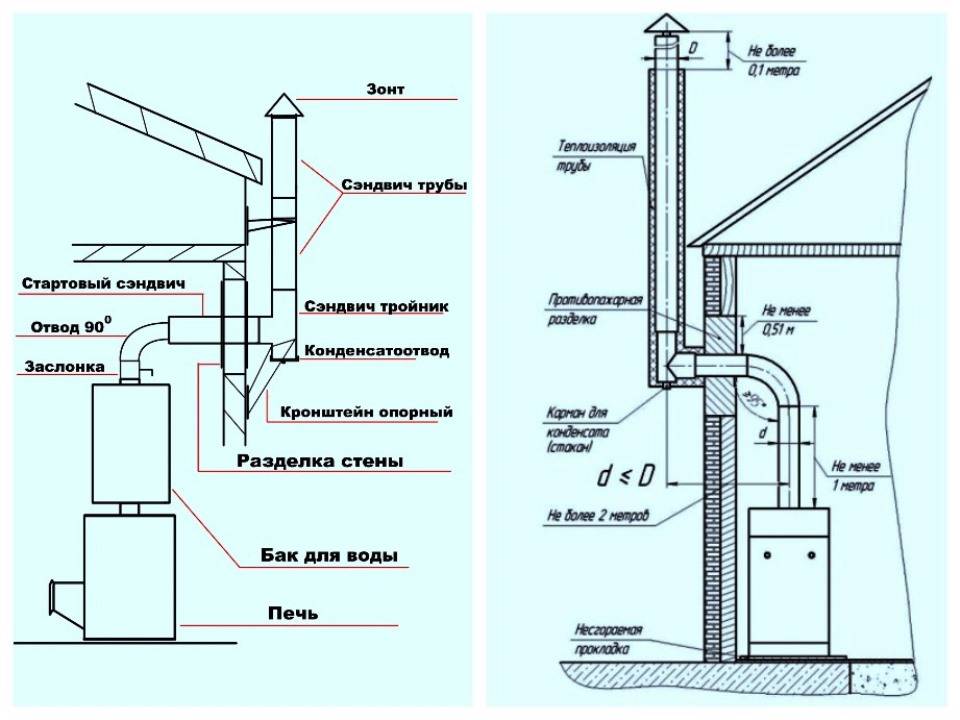

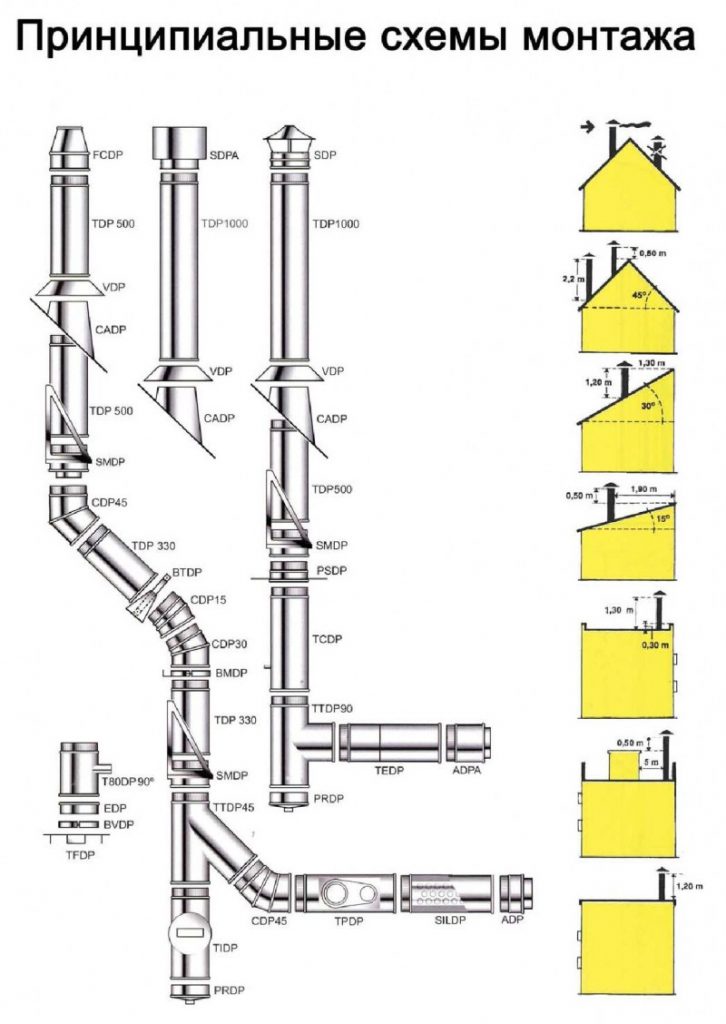

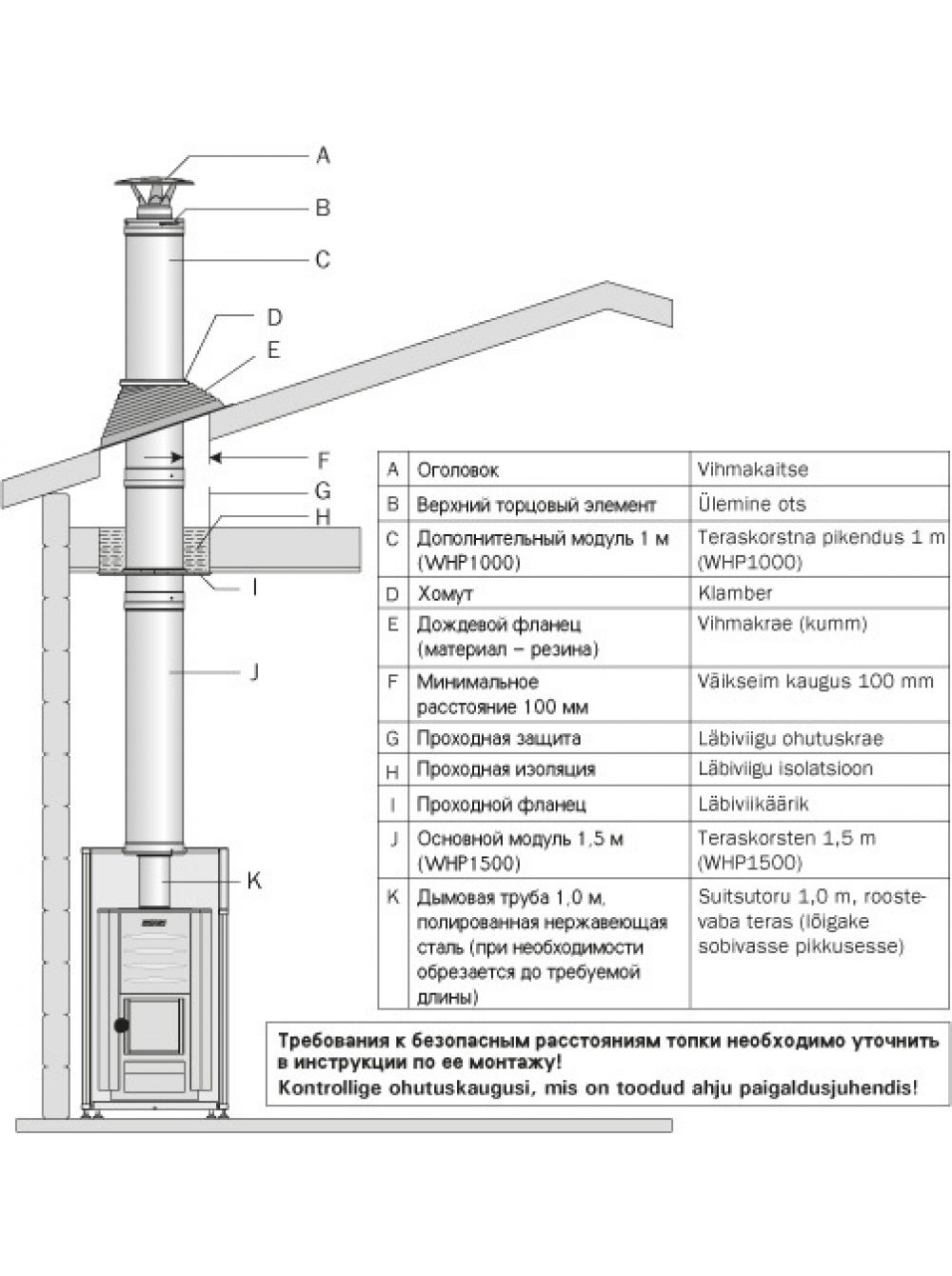

Before choosing a chimney material, decide on the option for laying it and sketch out a diagram. Recall the requirements for smoke exhaust pipes:

- the diameter (sectional area) of the channel is not less than the outlet of the boiler, stove or fireplace;

- the minimum height of the pipe is 5 m, it is considered from the grate (burner) to the upper cut;

- the head of the chimney should not fall into the zone of wind backwater formed behind the ridge of a gable roof or standing right next to a tall building;

- the maximum number of channel turns by 90° is no more than three;

- indentation of the pipe surface unprotected by insulation from combustible (wooden) building structures - 50 cm, protected - 38 cm;

- the length of the horizontal section connected to the boiler nozzle is a maximum of 1 m;

- according to fire safety requirements, all metal gas ducts laid through the rooms and attic of a residential building must be insulated with non-combustible material - basalt or kaolin wool.

The chimney for a stove or boiler must provide stable natural draft and removal of harmful gases outside from the room - this is the main requirement

It is equally important to comply with other fire safety regulations, for example, do not use corrugated aluminum sleeves on heating boilers.

Regulatory requirements for the height of the head and fire indents

Asbestos-cement pipes - the generosity of the USSR

Asbestos-cement pipes have been widely used since the days of the USSR. Why? Yes, they were cheap, they were easy to manufacture, there was enough natural asbestos in the country. Moreover, such pipes could be used without any preliminary insulation for a variety of agricultural needs. That's just for the arrangement of chimneys, they were never intended.

