- General terms of use

- Pros and cons of electric models

- Pipe cutter manufacturers

- Rules for operating a pipe cutter

- How to choose a pipe cutter

- Selection principles

- Advantages and disadvantages

- Manufacturers and cost

- Which pipe cutter to choose?

- Manual cutting technology with a pipe cutter

- Principle of operation and device

- 3 ZUBR EXPERT 23705-42

- Preparatory stage

- 4 KALDE GM Cobra

- What is the best way to cut plastic pipes?

- Cutting methods

General terms of use

Before testing a new cutting tool in practice, you should read the instructions attached to the pipe cutter, the general provisions of which boil down to the following rules:

Before using the pipe cutter, open the latch, and behind it the tool itself. The pipe cutter must be installed on the pipe, in the place of the intended cut. If there is a latch, be sure to close it so that the rollers do not deteriorate.

Align the rollers as soon as the guides touch each other. Turn the existing screw until the cutting rollers touch the pipe.

Tighten the screw a little more, about 180 degrees. If you have to use too much cutting force later on, loosen the screw a little.

Ready! Now you can start cutting.To do this, you need to swing the handle about 130 degrees, turning the handle 180 degrees after every third swing. Repeat the last 2 steps until you cut the pipe.

Having understood how to use a pipe cutter, it is advisable to learn how to care for the tool. Always use extremely sharp rollers, as blunt ones can lead to unpleasant cut deformations.

Slowly, turning the handle counterclockwise, open the sled at least halfway in order to proceed with the replacement. Check which way the unnecessary roller mount is knocked out, and then remove it. Replace the used roller with a new one. Insert the roller and its pin back into place.

When using a pipe cutter, hold it directly to the axis of the pipe being cut, this will significantly reduce the load, and your tool will last much longer.

Do not install different rollers in relation to each other, they must be of the same size and quality, otherwise they will all simply break.

Do not forget to remove rust before work, this will significantly reduce the load on the working body. Thoroughly lubricate cutting rollers before use and all tools before storage.

Pros and cons of electric models

Many professional craftsmen prefer manual pipe cutters when it comes to working with copper pipes. Meanwhile, in addition to manual models, there are more technically advanced electric devices.

In this case, the electric drive receives energy either from the built-in battery or from the network. That is, the tool does not lose its mobility properties, which is already an attractive point.

Another new addition to the copper cutter group is the electric pipe cutter.The design is quite convenient, significantly reduces the cost of the user's physical energy. For a quality result requires experience

The cordless tool is equipped with the mechanism of automatic capture of material. The range of pipe diameters available for the cordless pipe cutter is 12-28 mm. On the body of the device there are elements of illumination, which ensures the convenience of cutting in conditions of poor visibility.

An electric pipe cutter, of course, significantly reduces the physical burden of the user. All that is required for the owner of such a device is to hold the device weighing 1.5 kg in the desired position for several seconds in the cut mode. For example, the MILWAUKEE C12 model, at a working speed of 500 rpm, cuts a piece of pipe with a diameter of 12 mm in three seconds.

But the high cutting speed, and even in automatic mode, somewhat limits the quality indicators. So, the device does not allow cuts of copper pipes shorter than 12-15 mm, according to the instructions.

Such short pieces of copper pipe should not be cut with an electric pipe cutter. Failure to comply may result in tool breakage and risk injury to the user.

In the absence of experience with an electric pipe cutter, it is rarely possible to get a perfect cut due to the presence of vibrations from the engine. Finally, the working mechanism of the electric pipe cutter creates noise at a level of 70 dB (the norm for permissible noise according to SNiP is 55 dB).

Therefore, for craftsmen (especially in the field of refrigeration), manual pipe cutters look like the best tool with all the advantages of electric models.The cutter of manual use gives the master the opportunity to “feel” the course of the blade, set the optimal speed and depth of penetration into the body of the pipe.

As a result, the cut is even and of high quality, ideal for creating rolling or soldering.

Pipe cutter manufacturers

As we said above, you can make a manual pipe cutter for steel pipes with your own hands, but it's not worth it, because you can buy it in a store at a low price from the following manufacturers:

- Virax;

- Rothenberger;

- Jonnesway.

Virax is a French manufacturer of professional and semi-professional equipment for working with pipes of various materials. Among their tools, hydraulic pipe benders, roller pipe cutters, pipe clamps, bevelers, as well as gas and plumbing wrenches stand out for their quality.

Rothenberger is a German company that has been manufacturing the following tools for 60 years:

- Mounting;

- drilling rigs;

- Tool for cleaning water pipes;

- Tools and materials for working with various pipes.

