- The most popular options for homemade pipe benders

- Manual Lever Bender

- Structural elements of a profile pipe bender

- The procedure for bending a profile pipe on homemade machines

- Kinds

- The simplest pipe bender: what materials will be needed

- Types of pipe benders that can be made

- Roller Roll Benders

- Making a crossbow pipe bender

- Types of pipe benders on the market

- For profile pipe

- With center roller

- With break frame

- How is a pipe bender arranged?

The most popular options for homemade pipe benders

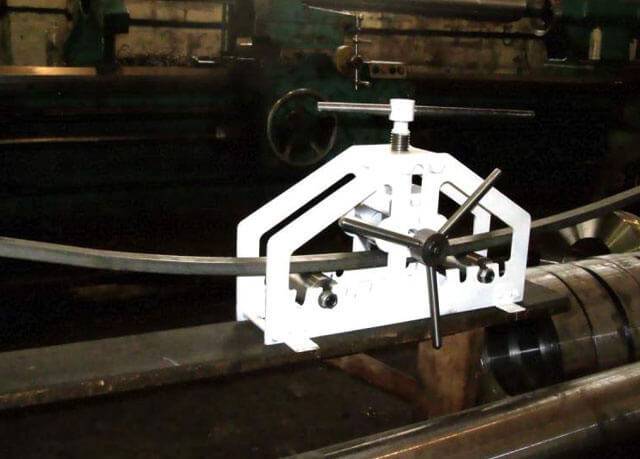

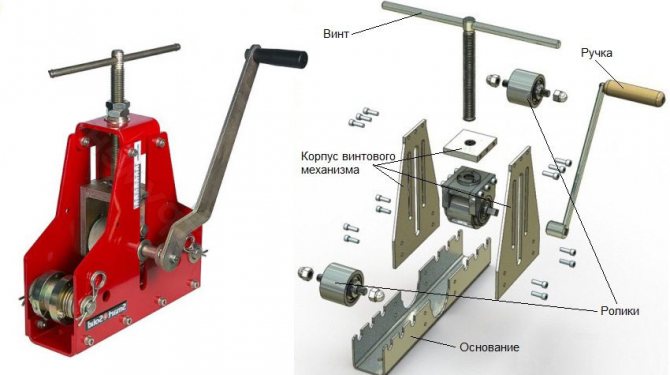

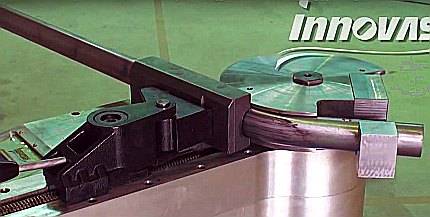

The most technologically advanced and versatile are pipe benders operating on the principle of rolling. It is these devices, often equipped with an electric drive, that are used by professionals who are constantly faced with the need to bend pipes from various materials, including stainless steel.

Homemade pipe bender option

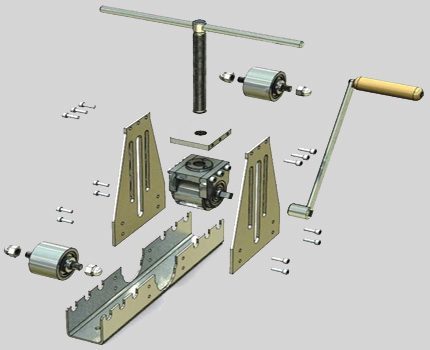

The design of such a device is based on three rotating rollers, one of which is a pressure roller. Due to the gradually increasing pressure of the pressure roller and the rolling repeated for each new position of the roller, the bending of the pipe is carried out in the most gentle way, its walls are subjected to tensile manipulations very evenly.

Do-it-yourself homemade electric pipe bender

Computer model of a pipe bender

Pipe bender computer model Clamp screw drawing

Shaft drawings

Shaft drawings Ring drawing

Pipe bender accessories

Tube Bender Accessories Assembly Process

Engine drive

Engine drive Shaft side view

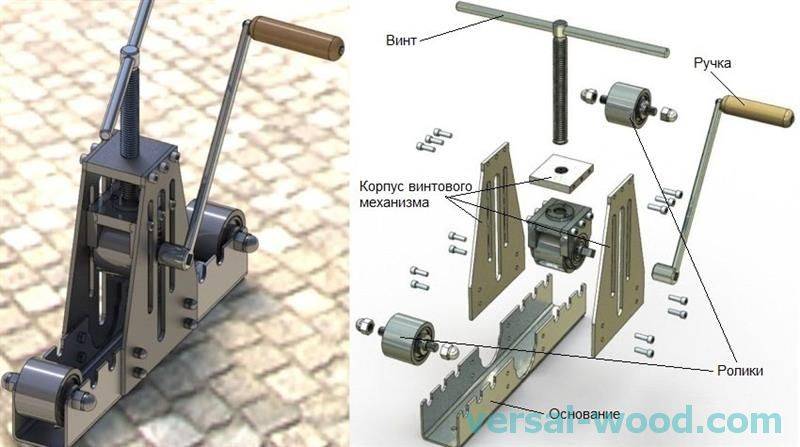

The most important thing that allows you to make such a pipe bender is to adjust the bending radius of the workpiece. There can be several design options for such a universal device: rotating thrust rollers are located on the elements of the frame structure, as well as a wheel with which the pipe is rolled; the side bearing surfaces and the base are made of sheet metal, and a screw gear is used to move the pressure roller. On devices of the second type, you can change the minimum bending radius, which is achieved by changing the position of the support rollers.

The shafts of this pipe bender allow you to comfortably work not only with round pipes, but also with profile pipes.