But the need for invention is cunning, as they say. The days of land reclamation have sunk into oblivion, but asbestos-cement pipes have remained. And during the period of mass construction of private houses, they went into use already as chimneys. Many opponents of such an implementation immediately appeared - first of all, environmentalists who claimed that asbestos cement releases many bad compounds into the environment. Although, according to scientists, the asphalt on the road is even more carcinogenic. But, nevertheless, even the roofs of buildings today are covered with a variety of expensive roofing instead of cheap and durable asbestos.

And yet, all these fears and myths have little to do with asbestos-cement chimneys pipes. And at the same time, they are not at all safe - this material has never been designed for high temperatures, and can catch fire even at 300 ° C. Therefore, if you already put them, then just not at the stove itself - but as close as possible to the roof, where the smoke is already going a little chilled.

But there is also a second point. Soot forms in any chimney, but the smoother the walls, the less it lingers on them.But asbestos-cement pipes just never differed in smoothness, and soot accumulates on them very, very much. And it’s easy for her to catch fire - any stove-maker knows this. Moreover, if soot ignites inside the asbestos-cement pipe, it will simply explode! Can you imagine the consequences?

And asbestos-cement pipes are severely destroyed by condensate. How can this be if they were originally designed for water? That's right - for water, and condensate is an aggressive environment from a mixture of combustion oxides and a very small amount of moisture. Moreover, the oxides also contain a good percentage of hydrochloric acid, which even destroys bricks, but asbestos also absorbs into itself, which can, transferring all this to the structure in the form of unsightly spots with the same unpleasant odor.

