- Ratchet pipe cutter

- Structure and properties of scissors

- How to use pipe cutters?

- Preparation and cutting of steel pipes

- Cutting of pipes of small diameters

- Cutting steel pipes of large diameter

- What tool can be used to cut plastic pipes

- 2 Kraftool 23410-42

- What else to consider when choosing

- Varieties and specifications

- In what cases you can not do without a pipe cutter

- Electric pipe cutters for plastic pipes

- Reciprocating Electric Saw

- Roller and guillotine electric pipe cutters

- Industrial professional pipe cutters

- Choice depending on material separation technology

- Classification and types of pipe cutters

- Instructions for use

- Electric pipe cutters

- Manufacturing materials

- The most efficient pipe cutting machines

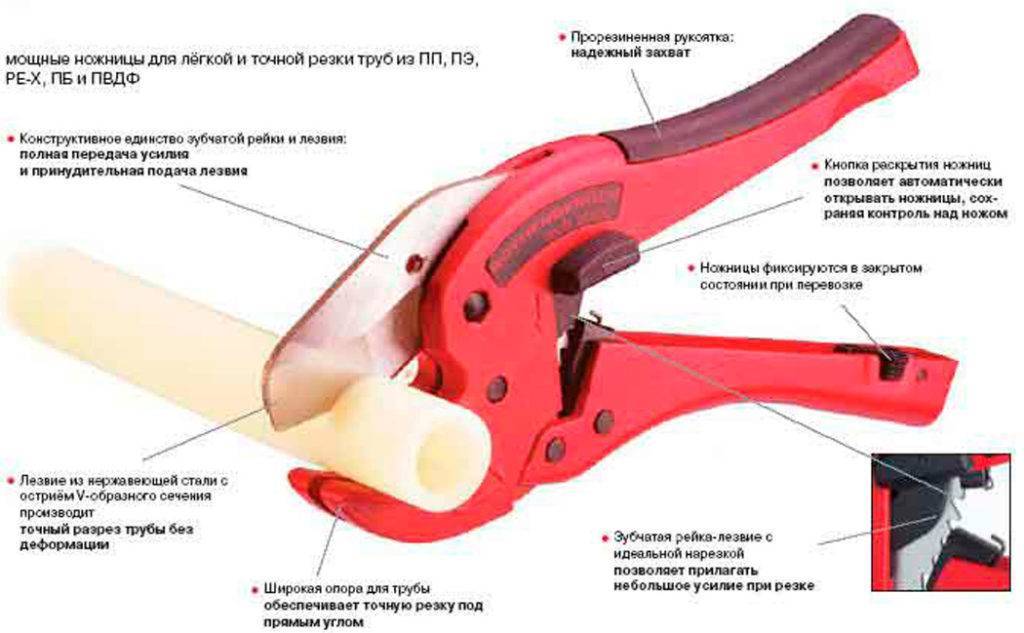

Ratchet pipe cutter

A guillotine pipe cutter with a ratchet mechanism is also called scissors. It has a built-in mechanism that allows you to cut the pipe with a blade not with a single movement, but with repeated force, which reduces physical stress on the muscles of the hand.

Structure and properties of scissors

A guillotine pipe cutter is similar to an adjustable wrench with two handles.It has one molded handle, ending in a wide C-shaped base for fixing the pipe, and a second handle that presses the cutting blade through a ratchet mechanism. The tool is equipped with a button to return the cutter to its original position and a latch of the closed state for ease of transportation.

When buying a pipe cutter, it is necessary to measure the looseness of the blade and the movable handle: the higher it is, the worse the quality of the cuts will be.

The working diameter of the scissors varies from 3 to 75 mm. A feature is a sharp increase in the cost of the device with an increase in the maximum possible thickness of the pipe over 42 mm.

The thicker the blade, the more likely it is to last. Thin cutting elements are placed only on cheap models of pipe cutters

Manufacturers try to design the cutter and blade in such a way as to minimize the required working space. Blades can be smooth or serrated. Some models are equipped with a built-in beveler, but the end of the pipe is processed after cutting, and not simultaneously with it.

The advantages of a guillotine pipe cutter are:

- Low tool cost.

- Possibility of cutting in limited space.

- Use when working with only one hand.

- No chips or burrs when cutting

The disadvantages of scissors are also enough:

- Fatigue of the hands with large amounts of work.

