- Procedure for replacing an obsolete boiler

- What documents are needed when replacing a gas boiler

- Do I need a new project when replacing a gas boiler

- Features of replacing a boiler of the same power

- Is it possible to replace a gas boiler with an electric one

- Requirements for the ventilation system

- Requirements for the territory and premises

- Glazing material

- Mounting Tips

- Boiler room equipment

- Regulations

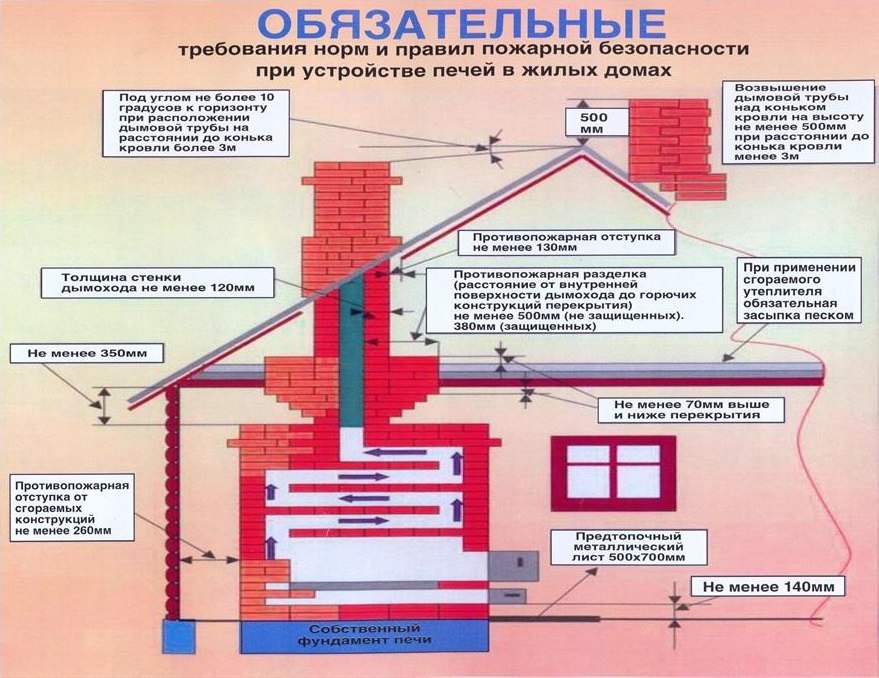

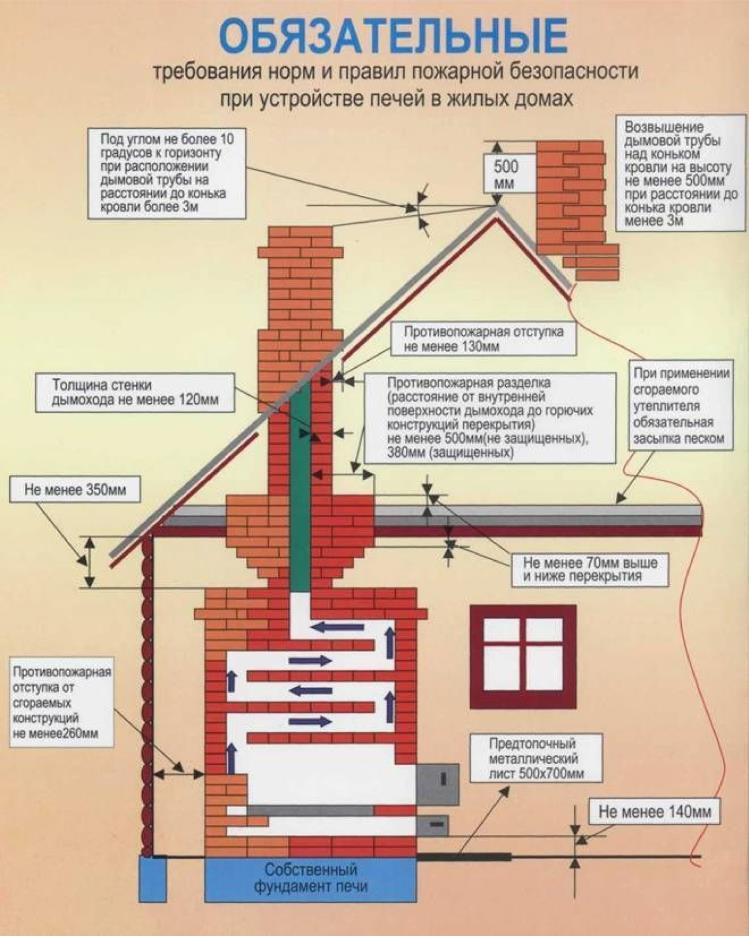

- Rules and regulations for installing a gas boiler in a private house

- Norms and requirements for operation

- Requirements for a room for installing a gas boiler

- Features of installing gas equipment in the basement

- New rules for the use of gas in residential premises

- Why equip a separate boiler room at home?

- Definition of fire hazard category

- Where can you place an autonomous boiler room?

Procedure for replacing an obsolete boiler

Gas equipment is considered a device of increased danger.

Therefore, all work on the installation and maintenance of gas appliances is also classified as work with increased danger. The existing rules unequivocally answer the question - how to replace a gas boiler in a private house - it is forbidden to install or replace boiler equipment on your own.Installation of boilers can only be carried out by special authorities (gorgaz, rygaz, oblgaz) through enterprises that have a license for such work.

To start replacing the boiler, you need to do the following:

- Write an application to the gas service for permission to replace the boiler. You need to know that when replacing an old boiler with a similar one, you do not need to create a new project, but if changes have occurred - a boiler of a different type, the location or gas supply scheme changes, then a new project is created.

- After receiving a response, you need to hand over a construction passport to the gas service. Collect and submit DVK inspection certificates, and if an imported boiler is installed, a certificate of conformity.