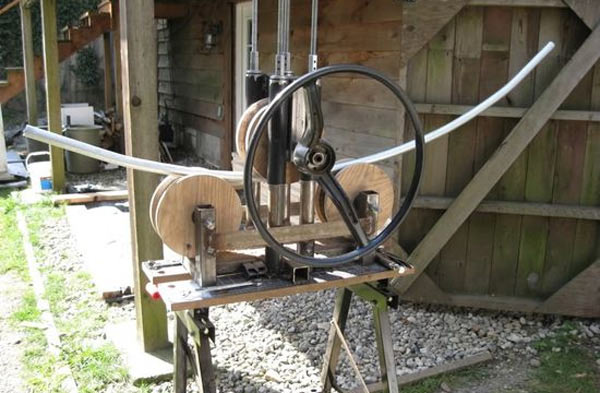

The supporting structure for such a pipe bender can be made of wood. The axes of the rollers, the rod, the fasteners and the handle for scrolling the rollers, which can also be made of wood or polymeric materials, will remain metal in it.

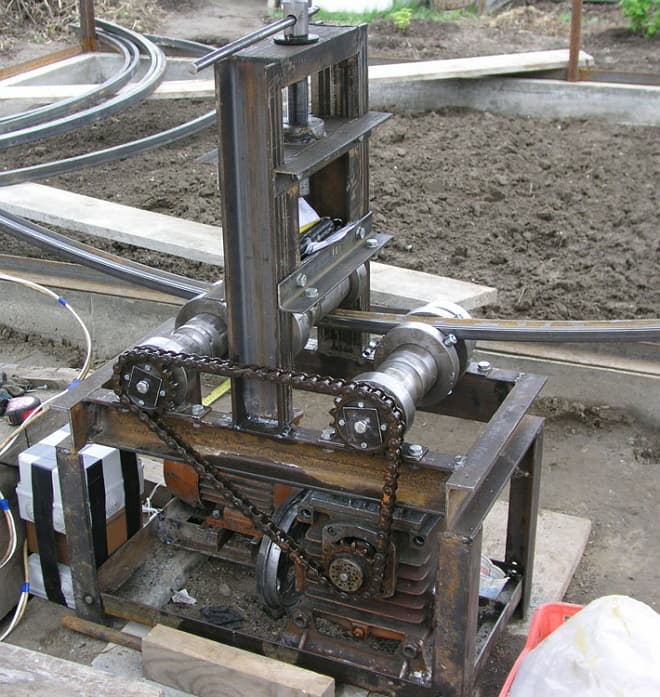

Above, we examined pipe benders in which the pulling process is ensured by the rotation of the pressure roller. There is also a category of devices in which the movement of the pipe is set by rotating the support rollers.

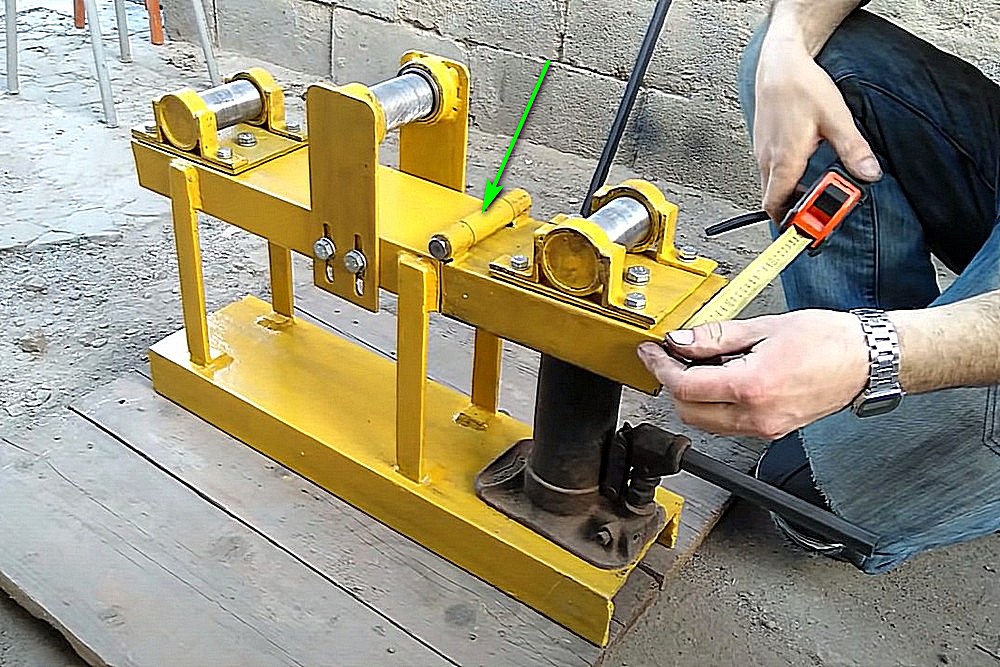

Variant with screw jack

An electric or manual pipe bender, in which rotation is transmitted to one roller, has limited capabilities. A pipe bender in which both support rollers rotate is characterized by a more complex design, since it is necessary to transmit rotation to two elements at once.

More convenient, according to many experts, is a pipe bender in which the pressure roller is located below. Some masters are of the opinion that it is much easier to control the bending of pipes on it, they are not blocked by the upper supporting structure.

