Tool Care

The duration of the tool's service life largely depends not only on compliance with the basic rules for working with it, but also on proper care. Compliance with the rules presented below will significantly extend the life of the device and ensure high-quality pipe cutting with it.

It is possible to start work for 1 time only after a detailed acquaintance with the instruction manual

Carelessness during operation can damage the device, the workpiece, and even cause injury.

After a long period of inactivity, the tool must be inspected for external features and the possibility of its normal functioning (it is better to check it on a test pipe).

Thorough lubrication of all moving parts is a must. The feed screw and cutting rollers especially need protection.

The device should be cleaned regularly immediately after use.

For this, a wire brush is used, on which a cleaning agent is applied.

Periodic check of all elements and connections of the tool, especially the sharpness of the roller, the accuracy of making a groove in the pipe.

Compliance with storage conditions - the tool must be stored in a warm and dry place (mainly at home). An uninsulated balcony and a garage will not work in this case, / since temperature changes, direct sunlight and high humidity levels can adversely affect the details of the pipe cutter.

Tool types

The tool for mounting polypropylene pipes can be divided into:

- welders;

- glue guns;

- pipe cutters;

- stripping.

Welders

Welders are of two types:

- Mechanical apparatus. It is used if it is necessary to connect pipes of large diameter or a lot of effort is required to align the joints. Device:

- support frame;

- instrument block;

- hydraulic drive.

Half-ring grips are located on the left and right. Between them, for pressure distribution and alignment, inserts are installed, the inner diameter of which corresponds to the outer diameter of the pipes being welded.

Mechanical welding machine

- Manual welding machine. Serves for welding pipes of small diameter up to 125 mm. Device:

- thermostat;

- a heating plate with holes in which nozzles with a non-stick coating are installed;

- a set of nozzles for installing the elements to be welded (in pairs), the Teflon coating prevents polypropylene from sticking to the heated nozzle.

Connecting with a handheld device

Glue guns

The use of a gun simplifies the installation work.A socket connection using couplings of connecting or other elements can be made using glue for polypropylene pipes. Advantages of a hot glue gun:

- setting speed - from 1 to 3 minutes;

-

the reliability of the seam is practically not inferior to other types of connections.

Surfaces to be bonded must be free of dirt and grease.

Pipe cutters

Types of pipe cutters:

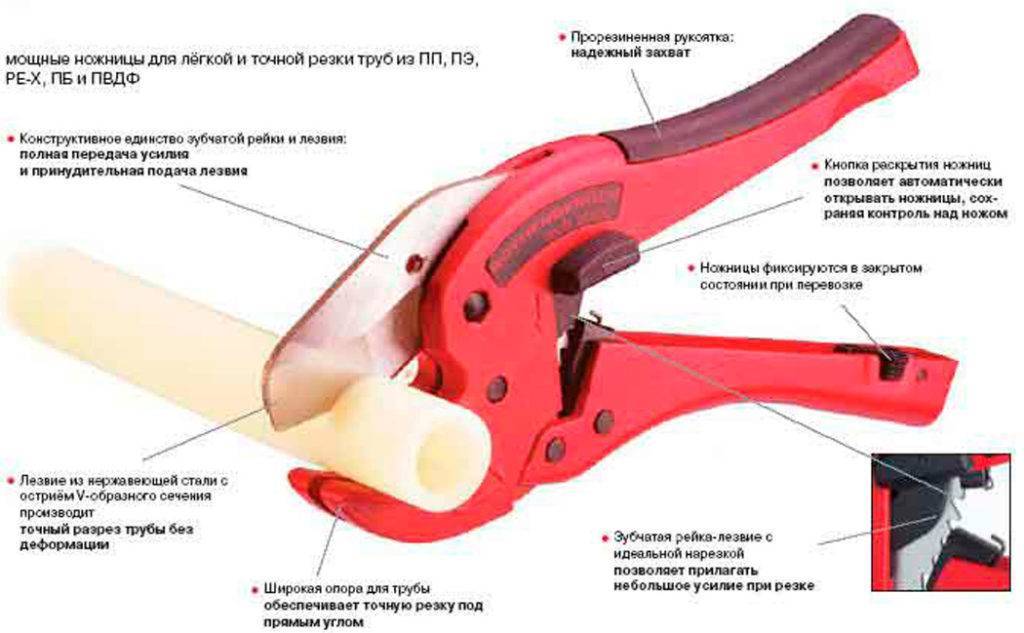

Precision scissors with a ratchet mechanism (for pipes up to 42 mm in diameter) have a steel blade with a gear rack.