- The need for sharpening blades.

- The high cost of replacement blades.

- Transverse deformation of pipes during cutting.

- The likelihood of acquiring an inexpensive tool that will become dull after a dozen cuts.

- Limited maximum pipe diameter.

Despite the disadvantages, guillotine modifications are an ideal option for the installation of plastic pipes of small diameters with small amounts of work being done.

How to use pipe cutters?

The process of cutting with a guillotine turbo cutter differs little from the work with conventional scissors, but has its own characteristics. To cut a pipe with this tool, you must perform the following actions:

- Draw the cut on the pipe.

- Place the pipe on the wide base of the pipe cutter so that the intended cut line is exactly opposite the blade.

- Using the handle, press the blade onto the pipe.

- After each full compression of the handles, loosen them, returning to their original position.

Rhythmic squeezing of the tool handles should be repeated until the pipe is completely cut.

During the cutting process, it is undesirable to keep the pipe on weight, because at the final stage it can break off and spoil the evenness of the cut.

A number of tools have a ratchet mechanism, each click of which notifies the movement of the internal ratchet mechanism by one clove. The clicking sound means that it is already possible to unclench the handles of the instrument and repeat the pressing from a more comfortable position.

Preparation and cutting of steel pipes

Before proceeding with cutting, the pipe material must be properly prepared:

- Moisten the intended separation area with oil. This will reduce the temperature of the metal during operation, clean the outer perimeter and partially remove scale.

- Using a clamp, fix the pipe in the holder, focusing on the cut line previously marked with a marker.

- Using the rod, move the cutting head around the perimeter of the part. Gradually increase the feed to achieve the desired cut.

- If the knives have the required strength and a good level of sharpening, the cut-off point will be smooth and will not require further processing.

In models designed for cutting pipes of small diameter (no more than 30 mm), the stem is combined with the handle. When it is set in motion, the cutting itself occurs.

Cutting of pipes of small diameters

For cutting steel pipe material of small diameter, the part to be processed is clearly fixed with a pipe cutter clamping mechanism. The handle of the tool is turned clockwise so that the cutting element comes into contact with the metal surface.

Then they make another turn of the handle, making sure that the beginning and end of the incision line are in contact, creating a clear closed circle without interruptions and other violations.

A manual roller pipe cutter is the most convenient and practical option for domestic processing of small diameter steel pipes. Its use does not require specific skills and professional knowledge.

If these parameters are met, the tool handle is shifted another half turn, pulling the cutting element closer to the pipe. When the cutters are clearly in the metal, the scroll is slightly accelerated and the handle is rotated until clipping occurs.

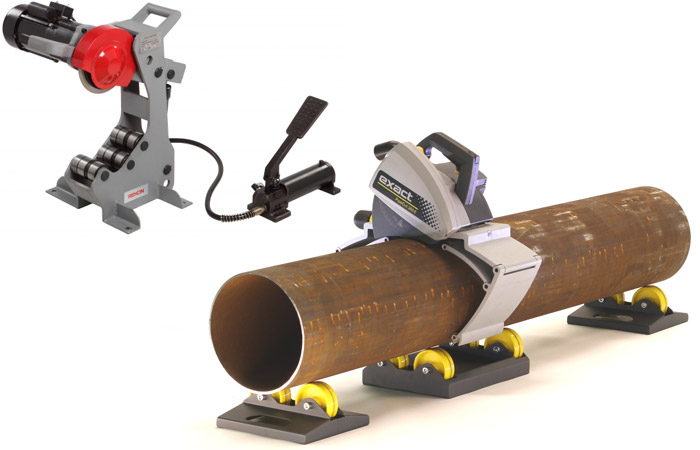

Cutting steel pipes of large diameter

In everyday life, cutting steel pipes of large diameter is practically not in demand. Basically, material of such dimensions is processed on an industrial scale. For this purpose, enterprises buy very powerful, expensive equipment.

The laser machine allows you to effortlessly and at high speed cut steel pipes of large diameter and large thickness.Through a computer control system, the operator can set the machine to a suitable program for making cuts of any complexity.

If, nevertheless, there is a sudden need for cutting large-diameter pipes, it is not necessary to purchase professional equipment.

You can use the usual grinder available in the arsenal of each owner, and by installing a cutting element for metal on it, make a quick, accurate and high-quality cut

But when working with this tool, you should not forget about safety precautions.

