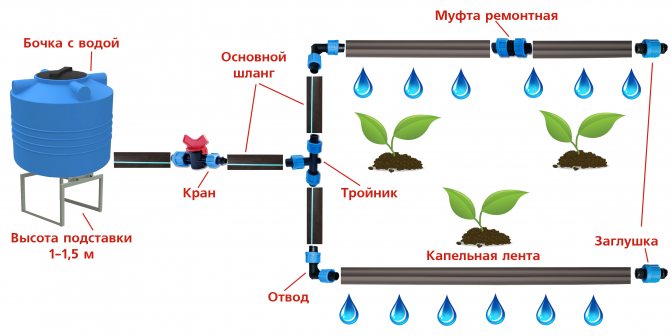

- Drip irrigation system components

- Main pipes

- Low Pressure Drip Hoses

- Droppers

- Automatic watering in a greenhouse from bottles

- Do-it-yourself gravity-fed irrigation system for the garden and greenhouse

- Varieties of irrigation systems for summer cottages and gardens

- Rules for working with drip pipes

- Clogging and flushing the system

- Prevention of root germination in pipes

- Pipe storage in winter

- Options for arranging a drip system

- Dropper system

- Drip Tape System

- underground system

- What are the benefits

- Self-construction of the irrigation system

- Timers for automatic watering

- Benefits of drip irrigation

- Materials and tools

- Why drip irrigation is better than the usual watering can

- Types of hoses for irrigation

- Rubber hoses

- PVC hoses

- plastic hoses

- Assembling a drip irrigation system from polypropylene pipes

Drip irrigation system components

A drip irrigation system consists of several components. Work is organized from any source of water. To assemble communications you will need hose for drip irrigation, droppers and main pipeline.

Main pipes

For the installation of the main pipeline, drip irrigation is organized from polypropylene pipes, elements from HDPE, LDPE or PVC. As a rule, fittings made of the same materials are also used.The listed pipes are used for self-manufacturing of irrigation devices. Also on sale are ready-made kits from the same materials.

Low Pressure Drip Hoses

Hoses are sold in a total length of 50-1000 meters in bays. They have built-in liquid flow points. Thanks to the internal labyrinths, the flow rate will be the same regardless of the curvature of the relief.

Depending on the characteristics, there are several types of hoses:

- Hard and soft. The first variety is called a hose, and the second is a tape. The service life of hard elements is up to 10 seasons, and soft elements will last only 3-4 seasons.

- Soft tapes are thin-walled and thick-walled. In the first case, the thickness of the material reaches 0.3 mm, and in the second - up to 0.81 mm. The duration of operation of the first tapes that fit only on the surface does not exceed 1 season. The latter are suitable for underground installation and will last up to 4 seasons.

- All hoses and tapes vary in length and diameter. They come with a section of 14-25 mm (hose) and 12-22 mm (tape).

- Depending on the intensity of irrigation, the elements are selected according to the water flow. The flow rate of liquid through one dropper at the hose is 600-8000 ml/h, for thin-walled elements - 250-290 ml/h, and for thick-walled elements - 2000-8000 ml/h.

- Dropper pitch 10-100 cm. They come with one or two outlets. With two holes, the irrigation area is larger, and the depth is smaller.

- According to the method of laying, they are divided into ground, underground and for combined installation.

- Depending on the use of a forced or gravity water supply system, the hoses are selected according to the working pressure. They are designed for 0.4-1.4 bar.

Droppers

Another name for this element is an injector for drip irrigation.This is a separate water supply device that is inserted into the hole in the hose. Droppers are suitable for watering shrubs and trees.

There are the following types of droppers:

- with constant and regulated watering;

- compensated and non-compensated (irrigation intensity depends or does not depend on the slope of the relief);

- spider-type devices (several tubes come from one outlet);

Automatic watering in a greenhouse from bottles

Now let's again pay attention to the system of automatic (or rather, "semi-automatic") watering from plastic bottles. Doubt the benefits of such irrigation systems over the good old watering can? Do you think that spending so much money, effort and time on automatic drip irrigation is too risky? Then this option is the best for you - it costs practically nothing and its arrangement in the greenhouse is unlikely to take you more than one day.

