- Short description

- Device and characteristics

- Material

- Dimensions and weight of pipe cutters

- Design features of the pipe cutter

- What are

- Fixture dimensions

- Soldering iron for pipes which company is better to choose

- How to choose a blade for a tool?

- What to look for when choosing

- Mechanical or electrical

- How to choose a blade for a tool

- Estimated price

- Top models on the tool market

- Budget models for home use

- Professional pipe cutting equipment

- The best telescopic pipe cutters

- Rothenberger Automatik-2 70142

- Super-Ego 735 Tube Cutter Inox 735

- Kraftool 23383

- Stayer 2340-32

- Why copper plumbing?

- Peculiarities

- Top models on the tool market

- Budget models for home use

- Professional pipe cutting equipment

- Varieties and specifications

- Pros and cons of electric models

Short description

To cut such elements, you can use a hacksaw for metal. But the result is of poor quality: there is no cutting accuracy, there are numerous burrs on the end. You have to additionally align the edges, using specialized tools for this purpose. In addition, a hacksaw cannot always be used, as there is a special material that is not suitable for these procedures.Precise 90-degree cuts are achieved by using only a pipe cutter.

When carrying out perpendicular cutting by equipment, the ends of the workpieces are smooth and of high quality. Its performance indicator far exceeds the capabilities of a hacksaw. Devices are widely used in the construction of new facilities, the dismantling of obsolete heating and water supply systems, and the replacement of damaged areas. With their function, they cope "excellently".

Device and characteristics

Structurally, different types of pipe cutters differ markedly from each other, but at the same time they have only two operating principles:

Orbital cutting, when the part is fixed motionless, and the tool wraps around it and turns, due to which the cutting part moves in a circle, forming a furrow deepening with each revolution until the workpiece is divided into two parts

With this method, it is important to leave enough free space at the point of cutting along the diameter of the pipe for the movement of the tool. This principle of operation makes it possible to cut pipe material in confined spaces directly on the installed pipeline.

The pipe cutter is in a fixed position, that is, it is permanently installed, and the part itself rotates about the longitudinal axis. For these purposes, a special machine is often used.

The method is used, for example, in the mass production of pipe material, or with a large pipeline diameter.

For these purposes, a special machine is often used. The method is used, for example, in the mass production of pipe material, or with a large pipeline diameter.

From both principles of operation, it can be concluded that a pipe cutter is a kind of tool or mechanism with a body of a specific shape for fixing on a pipe or gripping it.

In most cases, the body resembles a clamp, on the opposite side of which there is a cutting element that performs two functions: directly cutting the material and pressing the body as tightly as possible to the part, resting against it from the opposite side.

At least that's what most manual pipe cutters look like for working with metal blanks.

Material

Depending on the type of pipe cutter, its body can be made of aluminum, zinc alloy, tool steel or impact-resistant plastic.

To ensure corrosion resistance, metal tools are coated with chrome or powder paint resistant to mechanical damage.

A steel pipe cutter is often assembled from parts, some of which are additionally hardened.

This is done for greater stability of rubbing or maximum loaded nodes.

At the same time, the chrome-plated tool easily tolerates high humidity, is resistant to wear, corrosion, and, in addition, has an attractive appearance.

The cutting elements of the pipe cutter are made mainly of high-speed, tool and alloy steel.

Dimensions and weight of pipe cutters

The dimensions of any pipe cutter primarily depend on its design and the maximum diameter of the pipes for which it is intended to cut.

So, for example, scissors for 42 mm products weigh an average of 300 - 500 g, and their length is 250 - 350 mm.

For electric models, the dimensions and weight additionally depend on the power of the installed engine and the mechanism for fixing pipe fragments.

In this case, the indicators are completely individual.

Design features of the pipe cutter

The tool is designed to perform cutting actions in the same way as it has a similar purpose, for example, a hacksaw.

But if the cut made with a hacksaw cannot be obtained exceptionally even, without burrs and metal filings, cutting with a pipe cutter shows a completely different result:

- neat cut edges;

- strict perpendicularity relative to the axis of the pipe;

- smooth ends of the circle;

- absence of metal filings.

The last factor in the list is of particular importance for the use of a pipe cutter in refrigeration and air conditioning technology. Small metal filings that get inside the refrigeration system contribute to the rapid wear of equipment.

For all the time of using copper pipes, many designs of pipe cutters have been invented for this type of material. But in reality, no more than five types are used in practice.

