- Advantages and disadvantages of homemade tiles

- Table: comparing the advantages and disadvantages of artisanal paving slabs

- Industrial production of paving stones in factories

- Equipment for the production of

- Composition of the mixture

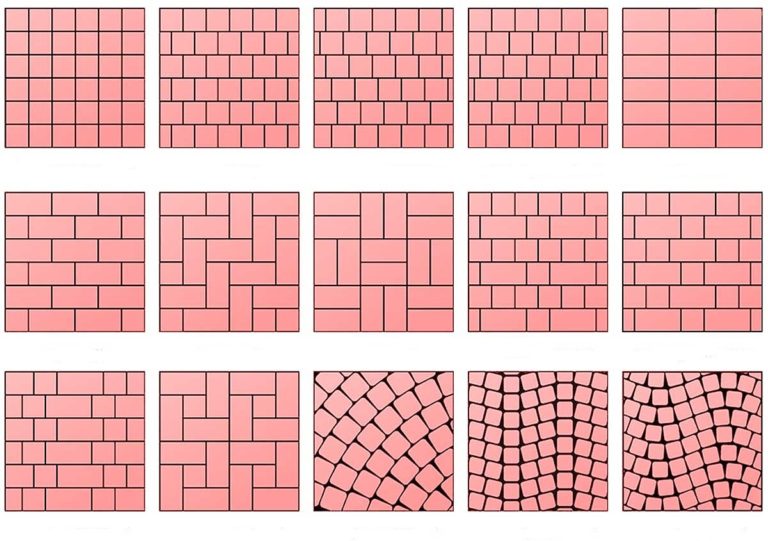

- Produced types

- How to lay tiles?

- Components of the material

- Raw material

- Reinforced concrete and polymer sand: who wins?

- Weight and transportation to the site

- Features of joining elements and tightness of joints

- Ability to resist moisture

- Resistance to aggressive substances

- Ease of connection to the pipeline

- Warranty period

- Advantages and specifics of the material used

- Factors to Consider

- Types and features

- Installation of polymer sand coating

- Do-it-yourself paving slabs from plastic bottles

- Advantages and disadvantages

Advantages and disadvantages of homemade tiles

Those who have not yet decided to create homemade tiles are afraid of two considerations: a significant investment of time and doubts about the quality of finished products. But when you consider the possibility of phased production, which allows you to do production on weekends or in your spare time, the process turns out to be not so long.In addition, the cost of materials will also stretch over time, because allocating 10% from the family budget for 3-4 months is much easier than spending half of the monthly income at once.

As for quality, it is enough to adhere to the technology and not try to save a lot, then the finished tile will serve for decades.

The combination of gray and beige tiles (made of white cement) looks stylish and helps save on pigments.

Table: comparing the advantages and disadvantages of artisanal paving slabs

| Advantages | Flaws |

|---|---|

| Saving money (from 30 to 60% depending on the equipment and materials used). | Large time investment (from 1 to 6 months, depending on the number of molds and the area of the tracks). |

| Unique tile design. | High probability of flaws with good detailing of the picture. |

| The ability to create non-standard corner and connecting elements that are not available in the manufacturer's catalogs. | Difficulty creating molds for precise details. It often happens that homemade corner tiles have to be laid with a large or uneven seam. |

| The ability to experiment with the composition of the tile, which allows you to save money or time, strengthen the standard composition, or add additional decorative filler. | Lack of guarantees of quality and durability. |

| The tile is suitable for all types of garden paths, recreation areas, outdoor terraces. | Reliable tiles for a territory with heavy loads (driveway, car parking area) are almost impossible to produce without special equipment and careful adherence to the recipe. |

| An exciting pastime, the opportunity to realize your ideas. | In practice, the work turns out to be physically difficult, requiring attention and precision. |

As you can see, for every drawback of homemade tiles, you can find a corresponding advantage. Therefore, if you want to proudly show your guests the work of your own hands, you can safely proceed to the implementation of the intended design of the tracks.

Industrial production of paving stones in factories

There are several types of paving stones, which differ in the material from which the products are made:

- stone (granite);

- concrete;

- clinker.

Stone blocks are made of granite, marble, basalt. The production technology of granite paving stones is elementary: the stone is sawn or split into fragments of the desired shape or size.

Clinker pavers are made from clay. At its core, this is the same brick, but of a slightly different shape and with higher strength.