What documents are needed when replacing a gas boiler

Before replacing a gas boiler, it is necessary to collect a lot of documents and obtain permits for such work.

You will need the following documents:

- If the equipment is from foreign manufacturers, then you need to provide a certificate in accordance with our safety standards;

- If the boiler is double-circuit, then it is necessary to have a sanitary and hygienic certificate for supplying hot water for domestic needs. Usually such a document is provided immediately with the warranty card;

- Document on checking ventilation and smoke ducts;

- Warranty contract for at least 1 year, which is concluded with a service company;

- A document with the results of connecting equipment to engineering networks.

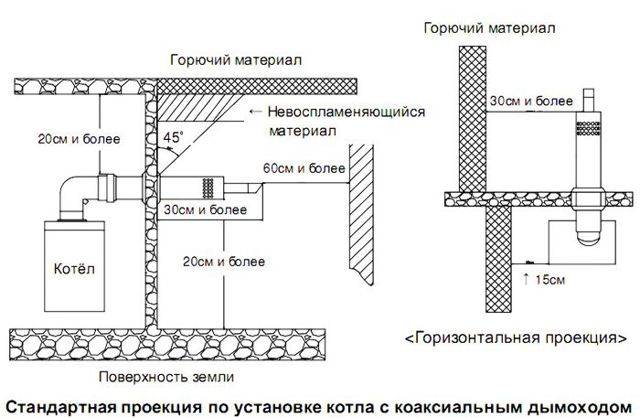

- Act on hidden work when installing a coaxial chimney through the wall;

- Project with changes. The main condition: the new boiler must be legalized.

You must collect all the documents yourself.If you do not have such an opportunity, then you can contact a special installation company. But in this case, additional costs must be calculated.

Do I need a new project when replacing a gas boiler

The project specifies the model, type and power of the heating unit. In addition, each boiler has its own serial number, indicated in the data sheet and included in the project documentation. Therefore, when replacing, you will need to make a new project with new data.

You need to go through the following steps again:

- Obtain specifications for the replacement of a gas boiler. At this stage, the gas distribution company can change the capacity of the unit based on the actual living area of the house.

- Make a new project.

- Obtain approval by submitting a gas distribution project, specifications, and the results of checking the chimney channel.

- Replace the old unit with a new one.

When replacing an old gas boiler with a new one, the following documents are needed:

- The passport.

- Documents of the owner of the dwelling.

- Technical passport for gas equipment.

- Specifications.

Standard prices for the replacement of already installed gas equipment are 1000-1500 rubles, depending on the region.

Features of replacing a boiler of the same power

If the gas consumption per hour of the new boiler is similar to the gas consumption of the old one, then this greatly simplifies the task. Since all that is needed from the owner is to submit a notification of the replacement to Gorgaz.

And to it should be attached:

- Boiler connection certificate.

- The act of inspection of ventilation, chimney.

- Contract for at least one year maintenance of gas equipment.

After consideration, the application is granted permission.After that, the equipment is replaced, tested and its operation begins. Thus, the RF GD No. 1203 p. 61(1) allows to operate.

Is it possible to replace a gas boiler with an electric one

Replacement is quite possible, but for this you will have to obtain permission from another organization involved in power supply. Documents are needed only if the electric boiler has a power of more than 8 kW. Up to this performance limit, the unit belongs to ordinary household water heaters by the type of boiler, therefore, it is installed without permits and approvals.

For productive electric boilers, a separate power supply line will be required. You will need to make a project and obtain permission to increase the amount of electricity generated. Separately, it is necessary to write a statement about disconnecting the gas boiler from the main.