Bottom line: we decided to take a chance and use a free asbestos-cement pipe for the chimney - be sure to clean it, and as often as possible. True, you are also tormented with this - it will not work to make revision windows in such pipes.

Base for chimney insulation

During the passage of smoke through the pipe, the inevitable cooling of warm flue gases occurs. As a result, the heat from the flue gases heats up the walls of the tube to remove the smoke into the atmosphere.

The draft in your stove is directly proportional to how quickly the walls of the chimney warm up. When the draft is reduced, the smoke begins to go along the path of least resistance, and simply begins to move from the furnace to the scrap, and this is fraught with carbon monoxide poisoning, especially if in a private house, the stove is located directly in a private house, and not in a designated boiler room.

Another important factor in favor of the insulation of the chimney and pipes.There is such a thing as the time for which the moment of manifestation of condensate is overcome.

The time spent on warming up the chimney channel depends largely on what it is made of.

Table for calculating the temperature regime of the chimney structure

A chimney lined with brick can warm up in 15-30 minutes

Photo of a brick chimney

A chimney made of steel warms up much faster - in 2-5 minutes;

Steel chimney

Since the hot stove chimney is constantly in contact with cold atmospheric air, condensation in the chimney can not be avoided. Together with the appearance of condensate, due to the mixing of water with carbon dioxide and other combustion products, an acid solution is formed, which, being absorbed into the walls of the chimney channel, gradually destroys it.

If the chimney is made of brick, then the condensate moisture is absorbed into the brick walls, and this most often leads to freezing of the brickwork of the pipe. The pipe, which has cooled down overnight in the frost, warms up again in the morning, it is from such frequent temperature changes that the brickwork of the chimney inevitably collapses.

Brick chimney after regular freezing

So why insulate chimneys? It is precisely due to the fact that the appearance of condensate can hardly be avoided, but on the other hand, we can protect the chimney from freezing and destruction, it is imperative to insulate any chimney, the sooner you do this, the longer it will be in operation.

Is it possible to paint a galvanized chimney

It is possible and even necessary to paint galvanized.Over time, rust still begins to penetrate the zinc layer and the paint will be a good means of additional protection.

However, a galvanized surface does not have the same adhesion as, for example, black steel. Therefore, conventional oil and alkyd paints, which oxidize on contact with zinc, lose their grip and peel off the painted surface, will not work here.

Invented special compositions:

- tsikrol, matt acrylic paint with high coverage, light fastness and adhesion;

- enamel Nerzhaluks, characterized by high adhesion and wear resistance;

- aluminum enamel Silver, reliably protecting against rust and adapted for outdoor use;

- a number of other compounds that can provide long-term protection from rain, exposure to sunlight, temperature changes, and not harm the human body.

Why is chimney insulation necessary?

The main task of thermal insulation of the chimney pipe is to create thermal conditions under which condensation will not form in the pipe cavity. As you know, due to a significant temperature difference between the interior of the operated chimney and cold outside air, condensate forms on the walls inside the pipe in significant quantities. Chimney insulation allows you to bring the so-called dew point outside the pipe, thereby eliminating the very cause of moisture condensation.

The condensate formed in the chimney contains water and a solution of sulfuric acid, which is obtained as a result of complex processes that occur during the combustion of fuel. The result of the impact on the pipe of such an "explosive" mixture is its active destruction from the inside.

To the maximum extent, this applies to single-layer pipes made of metal. Sandwich, brick and asbestos-cement pipes are somewhat less susceptible to harmful effects.

Condensation spots due to lack of pipe insulation

The nuances of the device and installation

The device of the pipe, as such, does not really matter. The number of bends, turns and other obstacles in the way of flue gases only worsens the draft, so you should try to make the pipe as straight as possible.

However, the main qualities of draft are determined by the height of the pipe, which is measured from the outlet of the boiler to the head of the pipe. The head of the pipe is called the end of the pipe, which is hidden under an umbrella. By the way, the existence of an umbrella is obligatory, it is protection intended, first of all, for the boiler itself. Moisture entering the combustion chamber can lead to damage to all boiler equipment.

Another point worth noting is the welding seams and places of passage through the building envelope, that is, the walls, ceiling or roof surface. Welding seams must be made with the utmost care.

Steel pipe chimney

Steel pipe chimney

All passages through the enclosing structures must be made in the form of a sleeve. A sleeve is a pipe with a section larger than the section of the chimney itself. The space between the sleeve and the chimney is clogged with sealant. This is done in order to protect the space surrounding the pipe from rising temperatures.

To summarize the features of the chimney installation:

- The height of the pipe must be selected in accordance with the power of the boiler.Special tables will help you choose the height, but it’s easier to just look at the boiler passport, as a rule, you can find the required pipe height there.

- All welds must be neat and without breaks.

- The places of passage through the fences are sleeved and sealed.

- The chimney must not be laid near the place where the wiring and other communications pass. The outer part of the pipe should be at a remote distance from the trees.

Chimney pipe through the ceiling

Chimney pipe through the ceiling

How to install a chimney?