If the pipes are installed in a plumbing system (for example, a copper plumbing), the presence of metal filings inside the plumbing is a risk of congestion during operation.

Working with a tool for cutting pipes is characterized by low labor costs in time. A locksmith (plumbing, mechanic) requires relatively little physical effort.

Products, as a rule, small-sized, having small weight, are placed in a working case. In general, devices produced in different designs look like convenient and practical devices.

Copper pipe cutters are very actively in demand and are used in working with climate technology. Small-sized pipe cutter designs are considered especially popular in this area.

What are

The best manufacturers produce popular models of the following types:

- Manual. Needed for do-it-yourself repairs at home. Can handle a small amount of work. Differ in compactness, ease, noiselessness, mobility.

- Electrical. They work with an electric motor. Performance is essential. Used to perform a large amount of work in a limited period of time. Requires a power source, which limits the range of its capabilities. Rechargeable models are independent of electricity. The noise level is superior to similar products.

- Hydraulic. The main feature is high power. The work uses hydraulic fluid, so the models are heavy and have limited mobility. In most cases, stationary devices are produced, but mobile options can also be found on store shelves. One of the varieties is electro-hydraulic devices. Operate in tandem with an electric drive.

- Pneumatic. They are powered by compressed air pumped by a compressor unit. Efficient device with low noise level.

Tools differ in the principle of operation, and therefore they are divided into the following types:

- Roller. They are used for fixed products in a limited space. The cutting element is rollers, the number of which varies from one to four. Single rollers are designed for products with a diameter of up to 50 mm, four rollers can cope with a diameter of up to 100 mm.

- Guillotine. The main difference is to ensure uniform blade pressure over the entire cross-sectional area. The main purpose is for polypropylene structures, as it guarantees the absence of deformation of the product during the cutting process.Popular models are available with lever and screw feed.

- Incisal. The main task is to cut thick-walled or thin-walled polymer and metal pipes. As a cutting part there is a rotating disk.

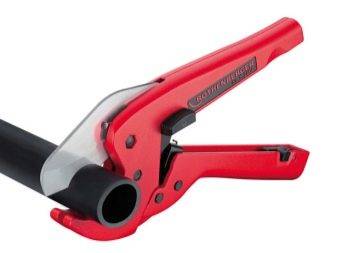

- Scissors. Scissor pipe cutters are used for reinforced plastic and plastic structures. Visually resemble scissors for metal. A distinctive feature is the presence of sponges with an adapted cylindrical profile. A blade is used as a cutting element - a sharpened blade. It is not recommended to use when working with thin-walled and metal products.

- Telescopic. Roller type. Also called universal. In addition to the cutting rollers, there are guides and a carriage, which makes it possible to work with products of various sizes. The possibility of adjustment allows the tool to be used for stainless corrugated products. The best manufacturers have launched the production of telescopic models with a built-in deburrer.

- Ratchet. A subspecies of a scissor tool. The principle of operation is the closing of several handles. Thanks to special gear racks, after the end of the cut, the blade returns to its original position.

- Orbital. They are floor or desktop electric machines on which workpieces are fixed by means of clamping jaws. They work with products made of non-ferrous and ferrous metals, plastic and stainless steel. Detachable and non-detachable models are available.

- Chain. Recommended for work with fragile compositions: concrete, cast iron, ceramics. The basis of the design is a chain, where the links are connected using cutting rollers, making the cutting process high-quality and uniform.

- With clamp type latch.They are distinguished by the presence of a rigid type of fixation, which is located along the entire diameter. Rollers are used as a cutting element, which can be replaced if necessary. This made it possible to increase the service life declared by the manufacturer. The adjustable handle makes it possible to use the unit in hard-to-reach places. Scope of use - cutting pipes with large dimensions and thick walls.