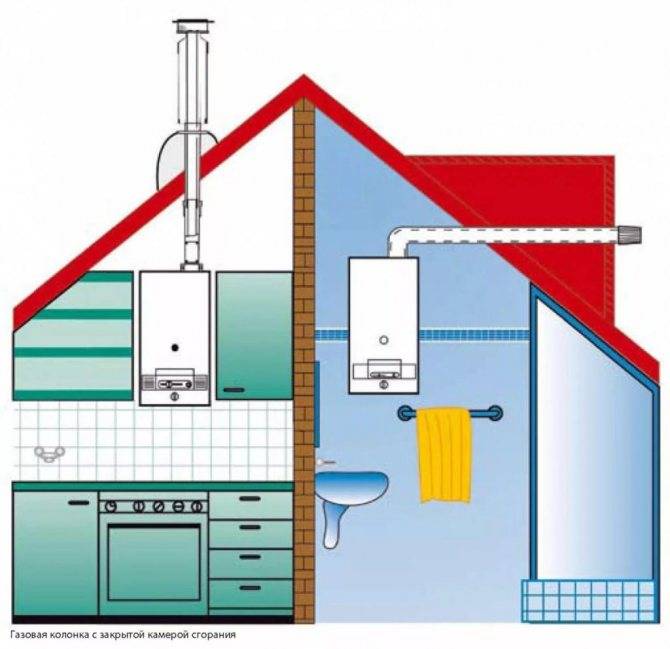

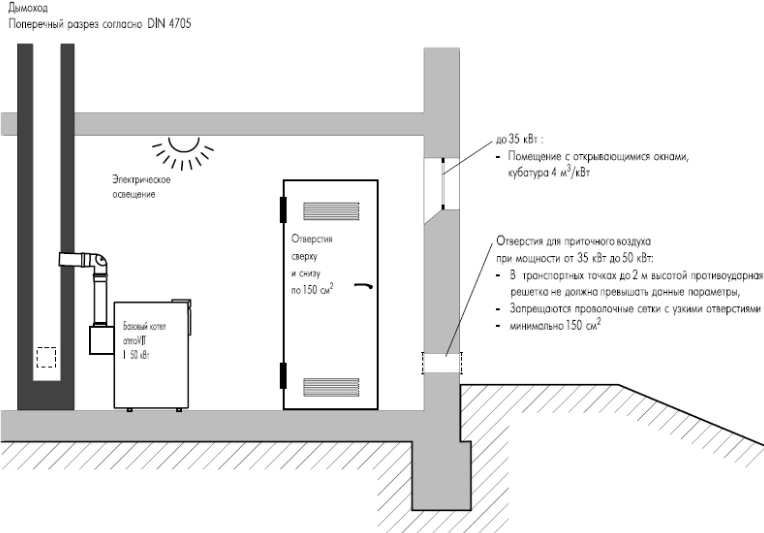

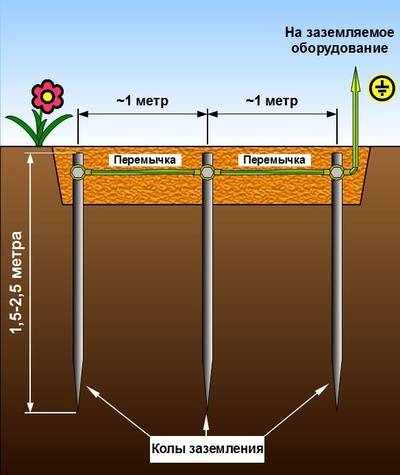

Requirements for the ventilation system

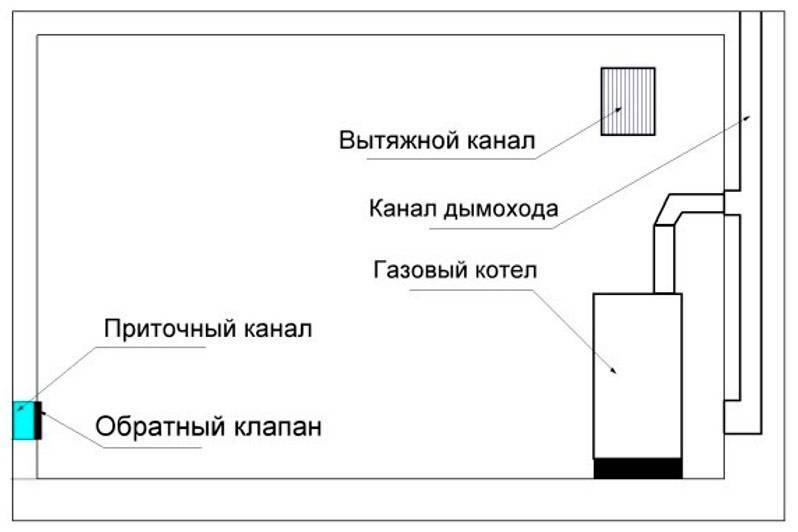

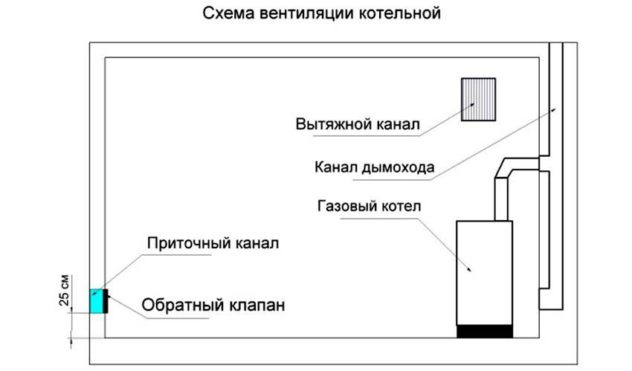

In order for the air in the room to circulate constantly and continuously, the following work is carried out:

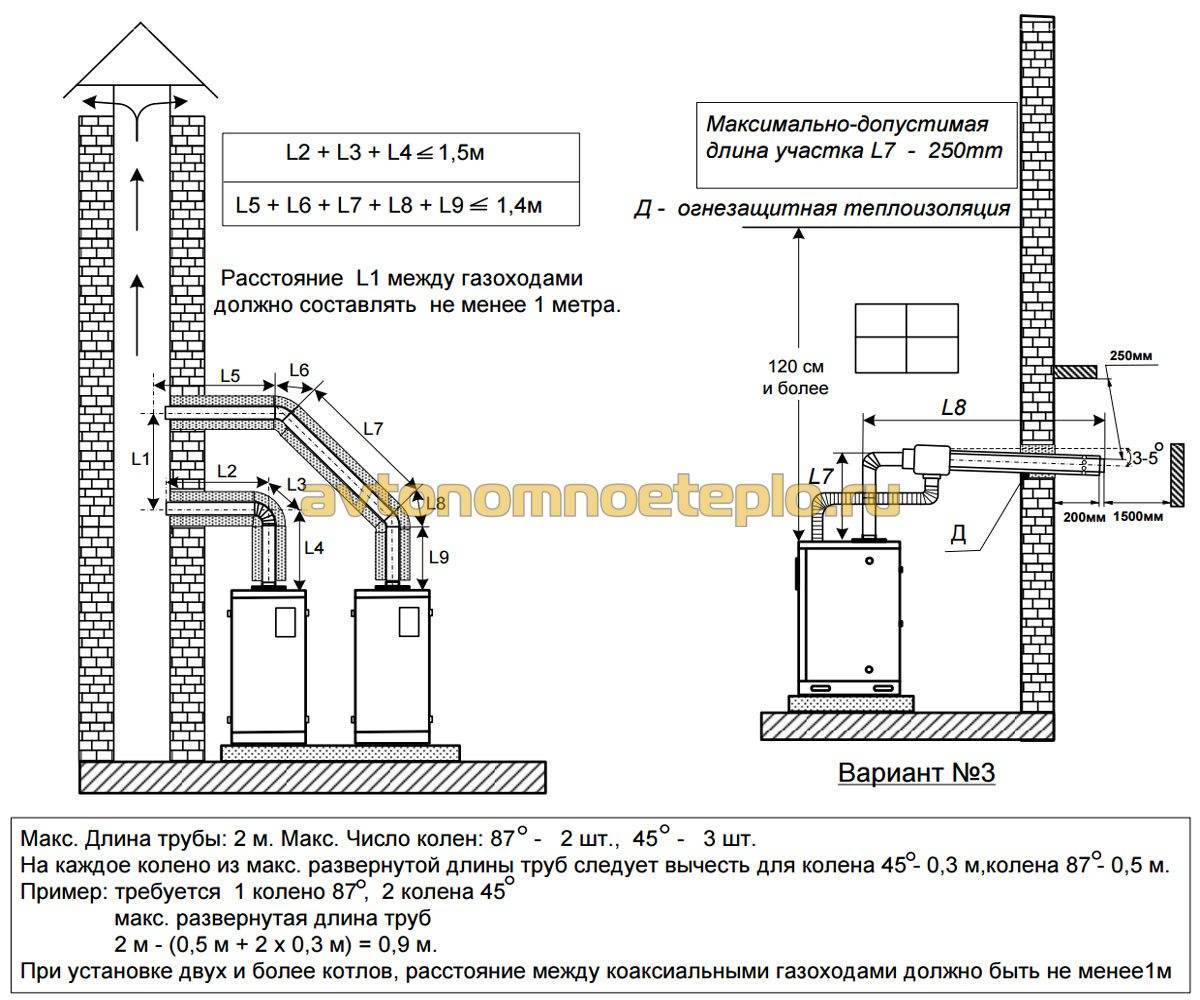

- A hole Ø 100–150 mm is punched in the wall at a height of 250–300 mm from the floor surface. The opening must be at a distance of 200-300 mm from the combustion chamber of the boiler. A piece of plastic or metal pipe is inserted into this hole, through which the ventilation route will pass;

- Outside, a fine mesh is attached to the threaded ventilation pipe, which acts as a coarse filter that protects ventilation from street debris and rodents;

- From the inside, a check valve cuts into the pipe, which will delay the air flow leaving the boiler room;

- Under the ceiling, preferably above the boiler, in the same way as below, another exit hole breaks through. This hole is not protected by a mesh, and a check valve must be installed on it.The only protection is the windshield.

If the boiler has a power of more than 30 kW, then it makes sense to think about forced electric ventilation, which will freshen the air, regardless of the weather and wind strength. The power of the fans will depend on the volume of the boiler room, but in any case, the rule of three-time air exchange must be observed - for an hour of operation, such ventilation should move three volumes of air in the room, no less. Ventilation device for gas heating

Requirements for the territory and premises

All industrial sites adjacent to the gas boiler house must be kept in order and clean, and waste from production activities accumulated on them must be removed in a timely manner. Sufficient lighting must be provided inside the boiler room.

It is prohibited to store any combustible materials and substances in the premises of gas boilers. When pipelines freeze, they can only be heated with steam or hot water. The use of open flames is strictly prohibited.

It is forbidden to store and dry clothes, oiled rags on the pipeline and boilers. If there is a cleaning material in the boiler room, it is allowed to store it in a metal container with a tight-fitting lid.

! The operation of household electrical appliances inside gas boilers is prohibited!

A sign must be placed on the doors indicating the responsible person, his position and contact phone number.

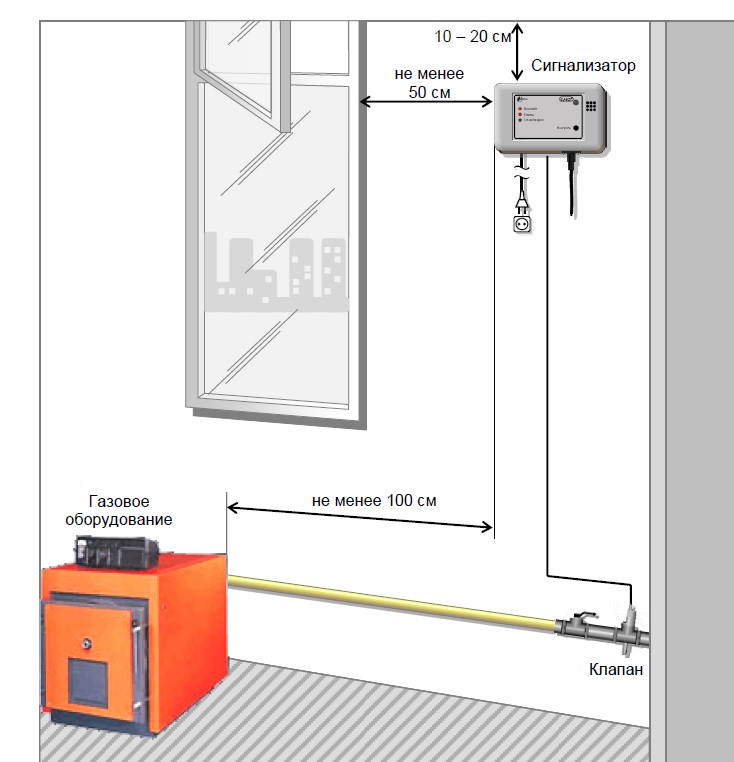

In the event of a gas leak, an automatic alarm should be provided for an increased concentration of gas in the room.

Boiler room

Passages to the building where the gas boiler is located, the fire safety of which is the main task of the organization's management, must be cleared of ice and snow in the cold season in case of a fire, so that fire engines can have easy access.

The boiler room must be reliably protected from third parties by locking the doors, the key to which must be kept by the responsible person and the guards.

Glazing material

When equipping a window for a gasified boiler room, special requirements are also imposed on the material of the frames. They must be resistant to high temperatures and made of environmentally friendly materials.

For the construction of the window structure, aluminum or metal-plastic is used. The aluminum profile protects the heated compartment from adverse climatic conditions. It provides a reliable seal that prevents the formation of a draft, does not allow the fire to go out in the boiler even with exile gusts of wind outside.

Metal-plastic frames are no less reliable and contribute to the preservation of heat in the furnace.