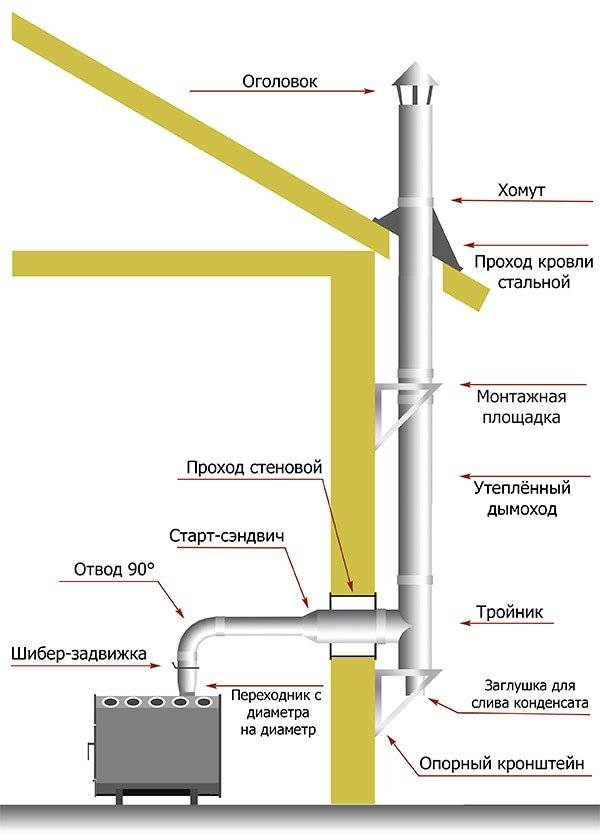

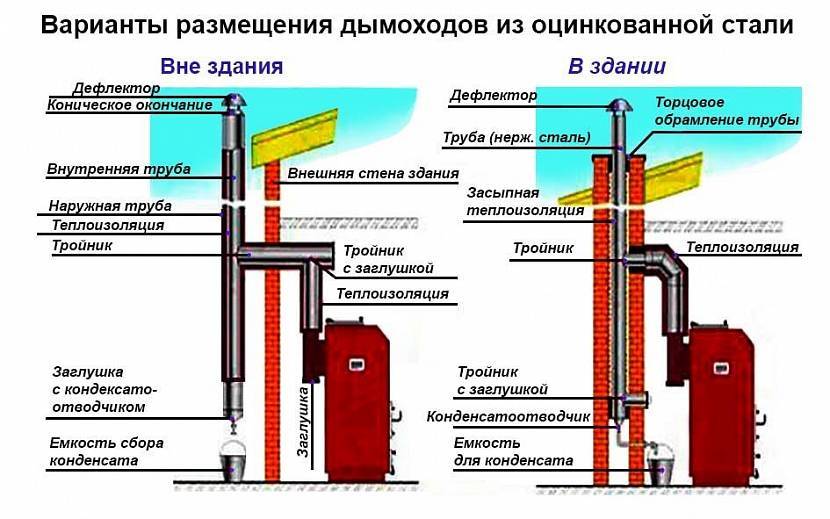

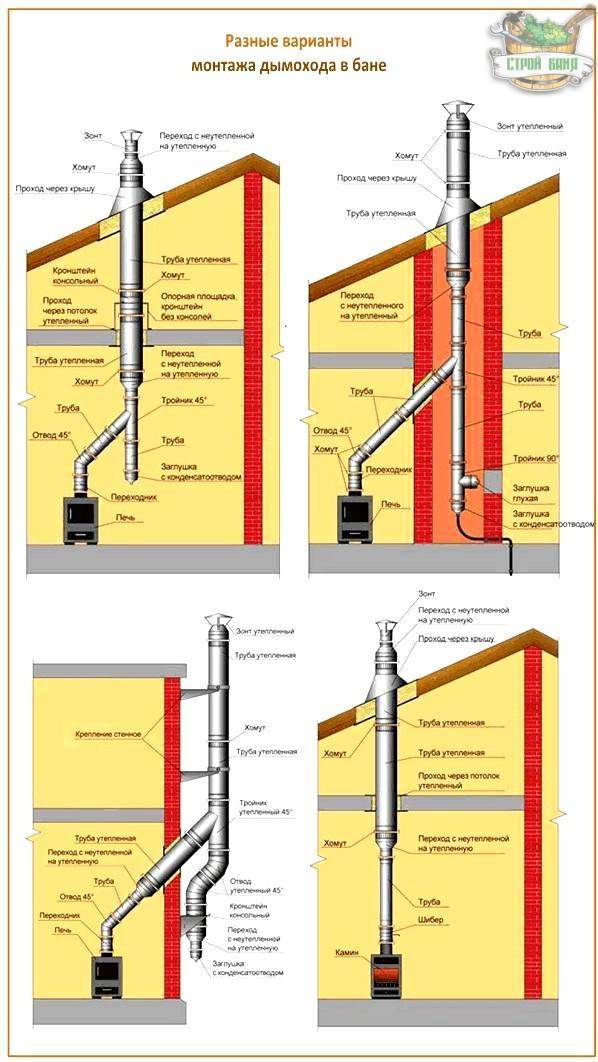

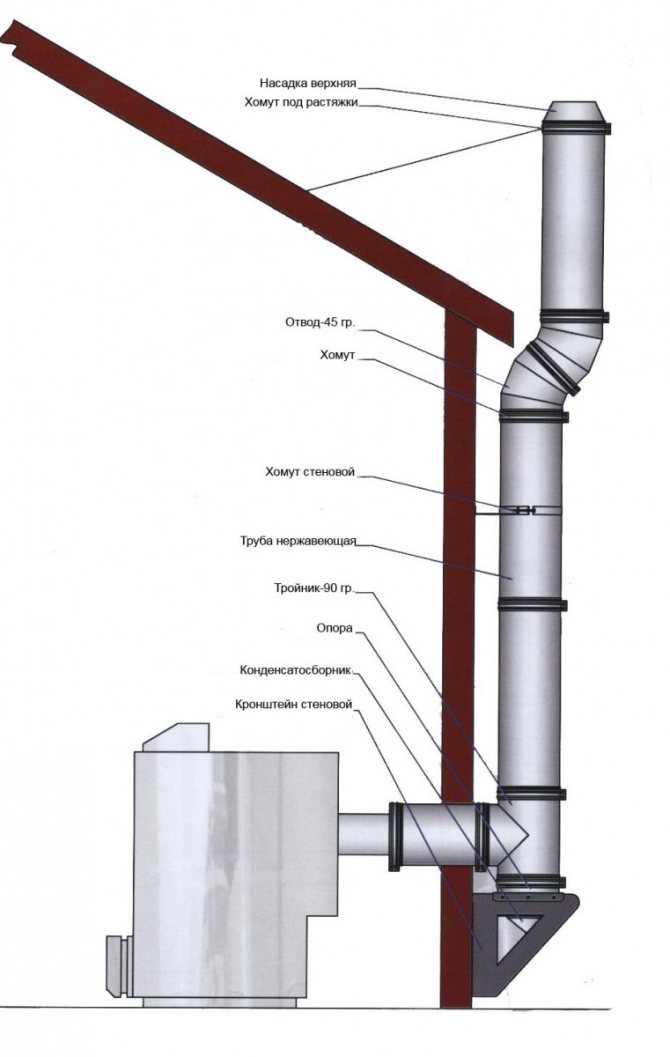

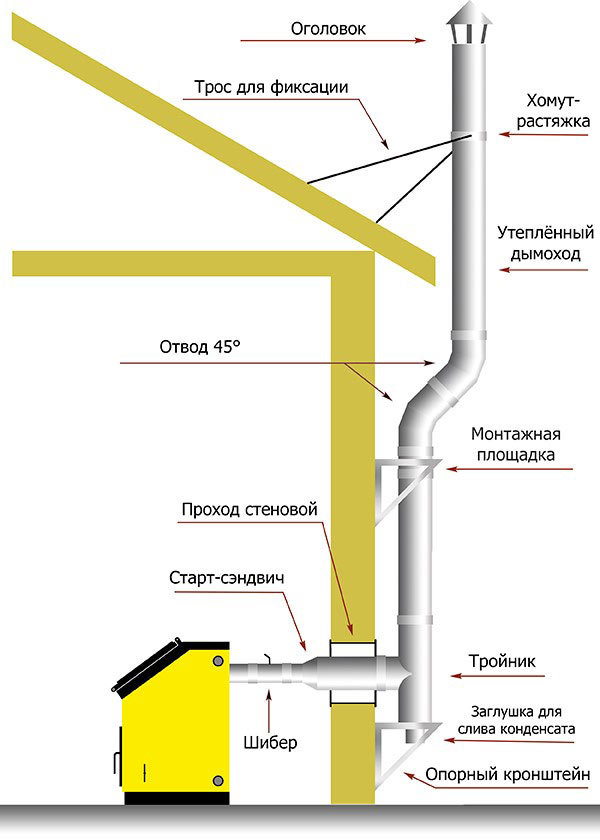

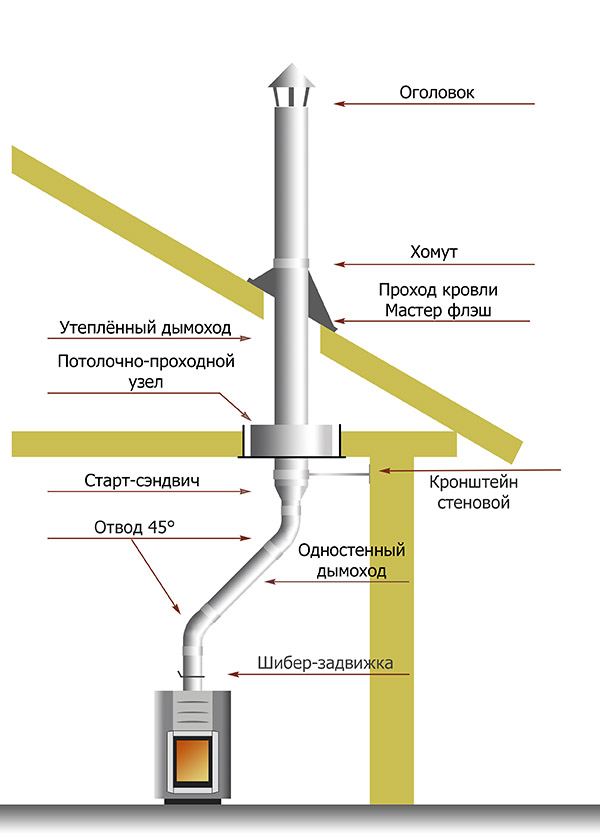

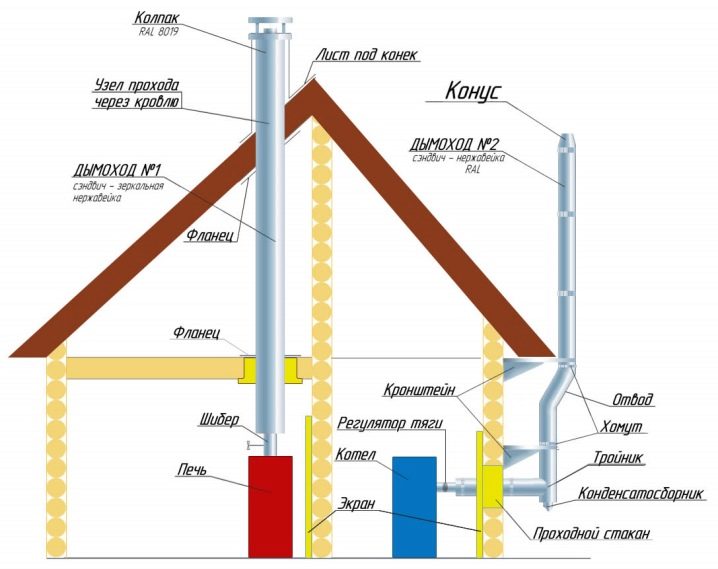

There are two options for installing a chimney - outdoor and indoor installation. An external (external) chimney is installed outside the building and connected to a stove or other heating unit by a pipe through the wall. Therefore, this installation method is also called "through the wall". The internal chimney is located directly in the heated room and is discharged through the roof.

How to make a chimney in the house? Both installation options - outdoor and indoor - have their own characteristics. Choose the best option, taking into account the pros and cons of each installation method.