When cutting steel pipes of large diameter, it is not recommended to put a working element for wood or stone on the grinder. A discrepancy in the density of the cutters can provoke damage to the workpiece, and subsequently lead to breakage of the tool itself.

But nevertheless, the angle grinder is only suitable for one-time cutting and cutting work. For regular large-scale events, it makes sense to acquire a more durable and strong unit.

You can read more about the different types of pipe cutting equipment in this material.

What tool can be used to cut plastic pipes

Considering that people in our country are artisans, then they manage to use the most unimaginable tools at hand to cut pipes. But one should not think that such a cut contributes to the excellent quality of the future pipeline. Therefore, consider tools that allow you to cut plastic pipes more perfectly:

- hacksaw for metal;

- self-sharpening knife (with small teeth);

- scissors for cutting plastic pipes;

- roller type pipe cutter;

- battery pipe cutter;

- guillotine pipe cutter.

Cutting off pipes with a hacksaw for an alloy or a knife should not be seriously considered, since their use leads to the fact that the end of the pipe is frayed, burrs are formed, which have to be eliminated with sandpaper or stripping with a knife.

In any case, the quality of the cut is tormented.

These methods can be used for single cuts. If the pipeline has a complex configuration and many connections of individual sections, then it is better not to use these tools. Pipe shears are mainly used for cutting plastic pipes.

The sharply sharpened blade of the knife is fixed only on one side of the tool. In place of the second blade, there is a rather extensive base with a slot designed to receive a cutting plate. Work with such scissors is done only due to the muscular strength of a person. Between the handles of the scissors there is a rounded gear rack, which, after closing the handles of the scissors, pushes the blade towards the base. The process of cutting the pipe occurs as follows:

- an excellently noticeable mark is placed on the surface of the pipe, marking the place of the cut with it;

- the base is placed over the mark given to us, controlling its position through the slot of the base;

- then, applying force, they cut into the pipe and, evenly increasing the force, create the final cut of the pipe.

The advantages of scissors are quite high efficiency and low cost of construction.

A shortcoming is considered a direct connection between the effectiveness of the inventory and the physical strength of the person working with it.In addition, during the cut, you need to watch the smooth movement of the brush, otherwise the blade may simply slide off the gear rack.

It is clear that with a large number of cuts, the hand quickly gets tired, because the speed of work is reduced. In addition, it is unrealistic to cut pipes of a huge diameter with scissors. The largest diameter of the processed pipes is 42 mm.

In terms of efficiency, a pipe cutter is no worse than scissors. But, unlike them, there is virtually no physical effort during work.

The cutting process itself is as follows:

- at the place of the cut put a mark with a marker;

- the screw is unscrewed from the clamp, and the bracket is brought to the place of the cut;

- then the screw is smoothly tightened (so that the pipe does not burst);

- after creating the necessary force on the cutting roller, the clamp begins to rotate around the pipe, while smoothly tightening the tension screw.

Thus, a circular cut of the pipe is made, while the end of the pipe comes out extremely even, without burrs.

The only danger when working with a pipe cutter is the occurrence of cracks on the pipe due to the very powerful clamping force of the screw.

The guillotine pipe cutter is used to work with pipes with a diameter of 63 to 350 mm. At the same time, the possibility of deformations or destruction of the pipe walls is virtually reduced to zero. The cutting process looks like this:

- mark the place of the cut on the pipe and insert it into the guillotine, fixing it in the sector from 30 to 60 degrees;

- a guillotine blade swings around it, which is mounted on wheels;

- after the first cut of the plastic, the blade is immersed in the pipe with the help of a rotating screw handle and, thus, the pipe is finally cut.

In this case, the cut comes out extremely smooth, without burrs.

Guillotine blades are simply replaceable. In modern guillotines, the blades are additionally coated with Teflon.

2 Kraftool 23410-42

Studying the market of pipe cutters, you quickly realize that there is a leader here, which is unlikely to be beaten by anyone. And now he is in front of us. This is a popular German brand, and in its arsenal there are more than a dozen types of different pipe cutters, both scissor and circular type. It is impossible to choose the best option among them, since, regardless of the model, they are all of the highest quality and reliability.

For example, this model has a hardened blade that does not require sharpening and is practically not dull. Very durable tool that does not require replacement modules for many years

The manufacturer pays special attention to ergonomics, and in fact, all of its models differ only in the convenience of the form factor. They always have rubber inserts on the handles, which prevent slipping out of the hands, and convenient locking mechanisms.