Concrete pavers are made from high-strength concrete. Let us dwell on the technology of its production in more detail.

Differences of paving stones by type of production

Stone (granite) paving stones

Clinker pavers

concrete pavers

Equipment for the production of

The list of equipment used includes a special vibropress, with which the mixture is compacted, concrete mixers for preparing the mixture, a drying chamber and a loader. Also, special molds are needed for the production of paving stones.

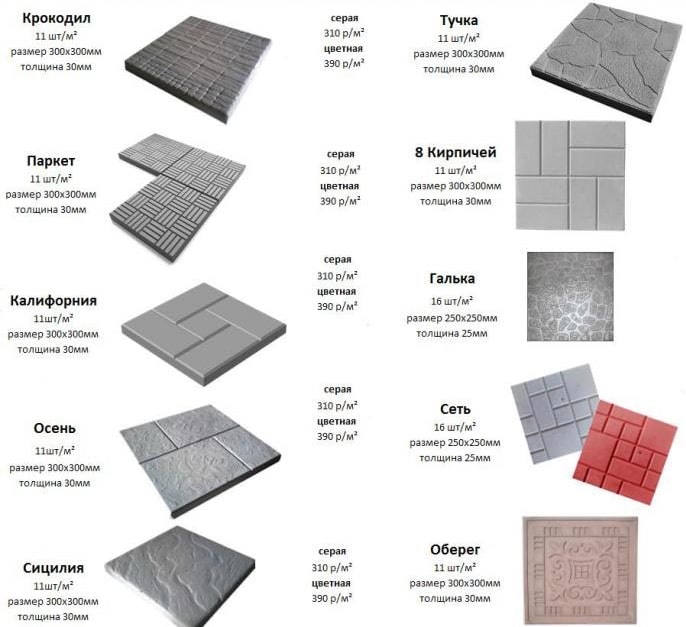

On the market there are forms of various configurations: both ordinary rectangular and figured or embossed. They can be made from various materials such as silicone, plastic, polyurethane:

- Silicone molds can be matte or glossy. They are easy to use and quite durable.

- Forms of polyurethane allow you to make paving stones with a relief surface, and it is easy to extract material from them. They have good strength, but their service life is much shorter than that of silicone molds.

- Plastic molds are usually square or rectangular, and may have a relief surface. Their service life is longer than that of plastic, but less than that of silicone.

The cost of forms depends on their volume, configuration and manufacturer. Plastic molds can be purchased for 25-65 rubles. for 1 piece A set of polyurethane molds for the production of 20 products will cost 4-5 thousand rubles.

Composition of the mixture

For the manufacture of 1 m3 of concrete mix, you need:

- cement brand 400 or 500 - 500 kg;

- crushed stone - 1 t;

- sand without impurities - 1 t;

- plasticizer - 2 kg;

- coloring pigment;

- water - 250 l.

A plasticizer is added to the mixture to increase the strength and wear resistance of products. It prevents the appearance of air bubbles and makes it possible to produce paving stones even at low temperatures.

Produced types

Polymer coating for sidewalks is already being produced at several enterprises today, since the ever-growing demand has made its production a fairly profitable business. A modern manufacturer offers two types of piece plastic products for garden paths on the building materials market.

The first version of the tile is made in the form of lattice squares 300x300 or 500x500 mm, while the shape of the lattice can be different. Grooves and protrusions are provided on the sides of the squares for fastening individual flat elements to each other into a single roadbed.

Paving slabs made of plastic in the form of lattice polymer squares do not exceed 20 mm in height and have a weight of not more than 1.5 kg. They are very easy to lay, since the preparation of the base is reduced to a simple leveling of the surface.

After that, the squares are interconnected and laid directly on the ground. In addition, this material is one of the few types of coverings through which grass can grow, which allows you to create very original compositions.

Polymer sand solid profile materials can have the same geometric shape as traditional tiles or stone and concrete pavers. They are quite massive and durable, but laying such plastic tiles will already require the preparation of a special base and.

How to lay tiles?

Before laying tiles, it is necessary to find out the technical properties of the material. This information can be provided by the paving stone seller. Before buying a tile, you should make sure that it is durable. This indicator determines the place of future installation. For example, some tiles can only withstand the loads that a person creates. Such material is not suitable for the organization of car parking.

