- What approvals are needed for ventilation in non-residential premises of MKD

- Performing calculations

- Air exchange calculation

- Aerodynamic calculation

- Air distribution calculation

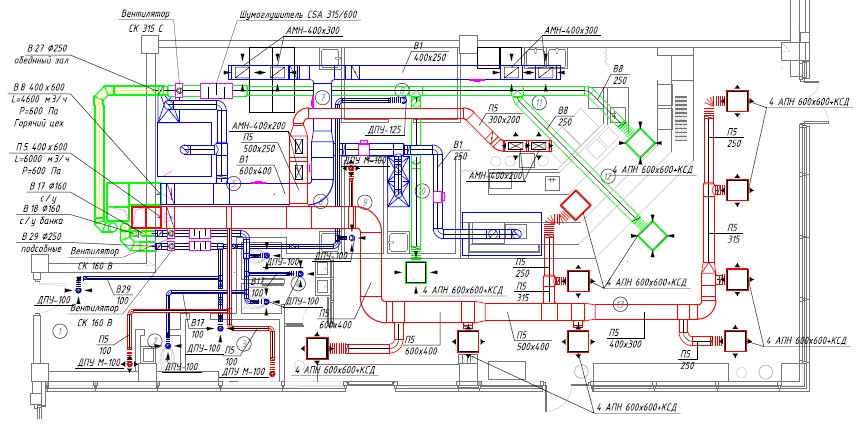

- Acoustic calculation

- Ventilation design for public building toilets

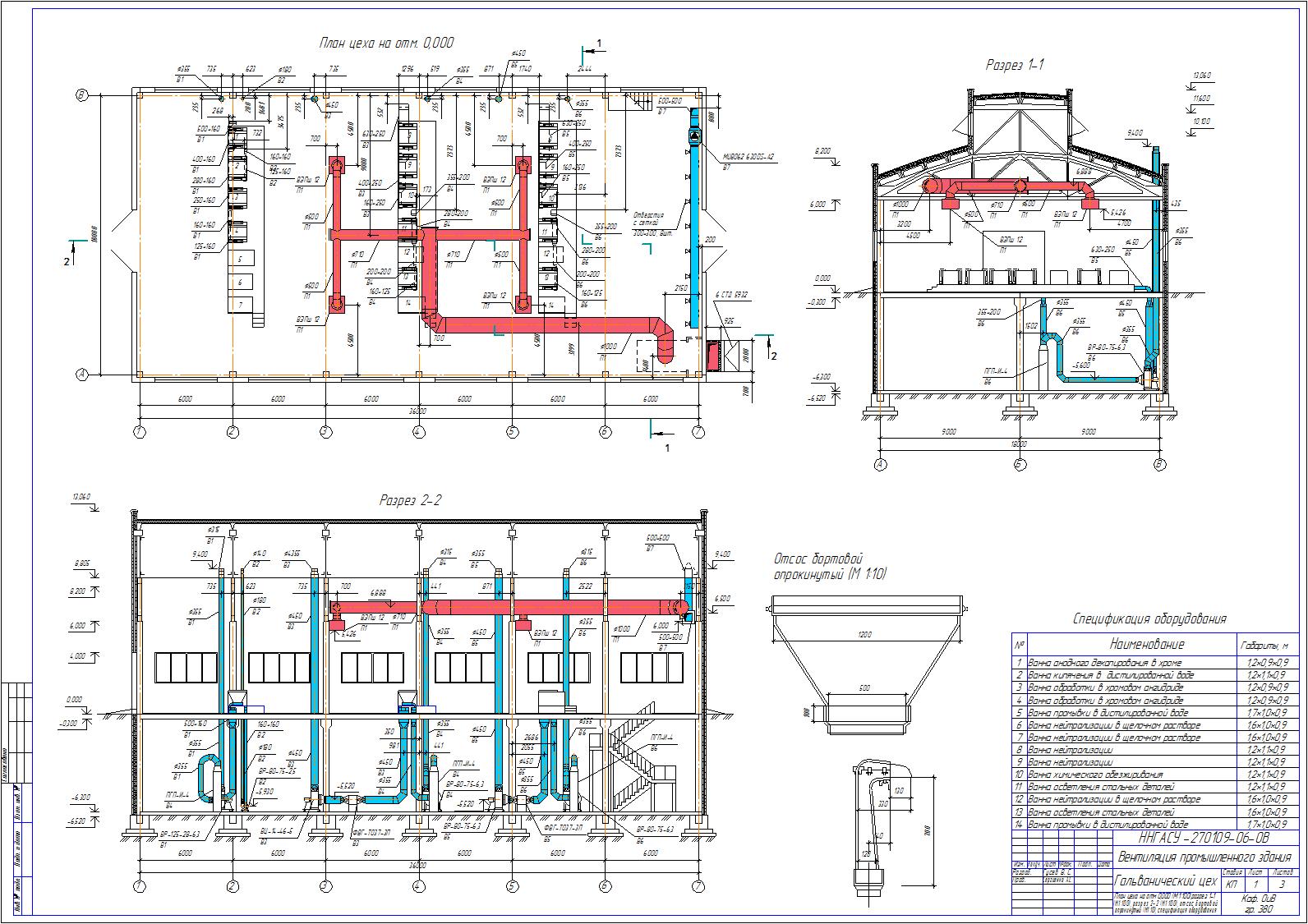

- Natural ventilation in production

- Composition of the ventilation project

- Initial data

- The grafical part

- Descriptive part

- Device and design features

- Calculation of shop ventilation

- For excess heat

- For explosive or toxic production

- For excess moisture

- By allocations from staff

- Calculation of the exhaust ventilation of the workshop

- Air distribution

- Features of hotel ventilation systems

- What are ventilation systems, are they necessary in non-residential premises of MKD

- Regulations

- in plain language

- At the stage of development of project documentation (project, stage "P")

- Design standards

What approvals are needed for ventilation in non-residential premises of MKD

Almost all work on the engineering systems of MKD premises requires mandatory approvals. The project goes through the following stages:

- for work involving common house property, a general meeting of owners is held, a protocol is drawn up with approval;

- the project, protocol and other documents are transferred to MosZhilInspection;

- after completion of work at the facility, you must again apply to the MZHI, obtain a commission act;

- to enter new data into the technical passport of the building, you need to submit documents to the BTI;

- to enter updated data on the premises to the USRN, you must order a technical plan, go through cadastral registration.

