- How a three-way valve works

- Thermomixing valve actuators

- Main design features and functions of the device

- Actuator for three-way valve

- Three-way control valve with electric drive

- thermostatic valve

- Valve Selection Criteria

- Types of valves by purpose

- Differences in design

- Different types of drives and their features

- Additionally

- Design

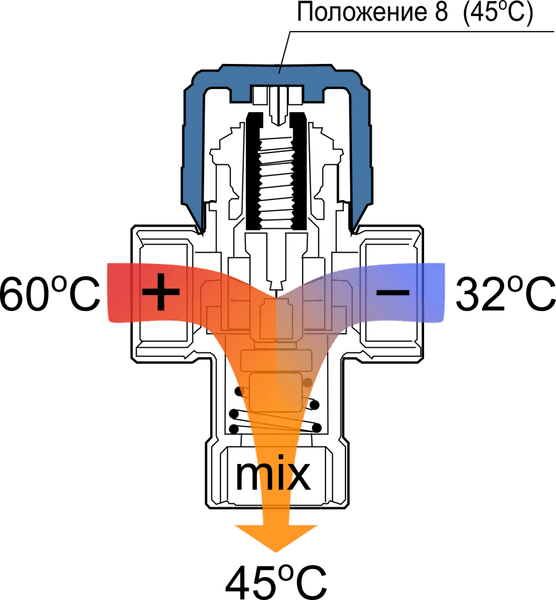

- Principle of operation

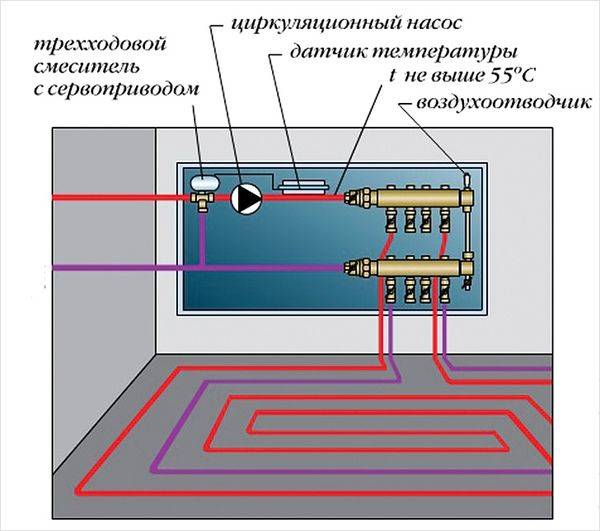

- For underfloor heating

- How does a three-way valve work in a heating system

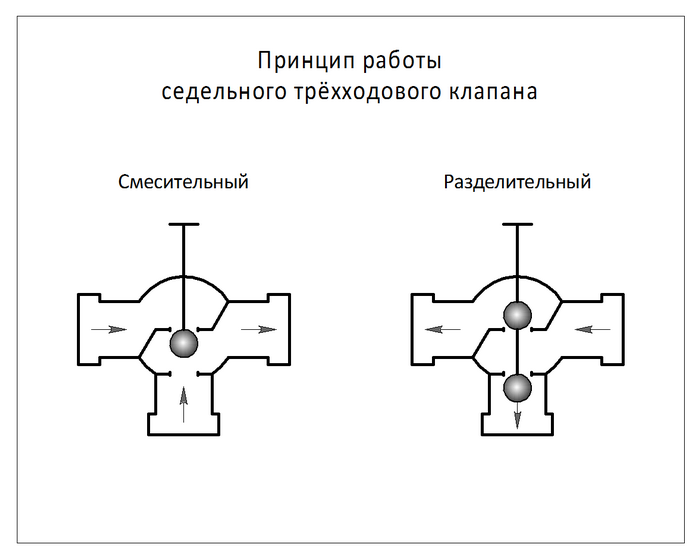

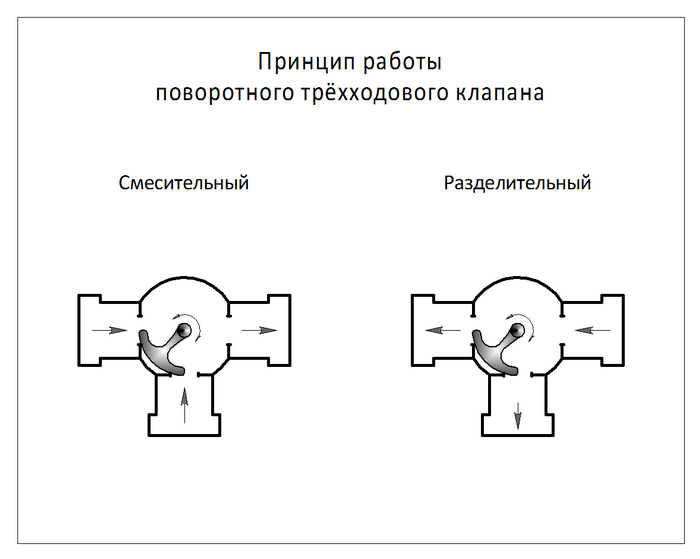

- Types of three-way valves according to the principle of operation

How a three-way valve works

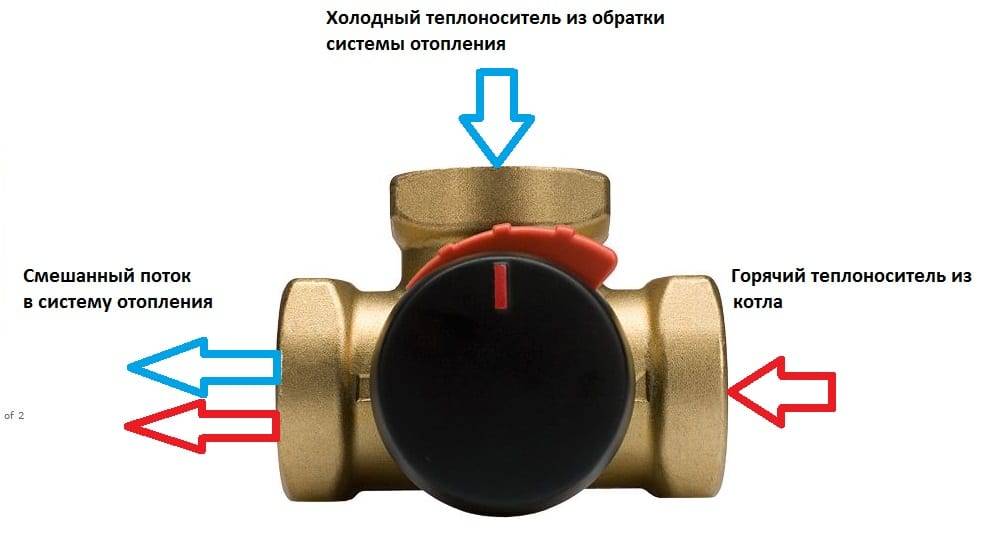

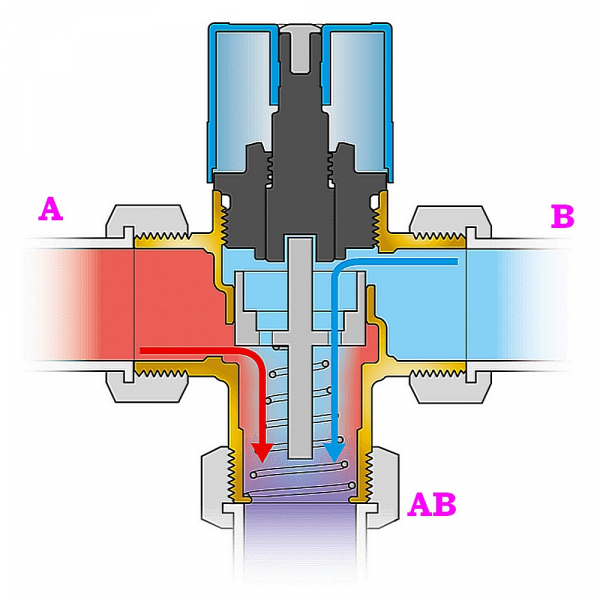

Outwardly, it looks like a bronze or brass tee with an adjusting washer on the top, and the device of the three-way valve depends on the model.

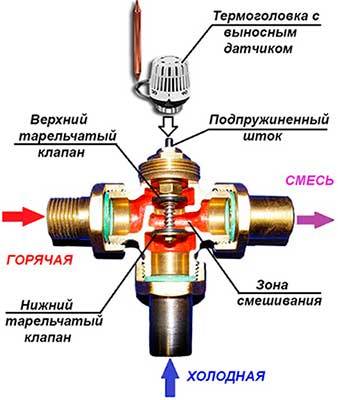

Option 1. In a molded body with three nozzles, there are three chambers, the passages between them are blocked by disc elements mounted on the stem. The stem exits the housing at the top. The principle of operation is as follows: pressing the rod smoothly opens the passage for the coolant flow on one side, while simultaneously closing the passage for the coolant on the other side. As a result, in the central zone, the coolant is mixed until the desired temperature is obtained and enters the circuit.

Option 2.The switching element inside the tee is a ball, part of which is figuratively selected. The drive rotates the rod with the ball fixed on it, as a result of which the coolant flows are redistributed.

Option 3. The principle of operation is the same as that of the design with a ball, but instead of a ball, a sector is fixed on the rod - its working part is able to completely block one coolant flow, or partially - two flows.