The Taiwanese company Jonnesway also produces quality equipment at a low price, but it differs in its lifetime warranty on pipe cutters.

Conclusion

In conclusion, it must be said that a quality repair or laying of a pipeline is impossible without a suitable pipe cutter, because without it you will not be able to achieve accuracy and reliability, and besides, spend a lot of time and effort.

Rules for operating a pipe cutter

To keep your pipe cutter safe and sound, you must follow simple rules of operation:

- Remember to clean the cutter roller, guide rollers and feed screw after use. It is recommended to do this with a special composition, which can be purchased at a hardware store.

- Check the lubrication condition of the feed screw and guide rollers.

- Avoid rough handling of the tool, do not allow chips and dents.

- Constantly check the sharpness of the incisors, because their dullness will lead to additional stress on the device. If the cutters become dull, they must be replaced immediately.

- Do not expose the instrument to harsh weather conditions, store it in a warm and dry place.

How to choose a pipe cutter

When choosing a specific pipe cutter model, you should pay attention to what additional functions the tool is capable of performing. Some models chamfer at the same time as cutting the pipe, which greatly simplifies the subsequent installation of connecting fittings. Roller varieties of the tool often leave irregularities and roughness in place of the cut, which spoil the appearance of the product and reduce performance.

A good pipe cutter will be equipped with an additional file resembling the surface of a small file to remove such defects.

Roller varieties of the tool often leave irregularities and roughness in place of the cut, which spoil the appearance of the product and reduce performance. A good pipe cutter will be equipped with an additional bit that resembles the surface of a small file to remove such imperfections.

If the tool is purchased for everyday professional use, special attention should be paid to the ergonomics of the device. Each of the options you like should be held in your hand, preferring a more convenient model.