Performing calculations

In a private house and apartment, the design of ventilation systems in terms of the exhaust is done taking into account a single air exchange, while the supply system gives a two-fold replacement of the mass. Part of the supplied air leaves through the cracks of window and door openings, and the exhaust system does not experience excessive load.

In the multi-apartment sector, there is no ban on the installation of supply fans, while the installation of exhaust turbines in the openings of the ventilation shaft is sometimes not allowed.

Air exchange calculation

The volume of incoming air depends on the number of residents, the area of the room

The volume of incoming air depends on the number of residents, the area of the room

To obtain the desired air exchange, two values are calculated: by the number of people and by the multiplicity, after which the largest indicator is selected.

Air exchange by the number of people is determined by the formula L = N Ln, where:

- L - the required output of the supply system (m³ / h);

- N is the number of people;

- Ln- air norm per person (m³/h).

The last value is taken for people at rest 30 m³ / h, and the standard figure for SNiP is 60 m³ / h.

The multiplicity is calculated according to the formula L = p S H, where:

- L - the required output of the supply system (m³ / h);

- p is the rate of air exchange rate (for housing - from 1 to 2, for offices - from 2 to 3);

- S - room area (m²);

- H is the height of the room (m).

After the calculation, the total required ventilation capacity is obtained.

Aerodynamic calculation

The air speed near the ventilation turbine is always higher than in other rooms

The air speed near the ventilation turbine is always higher than in other rooms

The calculation assumes that the air flow velocity decreases with distance from the ventilation turbine. It is done to select the cross-sectional area and parameters of the air ducts and calculate the pressure loss in the system.

The design of exhaust ventilation in terms of aerodynamics includes two stages:

- determination of the characteristics of the longest section of the pipeline;

- coordination with them of other main sections.

Air distribution calculation

The calculation of the air flow distribution index is important in the design of industrial ventilation. The calculation allows you to maintain a comfortable climate in the workshop without changing the technology and while ensuring the quality of the final product.

As a result, an even distribution of air is achieved in all areas of a large room, while the air values remain within the standard range. The economic and sanitary-hygienic efficiency of the ventilation system depends on the correct calculation.

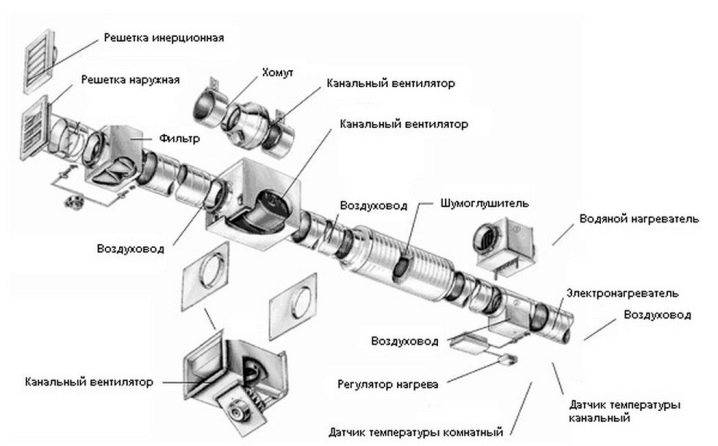

Acoustic calculation

In the presence of noise, a silencer is mounted on the ventilation pipes

In the presence of noise, a silencer is mounted on the ventilation pipes

The calculation allows you to determine the source of noise, its technical characteristics and develop measures to prevent or reduce sound and vibration. Design points are determined in the pipeline, where the calculation of the degree of sound pressure is made.

The obtained values are compared with the normative parameters and measures are taken to reduce the negative effects. After reflecting the measures in the ventilation project, new calculations are made taking into account the added elements.

Ventilation design for public building toilets

Sanitary unit ventilation for offices and public buildings is designed by a separate mechanical exhaust system, in accordance with SP 118.13330.2012 “Public buildings and structures. Updated version of SNiP 31-06-2009” and SP 44.13330.2011 “Administrative and amenity buildings Updated version of SNiP 2.09.04-87”. In administrative buildings with an area of up to 100 square meters and with a small number of latrines, it is necessary to provide for a natural inflow through windows or through wall valves for ventilation (toilets with frequent use). For latrines or shower rooms with more than 3 cabins, the use of natural exhaust through ventilation ducts in the main walls is not effective and it is necessary to design a mechanical duct ventilation system. When calculating the air exchange of the premises of public buildings, it is necessary to provide for a negative imbalance of 10% for toilets in order to exclude the penetration of odors into the building. The rate of air extraction from toilets in public toilets of buildings per toilet bowl is 50 cubic meters per hour per urinal 25 cubic meters per hour.

The design of ventilation for toilets serving a large number of visitors in separate buildings at central stations and airports, in shopping and large business centers provides for supply ventilation with a frequency rate of 2.5 times / hour and exhaust ventilation with a frequency rate of up to 5 times / hour, including building codes are described in SanPiN 983-72 "Sanitary rules for the construction and maintenance of public latrines". For the flow of fresh air from the latrines from the washrooms to the toilet cabins, doors with a loose connection or with cutouts of more than 75 mm are provided.The speed of air flow through the slots or overflow grilles in the door should not exceed 0.3 m/s, the pressure drop should not exceed 20 Pa.