The second important nuance is the appearance of the tile. Its surface should be rough so that people do not slip on the sidewalk after rain. The size of the tile and the future track should be taken into account

If they do not match, then the material will have to be cut along the curb, which you also need to pay attention to.

Most owners of private plots lay stormwater along the tile, providing a natural flow of water.

Immediately before buying, you need to calculate the amount of material that will be required to organize the sidewalks. To do this, you should prepare in advance a drawing of the site indicating the location and length of the tracks.

Components of the material

For the production of PVC paving stones, not only plastic bottles, but also other polymers can be used. In addition, you will need dye and sand. Ordinary containers are suitable as raw materials, which do not even have to be cleaned of food residues and stickers. Excess components themselves burn out during processing. In this case, the raw materials do not need to be sorted.

Plastic tile makers may also use parts from plastic cans, boxes, films and bags. Moreover, polyethylene parts are recommended to be used in order to give shine to the finished product.

Soft types of polymers can increase the plasticity of finished tile products. If they are not added during production, then the products are more fragile. Manufacturers adhere to the following proportions:

- solid polymer compounds - 60%;

- soft plastic - 40%.

Sand, which is used for the manufacture of polymer paving stones, is thoroughly cleaned of excess inclusions. At the same time, the manufacturing time of the product depends on the dryness of the sandy component. The quality of products depends on the uniformity of mixing of plastic with sand. The ingredients are taken in the following proportions:

- coloring matter - 1%;

- polymer elements - 9%;

- sand - at least 90%.

High-quality polymer paving stones are produced with the addition of inorganic dyes.

Raw material

Plastic paving slabs can be made from any waste:

- Plastic bottles;

- broken boxes;

- Plastic bags.

This is a very cheap raw material that can be bought from people for little money. For its purchase, special collection points should be organized. For 1 kg of plastic waste, you will have to pay only 3 rubles. In addition, you will need dye and sand. The cost of such products is sometimes much lower than that of its concrete counterparts. If you have firmly decided to engage in this type of income, then the business plan for the production of paving slabs and a description of the equipment can be found on the Internet on thematic resources. In addition, we recommend reading about. This option of earning, for sure, will interest you.

Reinforced concrete and polymer sand: who wins?

For a long time, reinforced concrete remained the only material for the production of wells. But its properties are far from ideal. Let's compare them with similar characteristics of polymer-sand raw materials.

Weight and transportation to the site

Reinforced concrete materials differ in significant weight. The meter ring has a mass of about 500 kg, which means that for its transportation to a construction site, special equipment is needed both for loading and unloading (crane) and for transportation (truck). Even if this is found, then such voluminous equipment will not always “squeeze” into the narrow construction space, especially in the city, where there are residential buildings nearby.

Due to less bulky components, polymer wells are easier to install, because large-sized equipment and many workers are not needed.

In diameter, polymer sand wells are not thicker than 1.1 meters, so they can easily fit into a regular trailer for a car

In turn, polymer-sand wells are much lighter. The mass of any structural fragment (ring, hatch, etc.) is up to 60 kg.This weight can be lifted by two people without using a crane. Yes, and the summer resident will be able to transport to the site with an ordinary trailer for a car. Another plus: it is easily mounted in a hard-to-reach place (for example, in the basement), because the owner of the site himself can roll up the rings and throw them into the mine.

One person can assemble a whole well from elements and mount it in the ground, because the weight of each element does not exceed 60 kg

Features of joining elements and tightness of joints

In reinforced concrete rings, the edges cannot be made absolutely even, therefore, during installation, you have to fiddle a lot with the tightness of the joints. And anyway, over time, they are washed away by water, as well as the walls. And if the well stands on moving ground, where groundwater has very strong flows in the spring, then the rings can move, breaking at the joints.

With the “groove-ridge” system, both structural elements are connected as tightly as possible, so the joints do not require additional sealing, except for lubrication with silicone

Polymer-sand elements are joined according to the “groove-ridge” system, thanks to which they are not afraid of soil movements. Such a connection absolutely does not let water through, and it is enough to coat all the grooves for insurance with silicone sealant or bitumen mastic.

Ability to resist moisture

Moisture is the main enemy of reinforced concrete structures. The concrete surface has large pores, and in winter, frost from the ground penetrates into them, expands and causes microcracks that will increase every year.

Due to the technology of "sintering" of particles, polymer sand rings have a water absorption level of only 0.03%.The well is able to withstand over five hundred freeze-thaw cycles (from -65˚ to +160˚С) without any structural damage.