Thermomixing valve actuators

An external drive is required to control the heat carrier flows passing through the three-way valve. The functionality and usability of the device depends on its type.

- Three-way thermostatic mixing valve. The design of the thermostatic actuator includes a liquid medium with high sensitivity to temperature changes. It is she who, expanding, presses the stem. Such a drive is installed on household devices of a small cross section, it can be replaced with a drive of a different type.

- Three-way mixing valve with thermal head. The thermal head is equipped with an element that is sensitive to the air temperature in the room. To adjust the temperature of the coolant, such a device is additionally equipped with a temperature sensor on a capillary tube, which is placed in the pipeline. In this case, the temperature regime of the circuit is more precisely regulated.

- Mixing valve with thermal head

- Electric three-way valve. The electric drive acting on the rod is controlled by the controller, which receives information from the sensors about the change in the temperature of the coolant. This is the most accurate and convenient option.

- Three-way valve with servomotor.The electric actuator directly controls the stem, without a controller, according to the signals from the sensors. Servo drives are usually equipped with sector and ball mixing devices.

Main design features and functions of the device

Having a rough idea of \u200b\u200bthe principle of operation of a three-way valve, it is better to study the operation of this mechanism in detail. The name "three-way" determines the main function of the device - water of various origin enters the valve through two inlets:

- hot coolant from a supply pipe connected to a heating device or to a riser of a central heating system;

- cooled water returning after passing through the water circuit.