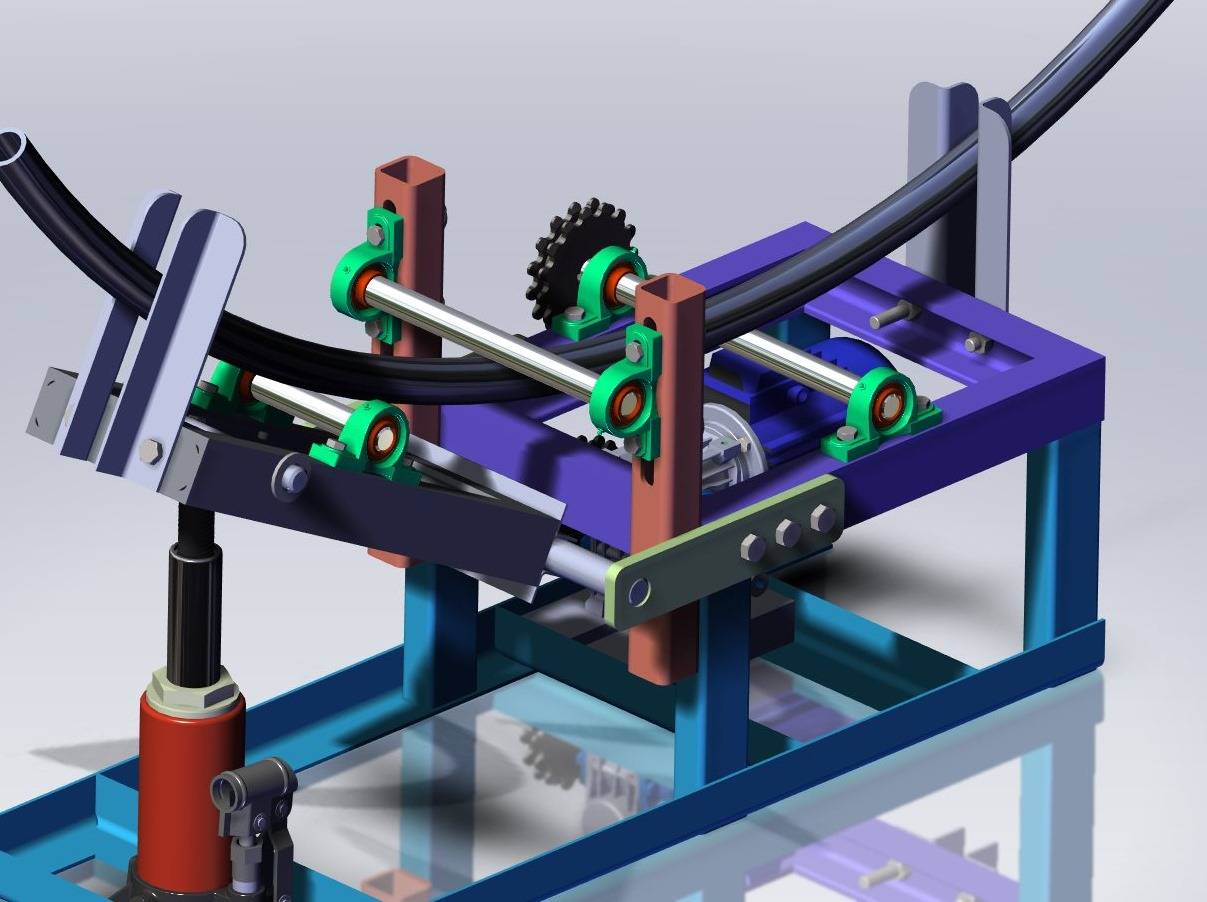

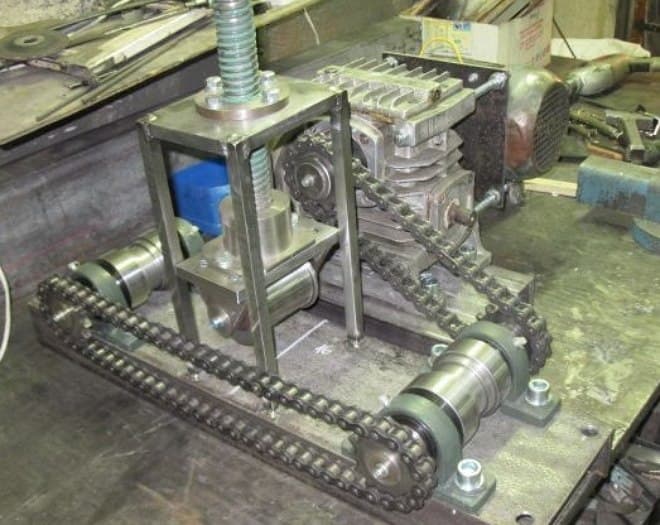

Pipe bender with electric motor and drive through two chains

Any device for bending pipes is a fairly simple device, the operation of which is based on the elementary laws of mechanics. If the need for bending stainless, metal-plastic pipes, as well as pipes made of other materials occurs infrequently, then you can limit yourself to a manual device.

Manual Lever Bender

If you do not need such a complex device, but only need to bend a small round steel pipe, then you can make a simple lever mechanism. It is designed for bending pipes with thin walls.

Watch the video for instructions on how to make.

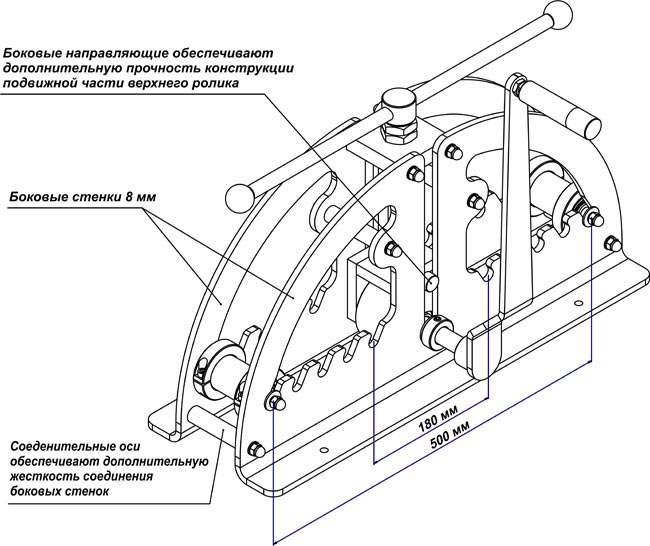

We also decided to try to assemble this pipe bender with our own hands. We need: a shaft with a round profile, a pressure roller, a metal sheet for 8 for the bed, studs, nuts.

Someone can make this device by eye, but it is better to prepare a pipe bender drawing or find a suitable option on the Internet. We decided to work according to the drawing.

Drawing of a lever pipe bender

Drawing of a lever pipe bender Drawing fork lever

Drawing fork lever

Let's start making:

- We make blanks for the fork. The size of the fork depends on the distance between the wheels, more precisely on the seat of the pipe, it should be equal to its diameter plus 1–2 mm. Cut from a metal sheet and grind:

- frame and cover for the shaft;

- support for the bed and a small stand for the lid;

- two rectangular plates, along the edges of which we make holes for the studs.

We cut blanks

We cut blanks

We make holes in the cover and frame for attaching the shaft.