Table 2. Features of the external chimney

| Advantages | Flaws |

| Does not violate the interior of the room, does not reduce the area. | Requires external insulation. |

| Relatively easy to install (no need to make passes through the floors). | Installing a chimney requires additional fasteners to the wall of the building. |

| It can be installed after the completion of construction and decoration of the building. | The chimney is exposed to temperature changes and precipitation. May interfere with the appearance of the façade. |

Table 3. Features of the internal chimney

| Advantages | Flaws |

| The heat from the chimneys heats the air in the room. | Takes up space in the room. |

| The chimney is not exposed to the destructive effect of precipitation, it is less exposed to temperature changes. |

Consider how to make the right chimney, using the example of stainless steel chimneys.

Mounting Features

To properly make a chimney, install it in the house, you need to follow the rules:

- The adjacent surfaces to the furnace, the pipeline must be covered with a layer of thermal insulation, which will prevent them from igniting.

- It is necessary to lay technical communications at a distance from the chimney.

- In places where the chimney passes through the roof, the ceiling must be fixed with non-combustible plates. Additionally, you can use a special sleeve.

- The system should be designed so that there are fewer bends and turns. The length of horizontal sections should not exceed 100 mm.

- The joints of individual pipes must be covered with a layer of heat-resistant sealant to increase the tightness index.

Chimney installation ( / termostatus_official)

brick chimney

The traditional method can be erected at the time of construction of the house and have a very different shape, even round, provided that the inner walls are correctly processed.

Brick chimney

The number of dignity can be replenished:

- reliability;

- durability;

- good heat dissipation;

- fire resistance;

- beautiful view.

But, there are also disadvantages:

- The accumulation of soot is much faster, due to the rough and uneven walls inside.

- Huge weight, which accordingly requires filling the "cushion".

- Under the influence of acids, condensate, the brick is gradually destroyed.

- High price.

Do not forget that the draft in such channels can be disturbed due to vortex flows.To minimize all the shortcomings, but at the same time get a monumental and reliable structure, a metal pipe can be inserted inside the brickwork. It will provide reliable smoke separation, and will not affect the protective frame. So the choice is up to the owner, which pipe in a private house is optimally mounted. If you use two configurations at once, think about the feasibility of such a massive structure. The price is quite huge, and for such funds you can install a more suitable configuration, such as a sandwich panel.

How to calculate the diameter of the chimney

When designing a chimney, it is necessary to choose the material to be used. And the material largely depends on what fuel will be used for heating. After all, the chimney is designed to remove the remains of the combustion of one fuel, and will not work with another. For example, a brick chimney works great with wood, but is not suitable for gas-fired heaters.

In addition, a correct calculation of the diameter of the duct pipe is required. If the chimney is used for one heating appliance, the problem can be solved by reviewing the technical documents provided by the manufacturer of the appliance. And if several different systems are connected to one pipe, then to calculate the chimney, you need knowledge of the laws of thermodynamics, professional calculation, especially the diameter of the pipe. It is wrong to assume that the diameter is needed more.

Swedish method

Among the different methods for calculating the diameter, the optimally suitable scheme is important, especially if the devices are low-temperature and long-term burning.

To determine the height, the ratio of the cross-sectional area of the chimney pipe to the internal combustion chamber is taken into account.The height of the pipe is determined according to the schedule:

Where f is the area of the chimney cut, and F is the area of the furnace.

Let, for example, the cross-sectional area of the furnace F is 70 * 45 \u003d 3150 square meters. cm, and the section of the chimney pipe f - 26 * 15 = 390. The ratio between the given parameters is (390/3150)*100%=12.3%. After comparing the result with the graph, we see that the height of the chimney is approximately 5 m.

In the case of installing a chimney for complex heating systems, it is important to calculate the parameters of the chimney

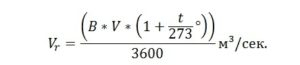

Accurate calculation

To calculate the desired section of the chimney, be sure to take into account all its characteristics. For example, you can perform a standard calculation of the size of a chimney connected to a wood-burning stove. They take the following data for calculations:

- the temperature of the combustion waste in the pipe is t=150°C;

- the speed of passage through the waste pipeline is 2 m/s;

- the burning rate of firewood B is 10 kg/h.

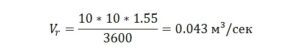

If you follow these indicators, you can do the calculations. For this purpose, the amount of outgoing combustion products is calculated according to the formula:

Here V is equal to the amount of air required to burn the fuel at a rate of v=10 kg/h. It is equal to 10 m³ / kg.

It turns out:

Then calculate the required diameter:

What should be the height of the chimney pipe for the furnace

The calculation of this parameter allows you to avoid the occurrence of reverse thrust and other possible troubles. This issue is regulated by the rules of SNiP and other documents.

SNiP requirements

The length of exhaust gas exhaust pipelines is regulated by the requirements of SNiP 2.04.05. The rules prescribe to observe several basic installation rules:

- the minimum distance from the grate in the furnace to the protective canopy on the roof is 5000 mm. Height above the flat roof covering level 500 mm;

- the height of the pipe above the roof slope or ridge should be as recommended. We will talk about this in a separate chapter;

- if there are buildings on a flat roof, the pipe should be higher. In this case, with a high pipe height, it is unfastened with wire or cable extensions;

- if the building is equipped with a ventilation system, their height should not exceed the cap of the flue gas outlet pipe.

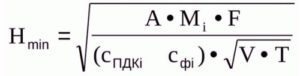

Self-calculation technique

How to independently calculate the height of the smoke channel, for this you will need to calculate according to the formula:

, where:

- "A" - climatic and weather conditions in the region. For the north, this coefficient is 160. You can find the value in other areas on the Internet;

- "Mi" - the mass of gases passing through the chimney in a certain time. This value can be found in the documentation of your heater;

- "F" is the settling time of ash and other waste on the walls of the chimney. For wood stoves, the coefficient is 25, for electrical units - 1;

- "Spdki", "Sfi" - the level of concentration of substances in the exhaust gas;

- "V" - the level of the volume of exhaust gases;

- "T" - the temperature difference between the air coming from the atmosphere and the exhaust gases.