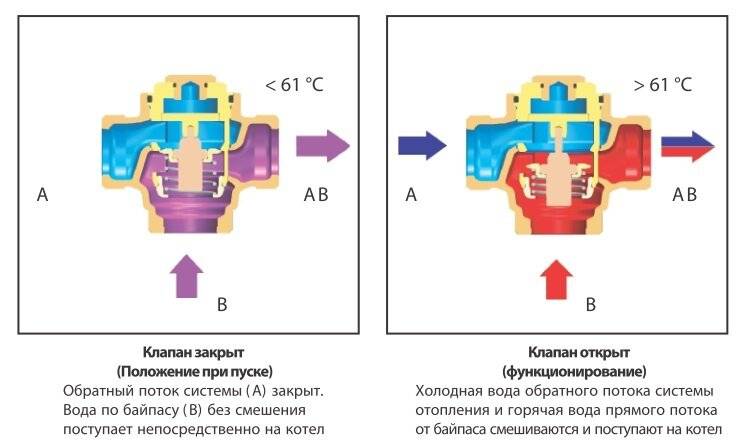

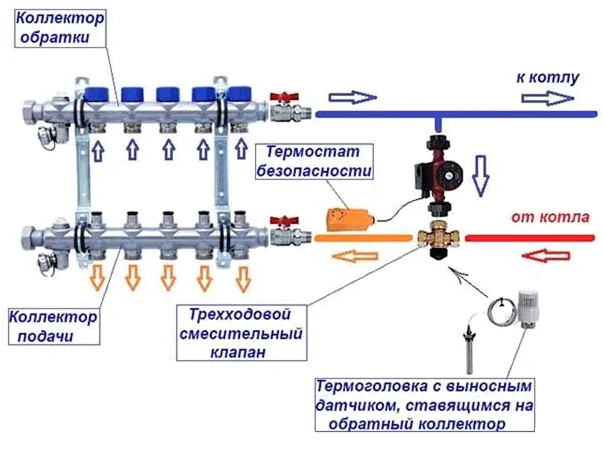

Mixing with each other in the valve in a certain proportion, the flows exit through the third branch pipe, having a given temperature value. The valve works constantly, since the principle of cyclic operation of warm floors is based on mixing hot water to the cooled coolant: heating - heat transfer - mixing - heat transfer - mixing.

The process of mixing two coolant flows of different temperatures must be constantly monitored, preferably in automatic mode. Otherwise, the intensity of heat exchange between the warm floor and the air in the room will not be tied to temperature changes in the room, and you will have to manually change the heating temperature of the coolant as necessary.

To carry out the admixture of hot coolant in automatic mode, a temperature-sensitive head controls the throughput of the valve depending on the temperatures of the mixed liquids in order to obtain a preset value at the outlet.

Depending on the purpose and operating conditions, various types of three-way valves are used.

1. Heating systems

For a heating system with radiators powered by an autonomous boiler, the simplest type of device is used. inexpensive and have a relatively simple design, which allows you to install them yourself. The adjustment of the mixing volume in this case is carried out manually.

2. Hot water systems

In DHW systems, three-way valves are used to maintain safe water temperatures in the communications system, eliminating the possibility of burns. The design of such devices is also quite simple and understandable. Such devices differ from valves for heating systems by the presence of a special protective block that shuts off hot water in the absence of cold water in the water supply.

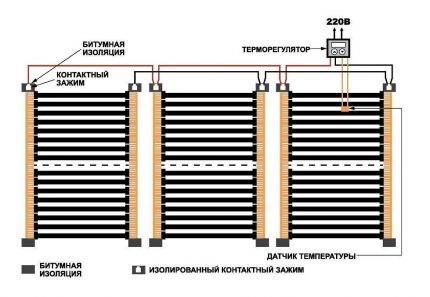

3. Warm water floors

Devices of this type are the most complex, as they are designed to maintain the desired temperature of the coolant in the heating circuits with reference to the air temperature in the room. The use of such devices in the mixing unit allows you to adjust the intensity of housing heating in automatic mode,

The layout of the mixing unit and the location of the three-way valve in it

The layout of the mixing unit and the location of the three-way valve in it

Three-way valve model with adjustment scale

For underfloor heating, the tap is equipped with an adjusting handle and a measuring scale, with which the device is adjusted.

Actuator for three-way valve

A servo drive is an electric motor controlled through negative feedback.In this case, the negative feedback will be the shaft rotation angle sensor, which stops the shaft movement when the desired angle is reached.

For clarity, consider the servo device according to the figure:

- As you can see, the following components are located inside the servo drive:

- Electric motor.

- A gearbox consisting of several gears.

- An output shaft by which an actuator turns a valve or other device.

- The potentiometer is the same negative feedback that controls the angle of rotation of the shaft.

- Control electronics, which is located on the printed circuit board.

- A wire through which the supply voltage (220 or 24 V) and the control signal are supplied.

Let's now dwell on the control signal in detail. The servo is controlled by a variable pulse width pulse signal. For those who don't know what I'm talking about, here's another picture:

That is, the pulse width (in time) determines the magnitude of the angle of rotation of the shaft. The setting of such control signals is not trivial and depends on the specific drive. The number of control signals depends on how many positions the output shaft can occupy.

The servo can be two-position (2 control signals), three-position (3 control signals), and so on.