Making holes

Making holes Finished blanks

Finished blanks

We fix the emphasis in a vice, weld the frame to its middle, and to the top of the stand under the cover, grind the seams.

We weld the parts

We weld the parts

We thread the pin into the hole in the village, put on the shaft and cover it with a metal sheet lid on top. Tighten nuts on both sides.

Installing the shaft

Installing the shaft

We fix the cover to the stand with bolts.

We fix the cover

We fix the cover

On both sides, we fasten two rectangular blanks onto the nuts.

We mount rectangular blanks

We mount rectangular blanks

From above, between these plates, we place a roller, which we fix with a stud and nuts.

Installing the roller

Installing the roller

We weld two plates of the fork by placing a blank from the channel between them.

We weld the plug

We weld the plug

We fasten the handle from a piece of metal profile.

We connect the handle

We connect the handle

Well, the lever pipe bender is ready, it turned out that almost any home craftsman can do it on his own.

Structural elements of a profile pipe bender

Since the energy consumption of the technological operation of bending even high-strength rolled products is small, most of the pipe bender elements can be made from ordinary steel of the St.5 type.

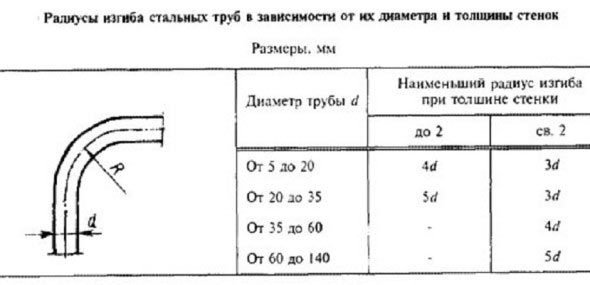

The diameters of the axes of the pipe bender rollers are selected according to the available sizes of rolling bearings, and for the base of the rubber clamping jaws, high-strength rubber is used according to GOST 7338-90. The rubber grade must be at least AMS (atmospheric oil-resistant), thickness - from 10 mm, hardness - T (such material can withstand pressure from 5 MPa).

The diameters of the axes of the pipe bender rollers are selected according to the available sizes of rolling bearings, and for the base of the rubber clamping jaws, high-strength rubber is used according to GOST 7338-90. The rubber grade must be at least AMS (atmospheric oil-resistant), thickness - from 10 mm, hardness - T (such material can withstand pressure from 5 MPa).

Particular attention is paid to forming rollers: they are made by finishing turning from U10 or U12 tool steel in accordance with GOST 1435-85.It is necessary to strictly observe the relationship between the executive dimensions of the roller and the dimensions of the cross-section of the workpiece (they are indicated earlier)

The chain transmissions of the pipe bender and the multiplier can be selected from ready-made parts available in the arsenal of the home master (for the multiplier, for example, a unit used for similar purposes in wrenches is suitable).

When assembling, it is worth considering the optimal conditions for lubricating the rubbing elements, and for ease of use, the handle is made with a corrugated plastic tube.

The pipe bender frame can be welded or bolted.

The procedure for bending a profile pipe on homemade machines

You are unlikely to be able to get the required bending radius at a time - too much effort is required for this. It is impossible to create it manually. Get the required bend in several passes:

First, the rollers are set so as to obtain a slight bend, the pipe is rolled in one direction, then it is removed from the rolls, unfolded and inserted with the other side. It is necessary to unfold to get an evenly curved pipe.

With the same position of the rollers, it is pulled several times until the curvature is no longer added.

If the required bending radius is not reached, change the position of the roller and repeat the steps again.

Electric tube bender

The change in the bending radius is obtained gradually, otherwise you cannot make an arc from a profile pipe on a home-made pipe bender. What if you need to repeat the same bend? Make a graduation - note to what height the roller moved, how many times it was rolled in each position. When repeated, the differences, if any, are insignificant.

The complexity of bending lies in the fact that there is no scale and it is difficult to get the intended bending radius without experience. Sooner or later you will get it, but a lot of material can be spoiled.

Kinds

Man invented and developed many types of pipe benders, which are usually distinguished by parameters.

For example, depending on the type of drive, I distinguish the following types of bending systems:

- Electromechanical;

- hydraulic;

- Manual mechanical;

- Combined.

First, the energy spent on the programmable deformation of the pipe is provided by an electric current connected to the device. Electromechanical pipe benders transmit mechanical action to a metal or plastic pipe through a gearbox that is connected to an electric motor. The gearbox reduces the torque, but at the expense of this increases the force of deformation.

In hydraulic machines, the basis of everything is a hydraulic cylinder filled with special oil. The force transmitted to the piston of the hydraulic cylinder increases according to the laws of physics. Such a device bends the pipe gradually. This works by stepping up oil pressure in the system. As a rule, hydraulic pipe benders have a manual drive in the form of a lever. By pressing the lever and returning it to its original position, the operator ensures smooth advancement of the rod on which the punch is fixed.

Manual mechanical pipe benders do not have a hydraulic cylinder in their design. Instead, the locksmith's work is facilitated by transmission mechanisms, which, due to the greater distance, make it possible to obtain a gain in strength. A fairly simple and at the same time common type of such bending machines is a roller pipe bender with a chain transmission.

The roller is pressed by a powerful screw, and a round or profiled workpiece is pulled between the pressure and supporting rollers by turning the handle, which drives the entire mechanism. The roller shafts are connected to each other by gears. The gears are selected so that by making a greater number of turns of the handle, it would be possible to move the product slightly, but with great force. The same principle is used in downshifting a bicycle when going uphill.

Combined types of benders can combine manual, electric and hydraulic components in various variations. An example is a classic machine with a hydraulic cylinder, where the movement of the piston is provided not by swinging the lever, but by a high-pressure pump with an electric motor. In this case, a person only controls the process, and the work is performed by an electric drive that advances the rod due to the growing pressure in the cylinder.