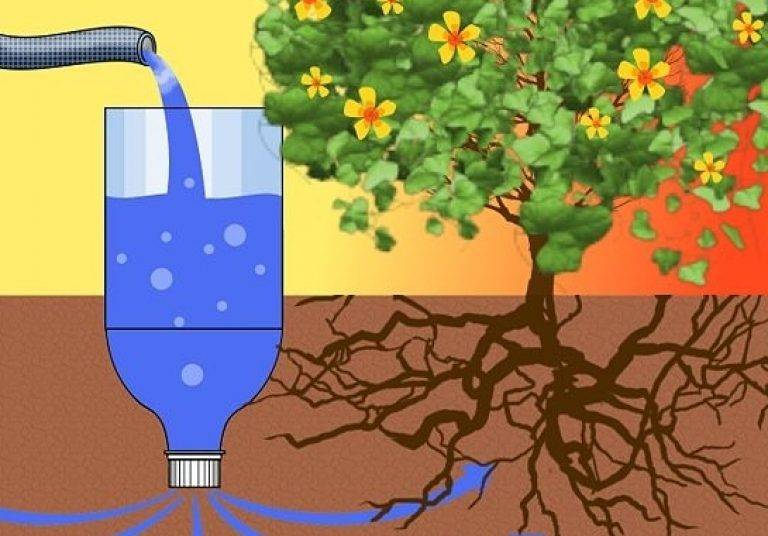

Drawing illustrating the principle of operation of drip irrigation from a bottle

Drawing illustrating the principle of operation of drip irrigation from a bottle

For watering in a greenhouse from bottles you will need:

- scissors;

- needle or awl;

- gauze, cotton fabric or nylon;

- empty plastic bottles with caps;

- shovel.

In most cases, bottles of 1 to 2 liters are used. This is enough for a period of one and a half to three days, depending on the weather and the plant's need for moisture. It is allowed to use larger containers, but you need to understand that they will take up too much space near the plant. It is up to you to choose between saving the usable area of greenhouse beds and the autonomy of the irrigation system.

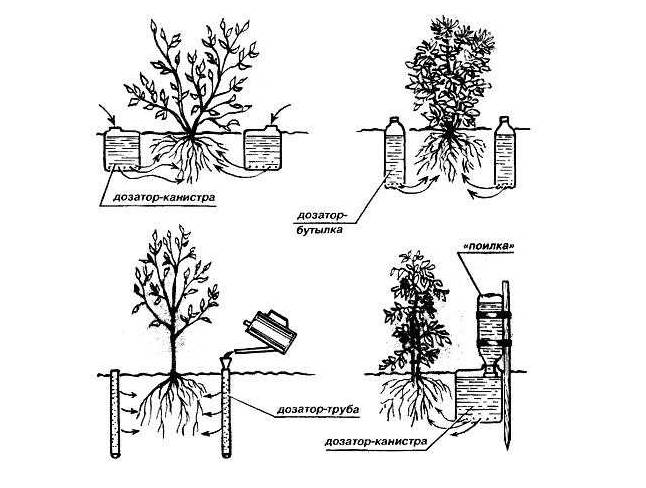

An example of using different types of containers

An example of using different types of containers

Step 1. Wash plastic bottles and wipe off paper labels, if any.

Step 2Cut the bottoms of the bottles about 5 cm with scissors.

Step 3 With a red-hot needle (or awl), make a series of holes in the plastic lids. The amount of liquid entering the soil per unit of time depends on their number and diameter.

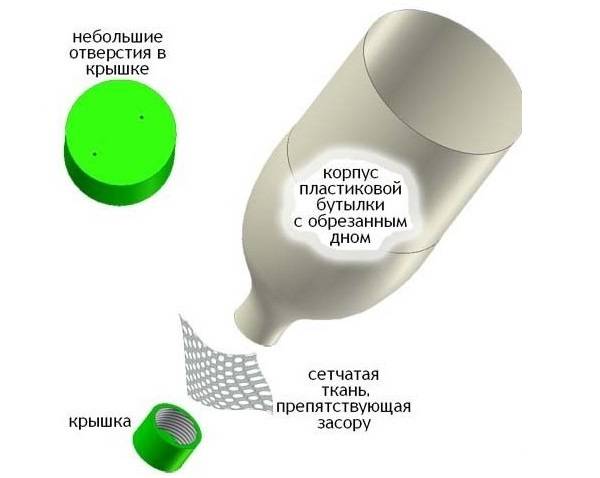

The ratio of the size of the holes and the amount of watering

Step 4. From the inside, put a piece of gauze into the lid. It will act as a kind of filter and will not allow the holes to clog too quickly. Instead of gauze, if necessary, you can use cotton fabric or nylon.