Resistance to aggressive substances

Together with water from the soil, aggressive substances enter the surface of the wells, destroying the structure of concrete, and if the well is a sewer well, then the biomass decomposition reactions will “spoil” it from the inside. To make these processes run weaker, reinforced concrete rings are lubricated with special antiseptics and waterproofing mastics.

The polymer product is not afraid of an aggressive environment. The composite material does not react with substances, therefore it is not afraid of salts, acids and alkalis and does not require additional processing.

Ease of connection to the pipeline

When connecting a well to a domestic water supply system, you have to drill holes or openings in it. In reinforced concrete, this is very difficult to do. Often a professional tool is required.

You can cut openings and holes for pipes in polymer sand wells with ordinary household tools, and the edges do not need to be processed with anything.

In the polymer ring, all openings are created with household tools. At the same time, it is not necessary to lubricate the edges of the cut piece with any compounds, because corrosion of plastic is not terrible.

Warranty period

For reinforced concrete products, manufacturers give a guarantee of about 50 years, but indicate that these parameters relate only to the main technical characteristics. Those. The ring will definitely not fall apart and will not become thinner. But they cannot give a guarantee for the tightness of the joints, so even the most durable factory wells can silt up in a couple of years if the installation was carried out illiterately.

With polymer sand wells, such incidents are excluded.Therefore, manufacturers give a guarantee of up to 100 years, although plastics decompose in nature for over 400 years, and the sand that is part of the raw material is eternal.

Advantages and specifics of the material used

The main advantages that distinguish the tile material, created by hand from improvised materials (tires, plastic bottles), include the following:

High strength, reliability and durability. For work, recycled tires are used, which can no longer be used in the design of the car. It is noteworthy that the tire design can withstand significant loads, and tiles have the same parameters.

Excellent moisture resistance due to some roughness. The surface, created by hand, is both soft and pleasant, capable of quickly absorbing moisture in large quantities.

Tire shredder

The maximum level of security. Thanks to the well-designed rough surface, you can easily walk on paving slabs, both with and without shoes, without the risk of falling or getting injured

If a fall has taken place, you don’t have to worry, the soft surface will not cause significant damage and even bruises.

Optimum care of the surface, taking into account that the surface is free of chips and damage, has a high margin of elasticity. If the coating is dirty, simply wash it with a hose, wipe it dry

To remove ice, it is enough to use an ordinary shovel, while debris can be removed with a broom.

Mini press for the production of crumb rubber tiles

Ease of installation, for which there is no need to use a set of special tools, as well as various devices, fixtures.Laying paving slabs can be done even by a non-professional, because the joints are formed quite simply, no cracks form on the surface.

Affordable and favorable cost, the parameter is several times lower than the similar price set for concrete. Do not forget that paving slabs are created from plastic bottles, and even with your own hands, therefore, only available material is used, which is in abundance.

The effect of noise absorption, which is created due to the unique structure, when used, you will not feel extraneous sounds. In particular, do-it-yourself paving slabs from plastic bottles, the production of which is now on a grand scale.

The resistance of the material to environmental changes, which will allow you to use the product as a track cover without any problems, regardless of the weather, climatic conditions. In particular, it is possible to operate the product without problems in conditions of falling rains, hail, and intense temperature changes.

Factors to Consider

Paving slabs are a material that is used to cover paths, yards and paths. Its main task is to give a civilized appearance to a suburban or private area. The choice of paving slabs should be based on the following factors:

- Large selection of shapes and colors, which will allow you to realize any design ideas;

- Ease of installation. The tile should be laid using a simple technology, using standard tools, this will allow any person to lay it. It should also be possible to replace damaged elements without much difficulty;

- Ecological purity.In the summer, the sidewalk will be strongly warmed up by the sun. In this regard, its composition should not contain substances harmful to humans that will begin to be released when heated;

- Durability. This is one of the main factors. The laid material must hold firmly and reliably and withstand the effects of temperature extremes, mechanical stress and atmospheric influences. High-quality material that meets these requirements will last a long time.

Types and features

types of tactile tiles

types of tactile tiles

Tactile tile products have the same appearance as standard tiles. However, it contains on its surface a relief pattern of a conical or linear shape.

Using a stick, a blind person can easily determine the direction of the stripes. For example, if they are across, then you need to turn left or right, and straight lines allow passage. Cone-shaped designations (reefs) serve as a warning that there is a danger zone along the way (car route, descent or ascent).

