- Design features

- Varieties of scissors

- Precision scissors

- Roller pipe cutter

- cordless scissors

- Types of scissors

- Selection Tips

- The nuances of the work

- Rechargeable

- Results

- Rules for use and care

- Operating principle

- How to choose?

- 1 RIDGID P-TEC 5000 40868

- Kinds

- Equipment service

- Conclusions and useful video on the topic

Design features

Structurally, pipe cutters differ in the type of cutting unit:

- rotary or rotary;

- with ratchet mechanism;

- telescopic;

- chain;

- with ratchet mechanism;

- incisive;

- roller.

The latter are most often used for cutting steel pipes. There can be several cutting rollers - up to three. In addition, the design also provides for guide rollers that hold the workpiece in the desired position. The more rollers, the larger diameter pipe the pipe cutter can cut.

Roller pipe cutter

Single-roller models cope with diameters of 15-50 mm, for three-roller models this range expands to 100 mm.

The cutting pipe cutter is a clip with cutters fixed in it - one or two. The movement of the working unit occurs under the influence of a threaded rod.

The action of chain pipe cutters consists in gradually tightening a chain equipped with cutting rollers around the pipe.

Varieties of scissors

Below we consider the types of cutting device.

Precision scissors

This type of tool is equipped with blades and a ratchet mechanism. The blades have serrated blades. These scissors are used to cut the pipe into small pieces with diameters from 3 mm to 4.2 cm. This is the simplest product, which is very convenient to handle.

In order to cut polypropylene pipes with such scissors, you do not have to make any effort. However, this choice also has its drawbacks.

Roller pipe cutter

This device is of two types. The first is telescopic, the second is equipped with a ratchet mechanism. In order to cut HDPE plastic pipes with such scissors, you need to drive along them with a special roller. It is possible to cut pipes of different diameters, including large ones, 50-75 mm. The positive side of this device is that it allows you to create absolutely smooth cut edges, but the execution speed will be low.

In telescopic versions of the device, cutting is provided by rotating the cutting edge around the polypropylene pipe.

cordless scissors

Cordless scissors are automatic, they are professional and equipped with a small electric motor.

With such scissors, you can cut the pipe very quickly (literally in 5 seconds). As you may have guessed, the advantage of choosing such a device is a very high speed. But, like all tools, it also has its downsides.

Types of scissors

There are the following types of the presented tool, which can be:

- precision;

- roller;

- battery (automatic).

Precision scissors for cutting polypropylene pipes are equipped with a special ratchet mechanism and blades, which are equipped with a toothed plate.

They are used for dividing into segments of pipes with a diameter of 3-42 mm. This product is very comfortable and easy to handle.

Cutting is done without the application of strong physical effort. The disadvantage lies in the fact that when performing work, the blade quite often shifts to the side and the cut edge does not always turn out to be sufficiently even.

Roller pipe cutter can be telescopic and ratchet. Trimming of polypropylene pipes is carried out in the process of rolling rollers over them.

The advantage of this tool lies in the fact that it forms perfectly smooth cut edges, and the disadvantage is the relatively slow speed of work.

Scissors for cutting polypropylene pipes

In telescopic modifications of the device, the cutting edge can rotate around the pipe, due to which cutting is ensured.

Automatic (battery) scissors are equipped with a compact electric motor.

This ensures the shortest cut time - only 5-7 seconds. As you might guess, the leading advantage of such a tool lies in the high speed of the work performed.

And the disadvantage lies in the fact that such a pipe cutter can be used to cut pipes with a maximum diameter not exceeding 40 mm.

Selection Tips

When choosing such a tool, it is important to ensure that the proposed price is fully consistent with the quality. If the product will be periodically used for minor repairs, then it would be most rational to buy scissors with an insufficiently high price.

If the product will be periodically used for minor repairs, then it would be most rational to buy scissors with an insufficiently high price.

But it should also be taken into account that the cheapest analogues are characterized by a reduced quality of the materials used to make the blades.

Choosing automatic scissors, you can be sure that they will allow you to cut those pipes that have a large diameter.

Precision scissors are distinguished by their versatility, coupled with an affordable price. This product has a high degree of reliability and very high user-friendliness.

The price may fluctuate depending on the diameter of the pipes to be cut. Most tools for work use the muscle power of the operator, and with a large amount of work, chronic fatigue can appear.

In the case of serial work, it is recommended to use a battery pipe cutter, and a guillotine cutter is suitable for pipes with a large diameter.

The nuances of the work

For convenience, the blade of the tool is equipped with a special rail, with small teeth on it.

This allows you to apply a minimum amount of effort during the work. The scissors are designed in such a way that they can be held with only one hand, and the second will be free to perform other actions.

When installing the pipeline manually out of habit, you can quickly get tired - electric scissors for cutting metal-plastic pipes will come to the rescue.

When choosing a tool, it is best to give preference to well-known manufacturers - lower-priced Chinese counterparts can fail pretty soon.