Put a mesh cloth inside the bottle so that it does not get clogged with debris.

Put a mesh cloth inside the bottle so that it does not get clogged with debris.

Step 5. With a shovel, dig a hole near the plant (or the place where it will be planted) with a bottle diameter and a depth of 10-15 cm.

Step 6. Insert a bottle with a closed lid into the dug hole. Everything, the system of "semi-automatic" watering is ready. Repeat the previous steps with the rest of the bottles, placing them next to each plant in the greenhouse.

Automatic watering from plastic bottles in the greenhouse

Automatic watering from plastic bottles in the greenhouse

Bottle upside down

Bottle upside down

Protective cap from a five-liter container

Protective cap from a five-liter container

There are two other ways to improve such a system. First, replace the holes in the lids with store-bought garden drippers - they clog less and better deliver moisture to the plants. Secondly, you can run a hose with branches from the water supply into the greenhouse and insert each of them into the bottle from above. Thus, there is no need to replenish them yourself - just open the valve and wait a while.

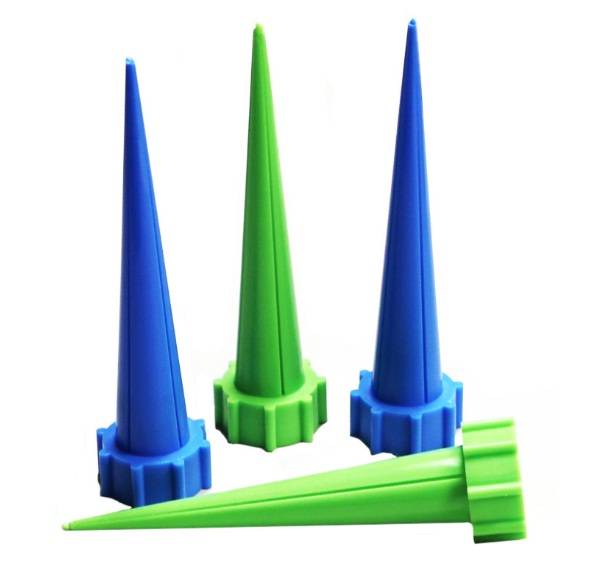

garden drippers

garden drippers

Droppers can be adapted for watering from bottles

Droppers can be adapted for watering from bottles

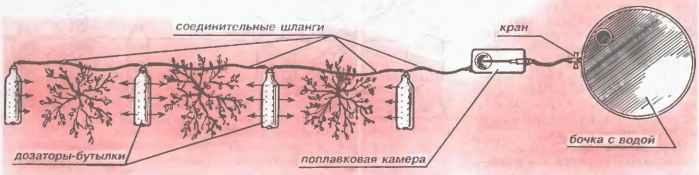

Scheme for replenishing bottles with a hose and a tank of water

Scheme for replenishing bottles with a hose and a tank of water

Do-it-yourself gravity-fed irrigation system for the garden and greenhouse

An automatic irrigation system in a summer cottage or garden plot significantly improves the quality of life on it. If the beds and flower beds are moistened by themselves, then time is released that can be spent more interestingly in the summer.

An automatic irrigation system significantly improves the quality of life. Author's photo