It should be noted that it has become almost impossible to bend large-diameter pipes made of strong grades without loss of strength and the formation of places of increased metal stress. For bending large, durable pipes, in addition to the mechanical effect on the workpiece, they also use thermal. The pipe is heated either with a special spiral, or with induction currents red-hot, and then gradually give it the desired shape. For this, large-sized electromechanical machines of high power are used. A heated and then tempered or hardened pipe will have no stress in it. It will not be affected by metal fatigue, and the bend will be smooth and even.

The simplest pipe bender: what materials will be needed

The simplest home-made pipe bender, in which the bend angle is adjusted, is made using the following materials:

- Hydraulic jack.

- Metal profiles, which are the basis for the construction of the structure.

- High-strength springs - 4 pcs.

- Metal shafts - 3 pcs.

- Chain.

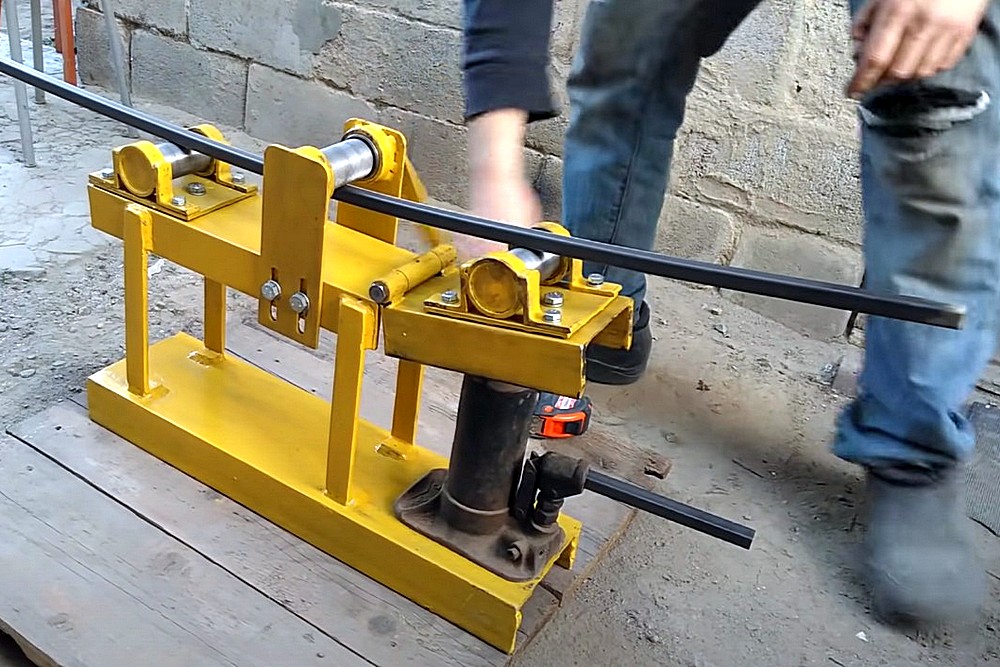

When designing a pipe bender with adjustable bending angles, two rollers are located on the lower base, and the third is installed at the top. When obtaining the desired bend, you only need to rotate the handle, which will move the shaft with a chain mechanism.

To create a device, which is shown in the photo above, there is no need to make grooves for adjusting the location of the rollers, which will greatly simplify the work. To get such a product, you only need the necessary material and a welding machine. The rest is the work of the master. It all depends not only on the skill of welding and grinder, but also on the imagination.

Types of pipe benders that can be made

These devices differ in their purpose. For example, if you need to bend a round metal pipe, bending machines are used that are designed specifically for round pipes.

As a rule, such home-made designs have rollers (or rollers) with a groove for a certain diameter of the workpiece. However, in some cases, dies with grooves for round tubes can also be used.

Slightly different devices are already used for bending square and rectangular profile pipes, as well as steel strips. And they are most often called profile benders (or pipe benders for a profile pipe).

Pipe bender designs may differ depending on what you want to end up with: just bend the pipe at a certain angle, or you need to make an arc or ring.

If you plan to make a serious structure with your own hands, which, if necessary, can be adjusted to different operating modes, then it will be difficult to do without a detailed drawing of a pipe bender.

Well, in the event that you need a simple budget pipe bender, then you can do everything without a drawing.

Some designs are quite compact and can be placed on a table or fixed in a vise without any problems. Other models - require a separate place in the workshop, and this must also be taken into account.