This is how a polypropylene pipe is cut

If during the process of facing the pipe section was damaged, then it should be removed, otherwise, the docking with the fitting will not have the necessary tightness. Slicing is performed with an orientation to the following algorithm:

- With the help of a marker, the surface of the pipe is marked with a mark in the place where cutting will subsequently be performed.

- Above the mark is the base blade. In order to more conveniently fix the tool, you can initially make a shallow cut in the material.

- Without pressing hard on the handles, it is necessary to insert into the pipe with a high degree of accuracy and to trim, applying effort for this.

- When performing work, sharp brush movements should be avoided, otherwise the scissors may accidentally slip off the guide rail and the whole process will have to be started again.

- The base blade must be positioned accurately along the surface of the pipe.

Thus, using this tool and following the instructions, you can easily cut off the desired section of the metal-plastic pipe.

Rechargeable

One of the youngest types of pipe cutters for plastic pipes is cordless. Just a few years ago, it began to be widely implemented. In fact, this is the same analog pipe cutter, but with an electric motor. A tiny motor drives the entire mechanism, thereby significantly increasing the cutting speed. On average, it takes up to 7 seconds to cut - this is its main advantage, in comparison with its analogue.However, with this dignity, this type has a nuance: the diameter of the pipes cannot exceed 42 mm. Pipes of larger diameter, alas, are cut by other devices. There are, of course, electric pipe cutters, but many of them are quite inconvenient for domestic use and are used only on an industrial scale.

The video shows in more detail how to use the pipe cutter. As for the choice, it depends on the intensity of use. If a pipe cutter is needed for one-time work and is unlikely to be needed in the future, you can choose the simplest options, the same scissors or rollers

However, if the tool will be used frequently or it is important that there is high-quality inventory at home, then, of course, the bowl of choice will lean towards the battery

Also, when choosing, it is advisable to pay attention to the handle of the tool. It should be massive and rubberized, this will allow you to comfortably hold it in your hands.

The rubberized nozzle will not allow the tool to slide during operation, which, of course, will affect the quality of the cut.

Results

To make the final choice, you should consider all of the above recommendations. Then the funds spent will really benefit, and the selected option will serve as long as necessary, performing all the necessary tasks.

Rules for use and care

Like any tool, the pipe cutter will function normally and for a long time if the user follows the rules for its use:

The tool must not be overloaded. It should work under the load for which it is designed.

The workpiece must be clamped securely in the pipe cutter, but without excessive rigidity.

The constriction threatens with a curvature of the line.

The sharpness of the cutting elements should be periodically checked, if necessary, they should be replaced immediately.

Pay special attention to the control of the condition of the electric cords and plugs of the pipe cutter. If damaged, repair or replace.

The tool must be stored in a warm and dry place.

Number of blocks: 30 | Total number of characters: 32100

Number of donors used: 7

Information for each donor:

Operating principle

According to the principle of operation, pipe cutters are classified as follows:

- manual;

- electrical;

- with pneumatic drive;

- with hydraulic drive.

Manual pipe cutters can be attributed to household tools. They are inexpensive, easy to use, so no special skills are required from the worker.

Electric ones are highly efficient, do not require excessive physical effort. They cost more than manual ones, so it makes sense to buy them only in case of large-scale work.

Manual pipe cutters

Use cutting fluids to extend the life of your electric pipe cutter and produce a high quality cut.

How to choose?

When choosing the right tool for cutting polypropylene pipes, it is necessary to evaluate the technical characteristics and functionality of each option. Devices may differ in some design features, price and quality.

When inspecting a tool in a store, you should pay attention to its main parameters.

Blade quality. It is desirable that this element be made of stainless steel

The value of the angle of sharpening of the part, which should be 30 degrees, is also important.

Device handle. It should fit comfortably in your hand.

Otherwise, it will be quite difficult to perform high-quality cutting of pipes. It is most convenient to work with a tool whose handles are rubberized.

Reliability of a support for pipes. This element should be stable and fairly wide. Otherwise, the pipe will be poorly fixed between the support and the blade rail, which will lead to an uneven section.

It is desirable that the device be equipped with an automatic retraction of the support and the blade rail so that these elements return to the open position after cutting.

Another important factor influencing the choice of scissors is the diameter of the pipes. By size and some characteristics, polypropylene pipes, which require special scissors to work with, can be divided into several types.

- PN 10 - such products are designed for cold water systems, as well as for underfloor heating. Such pipes can withstand the effects of coolant temperatures within 45 degrees and a pressure of not more than 1 MPa.

- PN 16 - this modification is used for laying centralized heating. The pressure inside the pipe should not be too high.

- PN 20 - this type of pipe has a universal purpose. The product can be used for laying not only cold water supply systems, but also hot ones. Products can withstand internal exposure to temperatures not exceeding 80 degrees.

- Pipes PN 25 are products coated with aluminum foil. This material makes it possible for pipes to withstand high temperatures (95 degrees) and a pressure of about 2.5 MPa.