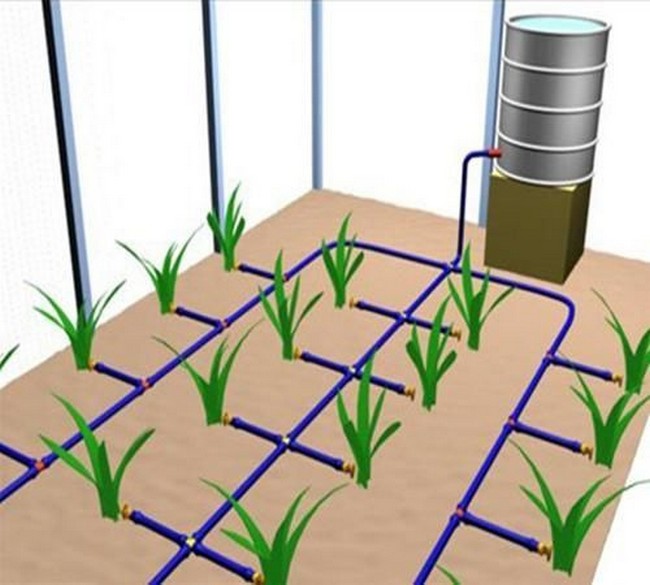

In this publication, we will consider the option of organizing the irrigation of a garden and a greenhouse using a specific example. The garden consists of 7 narrow stationary beds 60 cm wide and about 6 m long. In a small greenhouse (3 × 4 m) there are 3 stationary beds of the same width where tomatoes and peppers grow. It is better to supply garden and greenhouse plants with warm settled water, and not ice water from the main water supply.

The garden consists of 7 narrow beds 60 cm wide and about 6 m long. Photo by the author

For watering the vegetable garden and greenhouse, as well as to always have a reserve in case of interruptions in water supply, at the very beginning of the development of the site, a large barrel was installed (volume about 5.5 m³). Previously, it was filled with water, a hose was attached and the garden was watered by hand. The Belarusian set for automatic watering "Akvadusya" was used in the greenhouse. The system, which will be discussed, is in its second year, but continues to improve.

For irrigation with settled water, a barrel with a volume of about 5.5 m³ was installed. Author's photo

Varieties of irrigation systems for summer cottages and gardens

Existing irrigation systems can be divided into four categories, each of which has specific advantages and disadvantages:

- surface watering;

- drip irrigation;

- subsurface irrigation;

- sprinkling.

Each type of green space and horticultural crops needs different watering methods.

Each type of green space and horticultural crops needs different watering methods.

Useful advice! At the summer cottage, you can organize several irrigation systems, since each crop needs a certain moisture regime.

Surface irrigation is a less costly irrigation option. Water is supplied to the plant through dug grooves directly from a hose, which can be connected to a centralized water supply system or to a barrel for irrigation in the country. You can buy a container of any capacity. The irrigation system is located on the surface of the earth, so its independent laying is not difficult. This method deprives the roots of part of the oxygen, which can be detrimental to plants. Therefore, continuous use of surface watering is not recommended.

Rules for working with drip pipes

The efficiency of drip pipes is highly dependent on operating conditions. The equipment can last a month, or maybe five years - it all depends on following the elementary rules for its use. The main causes of problems with drip pipes are:

- clogging;

- root germination;

- improper storage in the off-season.

Further, the listed problems will be considered in more detail, as well as options for their prevention.

Clogging and flushing the system

Country watering is often carried out with water from a well or natural reservoirs, so periodic clogging of pipes is understandable.

To purify groundwater, a mesh filter will suffice, and when irrigating from reservoirs, an additional disc filter device must be installed. In the absence of pre-cleaning, clogging of droppers can occur after a few days.

Regardless of the presence of filters, drip pipes must be regularly cleaned of mechanical sediment with water pressure. This requires opening the far end of the pipeline and supplying water to the system at a rate of 6-7 l / min. Washing continues until the sediment is completely cleared.

You can break through a clogged hole in the dropper using a conventional foot pump. It is enough to attach the pump hose to the hole of an empty pipe and swing it sharply

The elimination of bacterial mucus from the system is carried out by flushing with 0.5% sodium hypochlorite solution. It is necessary to fill the system with the mixture and leave for 12 hours. After that, drain the chlorine liquid and flush the pipeline with clean water for 10 minutes.

As contamination is carried out, the drip system is cleaned from salt deposits with 0.6% nitric, phosphoric or perchloric acid. The water used should be as warm as possible. The pipeline is washed with an acid solution for 50-60 minutes. After the procedure, rinse the system with clean water for half an hour.

Prevention of root germination in pipes

Drip systems with round holes for water outlet are most susceptible to germination. The greater the moisture deficit experienced by plants, the stronger their roots reach for its source. Therefore, sufficient watering is the basis for the prevention of root germination. Additionally, you can periodically move the pipes a few centimeters to the side so that the roots do not concentrate near the droppers.

Especially important is the germination of plant roots in the holes of drip pipes in compact closed soils. It is recommended in such cases to periodically change the location of the water supply rod.