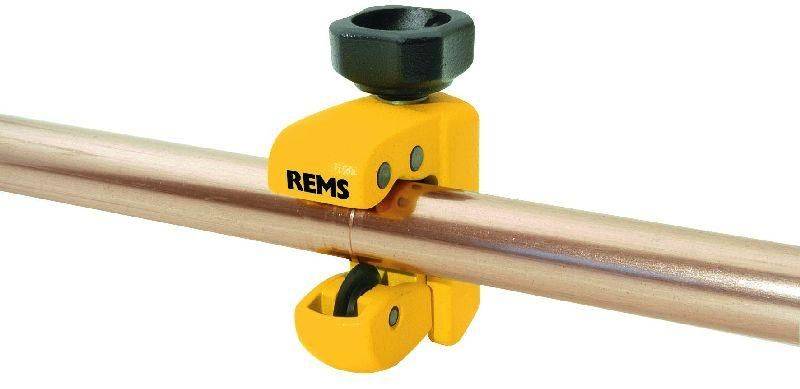

- C-shaped minipipe cutters. The cutting part is disks. Able to work in confined spaces. Differs in ease, convenient form, compactness. Able to make a cut in any hard-to-reach place.

Fixture dimensions

The weight and size of the selected device depend on where the tool will be used and what maximum diameter of the elements will have to be cut. Scissors for 42 mm products have an average weight of 300 to 500 grams, their length is from 250 to 350 mm. As for electrical devices, their mass and dimensions depend on the engine and the mechanisms for fixing product fragments.

After reviewing the data given in the product passport, the buyer can identify information regarding the minimum and maximum diameter of structures that the selected unit is able to handle. The pre-installed ratchet mechanism will help to cope with thin copper walls, however, the diameter of the working raw material should not exceed 42 mm. Electric and pneumatic models work with a diameter of up to 1500 mm, roller - 50 - 100 mm, cutting - up to 100 mm.

Soldering iron for pipes which company is better to choose

To buy a soldering iron for polypropylene and other types of pipes, you need to study the market of manufacturers, their experience, customer confidence, prevalence. It makes no sense to choose devices about "no-names", since, most likely, they will fail shortly after purchase. Any company on the list has a large staff with a multi-stage security check algorithm. Therefore, their products have been in demand for many years and continue to gain popularity. List of companies that have proven themselves to produce quality products:

- Candan is a Turkish company based in Istanbul and has been operating since 1997. Their leaders are sure that in order to reach a high level, it is necessary to have a one-sided orientation. Therefore, in their assortment there is nothing but thermal welding machines and their service elements.

- Wester is a group of companies "Impulse", formed in 1995. It includes production facilities in Russia, Italy, USA, Germany, Switzerland and other European countries. Their products are in great demand, so the authorities strictly monitor the condition of the premises so that they can withstand round-the-clock loads.

- Storm! The Russian company entered the market in 2003. During this time, the founders managed to expand the range by more than 1000 items. They are aimed at household needs for houses and adjacent plots. The brand's priority is to reduce costs while maintaining quality standards.

- Patriot - originates in 1973 in the United States. Initially, the brand was designed for the production of garden equipment, but today their production has expanded, enabling the development of household tools.

- Elitech is a Russian company that began its development in 2008.The main production factories are located in China and China. And individual elements are purchased from Italians, Japanese. Such a geographical spread confirms the serious intentions of engineers to create good tools.

- Dytron is a Czech brand that has been on the market for over 25 years. During this time, they have become leaders in equipment for the installation and connection of pipes from various materials.

- Nowatech has been based in Poland since 1997, where it designs and sells products for welding polymer pipelines. For the convenience of their customers, they made it possible to rent equipment for review. And for any problems, their technologists will consult.

How to choose a blade for a tool?

For steel pipe cutters, some specific features are relevant, in particular, regarding the working blades of the tool. For a high-quality cut, they must have a hardness that is 15 ... 20 HRC higher than the hardness of the processed pipe material.

This parameter can be determined by performing the so-called "spark test". It will reveal the approximate percentage of carbon and will make it possible to identify molybdenum, tungsten and manganese. In this way, it will become clear what the initial hardness is and what kind of steel grade was used to make the pipe.

If during repair and installation work it is necessary to cut both alloyed and unalloyed steel pipe material, it is advisable to purchase a set of cutting elements suitable for processing metal of different strength and quality

To carry out the test, the end part of the part is processed on an emery grinder and the spark generated in the process is carefully examined:

- a more continuous sparkling beam of light yellow color means low-carbon unalloyed steel;

- the medium-carbon composition is indicated by the same color, but more branched beam with a certain number of bright flashes;

- steel of standard quality gives a thin spark flow with short branches and an almost complete absence of flashes;

- alloyed steel is characterized by increased strength and does not show a tendency to brittle fracture. A stream of sparks shines with a thick and rich yellow color, and instead of light flashes, elongated shiny arrows are observed.

Having detailed information about the quality of the steel from which the pipe to be processed is made, it will be easy and quick to select the right equipment for cutting.