Without any dangling brackets and other inconveniences. But the downside here is the price. The tool is quite expensive and it hardly makes sense to buy it for rare home use.

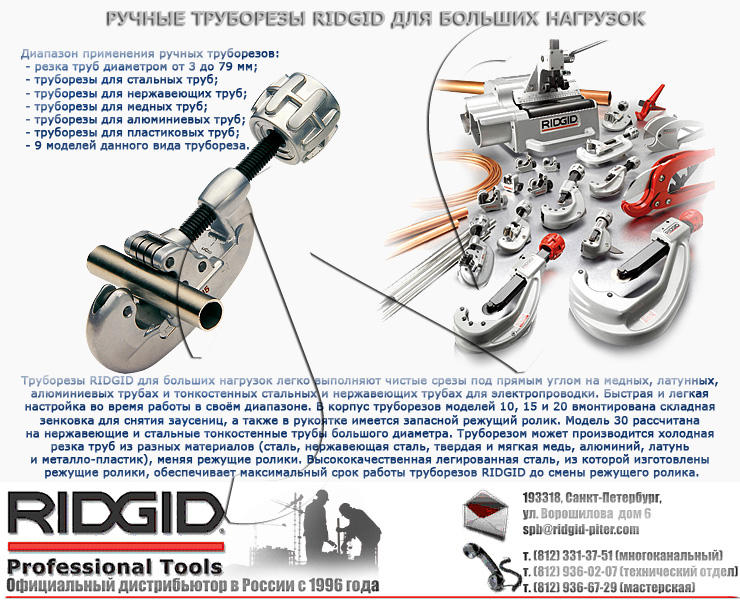

What else to consider when choosing

To choose the most suitable tool, it is additionally recommended to consider:

- type of drive. There are hand tools suitable for domestic purposes, cordless and electric pipe cutters that allow you to get the job done in a short time and with minimal effort. In most cases, power tools are used by professionals;

Pipe cutter with electric drive

- material for the manufacture of the cutting part and body of the device.Pipe cutters with steel knives (alloyed or stainless steel) have the longest service life. The body of the tool should also be metal, but lighter metal, aluminum, is preferred;

- dimensions of the cutting part, which determines the minimum and maximum diameter of the cut pipe;

- manufacturer. Professional craftsmen recommend purchasing models made by the brands Rothenberger (Germany), Ridgid (USA), Kraftool (Germany), Stayer (China), Virax (France).

How to use pipe cutters of various types, see the video.

If there are any problems in the process of selecting a pipe cutter for certain purposes, it is recommended to get qualified help from sales consultants.

Varieties and specifications

On sale you can find several types of pipe cutters:

- Roller - simple manual pipe cutters. Designed for cutting tubes fixed in different types of clamps. Metal walls are not cut, but are pressed through by rollers that can rotate freely.

- Orbital - tools with a collapsible design. Inside, the cutters rotate in a circle, with the help of which the walls of the parts are cut. The orbital pipe cutter can be used to chamfer thick-walled tubes.

- Chain - tools that are suitable for work in any conditions. The design has no rotating elements. It is a chain of numerous disks that wraps around the part to be cut. After mechanical force, the chain squeezes the pipe. The discs cut the material.

Depending on the type of drive, several types of pipe cutters are distinguished:

- mechanical - simple models;

- pneumatic - the working process is carried out due to pneumatic cylinders;

- hydraulic - working elements move under the influence of fluid pressure;

- electric - connected to a 220 volt network or powered by batteries.

Pneumatic, hydraulic models are installed at large enterprises where pipes are mass-produced.

Orbital pipe cutter

Orbital pipe cutter

In what cases you can not do without a pipe cutter

Plastic pipes are fairly easy to cut. To do this, you can use a hacksaw, a regular knife with a serrated blade, a grinder. However, it will not be possible to immediately obtain a straight line with their help, it will need to be further processed. This is extra work, a waste of time.

Meanwhile, the technology of joints requires that the cut must be perpendicular and clean. Therefore, when the scope of installation work is large, to speed up the work and ensure their quality, it is better to use a special tool - a pipe cutter.

Pipe cutters are used for:

- Cutting plastic bends for laying domestic water supply networks, heating, underfloor heating.