If the problem is not solved by the indicated methods, then it is possible to use special chemicals that inhibit the growth of the root system.

But it is recommended to use them carefully so as not to destroy the grown plants.

Pipe storage in winter

It is necessary to plan the cleaning of the drip pipeline in advance so that unexpected cold does not freeze the water in the system and damage the pipes.

Pipe reeling is ideal for long-term storage: hoses and built-in emitters are not crushed, and the roll can be easily protected from rodents

Before cleaning the pipeline for the winter, it is necessary to clean it from mechanical sediment, mucus and lime deposits. You need to wind up the drip system slowly, raising the hoses high to drain the water. Rolls should be stored in a dry room, preventing the penetration of rodents into it, which can gnaw on the equipment.

Compliance with the above rules will allow you to operate drip pipes without problems during the entire warranty period.

Options for arranging a drip system

Drip irrigation is recognized by gardeners and gardeners as one of the most convenient irrigation systems in

features, if we draw a parallel with the manual method

AT

during the period of solar activity, it is important to supply the beds with a sufficient amount of liquid to ensure their vital activity. Moisture deficiency leads to weakening and death of the plant.

In order not to spend every day in the garden, it is recommended to equip the plantation with drip irrigation.

Dropper system

The operating principle of the system is

pipeline laying

row spacing with

subsequent connection of droppers. Thin tubes deliver water to

to every plant. The speed of fluid movement

pipes is small, even when

tap water intake, it has time to warm up, so fear for

seedlings are not

costs. Also available for use in

as a source of large capacity, in which water is collected for sludge.

System with

droppers are arranged from the following elements:

distribution pipes (one or

several pipes arranged in parallel);

- droppers adjustable or

unregulated type (each

varieties is divided into compensatory and

non-compensatory products); - splitters fixed to

supply line (they are also called spiders);

- filter device;

- connecting parts (any suitable

pipe elements - fittings, fittings, pressure compensators, etc.); - start connectors.

Reference! An irrigation system with droppers assembled without violations can function for a sufficiently long period of time (up to

10 years).

The popularity of this type of irrigation is due to the following advantages:

- the ability to deliver fluid to

shoots growing on

different distances from each other; - devices with

adjustable droppers provide different intensity of moistening of individual crops; - irrigation process can be carried out without

direct human involvement.

When choosing this system, it must be taken into account that the pipeline operates only in the warm season, before the onset of frost it must be dismantled. A large number of connecting elements complicates the installation and maintenance of the device, in addition, you will have to deal with

frequent leaks, if

assembly errors.

Drip Tape System

This type of device provides for the installation of a supply pipe / pipes with

connected ribbons. The system is quick to assemble, but it

less durable. Irrigation occurs due to the release of liquid through the holes in

tapes that are made on

the same distance from each other

friend.

Advantages of a tape variety of drip irrigation:

- fast and

simple installation; - affordable price for materials;

- tape already

has holes, you don't have to drill them

manually.

- there are difficulties in arranging the irrigation structure for

crops growing at different distances from each other; - service life is not

exceeds 3

years; - the inability to regulate the intensity of the flow;

- garden pests often damage the tape.

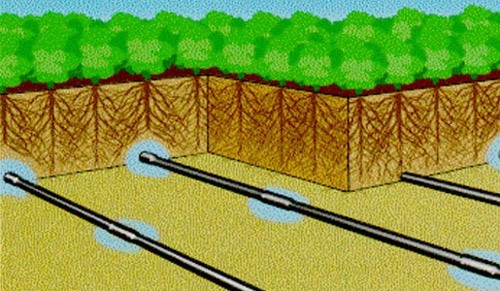

underground system

Polypropylene pipes in this system are buried in

soil along the rows of plants to a depth of 10 cm. Delivery of moisture directly to the roots makes irrigation ideal. Fluid flows through a pipeline to

built-in droppers, which practically do not

clogged with earth.

The underground irrigation option eliminates the evaporation of moisture, yellowing of greenery due to

water ingress. Resource consumption is economical, with

there are no above-ground obstacles in the passage between the beds. it

does weeding, mulching and

other activities for

care more comfortable.

The duration of operation of the underground system is at least 5-8 years. On the

winter period dismantle structure no

need. A significant disadvantage is the high cost of components.