It makes no sense to give a trial calculation - the coefficients and other values \u200b\u200bare not suitable for your unit, and extracting square roots will require you to download an engineering calculator.

Table "Height of the chimney above the ridge"

The table of the height of the chimney above the roof structure will help determine the dimensions of the pipes without carrying out complex calculations.First, we will analyze the selection of the length of the pipe for flat roofs.

| Selection of pipe length for flat roofs. | Min. pipe height in mm |

| There are no parapets and other structures and devices on the roof. | 1200. |

| A protective curb is built on the roof or other designs and distance to them up to 300 mm. | 1300. |

| Excess above other ventilation ducts | 500. The minimum distance to the ventilation shaft is 5000. |

| For pitched roof structures. | Min. pipe height in mm |

| The chimney exits to the roof at a distance of 1500 mm from the ridge. | 500. |

| The pipe is located at a distance of 1500-3000 mm from the ridge. | The pipe is brought out to the level of the roof ridge. |

| The distance from the ridge to the passage of the exhaust pipeline is over 3000 mm. | Set aside 100 from the cavity of the ridge. The top of the pipe should be at the level of this line. |

How and how to insulate a galvanized chimney

Among the heaters, basalt wool is in the first place - a reliable non-combustible agent that is successfully used for thermal insulation and insulation of smoke exhaust systems. Other types of mineral wool are used as a cheap substitute, the main thing at the same time is the incombustibility of the material.

The outlet is wrapped with the selected insulation, fixed with wire or other reliable and heat-resistant material. Then another pipe is put on the insulated channel, of a larger diameter, and, as a rule, made of galvanized steel. It turns out a self-made sandwich. A stainless steel product can be chosen as the inner pipe.

Pipe height

This size is determined by SNiP, which sets certain parameters:

- If the roof has a flat appearance, the chimney should rise 1.2 meters above it.

- If the chimney is located near the ridge, and the distance is less than 1.5 meters, it should rise above the ridge by 0.5 meters or more.

- When the pipe is located in the range of 1.5 - 3 meters to the ridge, it should not be below the ridge line.

- If the location of the chimney from the ridge exceeds 3 meters, its height should be on the line passing from the ridge, maintaining an angle of 10 degrees relative to the horizon.

To determine the height of the chimney, a large number of indicators are taken into account. The parameters presented above apply only to gas equipment. To make an accurate calculation, you need to use the services of a specialized company.

Brick chimneys - pros and cons

Such pipes are laid out of solid red brick, usually inside buildings, external attached options are less common. Masonry mortar consists of clay, sand and cement.

Homeowners have to deal with brick flues in 2 cases:

- the project provides for the location of the smoke channel inside the house - next to the exhaust shafts of the ventilation unit;

- when erecting a stationary stove or a classic fireplace.

Classic house (left) and attached chimney (right)

Previously, red brick was considered an ideal material for building a chimney, but with the advent of new products, it has lost its leading position. Advantages of brick gas ducts:

- Presentable appearance, which remains for a long time - during the entire period of operation.

- The shaft passing inside the wall transfers part of the flue gas heat to the premises.

- Stones and binding solution are non-combustible materials.

- A properly folded pipe successfully resists heating up to 1000+ degrees during soot burning (an example is shown in the photo). But with repeated or prolonged exposure to high temperatures, the structure will begin to collapse and become a fire hazard.

The disadvantages of brick pipes are much more:

- The uneven inner surface of the channel contributes to the deposition and accumulation of soot, which ignites in the event of overflooding.

- The rectangular (or square) shape of the shaft plus the roughness of the walls increases the aerodynamic resistance of the pipe and reduces natural draft.

- The construction is quite heavy and bulky, requiring foundations. Building a chimney or stove entirely with your own hands is not an easy task, hiring performers is expensive.

- Due to the peculiarities of the masonry, the dimensions of the channel are tied to the dimensions of the bricks, for example, 14 x 14, 14 x 21 or 21 x 27 cm. The standard shaft sections are presented in the table.

- Working in tandem with a gas boiler, a brick chimney collapses under the influence of condensate.

Condensation is the main scourge of stone pipes. The water vapor contained in the products of combustion penetrates into the pores of the brick, condenses and is seized by frost. Further it is clear - the material is peeling, the chimney is destroyed. The physics of the process will be explained by a specialist in the video:

How to deal with the disadvantages of brick mines:

- make external thermal insulation of the street section of the pipe;

- lay a stainless steel sleeve inside the channel - make a combined gas duct;

- operate the chimney together with a solid fuel boiler or stove - gases quickly warm up the walls of the mine, condensate practically does not fall out;

- lay out double brick walls, the inner row is made of industrial stone of the ShB-8 type.

Irregularities in masonry and brick pores can be protected by gilding

How to choose a pipe and not make a mistake

The choice of a pipe for a chimney, in addition to the desire of the owner, is influenced by objective factors. If the heating system is installed at the stage of building a house, then the choice of a constructive solution for the chimney is limited only by the requirement for equipment. If this is a pipe replacement in a residential building, then a steel chimney is the best solution.

You can't skimp on flue gas. From here:

Rule one: do not save on the choice of materials.

Overheating of the pipe leads to its cracking. Underheating allows a large amount of condensate and harmful emissions to settle on the walls, which also leads to the destruction of the structure, therefore:

Rule two: the pipe must match the equipment used.

For example, the requirements for steel heat resistance (thickness, alloy) for a sandwich pipe vary depending on the fuel used. GOST 5632-61 lists permitted steel grades for heat-resistant use

When buying a sandwich, it is important to pay attention to the steel grade. When constructing a brick pipe, it is worth using refractory materials

Rule three: Acquire the necessary pipe elements according to the plan.