The location of exhaust diffusers or grilles in the toilet cabin is made above each plumbing unit if the walls reach the ceiling, and if the partitions of the toilet cabins do not reach the ceiling, the number of exhaust devices can be reduced, but with a high flow, it makes sense to mount the exhaust duct directly above the cabins.

To reduce noise from powerful exhaust fans of toilets and showers in public buildings, measures are taken: installing flexible connectors on the fan, vibration isolators for hanging the fan to the ceiling, using noise suppressors, placing the fan in a utility room or in a ventilation chamber, using a fan in a soundproof housing, laying additional insulation on plaster ceiling.

Designing ventilation for showers and bathrooms is the same as for toilets in public buildings - a mechanical exhaust ventilation system is required for shower rooms with more than 3 units of plumbing fixtures. Exhaust wall fans should be provided in a splash-proof design, and in large rooms, for example, in baths or shower pools of sports complexes, duct exhaust fans with a remote motor or radial fans to prevent moisture from entering the electric motor.In order to save the energy consumption of the exhaust fan for a large shower room with a large number of but with occasional visitor placement, it is possible to design a humidity sensor in the room.

An example of toilet ventilation is the specification and cost of ventilation for toilets.

INSPECTION AND CERTIFICATION OF VENTILATION

- < Prev

- Next >

Natural ventilation in production

The natural system operates due to the physical properties of fluctuations in pressure and temperature of the air in the room and outside.

It differs in turn:

- Organized

- unorganized

Disorganized is considered when the air enters the room through leaky gaps in the building structure,

if there are no equipped devices for ventilation.

Organized ventilation system for industrial premises carried out by means of exhaust shafts, channels, vents, etc.,

with which you can control the amount and strength of the incoming air flow. Above the shafts of ventilation systems, an umbrella or a special device, a deflector, is often installed to increase traction.

Composition of the ventilation project

The main set includes general information on the drawings, indicating the statement of work schemes and plans, as well as a list of attached calculations, technical documents and references to certain sources. The list of sets of executive drawings is given.

General guidelines include a list of reasons for compiling documentation, for example, a project assignment, a feasibility study, approved justifications for investments in the construction of simple buildings. The description contains building rules and regulations that must be followed.

Initial data

Ventilation project for a private house: initial data - number of rooms

Ventilation project for a private house: initial data - number of rooms

The design takes place on the basis of an engineering task, architectural schemes and a design project of the building. The project is coordinated with state bodies of supervision and control, builders and other services.

The composition of the initial information includes information:

- location and neighboring buildings;

- climatic data of the region, temperature, wind speed;

- information about the operation of the building (work schedule, location of residents).

A constructive description of the building, its location relative to the cardinal points is given. A list of rooms is given in the form of a table indicating the volume and floor area.