Plain sheet glass is used as a glazing material. It is also allowed to install double-glazed windows that meet the requirements of GOST and perform the role of easily dropped structures.

Mounting Tips

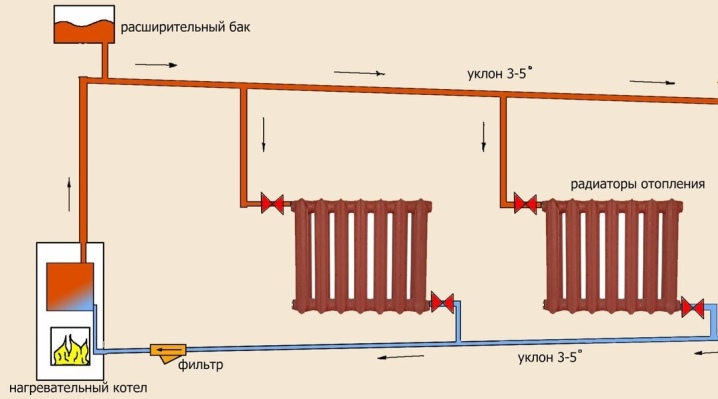

The scheme of the heating device in each private house is individual - and yet there are clear principles and criteria that are more or less universal.

The procedure for piping heating and hot water boilers with your own hands implies, first of all, the division into open and closed groups.

In the open version, the heating boiler is placed below all other components.The expansion tank is raised as high as possible: it is the difference in height between them that determines the overall efficiency of all equipment.

The easiest way to prepare an open circuit

In addition, it is non-volatile, which is very important for remote locations and for areas where power outages are frequent. But it must be understood that the continuous contact of the coolant with atmospheric air inevitably leads to clogging with air bubbles.

The coolant will circulate slowly, and it is impossible to accelerate its flow due to structural schemes. If these points are fundamental, and if there is a desire to also reduce the flow of the coolant, it would be more correct to make the heating according to a closed circuit.

If the boiler room is located in an extension, then it should be adjacent to a solid section of the wall. At the same time, at least 1 m of free space should be left to the nearest window or door. The building itself is made of fire-resistant material with guaranteed resistance to burning for at least 45 minutes. Wall-mounted boilers are mounted only on walls made of fireproof materials. Carefully monitor that all other walls are at least 0.1 m.

If powerful (200 kW and more) boilers are used, it is imperative to prepare a separate foundation for them. The difference between the height of this foundation and the height of the floor cannot exceed 0.15 m. When it is planned to use gas fuel, it is planned to install an apparatus on the pipe that urgently turns off the gas in a critical situation.

Furnace rooms are equipped with unreinforced or weakly reinforced doors: in the event of an explosion, they are thrown outward, and this reduces the risk of destruction of the entire building.

When a boiler room built into the house itself is mounted, it is allowed to install thoroughly reinforced doors. However, they are already presented with another requirement: to contain the fire for at least ¼ hour.

To improve ventilation, in any case, a hole is made in the lower third of the door, covered with a mesh. The entire volume of the walls from the inside is finished with fireproof materials. This must be done as soon as the installation of the boiler and its connection to communications is completed.

The number of circuits is also important. If you plan to limit yourself to heating, it is quite reasonable to choose a single-circuit boiler

For your information: it can also be used for hot water supply, but only in conjunction with a boiler. Installation of a boiler is justified under 2 conditions: a lot of hot water is consumed and there is a lot of free space. Otherwise, it would be more correct to order a double-circuit boiler.

Ventilation communications are mounted in the wall opposite the boiler. A mesh and damper must be installed in the ventilation pipe. In boiler rooms located in a separate room, you will have to make a ventilation duct in the door with a louvered grille.

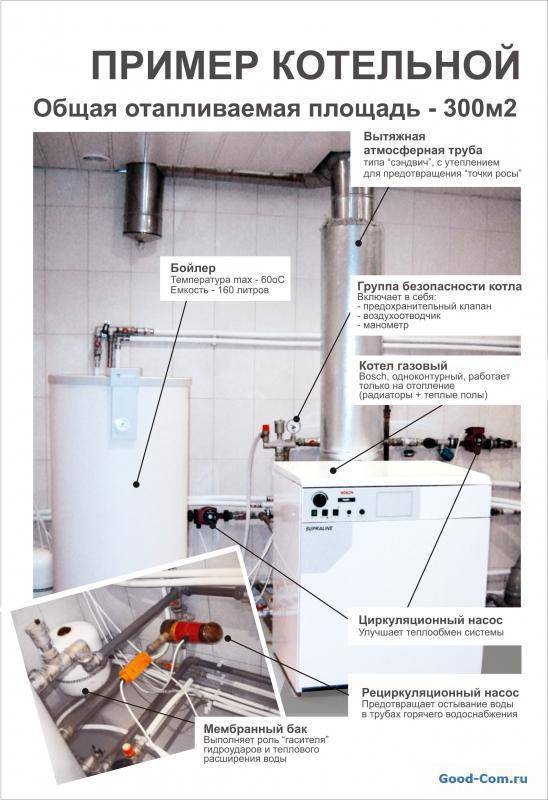

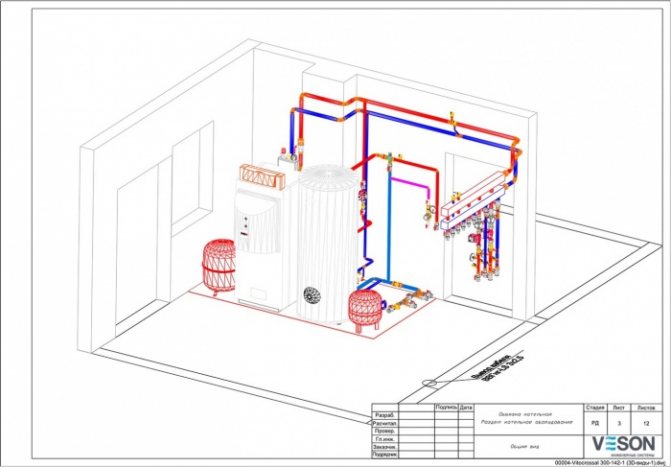

Boiler room equipment

Boiler - a device located in the boiler room. A device with a coolant, receives thermal energy from the heating elements of the fuel. Its property is to burn. It is an explosive item. Operation is carried out according to established requirements, norms, standards.