There are 4 types of corrugation:

- longitudinal - shows the direction in which you need to move;

- square - indicates an obstacle on the way;

- diagonal - indicates the need to make a turn;

- cone-shaped - means that there are steps ahead.

table of corrugation forms and purpose of tactile tiles

In addition, these tiles have a brighter color that sets them apart from other road surfaces. This feature is intended for people with impaired vision and the ability to distinguish shades.

This type of tile can be made from various materials. For example, in yard areas and in the premises of administrative buildings, polyurethane or rubberized products are most often laid, which are fixed on the floor using a special adhesive. Concrete products are laid on city streets.

Paths and curbs for the blind attract the attention of healthy people as well. In an intense flow of people walking, it is difficult to immediately notice a visually impaired person, and on the paving stones for the blind, you can avoid a collision with a disabled person

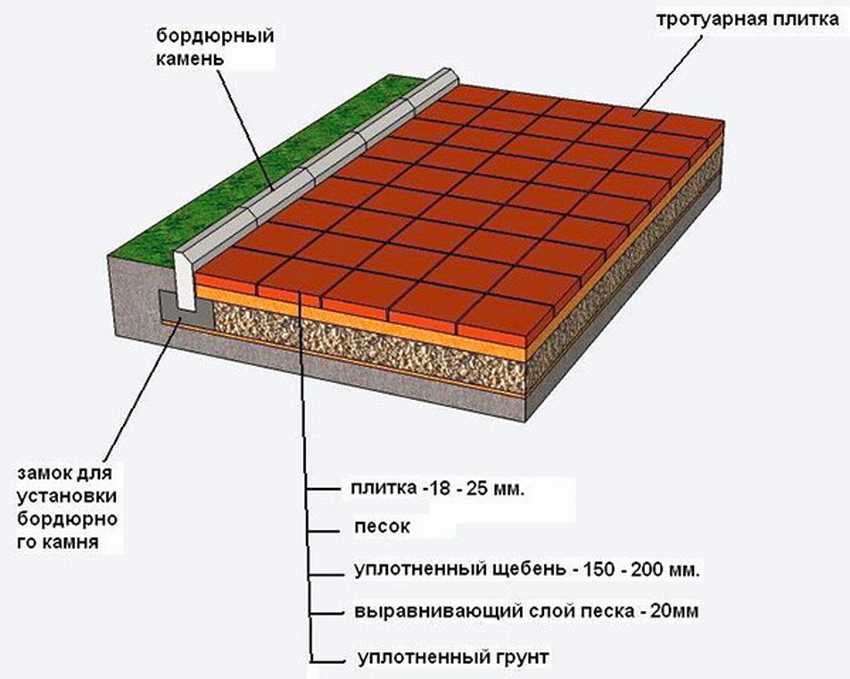

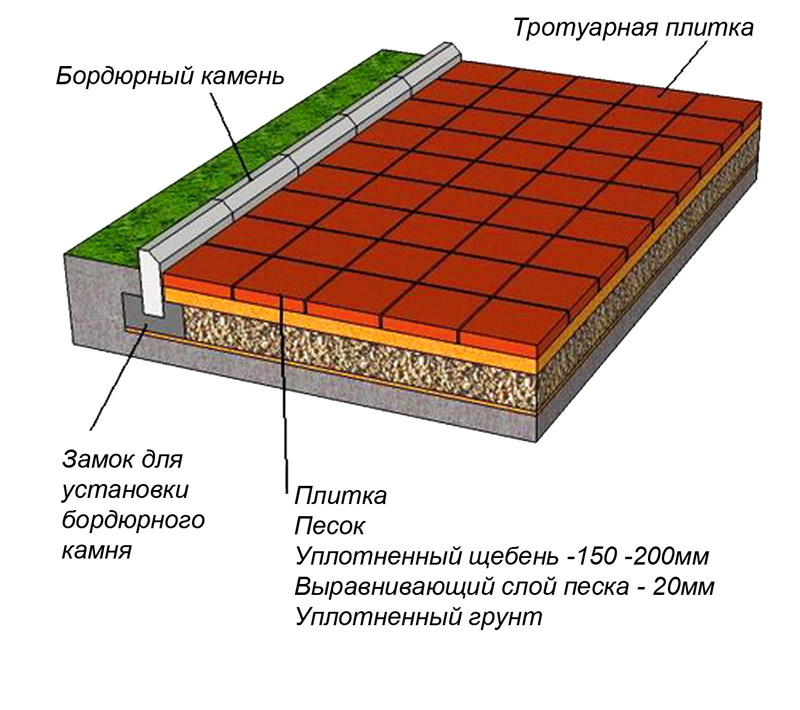

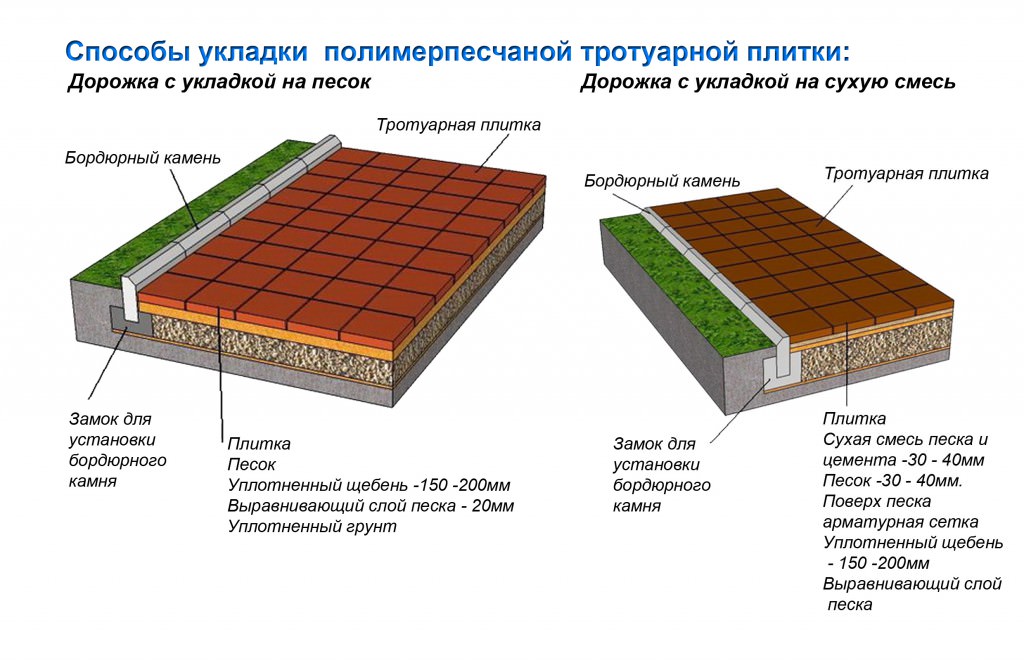

Installation of polymer sand coating

Laying plastic paving slabs on the surface is quite simple, and you can do it yourself. This will require the simplest construction tool, as well as:

- washed or river sand of a large fraction;

- crushed stone of medium fraction or gravel;

- cement grade PC400;

- tiles or paving stones made of plastic;

- concrete or plastic curbstone.