Each system option has its pros and cons, you should choose based on

budget and

bed features.All schemes are based on a supply pipe, which can be made of

different materials. High performance and

products made of polypropylene are distinguished by an affordable price.

What are the benefits

Not every gardener is ready to water the plantings manually or constantly move hoses and sprinklers around the site. There are more modern and practical options: drip irrigation systems. You can buy them ready-made or assemble them yourself. A high-quality system, selected taking into account the water supply and the relief of the site, has been operating for several years without needing repair. At the end of the season, it is dismantled, and in late spring, when the ground has completely thawed, it is mounted again.

In greenhouses and greenhouses, drip irrigation allows not only to ensure the supply of water to the roots of plants, but also to maintain the necessary air humidity. In heated shelters, the system can function all year round.

The principle of operation of the drip system is not complicated. Water is supplied from a water supply system (flow type) or comes from a separate container. The supply is regulated by a crane. The water then passes through the filter and irrigation controller, which distributes the moisture through the supply pipes or belts. They are distributed between plants, water flows directly to the roots through small holes.

- saving water;

- the possibility of watering at any convenient time;

- ensuring the level of humidity required for a particular crop;

- ease of installation, use and repair;

- affordable price;

- spot watering reduces the number of weeds on the site;

- the finished set can be improved by purchasing additional elements.

Expert opinion

Kuznetsov Vasily Stepanovich

A correctly selected and laid system does not spoil the appearance of the site: it is simply not noticeable under the lush foliage. If necessary, it can be increased by adding additional hoses. Transmission lines do not injure plants and do not interfere with their development.

Self-construction of the irrigation system

An effective automated irrigation system can be made with your own hands. Its device will cost much less than the assembly and installation of a ready-made set of pipes and fixtures. In addition, the application of your own strengths and skills will bring undoubted pleasure:

It is permissible to lay an automated irrigation system from a polyethylene pipe openly; it is not afraid of sunlight.

In open areas, it is not recommended to arrange pipelines made of PVC pipes; it is undesirable to use polypropylene if there are sources of open fire nearby.

Have you decided to do the installation of a summer water supply in your country house on your own, so as not to waste extra time and effort watering the plants manually? We recommend that you familiarize yourself with a step-by-step guide for laying an automatic irrigation system using pumping equipment.

Timers for automatic watering

Devices are needed to control an extensive system, monitor the operation of pumps, start water supply to several lines simultaneously. Timers are convenient for owners of a large subsidiary farm with a dozen greenhouses. There are electronic and mechanical devices equipped with a water meter.

The timers work on batteries, mechanical spring ones do not have programs, they are adjusted manually, and the charge is enough for a day. To ensure the supply of water to the greenhouse, a simple unit is enough; it will support the daily operation of the irrigation system (2 hours of watering).

Electronic - more complex devices with programs that the unit supports for a given period of time. Devices are convenient for operation in vegetable gardens with various crops. For each system, a program is set, which will turn on / off irrigation.

Benefits of drip irrigation

The main advantages of the irrigation system are:

- significant savings in water and electricity (if a pump is used for irrigation);

- clear and regular distribution of moisture, even if the bed is not located on a flat surface, but in difficult areas;

- lack of waterlogging of the soil, which helps to maintain the maximum amount of oxygen in the soil and maintain its friability;

- improving the development of the root system and increasing the absorption of nutrients by it;

- paying attention to each plant;

- reducing the number of weeds that simply cannot develop due to insufficient moisture for them;

- reduce the risk of diseases (due to the fact that the leaves remain dry, there is no humid microclimate that fungi and bacteria love);

- earlier ripening and long fruiting;

- a significant increase in yields;

- the ability to use any source of water (well, well, water supply or even a barrel).

Materials and tools

First of all, it is worth understanding why to use polypropylene. Firstly, it is many times cheaper and lighter than steel pipes, does not corrode, and does not accumulate salt on internal surfaces. Secondly, it wins over flexible hoses in terms of strength and durability, does not lose its properties from prolonged exposure to weather and climatic conditions.

But, perhaps, the main advantage of polypropylene pipes is the ease of their installation - a wide range of pipeline fittings of any configuration is presented on the market, the docking of products with which is carried out with a simple pipe soldering iron with an appropriate nozzle. However, polypropylene is also different.