Three-way control valve with electric drive

Various elements act as an electric drive for three-way control valves with an electric drive.

- There are two varieties:

- three-way valves for heating with an electric drive in the form of an electric magnet;

- three-way valves with servo-driven electric motor.

The actuator receives a command directly from the temperature sensors or from the control controller. Models of three-way valves for heating with an electric drive are the most effective, as they allow for the most accurate adjustment of heat flows.

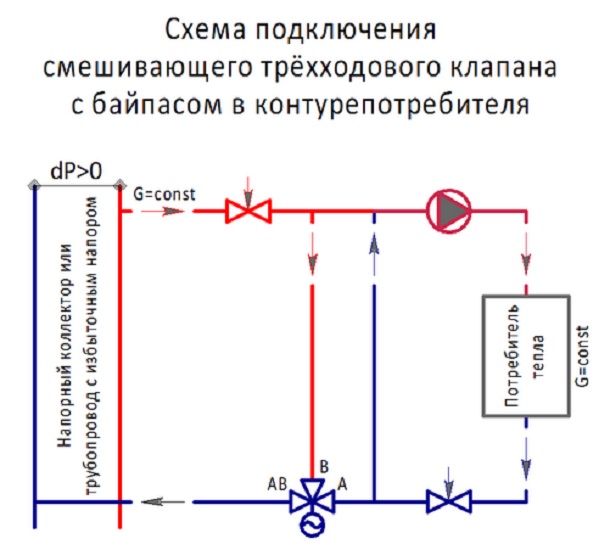

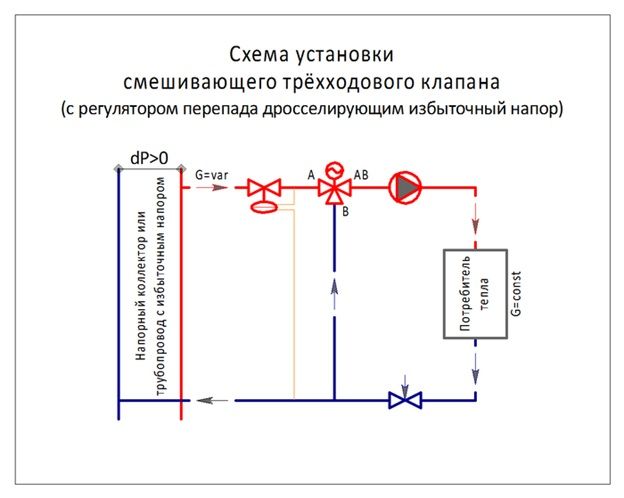

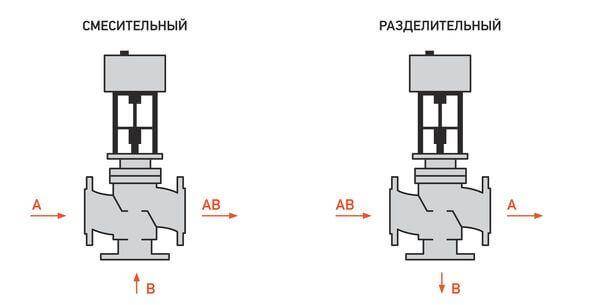

Three-way control valve - designed for mixing or dividing the coolant flow, therefore they are also called mixing and dividing valves. Three-way control valves have three branch pipes for connection to the pipeline.

They are most widely used in heat supply systems connected from autonomous boiler houses, in which there is no need to limit the flow while maintaining the mixing ratio.

They are installed to control the heat transfer of ventilation system heaters, heat exchangers of hot water supply and heating systems connected according to an independent circuit, control the mixing process in heating systems with dependent connection in the boiler room.

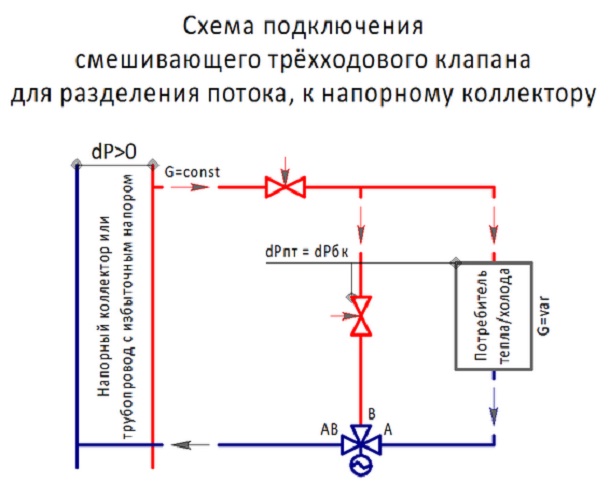

The valve is controlled by an electric drive, by a signal from an electronic regulator, or from a central dispatching system. The operation of a three-way valve is based on the creation of circuits with a constant and variable hydraulic regime in the circulation ring, due to the separation of one flow or mixing of two coolant flows.

Regardless of the position of the stem in the three-way valve, the circulation does not stop, therefore this type of device is not suitable for reducing the coolant flow. This is the main difference between a three-way ball valve with an electric drive and two-way valves, regulators and other devices.

This valve is designed for mixing or separation, distribution of flows. The diverter valve controls the amount of water by allowing some of the liquid to pass through the bypass instead of the direct route. Two nozzles of the device serve for the exit, and one for the entrance.