Selection principles

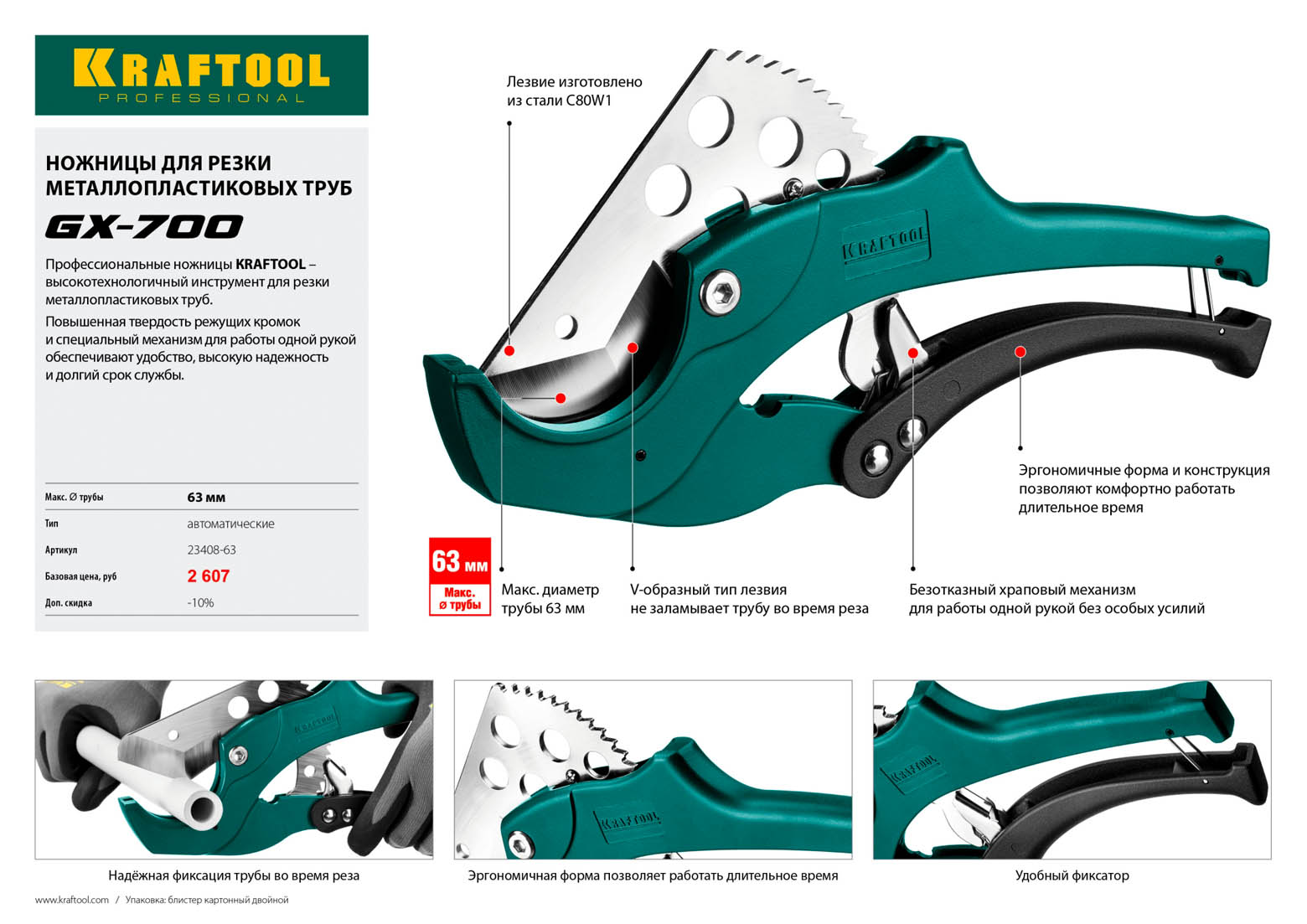

To choose scissors for cutting polypropylene pipes, you need to pay attention to a few points:

- blade material;

- tool dimensions;

- type of drive;

- availability of additional functions;

- blade dimensions.

Initially, you need to think about how often scissors will be used. If they are needed for permanent work, it is better to choose a professional tool. When choosing, you need to hold the scissors in your hands to understand how comfortable the cutter will be in the palm of your hand. If you need to cut parts of large diameter, you need to choose industrial tools.

Advantages and disadvantages

PPR cutting shears have strengths and weaknesses. Advantages:

- cuts are smooth, without burrs, plastic creases;

- before welding pipes, it is not necessary to perform additional processing of cuts;

- cutting tubes does not need to spend a lot of time;

- ease of work;

- easy to make a right angle cut.

Flaws:

- Restriction on the maximum diameter of the cut pipes.

- If manual models are used, it is necessary to expend physical effort to cut the parts, which leads to brush fatigue.

We must not forget that a dull blade can damage the tube.

Manufacturers and cost

Manufacturers of pipe cutters for polypropylene pipes:

- KRAFTOOL - the average price is 1200 rubles;

- RIDGID - 2000 rubles;

- TOPEX - 1100 rubles.

Pricing depends on several factors:

- popularity of the company;

- availability of additional functions;

- type of drive;

- the steel from which the blade is made;

- maximum allowable tube diameter for cutting.

Small pipe cutter for polypropylene

Which pipe cutter to choose?

For professional activities, it is better to purchase a pipe cutter with a ratchet mechanism for working with metal-plastic pipes, and a roller version for metal parts.

At the same time, you should not save on the tool.

It is better to choose scissors with a steel body for diameters up to 42 mm.

Their cost will be approximately 3.5 thousand rubles

You can pay attention to battery scissors with a power of about 0.75 - 1 kW, but they will cost 15 - 20 thousand rubles

As for roller options, it is advisable to buy a tool with wide rollers, because it is able to work both in manual mode and with an electric drive connected.

The main thing in professional activity is the speed of work and its quality.

For this reason, it is good if the roller pipe cutter is equipped with a special nozzle that allows you to deburr, as well as several spare rollers.

A pipe cutter for the home does not require additional functionality and the highest quality of workmanship.

Here the emphasis should be on its low cost.

A good solution would be simple scissors with plastic handles, a ratchet mechanism and a hardened steel blade. Such a tool will cost the buyer 300 - 500 rubles.

Manual cutting technology with a pipe cutter

Regardless of the technical characteristics of the pipe cutter, the sequence of actions for cutting pipes with it will look approximately the same:

- Preparatory work - you need to check whether the pipe according to its characteristics (material, diameter, wall thickness) matches the parameters of the pipe cutter, and also how realistic it is to achieve the desired goal with its help (cut at a specific angle and with a given accuracy).

- Installation of a pipe cutter on a pipe. To do this, the handle is rotated counterclockwise to expand the clamps as much as possible, then the pipe cutter is placed on the pipe at a predetermined location of the required cut, and the handle rotates clockwise until the cutting roller contacts the surface of the pipe.

Groove formation. At this stage, the cutting roller is slightly pressed into the surface of the pipe. To do this, the pipe cutter is rotated a full turn so that the roller makes a small groove in the pipe.

Cutting. After forming the groove, you need to tighten the screw by turning it 90 degrees, and then start rotating the pipe cutter itself. At the same time, it is necessary to gradually tighten the screw until it is completely cut off.