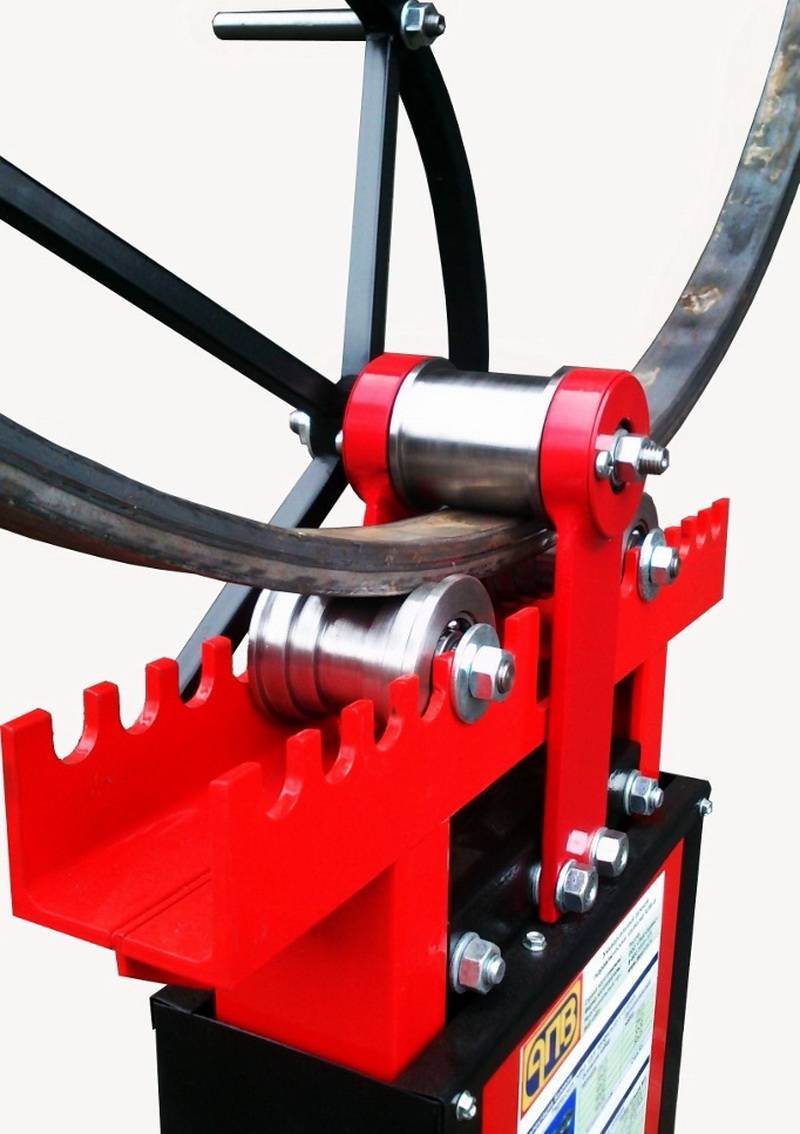

Roller Roll Benders

This design is quite popular among DIYers. Often improvised materials are used for its manufacture, which are in the garage or workshop.

At the same time, the dimensions of the device itself can be small, which allows you to easily install it on your desktop.

Make it so bendy do-it-yourself pipe bender under the power of everyone. And this will not take much time. One of the budget options is presented in the article on the site.

A metal plate acts as the base of the bending machine. Break-in rollers (or pinch rollers) can be made on a lathe. If there is no lathe, you can order rollers from a turner.

Two pressure rollers are installed close to each other, metal strips are attached to them. The pipe bender handle can be made from a small piece of round pipe.

A handle-lever with rollers and an emphasis for workpieces are attached to the base (metal plate).

The base can be fixed to the table with bolts, drilling holes, or simply fixed with clamps. You can also weld a piece of plate to the base to clamp it in a metal vise.

Making a crossbow pipe bender

One of the features of this design is that it can be used both in a horizontal and vertical plane.

And in this case, instead of rolling pressure rollers, a stamp (or template) is used for a specific pipe diameter. And these nozzles can be changed if necessary.

How to independently make a pipe bender with your own hands, which works vertically, you can read in the review article. In such devices, as a rule, it uses a hydraulic drive - from a car jack.

With this homemade bending machine, you can bend round pipes at different angles. Pipeline parts are usually bent at an angle of 45 and 90 degrees.

The stamp itself can be made from an old dumbbell pancake. It needs to be cut into four parts. Then three of them are welded together. A groove is made in the center for the required diameter of the round pipe.

From a channel or an I-beam (you can also use a corner or sheet metal), a pipe bender bed is made. The stamp itself is mounted on the jack rod. At the top of the bed, stops for the pipe are attached.

As for the central roller axle securely fastened to the frame of the bending machine, it should be made of good steel.

Approximately the same design for a bending machine that works in a horizontal plane. However, in this case, a mechanical or pneumatic jack is used.

Types of pipe benders on the market

Pipe benders are mechanical or hydraulic structures that help bend metal pipes, angles, bars, profiled steel without disturbing the internal structure of the product. Hand tools are mainly used to form a bend in one place, and large machines can change the shape of pipes at once along the entire length.

According to the principle of operation, pipe benders of the following types can be distinguished:

- Mechanical with direct manual effort. They are used when working with pipes of small diameters, during the deformation of which the force of one person is sufficient.

- With hydraulic drive. Mostly such tools are made according to the crossbow type, and they are designed to form a local bend.

- With ratchet. Pipe benders of this type use manual effort, but allow, after each pressing of the tool handle, to fix the achieved level of deformation.

- Electric machines. The electric motor greatly facilitates the process of pipe deformation, but also significantly increases the cost of the tool.

Features of working with some types are discussed below:

Structurally, pipe benders can be divided into 2 types:

- radius;

- crossbow.

In the first case, the pipe is bent around a template segment of a given diameter, and in the second case, it is extruded by a shoe between two support posts.

Radius pipe benders are very precise tools, so they are widely used in industry. They have interchangeable segments for different bending angles.

When making a pipe bender on their own, craftsmen usually rely on existing tool models that have proven their simplicity and effectiveness.When assembling a pipe bender at home, its design is greatly influenced by the available materials from which the tool will be made.

The presence of a pipe bender among the tools of a home master will allow you to make many useful structures and garden furnishings with your own hands:

For profile pipe

A profile pipe is often used to assemble frames for greenhouses, gazebos, gates and wickets, awnings and much more.

Therefore, the owner of a garage or a summer cottage sooner or later raises the question of how to bend a professional pipe at home.

A pipe bender will come to the rescue.

However, ready-made solutions cost a lot of money. Therefore, the best option is to do it yourself.

To make such a device, you will need the following tools:

- Angle grinder, colloquially - grinder;

- Drill with a set of drills for metal;

- Welding machine, best of all - a household electrode inverter;

- A set of keys or heads.

Before starting work, you need to draw up a drawing of the future bending machine so that all the details relate to each other.

The main elements of a home pipe bender are:

- Frame welded from a steel channel or I-beam with a thickness of at least 4 mm;

- roller shafts;

- The rollers themselves;

- Asterisks for connecting chain transmission;

- Chain for driving from an old bicycle or gas distribution mechanism;

- Screw lowering the pressure roller;

- Clamping screw and shaft rotation handles - hollow steel tube or solid rod;

- Various accessories: nuts, bolts, washers, grover, cotter pins.

It’s worth mentioning right away that if you don’t have rollers and shafts in your arsenal, it’s not possible to make them yourself without a lathe. As a last resort, the existing metal rods can be cut to size and sanded down. Barrels with an internal hole can be used as rollers.