The principle of operation of a three-way mixing valve with a thermal head is based on mixing a colder coolant with a hot coolant or a hotter one with a cold one. As a result, the qualitative characteristic, namely the temperature of the heat flow, changes, while the level of this change depends on the established proportion of the connected jets.

Two ports for input and one for output can also perform a separating function. Such valves can be used in various removals.

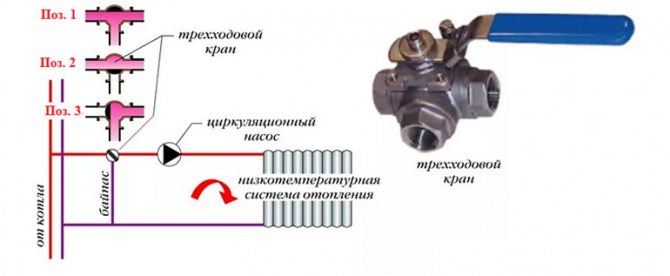

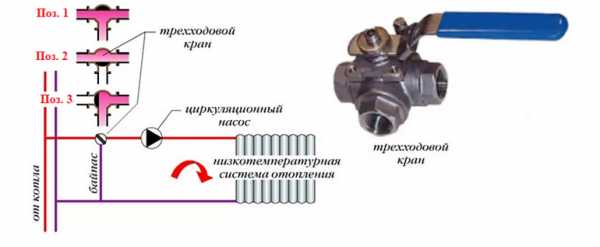

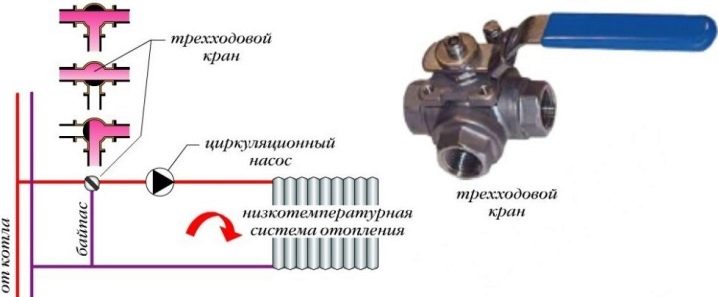

It is often relevant to use three-way valves for solid fuel boilers, in the chamber of which condensate forms at the beginning of the furnace. In this case, the valve helps to temporarily cut off cold water, and let part of the heated liquid flow through a short circuit.

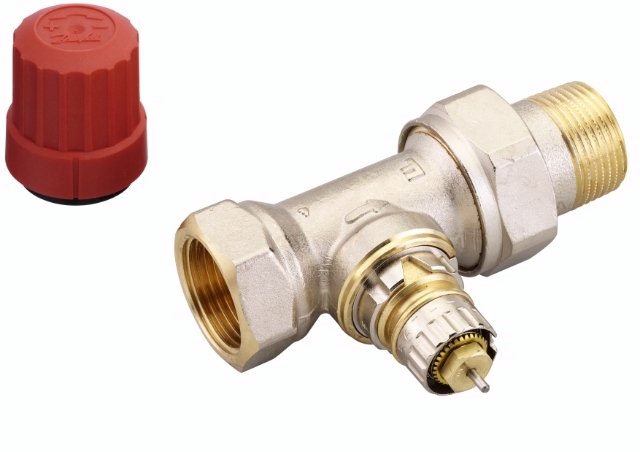

thermostatic valve

In modern realities, a thermostatic expansion valve is a preliminary norm for modern and reliable equipment in a heating system. The temperature of the valve is automatically regulated. Mixing operation heating system valves for radiators consists in limiting the supply level to a separate heating radiator. The valve stem makes movements to open and close the hole. Through this hole, the coolant enters the radiator. When the valve with a thermostatic head is heated, the inlet is closed, as a result of which the coolant flow rate is reduced. The thermostatic valve constantly changes its position.And an important factor is the quality of the materials on the basis of which this product is made. The product may fail due to stem sticking, as well as significant corrosion and breakthrough of sealing materials. But even if the thermostatic valve fails, you can extend its life by replacing the thermostatic element.

Heating system valves with thermal heads differ depending on the shape and type of supply to the heating system. They can be angular when approaching the radiators from the floor, they can also be straight, which connect the pipes to the battery relative to the wall surface. Axial, mainly when connecting pipes from the wall to the battery. When batteries are connected sideways, a special kit is required. It uses thermostatic heads and valves. Obviously, batteries coming with a bottom connection are equipped with valve-type liners.

Valve Selection Criteria

How to choose a three-way valve? When choosing, it is recommended to consider:

- purpose of the device;

- constructive execution;

- type of drive;

- Extra options.

Types of valves by purpose

A three-way valve for a boiler or other device can be:

- mixing, that is, the main purpose of the valve is to mix different fluid flows to a temperature specified by the user. A mixing valve is used in underfloor heating systems to prevent overheating and failure of communications and in hot water supply systems;

- separating. Unlike the previous view, the main purpose of the device is to distribute the supply flow of the coolant to different branches of the main, for example, when installing an additional radiator;

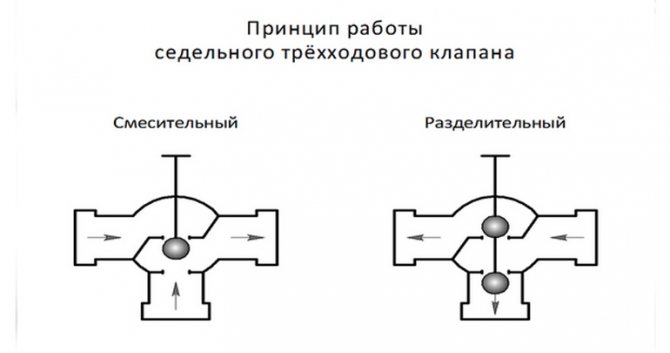

The difference in the operation of the mixing and dividing valve

switching, that is, redistributing the fluid flow in the system.