For example, when installing a modern sandwich, it is mandatory to install a gate (furnace damper), condensate collectors, revisions for cleaning and removing condensate resins.

The fourth rule, although it can be put in the first place: it is better to draft a chimney with a specialist, even if the installation is planned independently.

A professional project will allow you to arrange the chimney in the best way: both the pipe will be of the required length, made of suitable materials, and the design of the smoke exhaust device is correct.

What you need to purchase in addition to the pipes themselves: additional elements

Iron and ceramic chimneys are mounted using conventional tees and corners. When installing a discharge pipe, its parts are assembled like a designer using a sealant. But in addition to corners and tees, various special additional elements can be used when installing chimneys.

Of course, modern condensing boilers can also be installed in country houses today. But in most cases, ordinary units of this type are still used in private residential buildings. When assembling chimneys for such boilers, condensate traps and condensate collectors are often used as additional elements.

Installation of pipes that discharge combustion products is usually carried out through the ceiling and slopes of the roof of the house. And such designs of private country buildings in most cases are assembled from timber and boards. In order to ensure fire safety, when laying chimneys through wooden floors and slopes, special heat-insulated cartridges are used.

Above the roof, the chimneys are placed vertically. Therefore, precipitation can easily get inside such pipes. To prevent this from happening, the chimneys are covered from above with caps of a special design that do not prevent smoke from escaping to the outside.

Chimneys are mounted on the walls using conventional brackets and clamps. Also, when assembling such structures, special plugs and adapters can be used.They are used when connecting pipe sections of different diameters, blocking individual sections of the chimney, when installing steam traps, etc.

Material selection

The choice of material is determined by the mode of operation of the boiler equipment, the financial budget for construction and the personal preferences of the master. There are designs from:

- Brick. Brick is the most traditional chimney material. The only positive quality of a brick is thermal insulation properties and thermal inertia. The rest are solid cons: it takes some experience in order to create the right solution, which has a sufficient density so as not to let the gas through. Such a pipe has large dimensions and is difficult to connect to the boiler. Therefore, the use of bricks when creating a chimney on your own is a rarity.

- Steel. Steel is a wonderful material. Properly selected stainless steel will be an excellent material, easy to install and affordable for self-assembly. In addition, the pipe can be made independently by welding from a sheet of metal, which will significantly save on material. The only negative is the high coefficient of thermal conductivity. This means that, unlike brick or ceramic, steel needs a significant layer of insulation. In order to avoid such an unpleasant procedure, which requires some skill, you can use sandwich pipes.

- Glass. Indeed, glass pipes exist. But only a few words should be said about them, since there are practically no such goods on the Russian market. Glass pipes have almost absolute gas tightness, which is why they are loved in Europe.In addition, plexiglass goes well with a minimalist interior, which allows you to organically fit this design into the interior. Among the minuses: the price, the complexity of installation and the large weight of the structure.

- Polymer. Polymer pipes bend too easily, so they are used only as sleeves laid inside brick pipes. With the help of liner with polymer pipes, you can extend the life of the old brick chimney.

- Asbestos-cement. Asbestos-cement pipes are cheap and easy to install material. But at the same time, asbestos cement has a low heat capacity, and it is much more difficult to isolate it than the same steel. In addition, despite the ease of installation, pipes are almost impossible to lay at an angle.

Asbestos-cement pipes - a cheap and easy-to-install material

Asbestos-cement pipes - a cheap and easy-to-install material

Cons of a steel chimney

In addition to the advantages, steel pipes have a number of disadvantages. Their main disadvantage is the rapid absorption of heat. Steel heats up quickly, so they need to be insulated. If this is not done, the pipe may heat the materials it comes in contact with and cause a fire. In addition, when it heats up, it loses its ability to extinguish the sparks generated in the chimney.

Another disadvantage of steel pipes is the large formation of condensate. This feature of the material may vary in severity depending on the coating and type of construction. Least of all condensate falls on straight pipes without horizontal outlets.

Box manufacturing

About how to insulate the iron pipe of the chimney, it was said earlier. Now you can move on to the next step. Many people think that making a chimney box is too difficult a task. In reality, this is not so.It is enough to approach the work responsibly, with knowledge of the matter.

Required tools:

- Drill;

- Scissors for metal;

- Compass;

- metal sheets;

- Self-tapping screws.

Stages of work:

- Hole preparation. Along the edges, it is necessary to fix the bars, which will act as a support for the body.

- Two blanks are cut from a metal sheet. They are given a U-shape. Then the finished parts are screwed to the ceiling using self-tapping screws.

- Again, two blanks are made, but they are already fixed on standing sheets with a small spade. It turns out a solid frame in the ceiling.

- Now the bottom is made for the box from a metal sheet. In the center of the workpiece there should be a hole for the chimney, here you need a compass.

- The box contains four fasteners of two centimeters. They are cut and bent perpendicular to the bottom.

- Walls are attached to the bottom. Now a chimney is inserted into the box, it is additionally fixed with clamps. The voids are filled with an insulating layer.

Conclusion

Of course, the chimney is not just a pipe, but one of the most important parts of the heating system. She is responsible for the safety of the residents of the house, for the absence of fire, for the microclimate in the building. Any violations in the chimney, even microcracks that are imperceptible at first glance, can lead to disaster. Carbon monoxide, sparks, smoke, back draft or weak draft indicate a violation of the chimney. In such cases, immediate action must be taken.

When designing and installing a chimney, you can handle it yourself. To do this, first of all, it is necessary to study the standards, documentation of the boiler, if any. Carry out preparatory work, purchase everything you need.But if you don’t have the skills to install a chimney, you should invite a specialist for a detailed consultation, even if you have confidence in your abilities. If there is the slightest uncertainty, it is better to hire an experienced team of craftsmen.