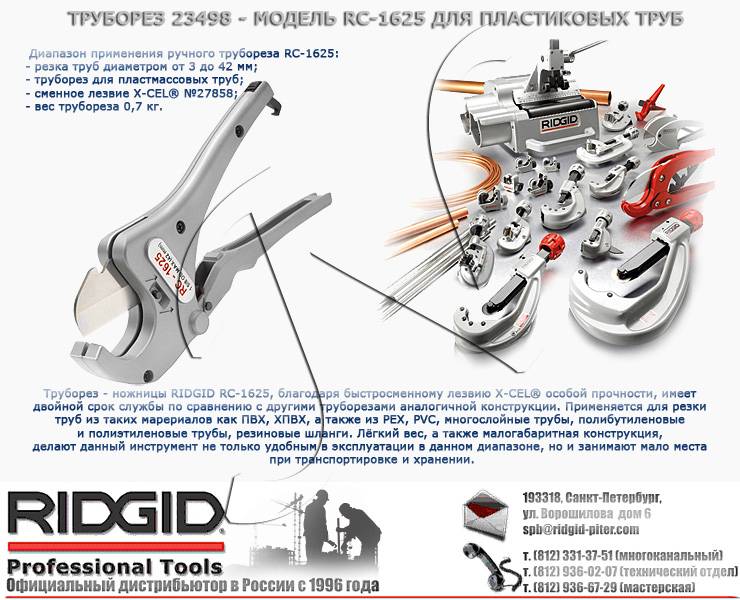

1 RIDGID P-TEC 5000 40868

A rotary pipe cutter is a tool that manufacturers still manage to modify by adding new features to it.For example, this model can not only cut plastic pipes, but also process the edge at the same time, making it inclined and convenient for further connection.

The cutting element here is a blade, not a disk, as in most models. It is installed in a special holder, made at an angle. By rotating the tool around the fixed pipe, it cuts and chamfers at the same time, a very handy feature that greatly speeds up the installation process. It should also be noted convenient and reliable blade supply mechanism. It is controlled by a button located on the handle. At the moment of turning, the operator gets the opportunity to gradually increase the pressure and, in a few turns, completely dissolve even the pipe with the thickest wall. And finally - compactness. The tool is very small and fits easily into a pocket.

The advantage is not the most important, but it has a place to be

Attention! The above information is not a buying guide. For any advice, you should contact the experts!

Kinds

Also, given the peculiarity of the cutting elements, the following types of tools are distinguished:

The pipe cutter is capable of performing the production task of threading a pipe with a diameter of up to 100 millimeters.

The chain pipe cutter is based on rotary mechanisms and a chain, with their help, cast-iron pipes are cut, as well as concrete and ceramic elements of construction activities.

The next type is a roller pipe cutter. A distinctive feature of the tool is the presence of cutting rollers in an amount from one to three.

The telescopic unit has a complete set that allows you to exert maximum pressure on the material prepared for cutting.

The ratchet tool is equipped with a simple device consisting of two handles and a blade. It is intended for work with material of not big thickness.

Equipment service

The life of the equipment depends not only on strict observance of the rules for working with it, but also on proper maintenance and care. Following simple operations, you can greatly facilitate your work and secure your activities:

- Before using the equipment for the first time, please read the instruction manual carefully. Remember that ignorance of simple rules can lead to damage to the workpiece or the device itself, as well as to injury. Working with a slightly damaged tool can cause it to wear out faster.

- After purchase or long-term downtime of the equipment, it is necessary to carefully inspect it for external damage. The possibility of the correct functioning of the tool is best checked on a test piece.

- Be sure to regularly thoroughly lubricate all moving parts of the tool, especially the cutter wheel and feed screw. This operation will not only extend the life of the tool, but also make it easier for the operator.

- Regular cleaning of all elements of the device at the end of work should be carried out using a special wire brush coated with a cleaning agent.

- Before work, you need to check the connection of all parts of the equipment and the quality sharpening of the cutting tool.

- It is necessary to store the equipment in a dry and warm place, preferably at home, as direct sunlight, temperature changes and high humidity can damage the components of the mechanism.

Conclusions and useful video on the topic

How a Clamp Pipe Cutter Works: A detailed video tutorial on how to use a manual pipe cutter equipped with a clamp latch. The reliable unit has good power and copes with parts with a diameter of 32 to 365 mm.

Cutting steel pipes with a roller pipe cutter: the video clearly shows the process of cutting steel pipe material with a diameter of 3 to 150 mm with a roller assembly.

The manual model copes well with one-time work, and the electric drive is suitable for larger repair and installation activities.

A split pipe cutter for steel at work: how a split cutter works with steel pipes is clearly seen in this video. The device has a useful feature that allows you to partially cut the pipeline even without access to the end of the system.

The device is equipped with an electric or pneumatic drive and provides maximum cutting accuracy while using the minimum space around the pipe for work.

Knowing all the above nuances, it will not be difficult to choose the optimal pipe cutter model. For additional advice before buying, you should contact the store staff. They will talk in detail about the proposed models and describe all the pros and cons of products from various brands.

Looking for a pipe cutter for home use? Or do you have experience with similar devices? Share it with our readers.Please tell us which model you chose, are you satisfied with your purchase? Write comments below the article.