Scissors for polypropylene pipes

Roller pipe cutter with ratchet mechanism. The pipe is inserted into a C-shaped recess and, when the handles are closed, it is cut off with a blade located opposite. The cutting must be carried out strictly at an angle of 90o. Deviation in the cutting process leads to deformation of the cutting line or even breakage of the scissors.

Roller pipe cutter for polypropylene pipes

- Cordless pipe cutter with a small electric motor that provides high cutting speed.

- Guillotine pipe cutter, which is used for cutting pipes of large diameter.

In the absence of a pipe cutter, you can use an ordinary hacksaw for metal or wood, but then the ends must be carefully cleaned of burrs. Also, when cutting, the pipe must not be deformed.

Cleanups

For hot water and heating systems, it is recommended to use reinforced polypropylene pipes. Pipes reinforced with fiberglass do not need to be stripped, since the mesh is located between the layers of polypropylene, it is not afraid of water and does not come into contact with the fitting.Aluminum foil used for reinforcement must be removed from the joint prior to welding. Aluminum in contact with water can cause electrochemical processes, which will lead to the destruction of the reinforcing film. In the case of external reinforcement, aluminum will interfere with the welding process of polypropylene elements. Therefore, pipes reinforced with aluminum foil need to be stripped. Types of cleaning tools:

- manual - with removable, non-removable handles or corrugation;

- drill bits.

Hand strippers and drill attachment

With small amounts of cleaning work and lack of experience, it is better to use a hand tool.

- For the outer layer, couplings with knives from the inside (material - tool steel), the so-called shavers, are used. The diameter of the tool is selected according to the diameter of the cleaned pipe. Double-sided couplings are often used, allowing work with pipes of two different diameters.

Shaver for polypropylene pipes

- For the inner layer, trimmers are used. Knives are located from the inner end. You just need to insert the pipe into the tool, turn it several times and you can weld.

Trimmer for polypropylene pipes

It is faster to remove the inner layer, because about 2 mm of foil is required to be removed. When removing the outer layer, it is necessary to remove about 2 cm.

Drill nozzle

Nozzles on a drill differ from manual strippers with a steel rod for installation in a drill, screwdriver or puncher. Serve to remove both the outer and inner reinforcing layer (the location of the knives determines the type of layer to be removed).

Scissors for cutting polypropylene pipes: types

In most cases, pipes made of polypropylene go on sale in the form of straight sections, the length of which is not more than 12 m, or in the form of coils.

Quite often, they have to be cut to the desired length in order to carry out subsequent welding.

To obtain a segment of a certain size, a special tool is used - scissors for cutting polypropylene pipes. And further welding is carried out with a relatively inexpensive device powered by the mains.

Polypropylene pipes: internal reinforcement

Advantages of working with polypropylene

A significant advantage of polypropylene pipes is their ability to withstand sub-zero temperatures without bursting. This is especially true in country houses, where gas and electricity supply can sometimes disappear. That is why the owners of cottages and dachas prefer to use polypropylene pipes in plumbing systems.

In turn, the presence of scissors for cutting polypropylene pipes allows you to instantly correct problems that arise in the home pipeline. Simply cut out the damaged part of the pipe and replace it with a new one. In this case, all work will take no more than half an hour. But in the presence of metal pipes, the replacement of the pipeline section will be carried out for at least several hours.

In general, polypropylene communications are successfully used at temperatures up to sixty degrees. If there is a need to transport liquids up to ninety-five degrees, then reinforced pipes are used, equipped with a thin aluminum shell on the outside.It is this shell that prevents sagging and softening of products.

Before welding, the outer sheath on reinforced pipes must be cleaned. To do this, there is a special knife that removes the coating from aluminum exactly to the depth of welding.

Today, some enterprises have begun to produce products, the reinforcement of which is made from the inside. In this case, pre-cleaning is not required for welding.