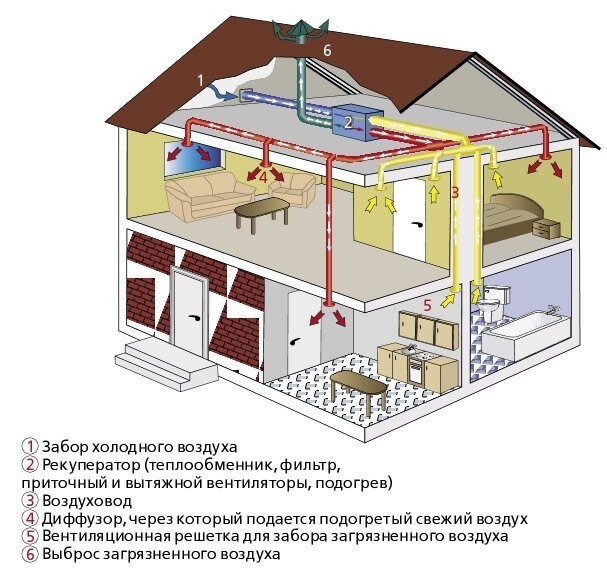

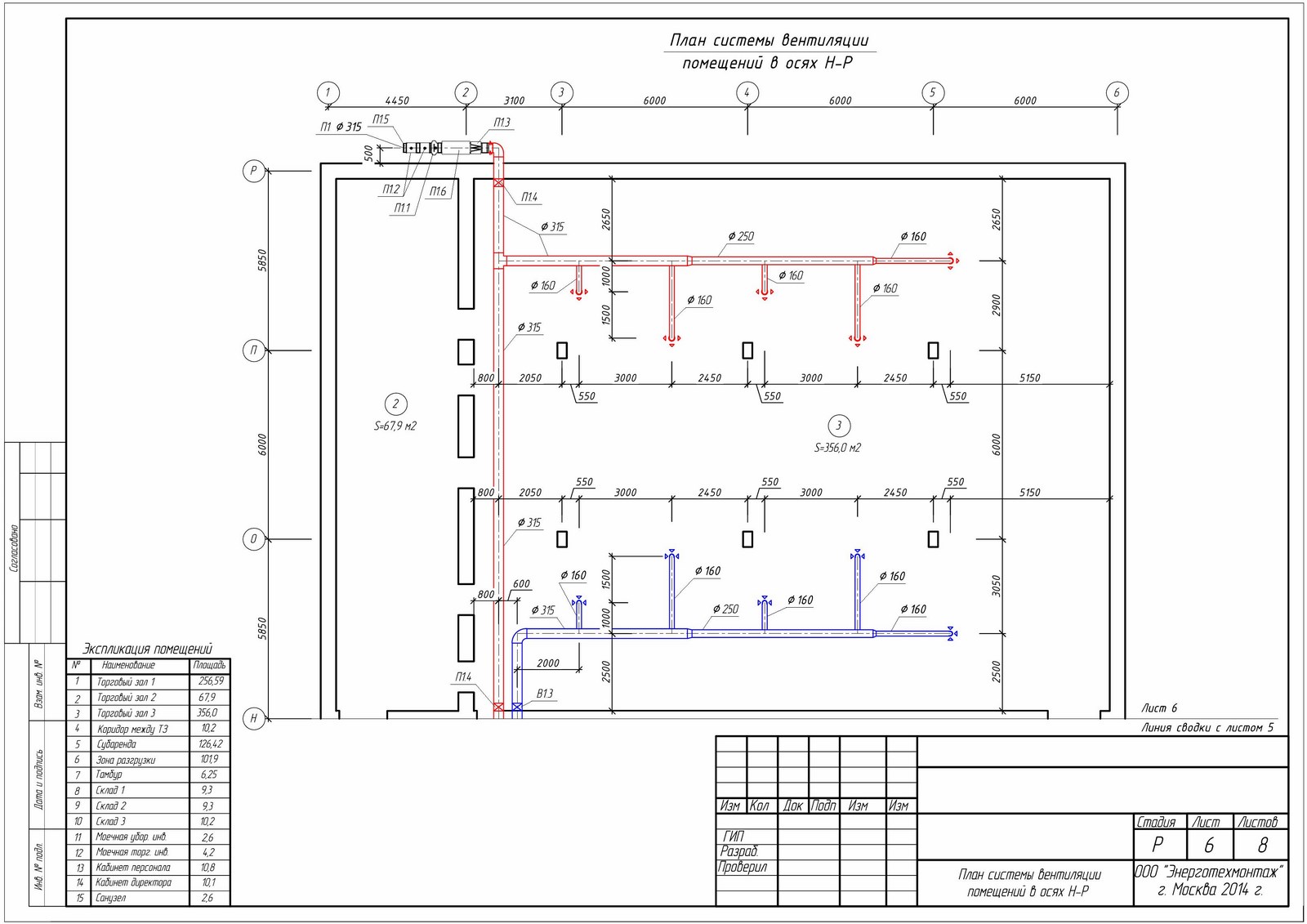

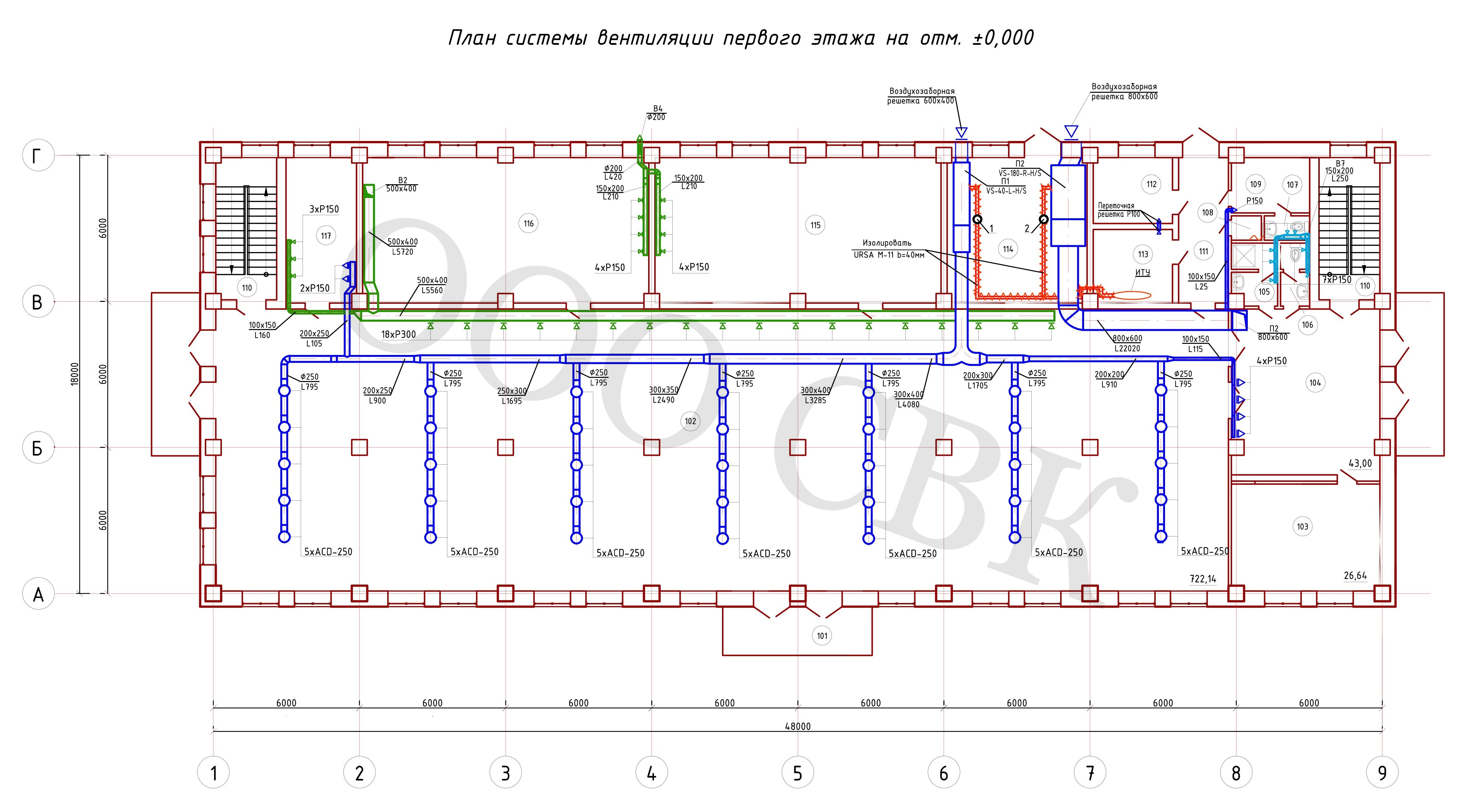

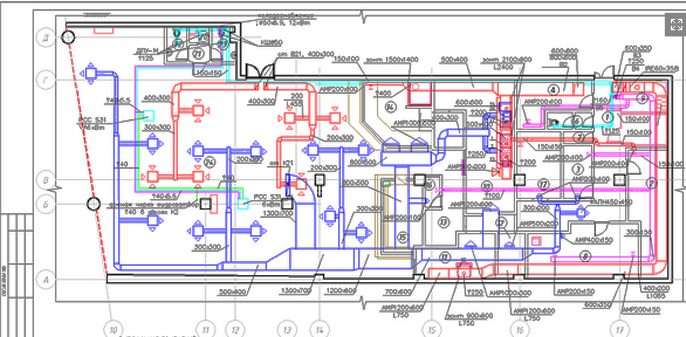

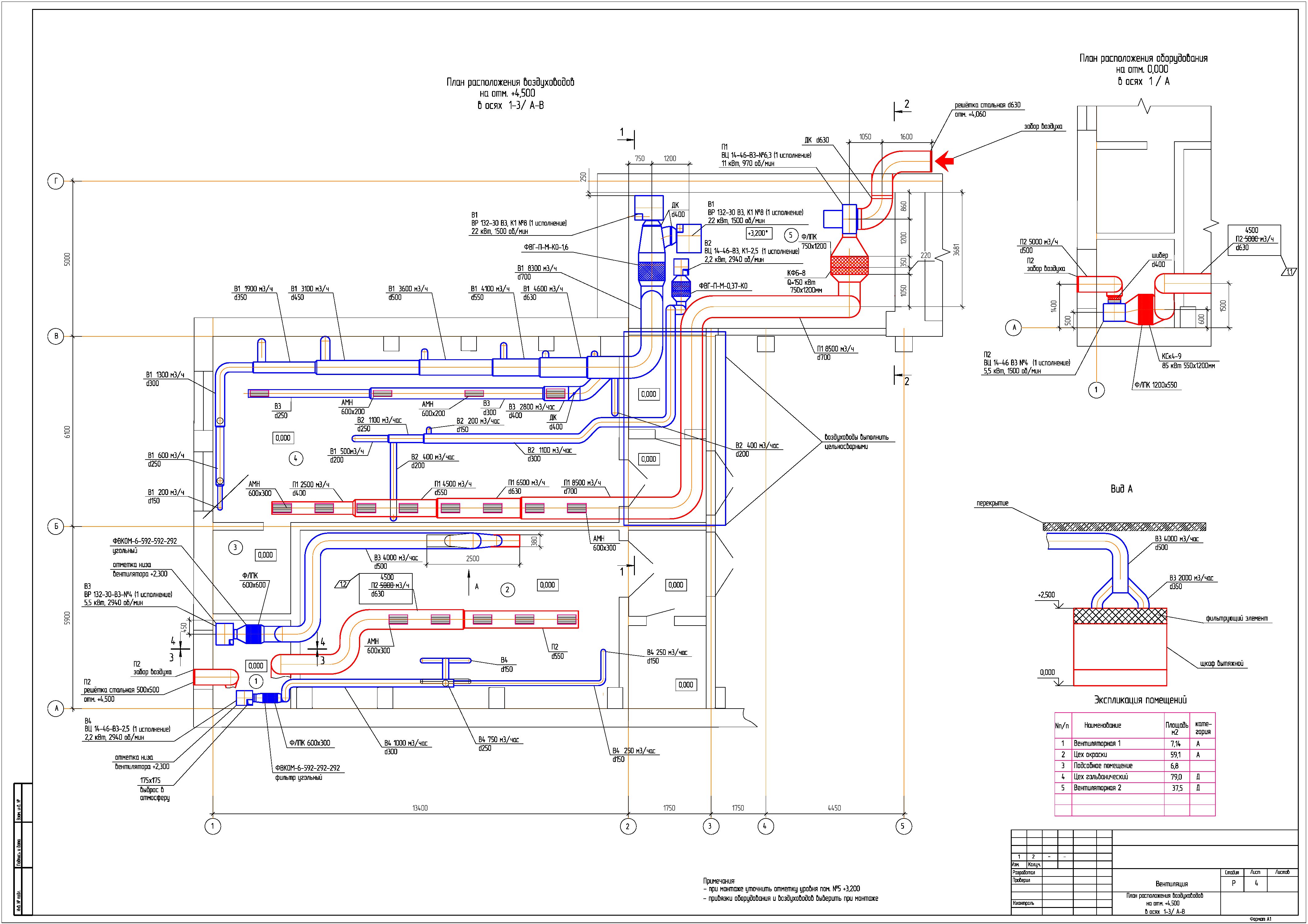

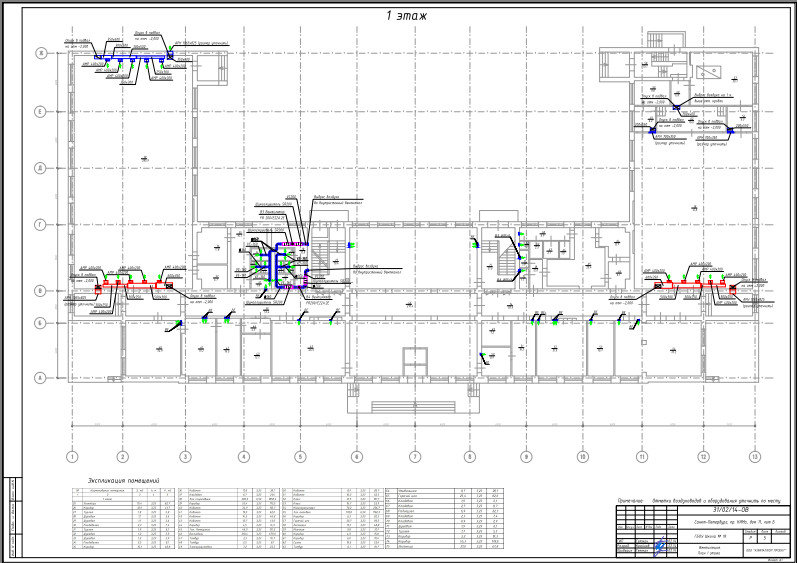

The grafical part

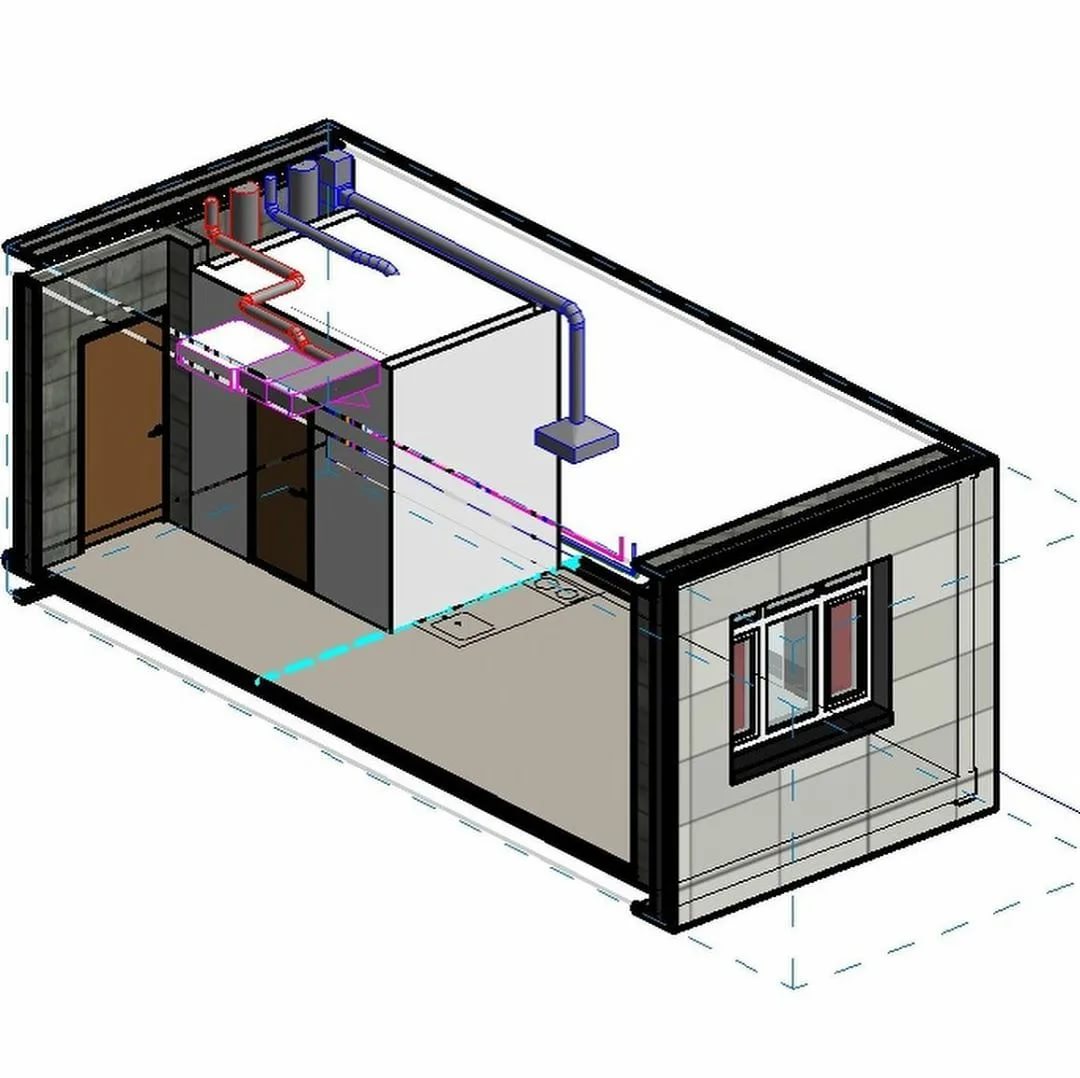

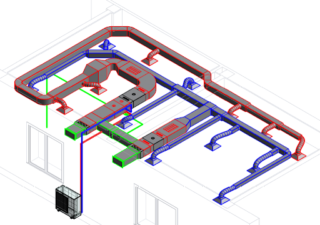

Drawings are developed at the detailed design stage and, in addition to the main set, include detailing of intersections and nodes of the main equipment with drawing of device piping. The primary supply and removal equipment is presented in the drawings in the form of a structural representation.

Schematically shows the equipment for ending the ventilation heads on the roof. The drawings contain tables indicating the dimensions of the ventilation ducts, and preventive maintenance zones are indicated. Special notes are written on each drawing.

Descriptive part

The explanatory note provides information on the energy consumption and power of the electric fan and other equipment. The characteristics and properties of the ventilation system are described, for example, dimensions, shape of pipelines, energy consumption.

A table of indicators for calculating the main line by premises is compiled, and the basics of designing automatic modules for controlling the system are given. Equipment specifications are added, ventilation line diagrams are inserted in axonometry.