Fuel in heating equipment is diverse:

- liquid;

- gas;

- hard.

Purchasing an electric boiler is the best, safest option. But in the first place are gas boilers. The choice should be made according to the approved parameters. Consider capacity, budget, layout.A specialist will help you to suggest the device. He will select a heating device for all family members, the features of housekeeping in a private house.

Another device in the boiler room is a boiler. Provides heating of water, economical in use, productive in work. Set different size, different properties. Continues to function during planned shutdowns of hot water, will provide the building, the site with water. Allows you to accumulate water, produce heating, supplies heat. Can be direct, indirect, combined heating.

A circular pump is located in the gas boiler room of a private house. Allows you to regulate the heating system, increases the performance of the equipment in the room. Provides heating, heat transfer. Reduces the load on the boiler. Located in the heating part of the house.

One of the devices in the room is a distribution manifold. Controls heating processes, proportionally distributes heat. Installation is not always required. Depends on the type of building, devices, available circuits. Control over uniform flow is important in a private home.

The gas boiler room includes - a hydraulic arrow, an expansion tank, pipes. The devices allow you to regulate the flow of heat into the house, prevent breakdowns and make payment calculations.

Regulations

The established requirements regulate the organization of the heating system for each type of boiler, its power and location.

The most commonly used equipment that runs on natural gas. This is due to high performance and low cost in use. The design and way of working allow it to be used also in public buildings.

Norms SNiP II-35-76 determine the conditions for the installation of solid fuel boilers. Electric boilers are mounted in accordance with the PUE standards.

These documents fix the requirements for the device of the heating system. In addition to them, there are many other heating units that regulate certain moments during construction.

Rules and regulations for installing a gas boiler in a private house

Since it is necessary to comply with a large number of rules, and sometimes agree on conditions with gas workers, designers, the fire inspectorate, the host, it is better to entrust the development of the project and the installation of a heating unit to an organization authorized to carry out such work and properly certified.

However, the owner's knowledge of the basic norms is advisable. The place of installation of the boiler is strictly regulated. Only small appliances can be placed in the kitchen or other area of the house up to 60 kW.

The volume of the boiler room is also established by the existing rules.

The place is determined as follows:

- A boiler with a power of up to 30 kW can be placed in any room of at least 7.5 m², except for the kitchen.

- If the kitchen is 15 m³ and the ceiling height is 2.5 m, it is allowed to have a boiler up to 60 kW.

- Equipment with a capacity of 30 to 60 kW can be installed with a room volume of at least 13.5 m³.

- The cubic capacity of the boiler room with equipment from 150 to 350 kW is provided in the amount of 15 m³ or more.

The heating system can have 1 or 2 circuits. In the first case, it serves only for heating and requires additional installation of a boiler, and in the second, it performs both functions, i.e. heats the house and heats the water.It is advisable to install a single-circuit boiler where a lot of hot water is used.

In 2019, a new requirement was introduced - a gas boiler house must be equipped with a system for detecting gas leaks. A special analyzer will stop the operation of the boiler if necessary.

The boiler is fixed on the wall or installed on the floor. In the first case, its power should be no more than 60 kW, and in the kitchen or hallway this figure is 35 kW.

Gas wall-mounted boilers are highly sensitive to water hardness. To soften it, a filter is installed at the inlet of the unit. Floor options heat large areas and are more durable.

For equipment maintenance, it is recommended to design a boiler room area of at least 7-10 m², and if there is other equipment, it is better to increase it to 12 m². Pressure gauges and other measuring devices are checked by a certified instrumentation laboratory according to a set schedule.

Norms and requirements for operation

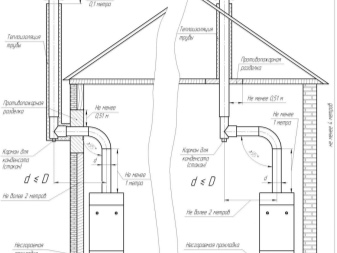

There are requirements regarding the design and installation of rooftop boilers, but they are minimal. All of them are based on ensuring safety during the operation of the structure.

In particular, the following should be done regularly:

- It is necessary to constantly check the supply and exhaust valves, due to which the boiler room is ventilated.

- It is necessary at the design stage to provide for the installation of sensors that detect any fires, gas leaks and other emergency situations. In addition, it is necessary to install a gas insulating flange capable of shutting down the entire system in the event of a fire.

- The roof of a multi-storey building should be equipped with an alarm system, which will immediately begin to notify others with sound and light signals about a fire in the boiler room.

- The boiler room should be equipped with windows and doors leading directly to the roof. A special fire elevator and a service exit are also needed. The lighting of the boiler room must comply with the standards.

- A separate chimney must be designed for each gas boiler, and they must all be of the same height. The distance between the pipes can be any.

To ensure a more stable and safe operation of the boilers on the roof, a separate branch of electricity should be connected to them. This will level out possible power surges in the house, which can lead to failure of the entire heating system.

It is also desirable to provide an alternative power supply, in particular, to purchase a diesel generator.

According to safety regulations, the chimney pipe must be at least 2 meters higher than the height of the roof of the boiler room itself

According to safety regulations, the chimney pipe must be at least 2 meters higher than the height of the roof of the boiler room itself

It is forbidden to install a gas boiler directly above residential apartments. Between them and the roof, you need to make a technical floor in order to comply with the mandatory list of conditions regarding boiler rooms. Gas units can only be placed on a floor made of reinforced concrete slabs.