- Repair work, when it is necessary to remove the damaged section of the outlet.

- Dismantling of old or damaged pipelines.

Electric pipe cutters for plastic pipes

The electric drive for pipe cutters greatly simplifies and speeds up the installation process. There are three types of electric pipe cutters:

- tools that simply copy the principle of a guillotine or roller mechanism;

- industrial stationary equipment with a complex internal structure;

- universal tools for cutting materials.

These types of tools should be considered in more detail.

Reciprocating Electric Saw

Reciprocating saws are similar in principle to a jigsaw. They have an electric drive, with the help of which the serrated blade makes fast reciprocating movements. The length of the files starts from 100 mm, and the width and height of the teeth varies from the material being processed. For plastic, a tooth pitch of 4 mm is used.

Not every reciprocating saw blade can bend a lot, so there is always a chance that it will break during a wall cut.

Additional equipment that facilitates cutting with a reciprocating saw is a chain or C-shaped pipe clamp. It is fixed to the body of the power tool with a special mount.

For cutting plastic products, there is a special type of blades "for wood and plastic", which provides high speed work and good cut quality.

The advantages of reciprocating saws when cutting plastic pipes are:

- Work safety.

- Removable blades are cheap.

- High cutting speed.

- Ability to work with pipes of any diameter.

- The ability of the blade to bend and cut pipes flush with the wall.

- Durability.

- The price of a household electric saw is comparable to the cost of a professional guillotine pipe cutter.

The disadvantages of reciprocating power saws include:

- The need for a local source of electricity.

- The resulting cut requires additional processing with a trimmer or beveler.

- The difficulty of ensuring the perpendicularity of the seam without a special pipe clamp.

- Difficulty cutting without fixing the pipe in a vise.

Especially for cutting plastic pipes, you should not buy a reciprocating electric saw, but if you already have one, then you can use it. This tool can be useful on the farm for cutting metal, wood, brick and other materials.

Roller and guillotine electric pipe cutters

This category of power tools for cutting plastic pipes has all the advantages and disadvantages of the corresponding manual equipment. Roller and guillotine electric pipe cutters greatly facilitate the cutting process, but their cost is many times higher than mechanical tools.

Due to the high cutting speed, the lack of fixation of the pipe and vibration, it is quite problematic to maintain a strictly perpendicular cut when using electric tools.

By design, the power tool resembles its manual counterparts only schematically, because it has a complex internal filling. Pipe cutters can have two sources of electricity: a household electrical network or a battery.

When working with electric pipe cutters, it is better to firmly fix the pipes in a vise: it is easier to control the perpendicularity of the resulting cut

Cordless tools are the most expensive, but allow you to work without reference to the terrain. Their prices start at $150. The charge should be enough for 1-2 hours of continuous operation. For the installation of home plumbing, this is quite enough.

Industrial professional pipe cutters

Industrial machines can cut pipes of any size, not just large ones. This equipment can be divided into several categories, depending on the design features:

- Electrical.

- Pneumatic.

- Hydraulic.

- Orbital type.

- With automatic control system.

The cost of such pipe cutters starts from several hundred dollars, so they are mainly used by professional installers.

Industrial pipe cutters are mainly used by construction companies laying main water pipes, sewerage and heating networks to new buildings.

Their advantage is the automatic control of the speed of movement and the pressure parameters of the cutting element, as well as the combination of cutting with the process of chamfering and cleaning the cut from burrs.

Choice depending on material separation technology

Cutting can be done with a tool that moves reciprocating or rotary. In the first case, cutting will be longer, since the working head has an idle (return) stage. Therefore, steel pipe cutters are always equipped with rotating blades. A multi-roller (or orbital) pipe cutter has two types of rollers: workers (their number can vary from one to three), and support, guides. With an increase in the number of working rollers, the technological capabilities of the device increase. In particular, the three-roller manual orbital pipe cutter will cope with pipe diameter up to 100 mm. The advantage of disk pipe cutters is that the resulting force applied (in case a manual pipe cutter is used for cutting steel pipes) is reduced due to the fact that the load is applied only along a small arc of contact between the working edge and the product being cut.

Roller telescopic pipe cutter for cutting stainless steel pipes

A manual orbital pipe cutter, regardless of the number of cutting rollers, has the disadvantage that the cut is intermittent, and therefore the edge will be chipped and uneven. Sometimes this is unacceptable and will require subsequent deburring of the resulting burrs. At the same time, this design, due to its long drive handle, is effective in separating pipes under water.