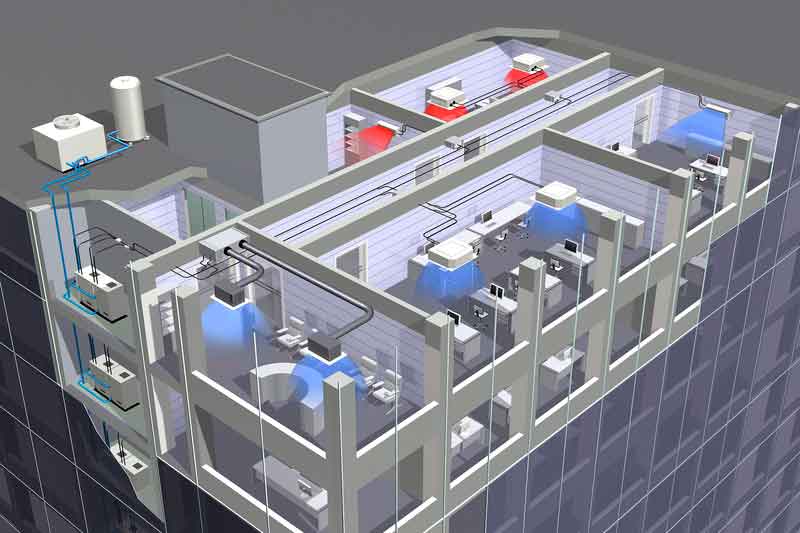

Device and design features

Most often, in 4-5 star hotels, a solution is used with central air conditioning, and the installation of chillers and fan coil units. This option allows you to ensure compliance with all requirements for ventilation and air conditioning of hotel premises, without violating the design of the building.

The chiller, together with the exhaust fan for extracting the exhaust air, is located on the roof of the hotel building, which makes it possible to ensure the quiet operation of the equipment for the guests of the complex. Fancoil units located behind the false ceiling allow you to set the optimal parameters of the microclimate in the rooms. In such a system, an important role is played by the central air conditioner, usually located in the basement of the building. For water circulation, a pumping station is used, which is most often located on the roof of the hotel complex. This solution has several undeniable advantages:

- All hotel ventilation standards are observed regarding temperature, humidity and air flow rate.

- This scheme is the cheapest, as it works on water. This allows you to significantly reduce the cost of maintenance.

Calculation of shop ventilation

In order to design and install ventilation, it is necessary to accurately and accurately calculate the scale of its work. The calculation of the ventilation system of the workshop is carried out on the basis of data on the volumes of emitted harmful substances, heat and various reference indicators.

The calculation of the ventilation system of the workshop is carried out separately for each type of pollution:

For excess heat

Q = Qu + (3.6V - cQu * (Tz - Tp) / c * (T1 - Tp)), where

Qu (m3) is the volume that is removed by local suction;

V (Watt) - the amount of heat that products or equipment emits;

c (kJ) - heat capacity index = 1.2 kJ (reference information);

Tz (°C) - t of polluted air removed from the workplace;

Tp (°C) - t supply air masses

T1 - t of air removed by general-exchange ventilation.

For explosive or toxic production

In such calculations, the key task is to dilute toxic emissions and fumes to the maximum permissible level.

Q = Qu + (M - Qu(Km - Kp)/(Ku - Kp)), where

M (mg * hour) - the mass of toxic substances released in one hour;

Km (mg/m3) is the content of toxic substances in the air removed by local systems;

Kp (mg/m3) - the amount of poisonous substances in the supply air masses;

Ku (mg/m3) is the content of toxic substances in the air removed by general exchange systems.

For excess moisture

Q = Qu + (W - 1.2 (Om - Op) / O1 - Op)), where

W (mg * hour) - the amount of moisture that enters the workshop premises in 1 hour;

Om (gram * kg) - the volume of steam removed by local systems;

Op (gram * kg) - indicator of supply air humidity;

O1 (gram * kg) - the amount of steam removed by the general exchange system.

By allocations from staff

Q = N * m, where

N is the number of employees

m - air consumption per 1 person * hour (according to SNiP it is 30 m3 per person in a ventilated room, 60m3 - in a non-ventilated one).

Calculation of the exhaust ventilation of the workshop

The amount of exhaust air can be determined using the following formula:

L = 3600 * V * S, where

L (m3) - air consumption;

V is the speed of the air flow in the exhaust device;

S is the opening area of the exhaust type installation.

Air distribution

Ventilation should not easily supply a certain amount of air inside. Its goal is to deliver this air directly to where it is needed.

When planning the distribution of air masses, the following indicators are taken into account:

- daily regimen of their application;

- annual cycle of use;

- heat input;

- accumulation of moisture and unnecessary components.

Any room where people are constantly deserves fresh air. But if the building is used for public needs or solving administrative problems, about half of it can be sent to neighboring rooms and corridors. Where there is an increased concentration of moisture or a lot of heat is released, it is required to ventilate the areas of water condensation on the enclosing elements. It is unacceptable to move air masses from areas with increased pollution to places with a less polluted atmosphere. The temperature, speed and direction of air movement should not contribute to the appearance of a foggy effect, water condensation.

Features of hotel ventilation systems

From properly designed ventilation systems, comfort directly depends, and, accordingly, the time spent by guests in the complex. That is why the hotel ventilation system must meet the following requirements:

- Efficiency. All air exchange regulations must be observed. In hotel rooms - 60 m3/h; in showers and bathrooms - 120 m3 / h; in conference rooms at least 30 m3/h. In other rooms, compliance with other standards is required, in accordance with the current SNiP and regulatory documents.

- Noiselessness.Silence is one of the defining requirements, since the main number of rooms in the hotel are bedrooms.

- Reliability. Ventilation networks and their equipment must operate 365 days a year and be available for repair and maintenance.

- Individuality. Any solutions should allow the creation of the most comfortable microclimate parameters for guests in each individual room.

There are many requirements for hotel ventilation. SNiP P-L. 17-65 allows the creation of a natural ventilation system with an extract from the bathrooms or toilets, if any in the rooms. In areas with an air temperature of -40 ° C during the cold season, mechanical air inflow with its heating and, if necessary, humidification should be provided. The same SNiP regulates the installation of thermal curtains at the entrances to hotels located in areas with outdoor temperatures in winter below -15C°.