The purpose of the valve is indicated on the body of the device.

Differences in design

The control valve, depending on the design, can be:

saddle - the movement of the rod occurs vertically to the saddle. As a rule, the functions of this type of equipment are the mixing of streams with different temperatures;

Valve with vertically moving stem

rotary - when the rod moves, the damper is rotated, which regulates the direction and power of the flows.

Gate device

In the household sphere, rotary valves are most widely used. Saddle mechanisms are installed only in cases of exposure to high temperatures and high throughput.

Different types of drives and their features

The three-way valve stem can be actuated:

temperature sensitive element mounted on the thermostat. The advantages of this type of control are simplicity, high accuracy and no need for power supply;

Three-way valve with thermostat

electric drive. Motorized valves receive parameters set by the user from temperature sensors installed in different places, or a common control controller. The cost of such equipment is high, but the main advantage is the maximum accuracy of the device.

Electrically powered equipment

Additionally

When purchasing a valve for a warm floor or other communication system, it is also recommended to consider:

- the diameter of the nozzles, which must correspond to the diameters of the pipes suitable for the device. If you cannot select a parameter, then you will need to install an adapter;

- valve capacity indicator (indicated in the technical documentation for the equipment);

- appointment. Valve for cold or hot water, heating, underfloor heating, gas, and so on (indicated in the documentation);

- the ability to connect additional equipment, for example, a thermal head, an electric drive, and so on, if the original device is not equipped with any control methods;

- manufacturer. The highest quality valves are produced by the Swedish company Esbe, the American company Honeywell and the joint venture of Russia and Italy - Valtec.

Design

By structure, a three-way valve includes two two-way valves combined in a single housing. At the same time, they regulate the intensity of the coolant flow so that you can influence the temperature of hot water in radiators and underfloor heating pipes.

The thermostatic mixing valve consists of the following elements:

- metal case;

- steel ball or stem with lock washer;

- fastening couplings.

If the valve is equipped with a stem, it can be connected to an electromechanical actuator. Then the control of the flow and temperature of the coolant can be automated. Manual valves are usually equipped with metal balls. The principle of operation of such devices resembles the operation of a kitchen faucet.

Principle of operation

The three-way valve is equipped with three nozzles for connecting lines. Between them, a valve is installed that regulates the water supply to two of the three branches.Depending on the orientation of the tap and its connection, it performs two functions:

- mixing of two coolant flows to one outlet;

- separation from one line to two weekends.

A three-way valve, like a four-way one, does not block the channels connected to it, but only redirects the liquid from the inlet to one of the outlets. Only one of the exits can be closed at a time, or both can be partially blocked.

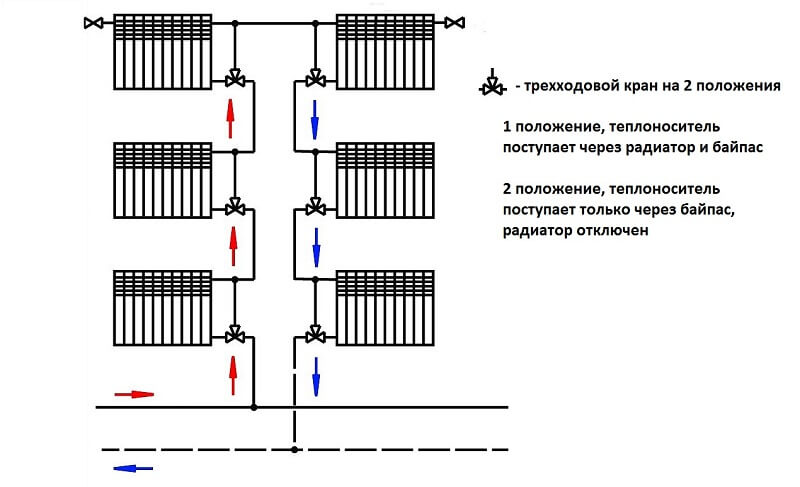

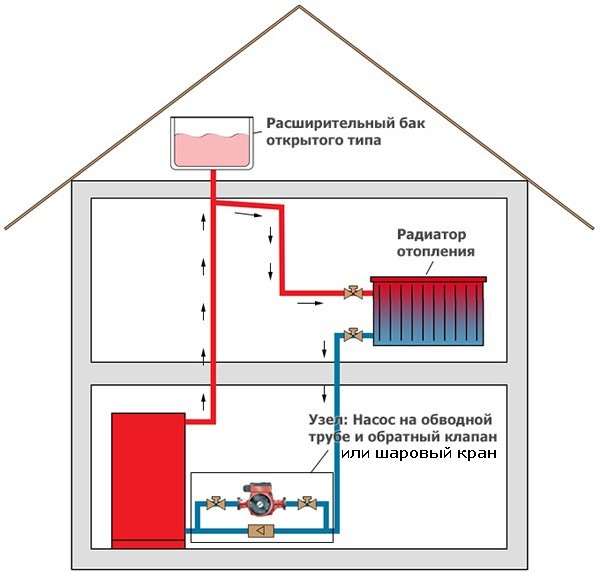

In the simplest version, the radiators are directly connected to the boiler, either in series or in parallel. It is impossible to adjust each radiator separately in terms of thermal power, it is only permissible to regulate the temperature of the coolant in the boiler.