With center roller

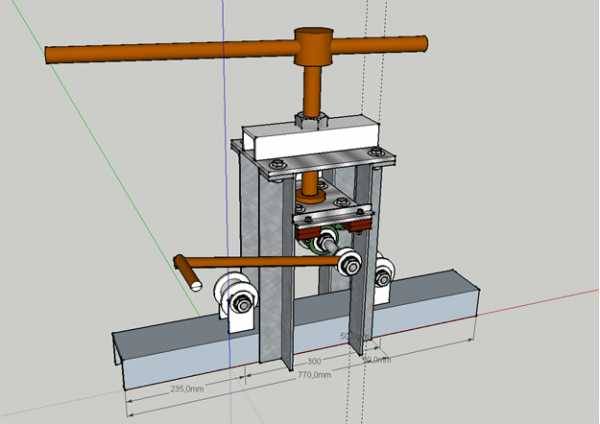

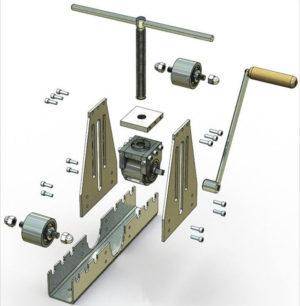

The sequence of actions when assembling a homemade pipe bender with a central pressure roller will be as follows:

- Using a grinder, cut the channel or I-beam into parts of the desired size. Grab them pointwise, and then, when the frame is ready, boil along the entire length. After, for aesthetic reasons, you can grind the seams with a grinding wheel.

- Provide either legs from scraps of the same channel, or mounting holes for bolts that will allow you to grab the machine to the workbench.

- Drill holes for the shafts. Also, using a drill and a grinder, make cuts in the vertical part of the frame. They will go up and down the pinch roller shaft. Insert the shafts with the rollers on into the holes made and fix them with cotter pins.

- The threaded connection of the pressure roller rod and the blind frame is done either with a lathe or with a tap. Remember that large diameter threads are very difficult to cut. Be sure to use grinding or other cheap lubricant when cutting threads.

- Gently grind the outer part of the shafts on both sides so that you can put stars on them. Put on the chain with a slight slack, if you make the grip too tight, additional strength will be spent to overcome the resistance.

- Attach a lever to one of the shafts - for fixing, use the same lock as for the sprockets.If there is a desire to strengthen the lever on the shaft, drill a hole and cut the internal thread. After screwing the bolt there, the lever will be fixed, and by unscrewing the bolt, the lever can always be removed for transportation. By turning the lever, it will be possible to pull the workpiece through the rollers. By tightening the clamping screw, you can change the radius of curvature of the bent pipe.

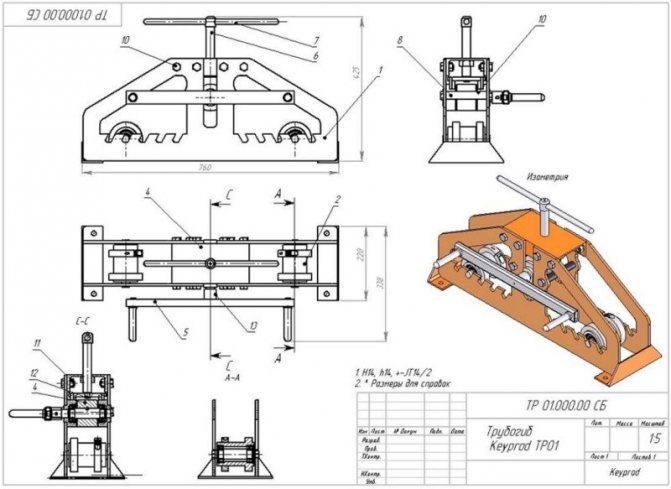

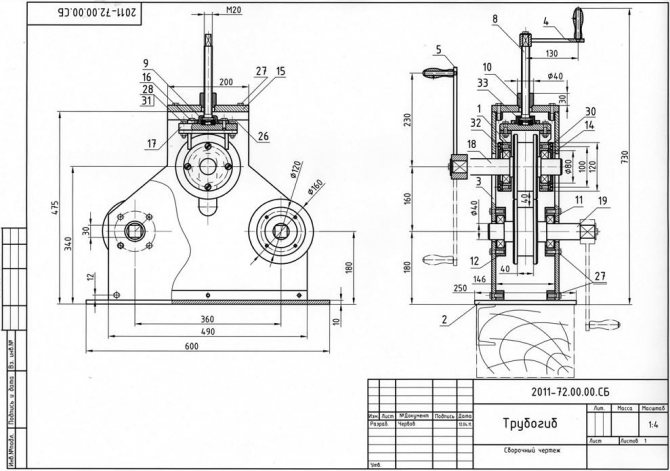

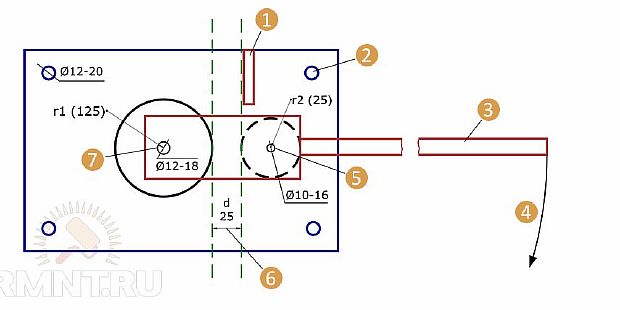

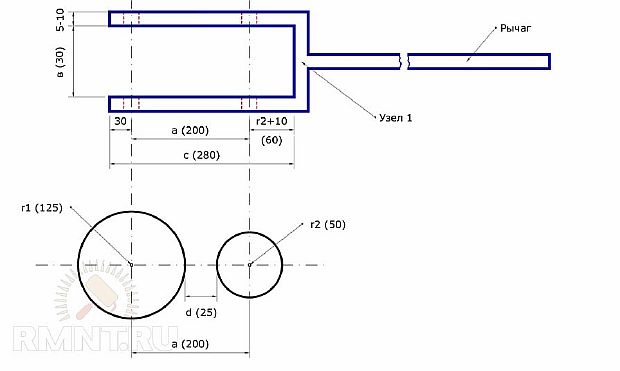

Drawings and dimensions of a homemade design:

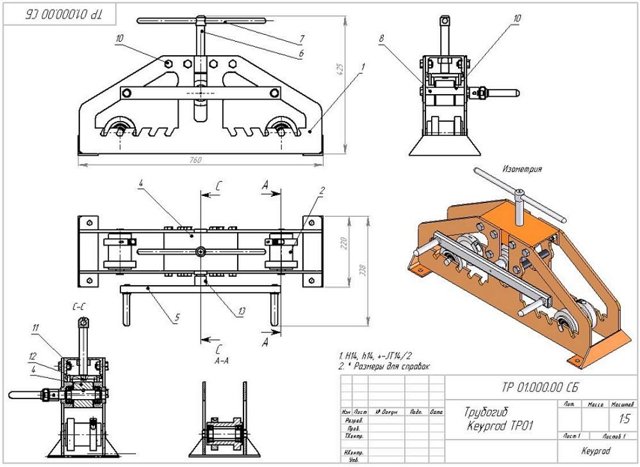

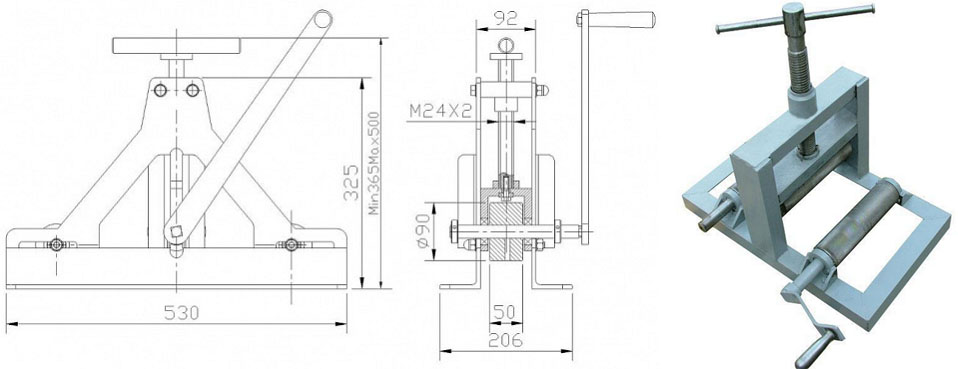

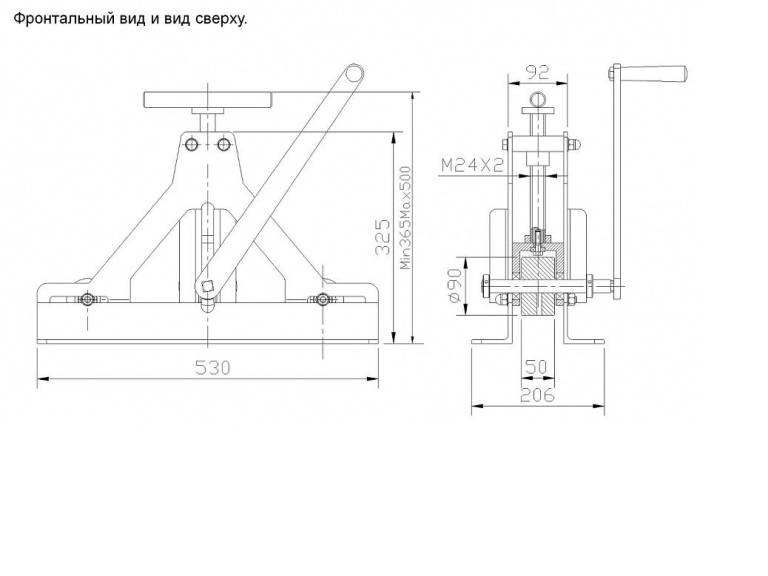

With break frame

No less popular in do-it-yourself manufacturing is a pipe bender with a breaking frame. Structurally, it differs in that all the rollers in it are stationary, that is, they only rotate, but move up and down.

The pressure on the pipe occurs by lifting the part of the frame where one of the extreme rollers is mounted. The assembly process is similar to the previous one, but has its own nuances:

- Make the frame for the fracture pipe bender not one-piece, but consisting of two parts. Two parts can be connected with a stud with two nuts.

- It is very convenient to lift the end roller with a screw lifting device or a jack.

- To rotate the sprockets, some craftsmen adapt an AC electric motor or even a gasoline one removed from a walk-behind tractor or a fuel generator.

But most often, such units still use the user's muscular strength. In this case, they require almost no resources. This is their value: it is very easy to put such a device in the trunk of a car and bring it to a construction site where there is still no electricity.

Below are the drawing and dimensions of a homemade pipe bender:

Another example:

How is a pipe bender arranged?

The specific design of the device depends, first of all, on its purpose, however, without fail, the pipe bender includes:

frame;

a pair of pipe stops;

hydraulic cylinder;

straps (upper/lower).

Note also that the frame can be either open or closed. As for the hydraulic cylinder, it is the main part of the device that performs the power function.

Also in the do-it-yourself pipe bender circuit there is an injection device, which is located on the back of the case; in the same place is the bypass valve screw, the handle. But on top of the cylinder there is a plug through which oil is poured inside and its level is checked. The unit bar located at the bottom is screwed onto the thread located in front of the housing, and then pressed with a special fixing nut. Additionally, the bar is fastened with a lock and a pair of screws.

For manual reinforcement, a retractable rod is used, which returns back thanks to a spring located in the cylinder. The pipe bender bars are made as a welded structure. On the transverse plates there are holes through which the stops are installed. In the lower part of the body there are also threaded holes for mounting bolts, adjustable in height.

Considering a do-it-yourself pipe bender, one cannot fail to note the fact that thin-walled profile pipes have become increasingly popular in recent years, moreover, they make it possible to create durable and attractive structures, as well as save on construction work. It is from such pipes that greenhouses and various sheds are made today. What is the difference between a profile pipe and an ordinary one? First of all, the cross section, which in this case is not round, but oval, rectangular or square.This is precisely what explains the design features of the pipe bender for this type of pipe - the rollers must be of the same cross section as the products being bent, otherwise the cross section of the latter may be deformed.