Remember that the boiler room is quite noisy, so it is important to soundproof it. Once the boiler room is designed and installed, it is necessary to organize its periodic maintenance.

To do this, it is enough to hire one or two people. From time to time, employees of the gas service will also come with inspections, who will monitor the condition of the equipment in operation.

Once the boiler room is designed and installed, it is necessary to organize its periodic maintenance. To do this, it is enough to hire one or two people. From time to time, employees of the gas service will also come with inspections, who will monitor the condition of the equipment in operation.

Requirements for a room for installing a gas boiler

Comprehensive information on the proper preparation of the premises is contained in one of the above documents. In particular, there are regulations on the dimensions of the boiler room, the arrangement of the front door, the height of the ceiling and other important parameters (see key requirements below).

It is immediately worth noting that if the maximum thermal power of a gas boiler is more than 30 kW, then a separate room must be allocated for its installation. Models with a lower capacity and with an appropriate location for the chimney outlet can be installed, for example, in a kitchen room. It is strictly forbidden to install a gas boiler in the bathroom.

You can not install it in the bathroom, as well as in rooms that are considered residential for their intended purpose. As an alternative, it is allowed to equip the boiler room in a separate building. At the same time, their own norms are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the basement level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

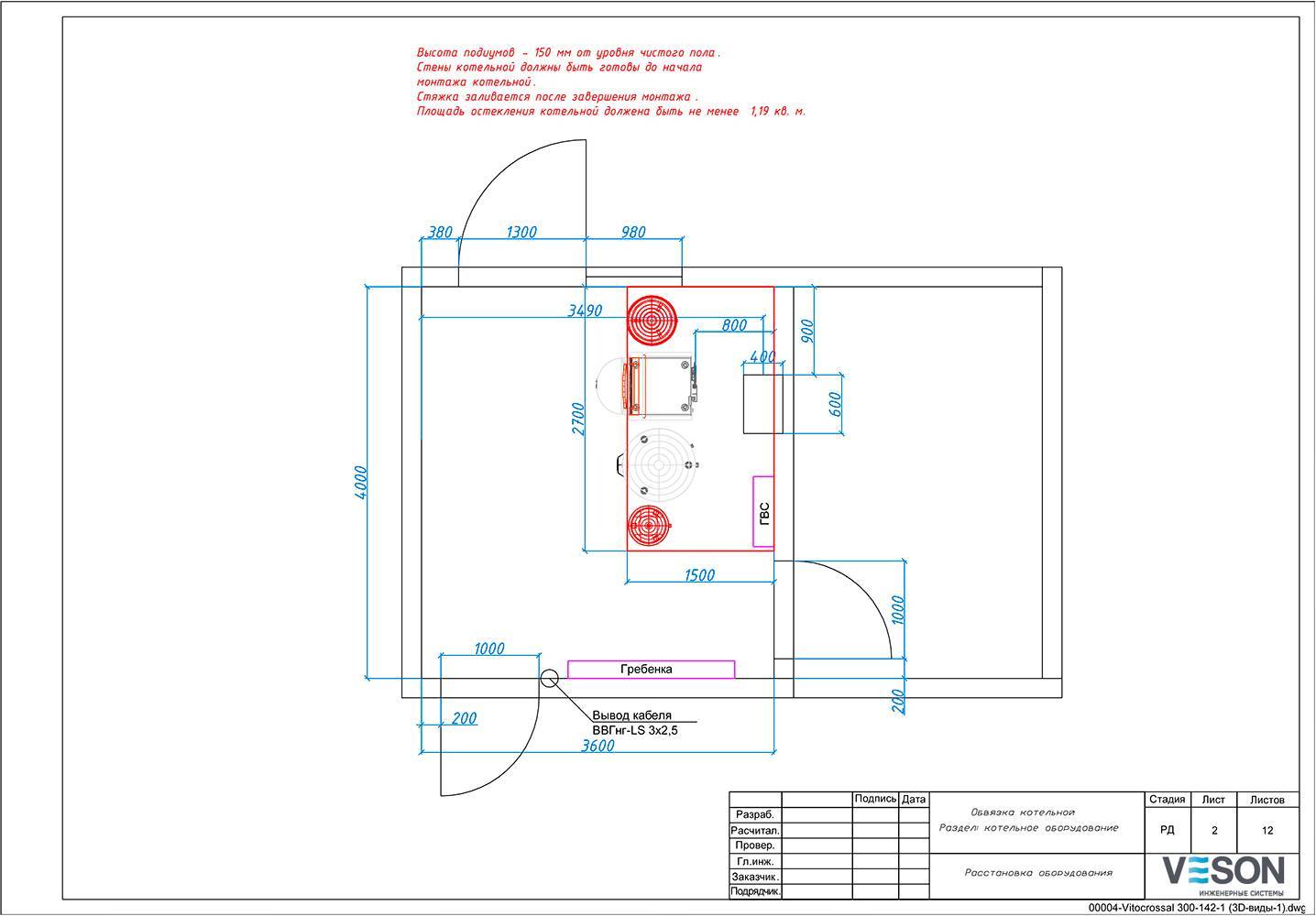

In accordance with the rules for installing a gas boiler in a private house, it must be equipped with the following criteria:

- The area is not less than 4 m2.

- One room is calculated for no more than two units of heating equipment.

- Free volume is taken from 15 m3.For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling should be 2.2 m (not less).

- The boiler is installed so that the distance from it to the front door is at least 1 m; it is recommended to equip the unit near the wall, which is located opposite the doorway.

- On the front side of the boiler, at least 1.3 m of free distance must be left for setting up, diagnosing and repairing the unit.

- The width of the front door is taken in the region of 0.8 m; it is desirable that it opens outwards.

- The room is provided with a window with a window opening outward for emergency ventilation of the room; its area must be at least 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or ignition.

- A separate power line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, with an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a top coat of absolutely non-combustible materials (ceramics, stone, concrete)

To make it easier to set the boiler, the floors are made strictly according to the level.