In order to still regulate each battery separately, you can insert a bypass parallel to the radiator and after it a needle-type control valve, with which to control the amount of coolant passing through it.

Bypass is needed to maintain the total resistance of the entire system, so as not to disturb the operation of the circulation pump. However, this approach is very expensive to implement and difficult to operate.

The 3-way valve effectively combines the connection point of the bypass and control valve, making the connection compact and easy to operate. In addition, smooth adjustment makes it easier to achieve the target temperature in a limited circuit containing one or two radiators in a particular room.

If you limit part of the coolant current from the boiler and supplement it with a return flow, water returning from the radiator to the boiler, then the heating temperature decreases.At the same time, the boiler continues to operate in the same mode, maintaining the set water heating, the water circulation rate in it does not decrease, but fuel consumption decreases.

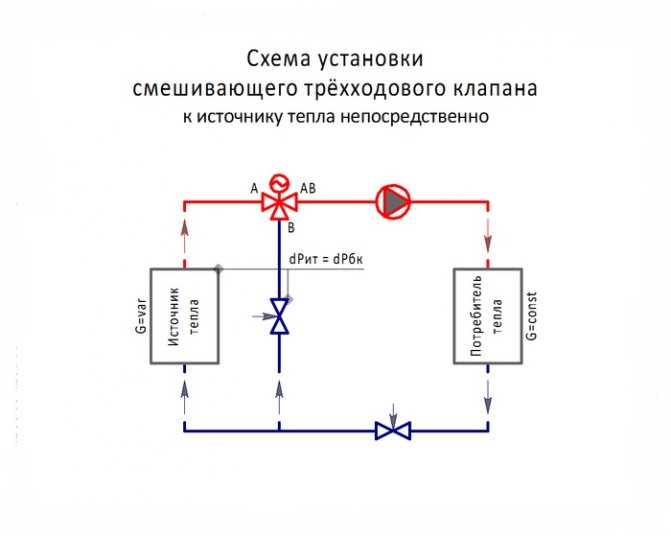

If one circulation pump is used for the entire heating system, then it is located on the side of the boiler in relation to the activation of the three-way valve. Install it at the return inlet of the boiler, through which the already cooled water flows from the radiators, acting as a flow separator.

At the inlet, hot coolant is supplied to it from the boiler, depending on the valve setting, the flow is divided into two parts. Part of the water goes to the radiator, and part is immediately discharged into the reverse direction. When the maximum thermal power is needed, the valve is moved to the extreme position, in which the inlet and outlet leading to the radiators are connected.

If heating is not needed, then the entire volume of the coolant flows through the bypass to the return line, the boiler works only to maintain the temperature in the absence of real heat transfer

The disadvantage of such a connection is the complex balancing of heating, so that the same amount of coolant enters each branch and each radiator, in addition, when connected in series to the extreme radiators, already cooled water reaches.

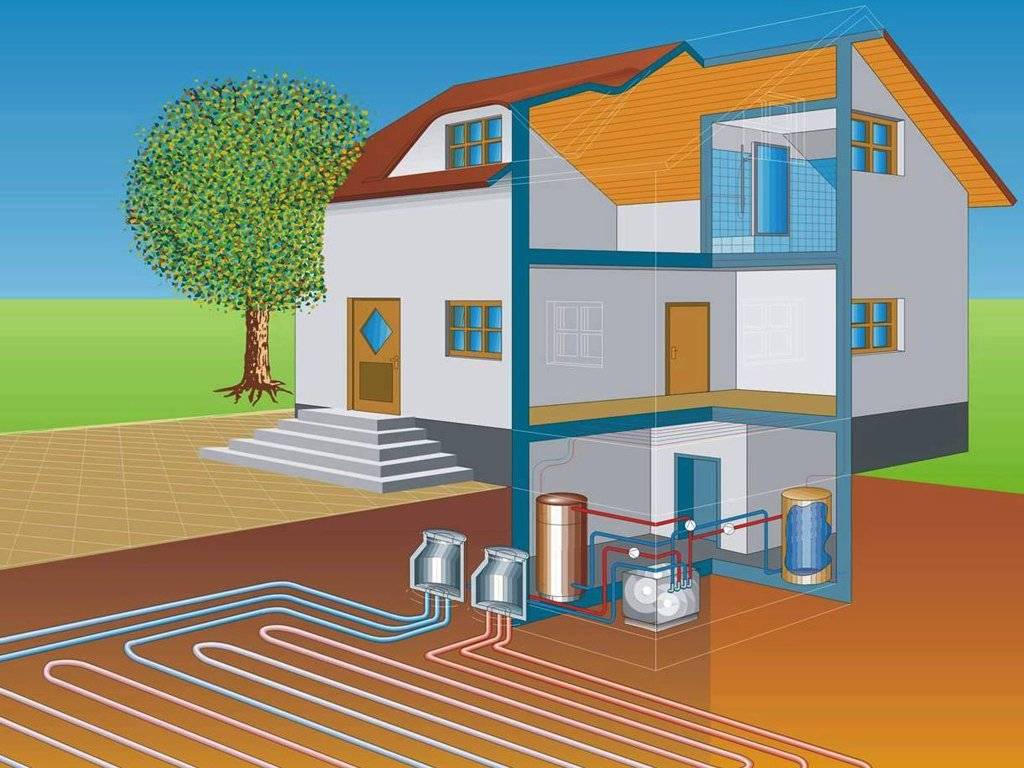

For underfloor heating

In multi-circuit systems, the easiest way to solve the problem of uneven heat distribution is to use a collector group with circulation pumps on each individual circuit

This is especially important in houses with two or more floors.

and a large number of radiators or in the presence of a warm floor

The three-way valve works to mix the two streams.One input connects the line from the boiler, and the second from the return pipe. Mixing, water enters the outlet connected to the heat exchanger.