For large diameter pipe cutting effective telescopic pipe cutter. Its working tool is also rollers, but unlike the previous version, the rollers are located along the perimeter of the outer generatrix of the workpiece. Then, with the help of a lever, these rollers are pressed into the interface, after which the telescopic pipe cutter separates the parts of the pipe. A telescopic pipe cutter is used when working with workpieces with a diameter of up to 200 mm, but it will require a significant working space, and therefore it is advisable for working mainly with external pipelines.

Classification and types of pipe cutters

The manual steel pipe cutter functions mainly by using human muscle strength. This is not bad, because all the work takes place directly under your control and it is very difficult to imagine an emergency situation when the technology of the cutting process can be suddenly disrupted. The simple design of a manual pipe cutter depends little on the influence of external factors, except that the hand may tremble. While any automatic equipment has many nodes that need to be constantly monitored and repaired.

The manual steel pipe cutter functions mainly by using human muscle strength. This is not bad, because all the work takes place directly under your control and it is very difficult to imagine an emergency situation when the technology of the cutting process can be suddenly disrupted. The simple design of a manual pipe cutter depends little on the influence of external factors, except that the hand may tremble. While any automatic equipment has many nodes that need to be constantly monitored and repaired.

Of course, not every pipe can be cut by a person only due to muscular effort.Sometimes even the presence of a system of levers that serves to artificially increase the strength of the application cannot always solve this problem. But in everyday life, this type of device is quite capable of performing all the necessary work.

Varieties of equipment for cutting pipes can be qualified depending on the characteristics of the cutting element and the size of the object to be cut. Therefore, the following types of tools can be distinguished:

- The cutting pipe cutter is used for cutting pipes with a diameter of up to 100 mm. This option is suitable not only for working with steel pipes, but also effectively used for cutting plastic pipes. Steel discs are used as cutting tools.

- The chain pipe cutter is widely used when cutting pipes based on dense materials (concrete, cast iron, ceramics). The presence of a flail mechanism for tightly fixing the pipe and the swivel arm and allow you to effectively cut such surfaces.

- The roller pipe cutter has in its design guides and from one to three cutting rollers. The diameter of the pipes that such a device can cut depends on the number of working rollers. A pipe cutter with one roller cuts pipes up to 50 mm in diameter, and with three rollers in the tool, you can work with pipes up to 100 mm or more.

- The telescopic pipe cutter is equipped with rollers, a carriage and guides. Such a device is able to fix the pipe, depending on the required cut angle. It is very effective when working with especially durable materials and pipes of great thickness, since its mechanism is able to create a lot of pressure on the surface of the pipe.

- The ratchet pipe cutter is small in size, so it can cut pipes of small thickness. Two handles and a cutting blade make up its uncomplicated design, which is the simplest in its class.

- The electric pipe cutter by its name makes it clear that it is equipped with an electric motor. The use of an electric motor almost completely reduces the need for operator effort when performing work. The main thing is to set the fixture correctly, and the rest of the cutting process is performed automatically. Moreover, this is a universal tool that cuts pipes from any material and regardless of the diameter of the product. Only insufficient power of the electric motor can limit the size of the workpiece. With the help of such a device, it is possible to effectively perform work on facing joints and chamfering from any surface of the pipe. The disadvantage is the difficulty of using this equipment in hard-to-reach places of work.

- The guillotine pipe cutter got its name because of the type of cutting tool. The processed pipe is fixed in the frame, the screw pushes the working guillotine during rotation, which cuts the material at a right angle. Such a device can cut pipes of small diameter and different structures (multilayer, single-layer, reinforced).

- Pneumatic pipe cutter makes a cut under the influence of rarefied air. This equipment is effective in use in manufacturing plants for cutting pipes with a diameter of up to 1500 mm, while doing an excellent job with both plastic and dense material.

- Orbital pipe cutters perform not only mechanical cutting of the workpiece, but also chamfer thin-walled materials at the same time. For this operation, the design of such devices includes special shaped cutters.

It should be noted that any types of devices can be additionally equipped with various devices that improve the quality of the cut and increase the safety of work. So, with the help of a fast crimping mechanism, it is possible to speed up the process of fixing large-diameter workpieces. And, of course, many devices are equipped with removable accessories.