Principle of operation and device

For a long time, people used a hacksaw to cut metal pipes. The resulting cuts were uneven, installation difficult. To make quality cuts, work faster, a pipe cutter was developed. There are two principles of this tool:

- The pipes are fixed in a vice, cut to the intended size. In this case, the cutting edge of the tool rotates around the surface of the fixed part.

- The tool is fixed motionless, the pipe rotates with the help of a special machine. This principle of operation is typical for industrial models.

The device of pipe cutters depends on the type of tool.

3 ZUBR EXPERT 23705-42

The blade is the main module of the pipe cutter, on which the quality of work depends.It dulls over time, and it is very difficult to sharpen it on your own, and in some cases, like in this one, it is completely impossible. The fact is that a special grade of steel is used here. Highly alloyed, extremely durable and practically blunt. This was achieved thanks to multi-stage processing, and such a tool will last a very long time, but when the blade does become dull, it will have to be changed, and not sharpened with your own hands.

Otherwise, this is a conventional scissor-type pipe cutter that allows you to cut plastic pipes with a diameter of up to 42 millimeters inclusive. This is a rather large size, but the tool has no problems with it either. The edge does not bend or flatten. But the ergonomics clearly let us down. No plastic inserts and other convenient elements. Not even a latch. Instead, a bracket protrudes, fastening the handles in a reduced position.

Preparatory stage

First you need to collect everything you need to solve the problem.

The list of tools includes:

- calibrator;

- pipe bender;

- wrench;

- any fabric.

As you know, metal pipes include a layer of plastic and an aluminum lining. They are firmly soldered by laser welding. The frame is an aluminum tube. The core of the product is quite smooth.

However, experts still recommend cleaning the surface of the structure from possible irregularities before starting cutting.

For stripping tubular products, a coupling must be used. The process of cleaning the surface of the product takes a little time.

4 KALDE GM Cobra

In addition to quality and strength characteristics, ergonomics is very important in a pipe cutter.First, the master makes serious efforts at work. Secondly, you have to cut plastic pipes very often when installing a water supply system, and if the tool is uncomfortable, your hands will quickly get tired. We have the best option in terms of convenience and practicality. There are very thin handles, which is extremely convenient. They are covered with rubber, soft and at the same time improving the grip. The tool will not slip even from wet hands.

The working mechanism of the scissors is in plain sight, and the blade mouth opens up to 40 millimeters. There are no complaints about the quality of the product on the network. This brand has long been known in the market, and is directly related to plumbing work and tools. The company's engineers know exactly what a good pipe cutter should look like, and this model is also inexpensive. Yes, not the cheapest option, but definitely worthy of being called the best value for money.

What is the best way to cut plastic pipes?

Metal-plastic pipes, as a rule, are sold in measured lengths. Therefore, during installation, they are required to be cut to pre-calculated dimensions. And if docking, turning or branching is necessary, special fittings for metal-plastic pipes are used.

Cutting methods

There are several ways to cut metal-plastic pipes:

- knife with teeth (self-sharpening);

- hacksaw for metal;

- special scissors;

- pipe cutter.

It is easy and effortless to cut metal-plastic pipes with a hacksaw, but the process will proceed more slowly and a uniform end is not always obtained. In the absence of a hand saw for metal, a self-sharpening knife can also be used, but the aluminum layer makes it difficult to work.Also, after applying these methods, small particles of plastic remain on the edges, which can cause clogging of filters during pipeline operation.

If, during the assembly of polypropylene pipes, uneven edges melt or the molten plastic overlaps them, then high demands are made on the accuracy of cutting metal-plastic pipes. During installation, it is tightly pressed into the cuffs and uneven edges on it are unacceptable - they can cause a leak. Therefore, it is best to cut with scissors designed for this purpose.

Technology for cutting metal-plastic pipes with scissors

Such scissors are designed for cutting pipes of small diameter - up to 40 mm. The technique does not require professional knowledge and experience, it is carried out with one hand without much effort. This is facilitated by a special gear rack on their blade.

When choosing such a tool, you should not give preference to the cheapest models, since their resource will allow for only a few cutting cycles, after which the return mechanism or a more significant part will fail.

Metal-plastic pipes with a cross section of more than 40 mm are strongly recommended to be cut with a pipe cutter. They are of the following types:

- telescopic - cutting is carried out by a round roller made of tool steel;

- with a ratchet mechanism - according to the principle of operation and appearance, they resemble scissors (cutting is carried out by closing the handles of the device).

When using a ratchet tool on the pipe, it is necessary to chamfer and restore its section using a calibrator.