Features of cutting polypropylene pipes

- Cutting can be done with only one hand, without requiring its maximum tension.

- On the blade of scissors, as a rule, there is a gear rack. It is due to its presence that the work of cutting polypropylene pipes is quite simple.

If you need to get a high quality cut without damaging the pipe, you can not use cheap Chinese scissors. In addition, these products are able to withstand only a couple of cutting cycles. After that, they fall into disrepair.

Types of scissors for cutting polypropylene pipes

Precision scissors option

The following types of scissors work with polypropylene pipes:

- Precision. They are equipped with a ratchet mechanism and are designed to work with pipes whose diameter is from three to forty-two millimeters. The blade in these scissors is equipped with a gear rack, so you don’t need to make a lot of effort to cut. It is convenient that you can work with precision scissors with only one hand.

- Roller pipe cutter. These are specific scissors, in which the pipe moves on guide rollers, and at the same time, another blade feeds the cutting roller under pressure to the cut point. Of the advantages - the perfect cut quality. Among the shortcomings - low speed.

- Cordless pipe cutter.Equipped with an electric motor, due to which the speed of work is very high: one operation can be completed in 4-7 seconds.

Roller pipe cutter

Varieties of scissors for cutting polypropylene pipes

PP pipes are sold in the form of even sections up to 12 meters, as well as in bays. Naturally, in the process of laying pipes, quite often there is a need for cutting and welding them.

Even though the polymer structure is quite soft, it is not easy to damage it. Cutting polypropylene pipes can be called a difficult process, especially considering that the cut must be extremely even. Otherwise, at the stage of pipe joining, it will be necessary to spend a lot of unforeseen time on aligning the joints. Since the pipeline is laid end-to-end, any, even the smallest deviation, will cause a poor result. Poor tightness, which is no secret to anyone, will cause the pipeline to burst.

When buying scissors for polypropylene pipes, each person wants to choose both a high-quality and inexpensive product. In this case, it should be understood that if you have plans for a simple repair, during which you will lay only a few segments of the pipeline, there will be enough scissors at the lowest price. They will be equipped with a blade made of cheap steel grades, therefore, in comparison with more expensive counterparts, their quality will be much lower, respectively, they will become dull faster. But is it worth it to overpay if you are going to use the tool for cutting polypropylene pipes several times?

If you plan to engage in the installation of plastic pipes very often, then in this case you simply cannot do without a high-quality tool (in more detail: “What tool is needed for polypropylene pipes and how to use it during installation”).

On sale you can find several varieties of scissors for propylene pipes.

There are precision scissors for polymer pipes, which are equipped with a ratchet. They have a simple design and are easy to use. Along with sufficient reliability, their price is at an average level and, as a rule, does not exceed $20. Additionally, the price can be influenced by the sections with which a particular product model allows you to work. Usually, with sections up to 42 mm, scissors will be cheaper. But if you plan to cut 63-75 mm pipes, you will have to pay a good extra for such a model.

You can purchase automatic scissors that are shaped like a gun. We can say that they are somewhat similar to the previous version. And even despite the fact that this kind of knife for plastic pipes costs much more, they are often bought by home craftsmen, since such a tool allows you to cut pipes of any section. Automatic scissors are ideal in places where pipes are located close to the wall. When cutting a pipe with this tool in a hard-to-reach place, you will need to apply less force with a brush.

Roller type pipe cutters. They are also easy to use. In inexpensive models, the movement of the knife for cutting plastic pipes is carried out by a threaded drive. The pipe is fed by rollers placed on a C-shaped arc, which in turn is mounted opposite the blade. For more expensive models, the mechanism is made according to the ratchet type.

Electric pipe cutter. The name implies that the tool is equipped with an electric drive - it has an advanced design of manual elements for cutting pipes. The only difference is that in this case the scissors do not work from the force applied by the operator's muscles, but from the electric motor. In order for the knife for cutting polypropylene pipes to do its job, you need to fix the pipe in the mechanism of the unit, and press the "Start" button. Now we wait until the blades cut the pipe - the result is an even cut. It does not require a lot of effort.

The disadvantage of an electric pipe cutter is that the device is not capable of operating pipes with a cross section of more than 42 mm, because the fasteners present do not allow this due to their size.