What to look for when choosing

The selection of the most suitable model is determined by the following factors:

- scope of future work.

- Categories and standard sizes of pipe products.

- The quality of the tool and the convenience of working with it.

- Buyer financial capacity.

For the installation of a home plumbing network or heating system, scissors with a ratchet rail will suffice. For laying external and internal sewerage, a chain or roller pipe cutter is the best choice. When finances allow, you can purchase a device with a chamfering function for laying polypropylene bends.

Mechanical or electrical

The choice of a unit from these categories is largely determined by the financial capabilities of the buyer. Electrical appliances are much more productive, but they are much more expensive.

If the amount of work is limited to a one-time installation of a home network, it makes no sense to overpay for an electric drive.

How to choose a blade for a tool

The performance of the device largely depends on the quality of the cutting element. Cutters, rollers and blades lose their sharpness over time

Therefore, it is important to choose a reliable working edge.

The best blade material is stainless steel. The sharpening angle should be 30°. Should be considered material when choosing blade size. So, for cutting PVC pipes, rollers with a blade height of 3.5, 7, 4.5, 10.5 and 12.5 mm are selected.

Estimated price

The cost of scissors - the simplest hand-held devices for mass use - starts from 300-400 rubles. More efficient roller pipe cutters cost from 1,500–3,000 rubles. The price of a professional tool starts at 3.5 thousand rubles.

Top models on the tool market

Among the manufacturers of cutting tools on the Russian market, such companies as RIDGIT, REED, Stayer, Gerat, Virax, REMS, Rotenberger, Zubr have managed to establish themselves. Let's take a quick look at their products.

Budget models for home use

Stayer pipe cutter for cutting plastic pipes with a diameter of 42 mm. The ratchet rail provides the possibility of manipulation with one hand. The price is 346 rubles.

Telescopic pipe cutter from the German brand Gerat. The device allows you to comfortably work with parts of different sections up to 63 mm.

Professional pipe cutting equipment

The telescopic pipe cutter of the Rotenberger brand is designed for cutting multilayer bends with a diameter of 35–42 mm. Able to work in narrow spaces. Equipped with a built-in deburrer.

One-handed cutting tool - RIDGIT PC 1375 ML. One of the most successful models of a famous brand "Rigit". The device cuts pipes with a cross section of up to 42 mm in just seconds. The price is 3600 rubles.

The pride of the American company REED is rotary or rotary pipe cutters used for cold cutting of bends in any conditions, including emergency situations.

Manual guillotine Virax, manufactured for straight cutting of PE pipes up to 225 mm. The cost is over 90 thousand rubles.

The best telescopic pipe cutters

Similar models are made in the form of a bracket with a cutting roller. On the axis there is a carriage with guides, which moves when the screw rotates and clamps the pipe. These cutters are compact and do not require much effort to operate.

Rothenberger Automatik-2 70142

5

★★★★★

editorial score

97%

buyers recommend this product

The hollow handle design allows the owner to store a spare cutting blade, making it easy to quickly access to replace it. The ratchet with automatic spring retraction guarantees convenient adjustment, which makes it easier to work with pipes of various sizes with a diameter of up to 127 mm.

The tool is made of aluminum alloy, is not afraid of sharp blows and corrosion. The weight of the model is 630 g. The protective coating based on epoxy resin increases the wear resistance of the case and helps it retain its original appearance for a long time.

Advantages:

- Ease of use;

- quick adjustment;

- corrosion resistance;

- protective covering;

- light weight.

Flaws:

high price.

The Rothenberger Automatik-2 is recommended for cutting copper, brass and thin wall steel pipes. An excellent choice for home use or a small workshop.

Super-Ego 735 Tube Cutter Inox 735

4.9

★★★★★

editorial score

95%

buyers recommend this product

The model is equipped with an ergonomic handle with a built-in spare roller. Quick adjustment depending on the diameter of the pipe and the small dimensions of the device provide comfortable work.A special wheel is provided to adjust the grip area in the range of 6.3-35 mm.

The body is made of metal and coated with a protective paint. This guarantees the resistance of the tool to mechanical damage and wear, long-term preservation of its original appearance. The small working radius simplifies operation in the conditions of limited space.

Advantages:

- high strength;

- quick adjustment;

- compact dimensions;

- protective covering.

Flaws:

heavy for its size.