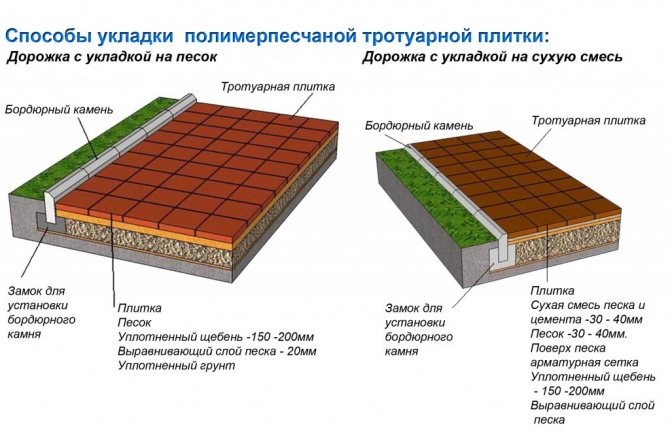

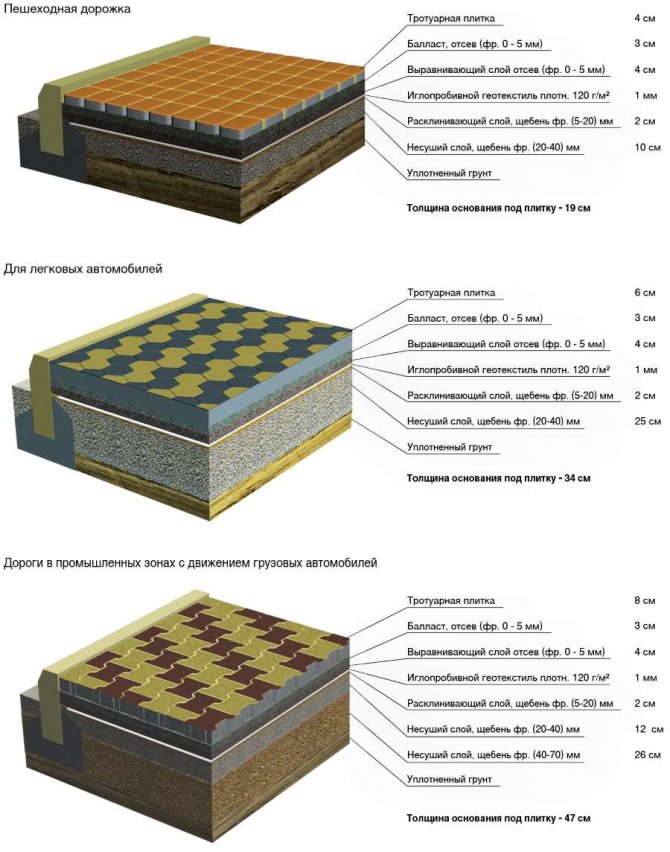

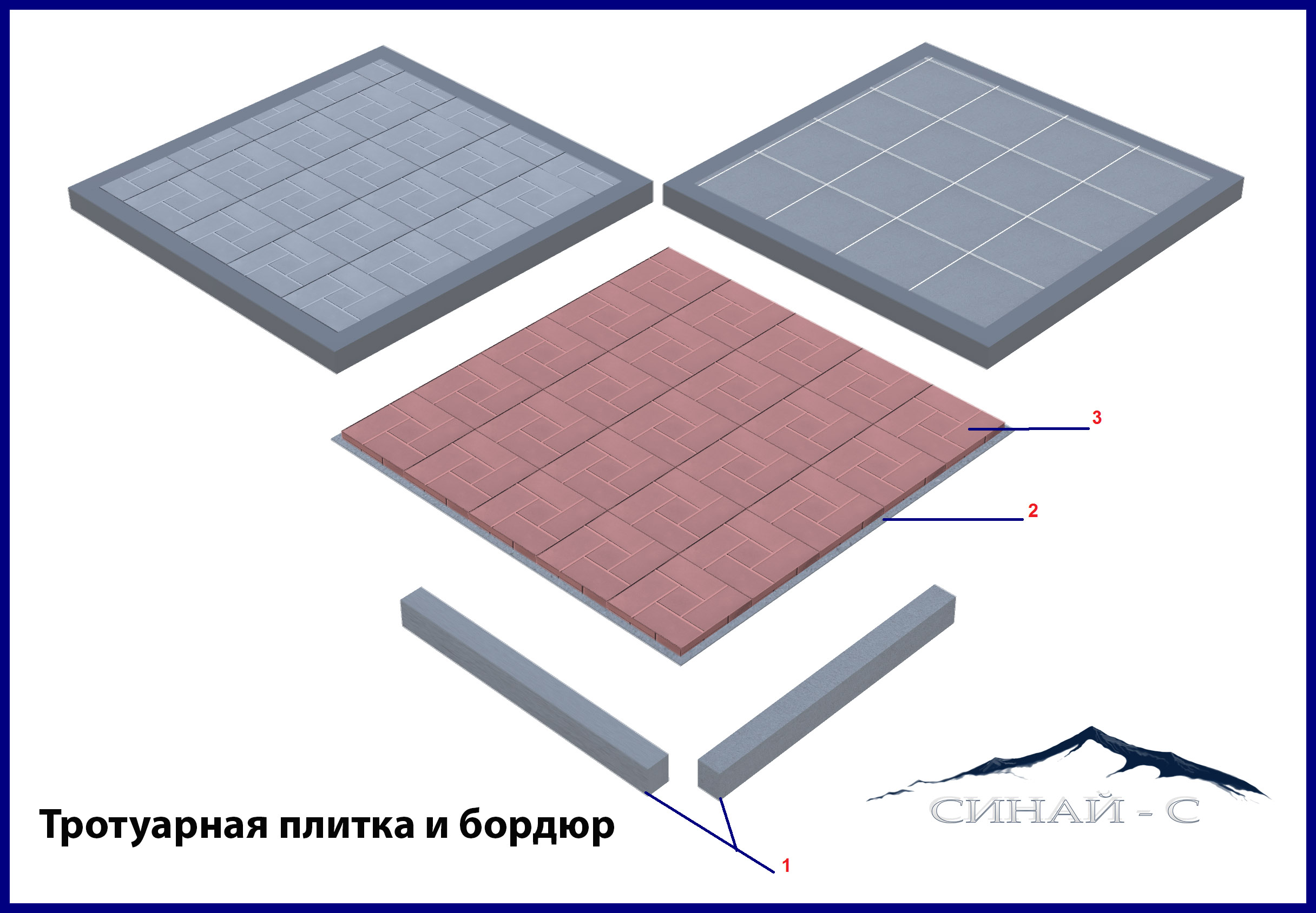

Two similar technologies are used for the device of sidewalk coverings made of polymeric materials. Laying on compacted sand and preparation of a cement-sand base. Both options require the following types of work:

- markup;

- removal of the top layer of soil to a depth of 25-30 cm;

- installation of a curbstone;

- at the bottom of the trench;

- backfilling and tamping of a drainage layer 10-15 cm thick from gravel or crushed stone;

- laying geotextiles on the drainage layer;

- backfilling and tamping of a layer of sand 5-15 cm thick.

Polymer paving stones are usually placed on clean sand, since it has a higher thickness of individual piece products and a smaller surface area. Such material, folded into a single coating, has great stability and does not require a particularly strong base.

Thinner plastic paving slabs are laid on the cement-sand mixture in order to have a solid base under relatively wide products.

It will ensure the stability of individual slabs even if weight pressure is applied to their edges.

Given the simultaneous strength and ductility, the preparation of a heavier concrete base is usually not required. The decision on its device is taken only by the presence of heaving and unstable soils on the site. In these cases, the sandy leveling layer is replaced with a reinforced concrete monolith.

The cement-sand mixture is prepared from PC400 cement and washed sand of the middle fraction in a ratio of 1:5. Mixing is preferably carried out in a concrete mixer to obtain the required level of quality.

The order of laying the material on the track is as follows:

- put along the curb about a meter row of paving slabs made of plastic or paving stones, leveling the height of the tiles with a rubber mallet;

- lay out one row across the path or sidewalk, while checking the presence of the necessary slopes with the building level;

- fill the area indicated by these rows with tiles or paving stones;

- further lay the material, filling such small areas.