- PN10. Designed for cold water and relatively low water pressure, as a rule, pipes from it are thin-walled and relatively flexible.

- PN16. It can work with medium temperature water (up to +60 C), withstands a pressure of 16 atmospheres, and is used in pipes with an average wall thickness.

- PN20. Working temperature reaches +95 C, high wall thickness and special composition allows pipes to withstand pressure up to 20 atmospheres.

- PN25. It has reinforcing layers, thanks to which it can withstand a relatively long exposure to boiling water, cope with a pressure of 20–25 atmospheres.

For drip irrigation, pipes of the PN16 brand are best suited, in some special cases they may be preferred to PN20, for example, in the central highways of large, highly branched systems. It is not advisable to use the PN10 brand due to low reliability, and it is not easy to find pipes from it on sale - the characteristics are too small by modern standards. Well, systems from PN25 pipes would come out too bulky and expensive.

The diameter of the products is determined in accordance with the flow of water, which, in turn, depends on the area of the irrigated area. It can be approximately calculated from the ratio of 500-750 liters per hour for every 100 square meters. m. Here are the pipe diameters suitable for different irrigation intensity.

- 500 l/h - 16 mm;

- 1000 l/h - 20 mm;

- 1500 l/h - 25 mm;

- 3000 l / h - 32 mm;

- 5000 l/h - 45 mm;

- 7500 l/h - 50 mm.

In addition to pipes, you will need accessories (turns at different angles, crosses, ball valves, adapters). If watering is carried out from a water supply system with low pressure, a water tank should be provided.

Main working tools

- pipe shears or electric jigsaw;

- soldering iron for polypropylene pipes;

- drill with drills;

- knife;

- means of measurement and marking.

Why drip irrigation is better than the usual watering can

The main and clear advantage is obvious - saving water and effort. Not every gardener has an abundance of water for irrigation, and how hard it is to carry a watering can, probably, even someone who has never done this can imagine. Considering that for each vegetable plant during normal irrigation, from 5 to 10 liters of water are needed, a lot of effort is required.

Drip irrigation is better than a regular watering can or hose

But drip irrigation has other advantages over sprinkler or furrow irrigation.

• Water flows constantly - no stress from drying out. Of course, our green pets have mechanisms to deal with drought. But why waste the power of plants in the struggle for life? After all, we do not grow Spartans, but vegetables.

• Drip irrigation, unlike sprinkling, does not contribute to the development of rot and fungal diseases.

• When irrigating in furrows, we simultaneously introduce a large volume of water. It compacts the soil, displacing oxygen from it, and loosening is required after watering. With drip irrigation, this compaction is not observed: minus one garden work, and besides, the plants feel much better in the soil filled with oxygen.

• The drip system is an opportunity to water the garden even when you are not at the dacha. Properly configured, she will do everything herself. And equipped with a watering timer, it will be able to work completely autonomously - according to a given schedule.

Drip irrigation does not compact the soil

And most importantly: regular watering, which gives drip irrigation, increases the yield of the crop by almost 10 times and allows you to grow vegetables and beautiful gardens where, it would seem, only gray sagebrush can feel good. So, according to experts, when growing tomatoes in open ground in the south of our country:

• when irrigated by furrows, the yield is 20 t/ha;

• Sprinkler irrigation - 60 t/ha;

• with drip irrigation - up to 180 t/ha.

Types of hoses for irrigation

Rubber hoses

Among different hoses pressure rubber are considered one of the best. They are reinforced with a thread braid, withstand up to 53 bar of water pressure, and serve for about 20 years.

The length of such products ranges from 20 to 200 m, the wall thickness is in the range from 4 to 6 mm, the diameter is usually 1/2ʺ, 3/4ʺ, 1ʺ (13, 19, 25 mm). Operation is available within a wide temperature range: -30…+90 °C. In the manufacture of rubber flexible pipes, environmentally friendly raw materials are not always used.

Advantages:

- high elasticity and strength;

- resistance to UV rays and significant temperature changes;

- no wrinkling and twisting;

- affordability and durability.

Flaws:

- relatively large weight;

- high percentage of toxic products.

Flexible conduits from rubbers are suitable for manual and automatic irrigation of cultivated plants and lawns. They are also suitable for use in industry and car washes.To supply drinking water, a food version is used, which is free of toxins.