Super-Ego Tube Cutter is suitable for cutting steel, copper, plastic, brass and aluminum pipes. The tool will withstand even regular use.

Kraftool 23383

4.8

★★★★★

editorial score

87%

buyers recommend this product

The body of the model, weighing only 300 grams, is made of aluminum and covered with a protective paint to prevent minor scratches. The presence of a special knife facilitates the cleaning of the treated surface from burrs and chips.

The maximum pipe diameter is 32 mm. Adjustment of the cutting force is carried out with the help of a screw located in the upper part. The roller is made of durable steel with gradual hardening and can be quickly replaced if necessary.

Advantages:

- compact size and light weight;

- fast force adjustment;

- a protective coating that provides resistance to corrosion;

- Ease of use.

Flaws:

thin cutting element.

A Kraftool pipe cutter is worth purchasing for precise cutting of small diameter copper, brass and aluminum pipes.

Stayer 2340-32

4.7

★★★★★

editorial score

85%

buyers recommend this product

The body of the cutter is made of high-strength aluminum alloy, the cutters are made of alloy steel.This guarantees the tool resistance to rapid wear and corrosion, and the preservation of its properties for a long time.

The maximum diameter of cut pipes is 32 mm. Additional features include a built-in chamfering knife. The handle has a perforated surface and is comfortable to grip. Tool weight - 220 grams.

Advantages:

- high strength;

- compactness and low weight;

- comfortable to hold;

- quick setup.

Flaws:

thin layer coating wears off over time.

Stayer will be useful when carrying out plumbing work. Inexpensive tool for cutting non-ferrous pipes.

Why copper plumbing?

A large selection of materials for the installation of a water supply system, heat supply or air conditioning, makes it possible to choose: plastic, metal-plastic, steel, copper. Practicing plumbers are sure that the best choice is copper pipes, which are superior in their properties to other materials:

- operation of copper pipelines with different temperature conditions, from low to high;

- resistance to mechanical stress;

- inertness to aggressive environments;

- durability;

- resistance to oxidative processes;

- compatibility with interior design.

These performance characteristics - the demand for material in the construction of engineering systems for apartments, houses, cottages and offices.

Peculiarities

In the construction market, you can most often find polypropylene pipes 12 meters long. When installing a water supply system or underfloor heating, the task often arises of cutting products into shorter segments. For these purposes, a special tool is needed. The speed and ease of installation depends on convenient and high-quality cutting.

There are many types of PPR cutting devices. Specialized tools are equipped with a sharp blade, since polypropylene is a durable material. Using a poor quality tool can severely damage the pipe. In addition, an uneven cut line will negatively affect the quality of the installation.

When connecting the elements of the water supply system end-to-end, it is important to ensure that the sealing of the seams is at a high level. Otherwise, it may cause leaks.

For this reason, it is recommended to use special scissors for cutting pipes.

Instead of special tools, polypropylene pipes can be cut with a metal hacksaw. However, this method of cutting is more time-consuming and of lower quality, since roughness remains on the edges of the cut, and the line itself in most cases turns out to be uneven.

There are many modifications of tools for cutting polypropylene pipes. Each type has its own design features and technical characteristics.

The following types of devices can be distinguished:

- precision scissors;

- manual roller pipe cutter;

- ratchet device;

- battery pipe cutter;

- guillotine pipe cutter.

Precision tools have a fairly simple design. You can operate this device with one hand. Such scissors are suitable for cutting pipes with a diameter of 3 to 41.5 millimeters. The device is equipped with a blade made of alloy steel. This option is suitable for small jobs.

The roller-type pipe cutter is an arc-shaped body with a handle, equipped with rollers and a flat round blade.The rollers perform the function of rotating the pipe, and the blade is equipped with a retractable mechanism. The cost of such a model is low. However, the roller-type tool is comfortable to use and allows for smooth cuts at an angle of 90 degrees.

Ratchet tools are a more convenient modification of roller scissors. Such devices are easy to use: the support and the cutting rail with a blade make it easy to open and close them without much effort. Thanks to the wide support, the tube is securely fixed in the device. The sharp blade easily cuts through the material without allowing it to change position. You can work with such a tool with one hand, without making much physical effort.

Cordless shears are characterized by a high speed of cutting pipes. Basically, such a tool is used by craftsmen in the work on laying water supply systems. The device is equipped with a small electric motor. This allows you to quickly and effortlessly cut pipes into a large number of segments.