After masonry is completed, all existing seams must be filled with dry, clean sand. To do this, the material is poured onto the surface and spread over it with a soft brush, thereby filling all the voids.

Do-it-yourself paving slabs from plastic bottles

Used plastic bottles are garbage, accounting for a third of all

waste of the planet. Such containers sell water, juices, beer and liquid household chemicals.The container is considered disposable, therefore, after use, it is useless for the initial

goals.

But today, plastic bottles are recycled into flex - plastic

crumb, which is further used for the manufacture of polymer fibers and various products used in everyday life and in production.

Paving slabs from bottles

in our country is considered an innovation,

although in the West this technology has been used for a long time. Therefore, the production of paving slabs from plastic waste is a profitable business with little competition.

Advantages and disadvantages

First of all, plastic bottle tiles attract buyers with their low

at a price that due to the cheapness of raw materials,

going to production. All you need is plastic containers, sand, dye and additives. But such a pavement

a large number of good performance characteristics, that is, the consumer pays little, but receives high-quality material.

The main advantages of polymer pavement:

·

in terms of strength, polymer tiles can compete with concrete pavement;

·

does not crack in the cold;

·

it is easy to remove snow from such paths;

·

no ice crust forms on the coating;

·

good adhesion with the sole of the shoe ensures the safety of pedestrians;

·

the surface is resistant to abrasion;

·

has high moisture resistance;

·

the material is light and easy to install;

·

not afraid of chemical influences;

·

withstands very low temperatures;

·

produced in different colors and textures.

Flaw

paving slabs from plastic bottles have only one - with

high temperature it increases slightly in size.

To avoid deformation of the coating under the influence of sunlight, when laying between the tiles, a distance of at least

a few millimetres.