Instructions for use

Consider the instructions on how to use the pipe cutter step by step.

1 step. Prepare the surface, for this you need a flat, clean plane that prevents any vibrations, carefully lay the pipe.

2 step. Next, you need to mark the place of sawing off on the prepared workpiece using a marker. Fix the parting to the workpiece with clamps or a chain.

3 step. In order to reduce the temperature of the metal during operation, it is necessary to moisten the sawing area with oil.

4 step. Close the latch of the pipe cutter tightly around the pipe, fix the desired part, pull the tightening knob.

5 step. Start rotating the tool while aligning the cutting rollers with the cut.

6 step. As the pipe cutter is pushed into the material, pull the handle with a pendulum motion.

7 step. If additional force is required to rotate the pipe cutter, loosen the feed screw slightly.

8 step. Slowly continue to work until the workpiece is completely cut.If the knives have the necessary strength, and are also well sharpened, then the cut-off point will be smooth and will not require further processing.

Electric pipe cutters

With a large amount of this kind of work, it is advisable to use a tool with an external drive, although their price is much higher. Especially convenient (in the presence of a stationary AC network) are electric pipe cutters.

A typical design of a pipe cutter with an electric drive for cutting ductile steel includes:

- Impact-resistant housing with ventilation slots.

- Drive high-speed electric motor, rated for 220 V.

- Three thrust rollers providing the necessary cutting accuracy.

- Cutting mill, fixed in the tool holder on the motor shaft, and protected from the thrust zone.

- Reduction gear.

The mass of electric pipe cutters does not exceed 1.5 kg, however, many designs provide for fastening the tool to a bench workbench. Lubrication of the working area during cutting is not required.

The design of electric pipe cutters for cutting more durable metal is characterized by the absence of a gearbox, and therefore the number of revolutions of the cutting tool reaches 3000 ... 4000 per minute. In such conditions, the supply of lubricant to the separation zone is mandatory. The working tool is made of hard alloy grades VK5 or VK8, and the disk itself is covered with a removable casing.

The design of the hydraulic pipe cutter includes a working cylinder, a rod and a piston, and the necessary pressure is created by a compact hydraulic pump, which is included in the package. The stroke of the cutter is controlled by changing the pressure of the working fluid - water.Hydraulic pipe cutters can be used in all conditions, but they are inferior in power to electric models.

Manufacturing materials

The body of the equipment is made of the following materials:

- impact-resistant plastic;

- zinc alloy;

- composition based on aluminum;

- tool steel.

In order to resist corrosion, individual elements of the body can be coated with a protective layer based on chromium or a special coloring composition (powder). The steel structure is assembled from individual elements, which are also subjected to a procedure such as hardening. This provides significant stability of loaded and rubbing against each other nodes. Chrome-plated components are not afraid of moisture, have a good wear resistance, are resistant to corrosion, and have an excellent appearance. Cutting elements can be steel, tool or made from a special grade of steel (alloyed).

The most efficient pipe cutting machines

With fast and accurate cutting of pipes made of highly combustible materials, flameless cutting units are better than others. They easily and accurately process any kind of polymer, including those that melt at a temperature of 180-200 ° C.

On our website there is a detailed article on how to choose a pipe cutter for plastic pipes, read on.

For cutting strong but ductile copper, classic roller models, both mechanical and electrical, are excellent. The same type of tool cuts pipes from more expensive materials (brass, bronze, etc.)

Gas-powered cutting machines cut steel pipes.For cast iron, this processing option is not suitable, since strong overheating is formed in the area of contact of the cutting element with the pipe body. This negatively affects the basic properties of the metal and creates obstacles for even, accurate and high-quality cutting.

For cutting pipe segments made of multi-component materials, various versions of the manual guillotine are ideal. They do not damage the thin aluminum reinforcing layer and do not crush the pliable polymer base.

Ceramic or concrete pipes are most often cut with an angle grinder. These materials do not react to thermal impact, and guillotine-type mechanical devices lead to coloring of the edge and destruction of the integrity of the entire pipe.

In addition to equipment designed exclusively for cutting pipes, other tools are also used for this purpose, for example, a cutting disc machine, a circular saw, a laser perforator and a band saw.

However, this is only true for one-time jobs. If cutting pipes of various shapes, diameters and densities is carried out regularly, it is better to acquire a special narrow-profile tool.