This connection scheme is especially relevant when connecting a warm floor.

It makes it possible to limit the maximum temperature of the water in the circuit, which is especially important, given the maximum allowable value of 35ºС at a temperature of the heat carrier from the boiler of 60ºС and above

The circulation of water in the pipes of the warm floor is constantly maintained, which is necessary for uniform heating without distortions. In fact, hot water from the boiler comes only to heat the cooling coolant in the underfloor heating circuit, and the excess is discharged back to the boiler.

Thus, even in high-temperature heating, where the boiler heats water up to 75-90ºС, it is possible to equip underfloor heating with heating 28-31ºС.

How does a three-way valve work in a heating system

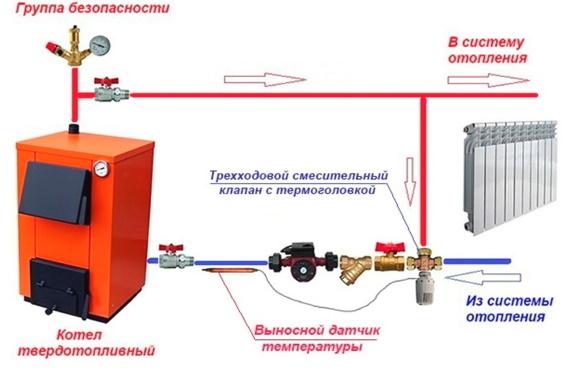

The principle of operation of the valve is to mix water flows with different temperatures. Why should this be done? If you do not go into technical details, you can answer this way: to extend the life of the heating boiler and its more economical operation.

The three-way valve mixes the heated water with the cooled water after passing through the heating devices and sends it back to the boiler for heating. To the question of which water to heat faster and easier - cold or hot - everyone is able to answer.

Simultaneously with mixing, the valve also separates the flows. There is a natural desire to automate the management process itself. To do this, the valve is equipped with a temperature sensor with a thermostat. In this case, the electric drive works best here.The quality of the functioning of the entire heating system depends on the drive device.

- Such a valve is installed in those places of the pipeline where it is necessary to divide the circulation flow into two circuits:

- With constant hydraulic mode.

- With variables.

Usually constant hydraulic flow consumers are used for which a high-quality coolant of a certain volume is supplied. It is regulated depending on the quality indicators.

A variable flow is consumed by those objects for which quality indicators are not the main ones. They care about the quantitative factor. That is, for them, the supply is adjusted according to the required amount of coolant.

There are in the category of valves and two-way analogues. What is the difference between these two types? A three-way valve works in a completely different way. In its design, the stem cannot block the flow with a constant hydraulic regime.

It is always open and set to a certain volume of coolant. This means that consumers will receive the required volume both in quantitative and qualitative terms.

Essentially, the valve cannot shut off the supply to a circuit with constant hydraulic flow. But it is capable of blocking a variable direction, thereby allowing you to adjust the pressure and flow.

If you combine two two-way valves, you get a three-way design. In this case, both valves must work reversibly, that is, when the first is closed, the second must open.

Types of three-way valves according to the principle of operation

- According to the principle of action, this type is divided into two subspecies:

- Mixing.

- Dividing.

Already by the name you can understand how each type works. The mixer has one outlet and two inlets.That is, it performs the function of mixing two streams, which is necessary to lower the temperature of the coolant. By the way, to create the desired temperature in underfloor heating systems, this is an ideal device.

Adjusting the temperature of the outgoing ceiling is quite simple. To do this, it is necessary to know the temperature of the two incoming streams and accurately calculate the proportions of each in order to obtain the required temperature regime at the outlet. By the way, this type of device, if properly installed and adjusted, can also work on the principle of flow separation.

A three-way dividing valve splits the main flow into two. So he has two options. and one entrance. This device is commonly used for hot water separation in hot water systems. Often, experts install it in the piping of air heaters.

In appearance, both devices are no different from each other. But if we consider their drawing in section, then there is one difference that immediately catches the eye. The mixing device has a stem with one ball valve.

It is located in the center and covers the saddle of the main passage. There are two such valves in the separation valve on one stem, and they are installed in the outlet pipes. The principle of their operation is as follows - the first closes one passage, clinging to the saddle, and the second at this time opens another passage.

- A modern three-way valve is divided into two types according to the control method:

- Manual.

- Electric.

More often you have to deal with a manual version, which is similar to a regular ball valve, only with three nozzles - outlets. Electric automatic systems are most often used for heat distribution in private housing construction.

Like any device, a three-way valve is determined by the diameter of the supply pipe and the pressure of the coolant. Hence the GOST, which allows for certification. Failure to comply with GOST is a gross violation, especially when it comes to pressure inside the pipeline.