The guillotine pipe cutter is used for cutting large diameter pipes (from 63 to 350 millimeters). The cutting tool is equipped with a sharp Teflon-coated blade. When cutting with such a device, the edges of the obtained pipe sections are perfectly even and smooth.

Top models on the tool market

They are distinguished by high cutting speed, work without backlash and distortions.

The American "Ridgid" and "Reed", the German "Rothenberger", "REMS", the French "Virax" have proven themselves.

Budget models for home use

Best:

Polish pipe cutter for cutting copper bends Ø up to 32 mm - "TOPEX". Produces a cut without deformation of the walls. Made of durable aluminum, it is possible to replace the cutting blade. Price - 450-600 rubles.

Telescopic apparatus "Kraftul" for sections 3-32 mm, costs 879 rubles.

Budget tools can also be found among the products, Zubr, Enkor, Gerat.

Professional pipe cutting equipment

Best:

- Pipe cutter for copper pipes (up to 28 mm) RIDGID 32573 refers to a mini-tool. Equipped with a ratchet mechanism. Price from 3 419 rubles.

- Pipe cutter RIDGIT PC 1375 ML. One of the most popular models of the company. Work can be done with one hand. The device cuts pipes Ø up to 42 mm in a few seconds. Price from 3.6 thousand rubles.

- Tool - AUTOMATIC I 70030 with ratchet. Cuts channels with a section of 67 mm. It costs 9 135 rubles.

Varieties and specifications

On sale you can find several types of pipe cutters:

- Roller - simple manual pipe cutters. Designed for cutting tubes fixed in different types of clamps. Metal walls are not cut, but are pressed through by rollers that can rotate freely.

- Orbital - tools with a collapsible design. Inside, the cutters rotate in a circle, with the help of which the walls of the parts are cut. The orbital pipe cutter can be used to chamfer thick-walled tubes.

- Chain - tools that are suitable for work in any conditions. The design has no rotating elements. It is a chain of numerous disks that wraps around the part to be cut. After mechanical force, the chain squeezes the pipe. The discs cut the material.

Depending on the type of drive, several types of pipe cutters are distinguished:

- mechanical - simple models;

- pneumatic - the working process is carried out due to pneumatic cylinders;

- hydraulic - working elements move under the influence of fluid pressure;

- electric - connected to a 220 volt network or powered by batteries.

Pneumatic, hydraulic models are installed at large enterprises where pipes are mass-produced.

Orbital pipe cutter

Pros and cons of electric models

Many professional craftsmen prefer manual pipe cutters when it comes to working with copper pipes. Meanwhile, in addition to manual models, there are more technically advanced electric devices.

In this case, the electric drive receives energy either from the built-in battery or from the network. That is, the tool does not lose its mobility properties, which is already an attractive point.

Another new addition to the copper cutter group is the electric pipe cutter. The design is quite convenient, significantly reduces the cost of the user's physical energy. For a quality result requires experience

The cordless tool is equipped with the mechanism of automatic capture of material. The range of pipe diameters available for the cordless pipe cutter is 12-28 mm. On the body of the device there are elements of illumination, which ensures the convenience of cutting in conditions of poor visibility.

An electric pipe cutter, of course, significantly reduces the physical burden of the user. All that is required for the owner of such a device is to hold the device weighing 1.5 kg in the desired position for several seconds in the cut mode. For example, the MILWAUKEE C12 model, at a working speed of 500 rpm, cuts a piece of pipe with a diameter of 12 mm in three seconds.

But the high cutting speed, and even in automatic mode, somewhat limits the quality indicators. So, the device does not allow cuts of copper pipes shorter than 12-15 mm, according to the instructions.

Such short pieces of copper pipe should not be cut with an electric pipe cutter. Failure to comply may result in tool breakage and risk injury to the user.

In the absence of experience with an electric pipe cutter, it is rarely possible to get a perfect cut due to the presence of vibrations from the engine. Finally, the working mechanism of the electric pipe cutter creates noise at a level of 70 dB (the norm for permissible noise according to SNiP is 55 dB).

Therefore, for craftsmen (especially in the field of refrigeration), manual pipe cutters look like the best tool with all the advantages of electric models. The cutter of manual use gives the master the opportunity to “feel” the course of the blade, set the optimal speed and depth of penetration into the body of the pipe.

As a result, the cut is even and of high quality, ideal for creating rolling or soldering.