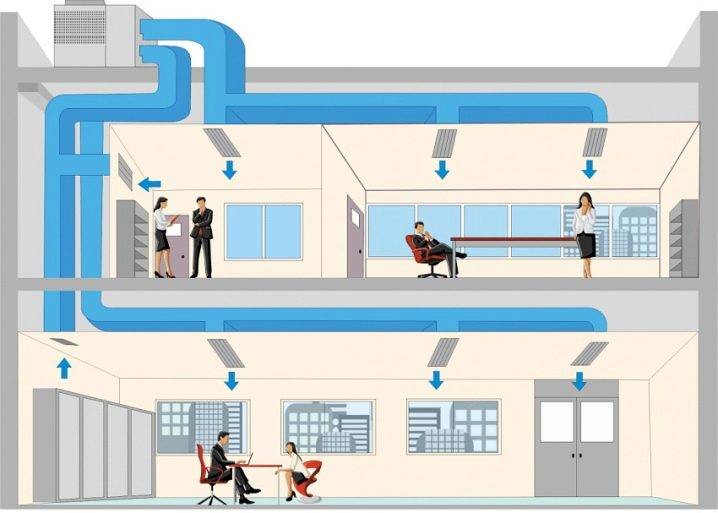

What are ventilation systems, are they necessary in non-residential premises of MKD

The ventilation system of the building and its premises includes channels, air ducts and special equipment that ensures proper circulation and exchange of indoor and outdoor air. Moreover, modern systems and solutions make it possible to achieve the necessary circulation for different types of premises and parts of the building, take into account the indicators of external and internal air, provide additional protection from dust, gas combustion particles, and other harmful factors. For non-residential areas of MKD, the following rules and regulations apply:

- when transferring premises from non-residential and residential, it is unacceptable to block or dismantle the ventilation ducts that are part of a single MKD system;

- ventilation of non-residential premises must comply with the sanitary standards regulated for residential buildings;

- many works to change the characteristics or transfer of ventilation fall under the redevelopment or reorganization, i.e. require special approvals for the project.

It is also necessary to take into account the types of activities for which the non-residential premises of the MKD are used. In some cases, it is allowed to open shops and catering establishments, points for the provision of personal services to the population. In order to eliminate negative impacts on the home's occupants, the owner of the space must design and approve a proper ventilation system.

Regulations

The development of a project for a new apartment building, including all its systems, is carried out in accordance with the norms of the Civil Code of the Russian Federation, Decree of the Government of the Russian Federation No. 87. To design a new ventilation system in an MKD, or to make changes to existing equipment for air exchange, the following guidelines must be taken into account :

- SP 60.13330.2012 (download);

- SP 54.13330.2016 (download);

- SP 336.1325800.2017 (download).

These are the three main sets of rules that designers' decisions must comply with. In particular, according to SP 60.13330.2012, it is necessary to choose solutions that meet the standards of sanitary, environmental and other safety, according to acceptable indicators of air purity, noise protection for ventilation equipment. According to SP 54.13330.2016, he will check the performance of ventilation ducts and air ducts within the framework of a single ventilation system at home, compliance with microclimate indicators.

in plain language

Non-residential premises in an MKD can be used to house an office, trade or service enterprises, to open small cafes and restaurants (with significant restrictions). In each of these cases, non-residential premises must have a ventilation system:

- providing own needs for the owner or tenant of non-residential premises, visitors and business clients (for example, the air exchange system for a cafe will include hoods, air conditioners, and other professional equipment);

- keeping the general ventilation and air conditioning system for the MKD unchanged (in particular, it is unacceptable to close up the ventilation ducts provided for by the original project for the house);

- corresponding to energy efficiency indicators, since for MKD this is one of the mandatory standards.

To carry out work on ventilation systems in an existing non-residential premises, MKDs may require redevelopment and (or) reorganization projects. They must be coordinated with the Moscow Housing Inspectorate, since this department oversees the conduct of any work in the housing stock of Moscow. Moreover, if changes are made to the general ventilation system of the house, or if load-bearing structures or common house property are involved in the work, it is additionally necessary to obtain the consent of the owners of the house.

The ventilation system includes hoods, ducts, channels and other elements of air exchange

At the stage of development of project documentation (project, stage "P")

- cover and title page;

- main technical solutions for ventilation systems (summary);

- terms of reference for the creation of a ventilation system;

- calculations are made that are not included in the design documentation:

- calculations of heat and moisture ingress into the premises;

- calculation of assimilation of harmful gas emissions (mainly carbon dioxide CO2);

- engineering calculation of air exchange in the building;

- calculation of the main ventilation equipment using software products of the equipment manufacturer;

- calculation of air distribution devices;

- aerodynamic calculation;

- main set of drawings:

- placement of the main ventilation equipment in ventilation chambers;

- placement of terminal ventilation equipment (air distributors, consoles);

- placement of air ducts, ventilation lines and other elements;

Design standards

It will not work to consider exactly how ventilation systems projects are prepared in all possible cases.

Therefore, it is important to focus on common characteristic points. The principles are enshrined in the following three regulations:

- SNiP;

- sanitary and epidemiological standards;

- SanPiN.

Important: the ventilation systems of warehouse complexes and factory floors are not subject to the same building and sanitary rules that are needed for the design of residential premises. It is strictly forbidden to confuse these regulations

Any project must meet the following requirements:

- purity of air and microclimate;

- long-term operation of ventilation and air conditioning equipment;

- simplification of repair of these systems;

- limited noise and vibration activity (even for emergency ventilation);

- safety in fire, sanitary and explosive terms.

It is forbidden to provide in the projects all those materials and structures, as well as their combinations, which are not allowed for this type of building or for a certain area.All materials and parts that must be certified are mentioned in the projects only together with information about the certificates. The minimum air intake per person in rooms and premises with natural air intake should be from 30 cubic meters. m. For areas that for any reason are not ventilated through windows, this figure should be at least twice as high.