PVC hoses

Polyvinyl chloride hoses are becoming more and more popular. They are produced in 1-, 2-, 3-, 4-ply with cross-braid and mesh braid - the latter is more preferable.

1-layer options without reinforcement are often transparent, which leads to the appearance of algae in the cavity of the pipeline. Products withstand pressure up to 40 bar, operate in a temperature range of ‒25 ... +60 ° C, are offered in lengths from 20 to 100 m or more, and are in operation from 5 to 35 years.

Advantages:

- the ability to choose products with a different number of layers - with or without reinforcement;

- lack of bloat, kinking and other disadvantages in reinforced versions;

- availability of connection of fragments with the help of special fittings;

- environmental safety - polyvinyl chloride does not emit substances harmful to health;

- light weight and low cost of modification with 1 layer.

Flaws:

- loss of shape of single-layer PVC hoses under the influence of ultraviolet and high pressure;

- the appearance of algae in transparent specimens;

- low service life of versions with 1 layer - up to 2 years.

PVC flexible pipes are used both for watering the garden / vegetable garden and for drinking purposes. Single-layer products, based on the characteristics, are more often used in ordinary chores.

Silicone analogs differ little from PVC hoses. The characteristic features of the latter are that any modifications of them do not break, do not bend, do not crack. At the same time, single-layer versions can withstand no more than 5 bar. Outwardly, it is quite difficult to distinguish between PVC and silicone pipes.

plastic hoses

Plastic hoses are not very popular.They are offered in lengths from 20 to 50 or more m, in diameter from 1/2ʺ to 1ʺ. Products withstand pressure up to 7 bar and temperatures up to +65 °C.

Since plastic does not have much flexibility, the pipes are made in a corrugated form - thanks to this solution, low strength characteristics are further increased. You can work with this hose for a long time in the sun - ultraviolet rays do not affect the material of manufacture.

Advantages:

- resistance to UV radiation and temperature changes;

- lack of conditions for the formation of algae;

- light weight and decorative appearance;

- optimal price / quality ratio.

Flaws:

- fast deformation and easy breaking when bending;

- the formation of limescale from the inside;

- short service life - up to 2 years.

Flexible plastic pipelines are suitable for watering the garden and garden, as well as home gardens. Since they are not durable, they are used as temporary fixtures in country plots, in farms and greenhouses.

In terms of durability, plastic products are similar to nylon, which also operated no more 2 years old The fragility of the latter is due to instability to temperature fluctuations and the inability to withstand high pressure. Among the advantages of nylon piping are lightness, flexibility and strength.

Assembling a drip irrigation system from polypropylene pipes

Before organizing watering, the summer resident must prepare a project. It must indicate the placement of the beds, the distance between them and individual plants or young seedlings. To compile it, you need to take a construction tape measure, take all the measurements and sketch it on paper.

For cutting polypropylene pipes for bends, special scissors are used. You can also use a construction knife or a hacksaw for metal.

The installation of the irrigation system is preceded by marking the site:

- It is divided into beds, in each of which grooves for pipes are located at a distance of 20–60 mm.

- Then the length of the segments is determined, the pipes are cut into sections, the need for fittings is calculated. In complex and highly branched structures, pipes of a slightly larger diameter are chosen for the central pipelines than for the periphery.

- In all pipes that will be laid in the grooves, holes with a diameter of 2–3 mm are drilled at regular intervals (usually 7–15 cm).

- When each separate branch of the system is ready, proceed to the assembly.

- Pipes and fittings are joined with a soldering iron, excess plastic is cut with a knife. It is better to use modular technology - to assemble individual sections of the system, put them in their places, and then continue assembling already in the "working area".

- It is possible to lay pipes directly on the ground, but it is better to provide small stops (up to 5 cm above the ground). This will prevent clogging of the holes.

Please note that the holes should not be directed strictly down, but at a slight angle. It is better not to install the drill strictly perpendicular to the axis of the pipe - this will help distribute moisture more evenly. Now you can test run

If it shows leaks, they can be eliminated by "cold welding" - a composite adhesive. But it will be more reliable to solder weak points

Now you can do a test run. If it shows leaks, they can be eliminated by "cold welding" - a composite adhesive. But it will be more reliable to solder weak points.