On a curved surface, the installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is forbidden to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not work correctly, with increased noise and vibrations.

To fill the water heating system and feed it during operation, it is necessary to enter a cold water pipeline into the boiler room. To drain the system for the period of maintenance or repair of equipment, a sewer point is equipped in the room.

There are special requirements for the chimney and ensuring air exchange in the boiler room of a private house, therefore this issue is considered in a separate subparagraph below.

If the room for the installation of a gas boiler is equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- the presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- it is allowed to install no more than two gas boilers in the same boiler room;

- the presence of a properly equipped chimney;

- it must be freely accessible for cleaning and other operations;

- for supplying piece lighting and heating equipment, a separate input with an automatic machine of the appropriate power is provided;

- the water supply must be organized so that the mains do not freeze during the cold season.

Mini-boiler room mounted near the house.

The floors, walls and ceilings of a separately equipped boiler room must also be made and finished with materials that correspond to the class of non-combustible and heat-resistant.

Features of installing gas equipment in the basement

Placing a gas boiler in the basement is convenient for people living in a private house, but this is not always allowed. The exceptions for a long time were liquefied hydrocarbon gas systems, which were used everywhere for a long time.

Boilers of such a system operate on fuel extracted from oil. As soon as natural gas became widespread and special equipment for residential buildings was produced for it, restrictions on installation in basements were completely removed.

Now the requirements of SNIP allow up to 4 gas units of any type located in the basement, the total power of which should not exceed 200 kW. The degree of security is so high that their location is possible even in the attic.

One of the main requirements before starting installation work on the installation of gas equipment is an approved boiler room design. This must be done before starting the system, since its operation is a factor of increased fire hazard, as a result of which it may be prohibited by the fire inspection. In this case, it comes even to the dismantling of the boiler room or the restructuring of the system.

New rules for the use of gas in residential premises

All residents of apartment buildings are required to listen to a briefing on safety measures when operating gas equipment. The event is held after the conclusion of an agreement with representatives of GorGaz. Also, the briefing is repeated after each scheduled inspection.

Residents are required to provide GorGaz employees with access to the premises where gas equipment is installed at any time of the day. Otherwise, you will have to pay a hefty fine. In the absence of residents in the house or apartment for more than 24 hours, it is imperative to turn off the gas supply valve.

The new rules require management companies to regularly check basements and ventilation conditions once every 10 days.

Residents are required to:

- monitor the cleanliness of ventilation;

- before you start cooking, ventilate the room;

- do not install flammable furniture close to the stove.

If there is a smell of gas in the room, urgently turn off the tap, open the windows and call the emergency service.

Improper use of gas appliances in residential buildings can lead to sad consequences.

Improper use of gas appliances in residential buildings can lead to sad consequences.

The new rules are effective May 9, 2018.

Why equip a separate boiler room at home?

When arranging the heating system, the owner of the house faces a choice where the gas-using equipment will be located.

The decision may be due to aesthetic and design considerations, the issue of security (in the presence of disabled persons at home, as well as children). But in addition, this may be dictated by the current standards for equipment power.

The decision may be due to aesthetic and design considerations, the issue of security (in the presence of disabled persons at home, as well as children). But in addition, this may be dictated by the current standards for equipment power.

Consider the types of location of boiler rooms.

Boilers can be located:

- inside the house - usually provided for even at the stage of building a house, since in the built one there may not be a free room that is suitable in terms of parameters;

- on a separate foundation as an extension, along a blank wall and observing a distance from the nearest door and window of 1 meter without a major connection to a residential building;

- detached - located at some distance from the main house.

The regulations determine that if the power of gas-using equipment does not exceed 60 kW, it can be placed in the kitchen (except for the kitchen niche), in the kitchen-dining room, and in other non-residential premises, except for bathrooms and bathrooms.

The minimum volume of furnace for 30 kW of power is at least 7.5 cubic meters. m. From 60 to 150 kW require the arrangement of a separate room. The minimum volume of the room is 13.5 cubic meters. m. From 150 to 350 kW.The minimum volume of the room is from 15 cubic meters. m.

A freestanding gas boiler room must be designed before construction or installation. Follow all the rules for its arrangement, otherwise, the location of gas-using equipment in it will not be approved

A freestanding gas boiler room must be designed before construction or installation. Follow all the rules for its arrangement, otherwise, the location of gas-using equipment in it will not be approved

We are talking about individual boiler houses, that is, with equipment power from 60 to 350 kW.

Definition of fire hazard category

According to the Technical Regulations (FZ No. 123), the category of gas boilers for fire safety should be determined. The gas boiler room belongs to class F5 as a production type building (Categories and classes of buildings for explosion and fire hazard). Then you should refer to Building Regulations 12.13130.2009, which defines the fire hazard subclass. The subclass is calculated based on the factors that can provoke a fire. This takes into account:

- type of fuel in the boiler room;

- type of equipment used;

- design features of a gas boiler.

In calculations, the boiler room is conditionally divided into three zones: pipelines, directly boilers, chimney. Additionally, it is necessary to take into account the pressure in the gas pipeline. As a result, a category is assigned for a gas boiler house from A to G. The data obtained must also be placed on the entrance doors to the boiler room.

Where can you place an autonomous boiler room?

It is very important to choose the right place for installing heating units. So, a gas boiler house on the roof of a high-rise building is considered the most preferred option.

Often they are also installed in basements or basements.

To service the boiler house, it is enough to hire only one specialist, and this is a real money saving every month.

To service the boiler house, it is enough to hire only one specialist, and this is a real money saving every month.

By far the best option in terms of safety and serviceability is to build a separate building close to the residential building. Residents will not be threatened by possible fuel leaks, gas accumulation in the basement.

But you will have to build an additional building, lay the foundation for it, do a lot of land work, draw up a number of documents. This immediately scares away potential investors. Therefore, a basement or roof gas boiler room can be considered the best options.